Académique Documents

Professionnel Documents

Culture Documents

Gunpower Talon

Transféré par

olhodeboiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Gunpower Talon

Transféré par

olhodeboiDroits d'auteur :

Formats disponibles

An Introduction to Tuning the Gunpower Stealth

By Bob Craske

The Stealth is an innovative and enormously efficient airgun due to a design which is free of all but the most basic valving and triggering mechanisms, and which possesses an air path which is free of bends, restrictions and convoluted metering systems.

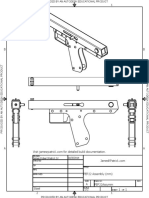

The Gun is cocked by means of the cocking handle A which is screwed into the Breech Cover. The Breech cover, which incorporates 2 O ring seals, is tubular in design and slides around the barrels periphery. It is pushed forward which in turn pushes the Hammer Slide D against its spring F which is compressed against the Barrel Mounting Ring G. As the rear edge of the hammer slide passes over the Trigger release Sear E, the sear pops upward under spring pressure locking the hammer in the cocked position. The Cocking lever is manually drawn backwards by the firer to the rearmost position when the two O rings shown at C, form an airtight seal between the breech end of the barrel and the Air Bottle Release Valve B. When the gun is fired, operation of the trigger causes the Trigger Release Sear to rotate about its pivot in a clockwise direction causing the release of the Hammer Slide. The Hammer Slide, propelled by its spring impacts with the front face of the Breech Slide transferring its energy through the slide and directly onto the face of the Air Bottle Release Valve. The Valve is momentarily forced from its seat against the air pressure in the bottle. A charge of air passes through the opened valve and through a longitudinal hole drilled in the valve body and impinges directly on the rear of the pellet which is pre-positioned in the rear of the barrels breech. Once the energy from the Hammer Slides impact has been dissipated, the Air Bottle Release Valve, acting under the influence of the high pressure air in the bottle and a small internal spring, returns to its sealed position shutting off the air supply. The cycle is repeated for each shot. Tips, Tweaks and Sneaky Snippets Even with such a simple mechanism, there are factors which can effect the firing cycle of the gun and cause erratic accuracy and power.

It should be understood at this point that accuracy and power in the gun are very closely related, especially with the heavier ammunition this gun prefers. The pellet relies entirely on the blast of high pressure air generated during the valve open phase of firing to not only expel the pellet from the barrel but do so at a known and consistent velocity. Any alteration in the pressure generated will effect not only the trajectory of the pellet but also its stability due to the spin imparted by the barrels internal rifling. There are several crucial factors which can affect the delivery of air into the breech of the gun and, for the sake of brevity, they are listed below. 1. Unlubricated hammer slide bearing surfaces 2. Unlubricated breech seal surfaces and O rings 3. Worn Breech Seal O ring seals 4. Weak Hammer Spring 5. Dirty or Damaged Air Bottle Valve Stem 6. Loose Air Bottle Valve Stem 7. Incorrect Air Bottle Pressure (Too low or too high)

It has been demonstrated that a dry hammer slide will chatter as it travels rearwards during the firing cycle. This chatter will dissipate a surprising amount of the hammers energy which is required for opening the air valve. A dry slide will also travel rearwards more slowly, thus, the valve receives an insufficient impact to fully open and a short charge results. This is often heard as a muffled report from the gun and a shot which passes wide of the target.. Unlubricated breech seal surfaces and O rings will also absorb Hammer Impact Energy and can also allow air leakage at the O rings. It is advisable to regularly grease the assembly with a silicone based lubricant to both prolong O ring life and maximise efficiency by reducing wear. The hammer spring is, in the opinion of the author, rather weak for the task it is required to do. Basically, its job is to knock the air valve fully open as quickly as possible after trigger release and it often fails to do this for the above mentioned reasons. Increasing the preload on the spring has been shown to have a dramatic effect on the consistency of the valving system and is easily achieved by packing the spring it its foremost end where it abuts the rear Barrel Mounting Ring. Steel or Brass washers of a suitable internal and external diameter are the most suitable items for use as shims and usually packing to a depth of approximately .25 is sufficient to achieve a marked improvement. This will normally increase the muzzle velocity of the weapon and care should be taken in readjusting the gun back down to legal energy limits. Note: On American guns there is a Power Adjuster which simply preloads the hammer spring by means of a movable spring packing device on a thread. A slight more complex improvement is to have an exact copy of the hammer made up in a heavier material, brass being the obvious choice because of its weight and corrosion resistance. A heavier hammer will suffer less from countering forces and will more effectively deliver energy from a correctly tensioned spring to the valve during impact. It will also cause the valve to remain open for fractionally longer increasing power delivery. The Air Bottle Release Valve The Air Bottle Release Valve neck is threaded to accept a small Top Hat adapter which engages with the Breech Slide O ring seals to form an airtight join during firing. The Top Hat assembly

may be screwed in and out on its stem and, by so doing, affect the amount by which the valve is struck open during hammer impact. The further out the greater the opening and vice versa. Screwing in the Top Hat will reduce the rifles Muzzle Energy while screwing it out will increase it. In order to prevent the adjustment being lost during the rigours of hammer impact, a small recessed securing screw is set into the outer collar of the Top Hat and tightened by means of an Allen Key (Hexagon Wrench). The default setting from which to start calibrating is approximately 1.5 turns out from the fully home position.

One of the most common causes of erratic firing with this gun is a loosening of the Top Hat Collar. The grub screw used for securing purposes is rather inadequate for the job and, after setting-up the gun in conjunction with the other adjustments described here, the application of a small quantity of thread sealing compound is highly beneficial. There have been threads on the various BBSs which have recommended drilling out the valve stem for more power. DONT DO IT! Firstly its irrevocable, Secondly it weakens the stem and Thirdly its not necessary. On the bench and in test conditions, Ive shot 32 Foot Pounds over my chrony using just the tweaks described above. The Barrel The barrel plays a crucial part in the delivery of the projectile and a worn, bent or damaged barrel will produce at best, indifferent results. Sharp, hard and abrasive objects should never be introduced into a Stealth barrel as this could damage the rifling and adversely affect projectile control. Early guns had a proprietary barrel which gave less than ideal results. However, later Stealths (Stealth 2000 for example) have a Walther match grade barrel which produces almost frightening accuracy, especially in conjunction with the optional bipod. The single most common problem with the Stealth barrel is mounting. Ive found loose barrels, barrels mounted at an angle due to foreign objects inside the gun body and even barrel support rings missing or damaged. Put simply, a clean, solidly mounted and firmly secured barrel in good condition WILL deliver accurately. A nice touch which will (marginally) improve accuracy is to get the plastic barrel mounts remade in brass or steel at your local machine shop.

Removing the Barrel

Turn the Gun onto its back and undo the single Allen screw securing the plastic foregrip to the rifle body. Locate the 3 grub screws securing the barrel and muzzle end cap assemblies to the rifle body. Starting from the muzzle, the first screw secures the steel insert which bears the thread on which the end cap and/or optional silencer are screwed. With the silencer attached (if fitted) remove the grub screw and gently pull the compete insert forwards, detaching it from the gun. Further to the rear of the weapon at 1.75 and 5.25 respectively are the 2 screws which secure the Barrel Mounting Rings. Undo the rearmost screw first and set aside. Now, with a finger inside the front of the muzzle housing holding the barrel against the Hammer Spring pressure, undo the second grub screw. As the screw is released the barrel assembly will jump forward slightly against your finger . Gently release the pressure and, holding the gun in one hand with the muzzle pointing downwards, gently withdraw the barrel as a unit with the other. The Hammer spring and spacers should come out with the barrel, if not return the barrel slightly into the gun body and tap the gun gently to dislodge the Hammer slide. See diagram 2- Stealth Schematic.

Depending on the weapon you have you may find several small plastic spacer ringsapproximately . 5 thick. These are Hammer Spring preload spacers and are factory fitted to bring Hammer Spring tension within tuneable limits. As previously discussed, adding to these will improve the situation further. These spacers, and any further packing, should be fitted at point A on the above diagram unless you wish to increase the Hammers effective mass when additional spacers may be fitted adjacent to the hammers front face. Be aware that increasing the hammers mass and spring tension will dramatically alter the performance of the gun and may make it illegal. To reassemble the barrel Proceed as follows WITH THE AIR BOTTLE DETACHED: 1. Thoroughly clean all components and grease liberally with silicone compound. 2. Fit the required spacers against the rear barrel locating ring followed by the Hammer Spring 3. Now, after greasing the Hammer slide liberally inside and out, slide it onto the barrel and introduce the barrel assembly intro the gun body aligning the screw holes in the barrel locating rings with the holes in the bottom of the barrel housing. Gently locate the barrels breech into the Breech Cover against the Hammer Springs pressure and, whilst holding the barrel assembly in with the finger against the muzzle, align the rear mounting screw hole with its mounting ring and secure the barrel ring with a grub screw. Do not tighten fully at this point. 4. Now insert the second barrel ring screw finger tight only. Do not tighten fully at this point 5. Take the end cap/silencer threaded insert and, aligning the securing holes, push it gently into the front of the barrel housing. Secure firmly with its grub screw. 6. Now tighten both barrel mounting screws equally and in stages until firmly finger tight with a 3 Allen key. 7. Check the cocking and safety action for correct operation and work 20 or so times. When satisfied, remove excess grease from the weapon with a clean lint-free rag. Test fire the gun in a safe manner for 20 or shots until the valve mechanism has seated in and check the safety and trigger sear are operating correctly with no slip or unintended release. Adjust Muzzle Velocity using a Chronograph as detailed earlier. Back to Alpinetek's Talon Page

Vous aimerez peut-être aussi

- Mod Firearm Beretta - US Patent 5596162Document9 pagesMod Firearm Beretta - US Patent 5596162luanfunari100% (1)

- Building a Home Defense Remington 870 ShotgunD'EverandBuilding a Home Defense Remington 870 ShotgunÉvaluation : 3.5 sur 5 étoiles3.5/5 (5)

- Trigger Slap and Doubling Trouble ShootingDocument8 pagesTrigger Slap and Doubling Trouble ShootingAdam Hemsley100% (2)

- Operator'S Manual: B&T Tp9-Us Bt-30105-2Document36 pagesOperator'S Manual: B&T Tp9-Us Bt-30105-2KnesekGuns100% (1)

- Dd5e Old Gus Weird West PHB v145Document40 pagesDd5e Old Gus Weird West PHB v145Stefano Alves DrakhaliPas encore d'évaluation

- HK Flat Bending JigDocument7 pagesHK Flat Bending JigRon Walsh100% (1)

- How To Make Paintball GunDocument10 pagesHow To Make Paintball GunAinis ŠtelemėkasPas encore d'évaluation

- MPA 22 ManualDocument16 pagesMPA 22 ManualChris Choat100% (1)

- Ruger Redhawk Model 5033 Revolver SpecsDocument1 pageRuger Redhawk Model 5033 Revolver SpecsAmmoLand Shooting Sports NewsPas encore d'évaluation

- BHP Trigger JobDocument8 pagesBHP Trigger Jobssnvet100% (3)

- Popular Woodworking - 050 - 1989Document80 pagesPopular Woodworking - 050 - 1989Thiago Lima100% (1)

- Glock Generation PDFDocument18 pagesGlock Generation PDFสุรา ไทประดิษฐ์100% (2)

- Us 3722358Document9 pagesUs 3722358awe234Pas encore d'évaluation

- Us 20060101695Document11 pagesUs 20060101695galak12001100% (1)

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsD'EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsPas encore d'évaluation

- James Robert Patrick IV 10/3/2014: Drawn Checked QA MFG Approved TitleDocument1 pageJames Robert Patrick IV 10/3/2014: Drawn Checked QA MFG Approved Titlekolas hernandezPas encore d'évaluation

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongPas encore d'évaluation

- Symbol of Violence, War and Culture: Chapter OneDocument10 pagesSymbol of Violence, War and Culture: Chapter OneMister BurdsPas encore d'évaluation

- P226Document2 pagesP226Pedro Perez Galdos33% (3)

- Checkmate II .22lr Manual.Document2 pagesCheckmate II .22lr Manual.Griffin Armament SuppressorsPas encore d'évaluation

- A1 To A2Document45 pagesA1 To A2leeyangseopPas encore d'évaluation

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3Pas encore d'évaluation

- GRT-III Trigger Blade InstructionsDocument5 pagesGRT-III Trigger Blade InstructionsPatrik Avlo100% (2)

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongPas encore d'évaluation

- Io Inc January 2016 News Press ReleaseDocument4 pagesIo Inc January 2016 News Press Releaseapi-242710584Pas encore d'évaluation

- 级触发自动武器 PDFDocument15 pages级触发自动武器 PDFJin SongPas encore d'évaluation

- AR-7 Henry Repeating Arms Semi Auto 22LR Brochure PDFDocument1 pageAR-7 Henry Repeating Arms Semi Auto 22LR Brochure PDFLeonel Montilla100% (1)

- Chimera ManualDocument12 pagesChimera ManualticocrazyPas encore d'évaluation

- Carl Gustav SMGDocument18 pagesCarl Gustav SMGJorihood100% (1)

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongPas encore d'évaluation

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongPas encore d'évaluation

- CZ 452 Varmint Custom Is at I OnDocument9 pagesCZ 452 Varmint Custom Is at I Onernst1978Pas encore d'évaluation

- Dokumen - Tips Colt m1911 Frame BlueprintsDocument9 pagesDokumen - Tips Colt m1911 Frame BlueprintsRaul AlvarezPas encore d'évaluation

- RPD Build - Red Neck EngineerDocument6 pagesRPD Build - Red Neck EngineerDale Wade67% (3)

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongPas encore d'évaluation

- Muzzle Threading: Getting StartedDocument5 pagesMuzzle Threading: Getting Startedwdafon100% (1)

- The Gun Digest Book of Tactical Weapons Assembly/DisassemblyD'EverandThe Gun Digest Book of Tactical Weapons Assembly/DisassemblyPas encore d'évaluation

- @VLNNR:: Beretta 3,021,763Document8 pages@VLNNR:: Beretta 3,021,763wererPas encore d'évaluation

- Jewel 2-Stage TriggerDocument13 pagesJewel 2-Stage TriggerAdam BallPas encore d'évaluation

- Pistol Nickl Us1427966Document11 pagesPistol Nickl Us1427966cll1968Pas encore d'évaluation

- Eng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFDocument4 pagesEng-Template-1 - C: Scale: Drawing No: Rev: Sheet: OFlogostar5Pas encore d'évaluation

- Hexalubulour BoltDocument20 pagesHexalubulour BoltMitesh MakvanaPas encore d'évaluation

- US20080086926A1Document19 pagesUS20080086926A1ProfessorPas encore d'évaluation

- Pep 22 Barrel MMDocument1 pagePep 22 Barrel MMkolas hernandezPas encore d'évaluation

- PEP22 AssymmDocument1 pagePEP22 Assymmkolas hernandezPas encore d'évaluation

- Model-16S 181 - 1316.055.200Document53 pagesModel-16S 181 - 1316.055.200Cute little mochiPas encore d'évaluation

- Replacing The Hood MaxfireDocument2 pagesReplacing The Hood MaxfireAl MalleyPas encore d'évaluation

- A 518298Document19 pagesA 518298browar444Pas encore d'évaluation

- Klashnikovak 47 130330015107 Phpapp01Document15 pagesKlashnikovak 47 130330015107 Phpapp01elvergonzalez1100% (2)

- GG3 Operators Manual Quickstart PDFDocument5 pagesGG3 Operators Manual Quickstart PDFRebecca MathewsPas encore d'évaluation

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияPas encore d'évaluation

- LatheDocument14 pagesLatheHimanshu ModiPas encore d'évaluation

- F69FZ Cip 22lr ChamberDocument1 pageF69FZ Cip 22lr ChamberJorho JorhoPas encore d'évaluation

- Print Page - Welrod B - A Pistols - Toward A Scratch BuildDocument58 pagesPrint Page - Welrod B - A Pistols - Toward A Scratch BuildAndrew MichaelsPas encore d'évaluation

- AK Accurizing TipsDocument27 pagesAK Accurizing TipsEmilio Torres EsguerraPas encore d'évaluation

- 48Document20 pages48UralguyPas encore d'évaluation

- GG2 Operator's ManualDocument30 pagesGG2 Operator's ManualWerner Patric WengPas encore d'évaluation

- VNPX 710sgd-34gl - Parts - 2005Document66 pagesVNPX 710sgd-34gl - Parts - 2005Centrifugal Separator100% (1)

- M-LOK Release FAQs PDFDocument10 pagesM-LOK Release FAQs PDFEric Cheng100% (1)

- Home N Ew Arrivals C Loseouts Schem Atics Sell Your PartsDocument2 pagesHome N Ew Arrivals C Loseouts Schem Atics Sell Your Partstwinscrewcanoe100% (1)

- KSC or KWA Glock 18C Hammer Spring InstallationDocument8 pagesKSC or KWA Glock 18C Hammer Spring Installationapi-3829577100% (1)

- Modifying .223 Magazines For The SAR-3Document13 pagesModifying .223 Magazines For The SAR-3Arkane1988100% (1)

- FN FAL Gas Block Conversion InfoDocument2 pagesFN FAL Gas Block Conversion InfoAdam HemsleyPas encore d'évaluation

- Bonaire Evaporative Touch Pad ControlDocument32 pagesBonaire Evaporative Touch Pad ControlMartin huntPas encore d'évaluation

- Brochure Cut5062 en 2020-01-004.00 ScreenDocument6 pagesBrochure Cut5062 en 2020-01-004.00 Screenمحمدعبدالخالق العلوانيPas encore d'évaluation

- SUPRA 950U / 950U Mt° Spare Parts ManualDocument79 pagesSUPRA 950U / 950U Mt° Spare Parts ManualNizarChouchene100% (1)

- Section 4: Column Wear PlatesDocument13 pagesSection 4: Column Wear PlatesMartín Dominguez BarreraPas encore d'évaluation

- Carrier FV4B SeriesDocument20 pagesCarrier FV4B SeriesjojoafernandezPas encore d'évaluation

- 2 Simple MachinesDocument23 pages2 Simple Machines06.Thanapoom ChumraksaPas encore d'évaluation

- Pintsch Bubenzer KBTDocument5 pagesPintsch Bubenzer KBTSebek kPas encore d'évaluation

- Product Data: 24ABB3 Comfortt13 Air Conditioner With Puronr Refrigerant 1 - 1/2 To 5 Nominal TonsDocument22 pagesProduct Data: 24ABB3 Comfortt13 Air Conditioner With Puronr Refrigerant 1 - 1/2 To 5 Nominal TonsPrimero Valencia LuisPas encore d'évaluation

- Thunderers (Mordheim) (496pts) : Warband (Dwarf Treasure Hunters) (496pts)Document4 pagesThunderers (Mordheim) (496pts) : Warband (Dwarf Treasure Hunters) (496pts)Kajetan BłaszczykPas encore d'évaluation

- Component 4 Install PVC Pipe and Fittings Wps ParDocument9 pagesComponent 4 Install PVC Pipe and Fittings Wps ParBenedictPas encore d'évaluation

- GBH 2 SR Manual 160841Document94 pagesGBH 2 SR Manual 160841RobertAragónLduPas encore d'évaluation

- Booster and Irrigation Pump CalculationDocument4 pagesBooster and Irrigation Pump CalculationNIDHILPas encore d'évaluation

- Microtomy and Cutting Sections ChapterDocument28 pagesMicrotomy and Cutting Sections ChapterAlex LiganPas encore d'évaluation

- Model No: MT814: Page 1 / 3Document3 pagesModel No: MT814: Page 1 / 3Zaidu zamaanPas encore d'évaluation

- Dynamometer: Types of Dynamometers: There Are Mainly Two Types of DynamometersDocument11 pagesDynamometer: Types of Dynamometers: There Are Mainly Two Types of DynamometersKumar BabuPas encore d'évaluation

- Actuadores MASTER VALVEDocument12 pagesActuadores MASTER VALVEMartin Katz alorPas encore d'évaluation

- Optional Functions Basic FunctionsDocument68 pagesOptional Functions Basic Functionsjitesh.chauhanPas encore d'évaluation

- Filter Oil Comressor BaruDocument1 pageFilter Oil Comressor BaruSyahrul SaputraPas encore d'évaluation

- Precision Rifle Series: 20 18 R Ules & Standard OperatingproceduresDocument27 pagesPrecision Rifle Series: 20 18 R Ules & Standard OperatingproceduresJose CarlosPas encore d'évaluation

- PH IkusafudeDocument11 pagesPH IkusafudeJames Ryan AlanoPas encore d'évaluation

- Document No.: FFS - S/N 1829Document5 pagesDocument No.: FFS - S/N 1829Matias MiroPas encore d'évaluation

- 22 BallandneedlevalvesDocument4 pages22 BallandneedlevalvesmedkvPas encore d'évaluation

- Common Fastener Related Abbreviations: Abbreviation MeaningDocument3 pagesCommon Fastener Related Abbreviations: Abbreviation MeaningezhiljananiPas encore d'évaluation