Académique Documents

Professionnel Documents

Culture Documents

Editorial: Welding and Microstructure Evolution in Power Generation Plant

Transféré par

aliswatch0 évaluation0% ont trouvé ce document utile (0 vote)

27 vues1 pageThe increasing number of aging plants emphasises the need for improved understanding of material behaviour in service-critical components. Harmonised procedures for material testing, analysis, and condition assessment contribute to materials development, design of components, and defect assessment for remaining service life.

Description originale:

Titre original

s1

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe increasing number of aging plants emphasises the need for improved understanding of material behaviour in service-critical components. Harmonised procedures for material testing, analysis, and condition assessment contribute to materials development, design of components, and defect assessment for remaining service life.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

27 vues1 pageEditorial: Welding and Microstructure Evolution in Power Generation Plant

Transféré par

aliswatchThe increasing number of aging plants emphasises the need for improved understanding of material behaviour in service-critical components. Harmonised procedures for material testing, analysis, and condition assessment contribute to materials development, design of components, and defect assessment for remaining service life.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

Editorial

Welding and microstructure evolution in power generation plant

Advanced design and assessment methods for welded components are needed for the long-term reliable, safe, and economic operation of thermal power generation plant. Materials, operational, and generic factors contribute to the high-temperature performance of engineering structures. Therefore, development of advanced materials for enhanced performance as well as condition assessment of materials in-service stand as challenges for scientists and technologists alike. In particular, the increasing number of aging plants emphasises the need for improved understanding of material behaviour in service-critical components and advanced inspection and monitoring techniques. In addressing this need, harmonised procedures for material testing, analysis, and condition assessment contribute to materials development, design of components, and defect assessment for remaining service life. These issues were among those addressed at the International Conference Welds 2009, held at Sanibel, Fort Myers, FL, USA on 2426 June 2009, which followed the successful Welds 2005 event at GKSS, Geesthacht, Germany. The conference was supported by the Electric Power Research Institute (EPRI), the Versailles Project on Advanced Materials and Standards (VAMAS) and the European Structural Integrity Society (ESIS). Special sessions at Welds 2009 were dedicated to the EPRI led programme on Materials for Ultra Supercritical Plants and the International VAMAS TWA31 collaboration on Residual Stresses in Weldments. A back-to-back conference on Welding and Fabrication for New Power Plants, organised by EPRI at the same venue, also contributed to achieving the above-stated goal that spans basic science and engineering, testing, inspection, and assessment of components, through to the design of new power plants. Welds 2009 included keynote, oral, and poster presentations addressing the following themes: welding processes and high temperature (HT) behaviour of welded components; similar and dissimilar welds; weld material characterisation; weld failure modes and life management; weld strength reduction factors; welding of advanced materials (for example, for ultra-supercritical plants); weld repair of aged components; HT testing, inspection, and failure analysis of weldments; numerical analysis of HT welded components; modelling and measurement of residual stresses; effect of load history and creep-fatigue damage on weldments; creep-fatigue crack initiation and growth in weldments; thermo-mechanical and low cycle fatigue of welded components; evaluation of advanced non-destructive testing methods; preventing failures by monitoring plant behaviour; risk-based methods and investigations of failures; emerging guidelines and codes of practices. A panel discussion on Industrial needs and future direction of welding science and engineering was organised at the end of the conference, with participants from industry, academia and utilities. The state of the art was presented and a road map was proposed. The conference served as a platform to discuss progress in the conference themes with participation of over 90 experts, academics and researchers. Four plenary lectures and 52 presentations were delivered over the two and a half days of the conference. A selection of peer-reviewed papers based on these presentations is published in this special issue of Energy Materials. Thanks are due to the conference organisers, sponsors, and exhibitors, and in particular to participants and presenters that made Welds 2009 a success.

Bilal Dogan Electric Power Research Institute Charlotte, NC 28262, USA bdogan@epri.com

Published by Maney Publishing (c) IOM Communications & W S Maney & Son Ltd

Guest Editor

2011 Institute of Materials, Minerals and Mining and W. S. Maney & Son Ltd DOI 10.1179/174892310X12827282069062

Energy Materials

2009

VOL

NO

49

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Transparency Documentation EN 2019Document23 pagesTransparency Documentation EN 2019shani ChahalPas encore d'évaluation

- SPH4U Assignment - The Wave Nature of LightDocument2 pagesSPH4U Assignment - The Wave Nature of LightMatthew GreesonPas encore d'évaluation

- Internship ReportDocument46 pagesInternship ReportBilal Ahmad100% (1)

- Section 8 Illustrations and Parts List: Sullair CorporationDocument1 pageSection 8 Illustrations and Parts List: Sullair CorporationBisma MasoodPas encore d'évaluation

- Capital Expenditure DecisionDocument10 pagesCapital Expenditure DecisionRakesh GuptaPas encore d'évaluation

- Feasibility Study of Diethyl Sulfate ProductionDocument3 pagesFeasibility Study of Diethyl Sulfate ProductionIntratec SolutionsPas encore d'évaluation

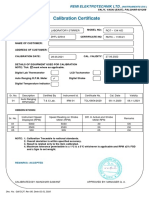

- Calibration CertificateDocument1 pageCalibration CertificateSales GoldClassPas encore d'évaluation

- Ytrig Tuchchh TVDocument10 pagesYtrig Tuchchh TVYogesh ChhaprooPas encore d'évaluation

- Water Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Document160 pagesWater Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Aldrian PradanaPas encore d'évaluation

- Experiment On Heat Transfer Through Fins Having Different NotchesDocument4 pagesExperiment On Heat Transfer Through Fins Having Different NotcheskrantiPas encore d'évaluation

- Oem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Document43 pagesOem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Farhad FarajyanPas encore d'évaluation

- Hotel ManagementDocument34 pagesHotel ManagementGurlagan Sher GillPas encore d'évaluation

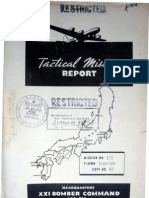

- 21st Bomber Command Tactical Mission Report 178, OcrDocument49 pages21st Bomber Command Tactical Mission Report 178, OcrJapanAirRaidsPas encore d'évaluation

- Reference Template For Feasibility Study of PLTS (English)Document4 pagesReference Template For Feasibility Study of PLTS (English)Herikson TambunanPas encore d'évaluation

- DesalinationDocument4 pagesDesalinationsivasu1980aPas encore d'évaluation

- Building New Boxes WorkbookDocument8 pagesBuilding New Boxes Workbookakhileshkm786Pas encore d'évaluation

- Year 9 - Justrice System Civil LawDocument12 pagesYear 9 - Justrice System Civil Lawapi-301001591Pas encore d'évaluation

- Ibbotson Sbbi: Stocks, Bonds, Bills, and Inflation 1926-2019Document2 pagesIbbotson Sbbi: Stocks, Bonds, Bills, and Inflation 1926-2019Bastián EnrichPas encore d'évaluation

- Dry Canyon Artillery RangeDocument133 pagesDry Canyon Artillery RangeCAP History LibraryPas encore d'évaluation

- TLE - IA - Carpentry Grades 7-10 CG 04.06.2014Document14 pagesTLE - IA - Carpentry Grades 7-10 CG 04.06.2014RickyJeciel100% (2)

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesDocument13 pagesThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6Pas encore d'évaluation

- Production - The Heart of Organization - TBDDocument14 pagesProduction - The Heart of Organization - TBDSakshi G AwasthiPas encore d'évaluation

- XgxyDocument22 pagesXgxyLïkïth RäjPas encore d'évaluation

- LOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCDocument1 pageLOG-2-8-FLEETWAREHOUSE-TEMPLATE-Waybill-Delivery Note-IFRCMPas encore d'évaluation

- Section 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsDocument27 pagesSection 26 08 13 - Electrical Systems Prefunctional Checklists and Start-UpsMhya Thu UlunPas encore d'évaluation

- Pneumatic Fly Ash Conveying0 PDFDocument1 pagePneumatic Fly Ash Conveying0 PDFnjc6151Pas encore d'évaluation

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument25 pagesCondition Monitoring of Steam Turbines by Performance Analysisabuhurairaqazi100% (1)

- FIRE FIGHTING ROBOT (Mini Project)Document21 pagesFIRE FIGHTING ROBOT (Mini Project)Hisham Kunjumuhammed100% (2)

- RYA-MCA Coastal Skipper-Yachtmaster Offshore Shorebased 2008 AnswersDocument28 pagesRYA-MCA Coastal Skipper-Yachtmaster Offshore Shorebased 2008 AnswersSerban Sebe100% (4)

- The Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageDocument5 pagesThe Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageHenny ZahranyPas encore d'évaluation