Académique Documents

Professionnel Documents

Culture Documents

The Basics of Solar Power For Producing Electricity

Transféré par

Steven RankineDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Basics of Solar Power For Producing Electricity

Transféré par

Steven RankineDroits d'auteur :

Formats disponibles

The Basics of Solar Power for Producing Electricity Learn the essential basics of using solar power so you

can understand your project. Planning your project begins with understanding the basics found in this section. An excellent place to start for those just beginning. Solar power works well for most items except large electric appliances that use an electric heat element such as a water heater, clothes dryer and electric stove - for example - or total electric home heating systems. It is not cost effective to use solar power for these items. Conversion to natural gas, propane or other alternatives is usually recommended. Solar power can be used to operate a gas clothes dryer (Maytag, etc) because the electrical requirement is limited to the drum-motor and/or ignito-lighter, but not a HEAT element for drying the clothes, for example. We recommend you also review our page Helpful Solar Power Glossary which will provide useful terms and General Construction Techniques for insight into energy efficient new construction or retrofitting energy efficient principles into your building project.

The basics of solar power:

Using solar power to produce electricity is not the same as using solar to produce heat. Solar thermal principles are applied to produce hot fluids or air. Photovoltaic principles are used to produce electricity. A solar panel (PV panel) is made of the natural element, silicon, which becomes charged electrically when subjected to sun light. Solar panels are directed at solar south in the northern hemisphere and solar north in the southern hemisphere (these are slightly different than magnetic compass north-south directions) at an angle dictated by the geographic location and latitude of where they are to be installed. Typically, the angle of the solar array is set within a range of between site-latitude-plus 15 degrees and site-latitude-minus 15 degrees, depending on whether a slight winter or summer bias is desirable in the system. Many solar arrays are placed at an angle equal to the site latitude with no bias for seasonal periods. This electrical charge is consolidated in the PV panel and directed to the output terminals to produce low voltage (Direct Current) - usually 6 to 24 volts. The most common output is intended for nominal 12 volts, with an effective output usually up to 17 volts. A 12 volt nominal output is the reference voltage, but the operating voltage can be 17 volts or higher much like your car alternator charges your 12 volt battery at well over 12 volts. So there's a difference between the reference voltage and the actual operating voltage. The intensity of the Sun's radiation changes with the hour of the day, time of the year and weather conditions. To be able to make calculations in planning a system, the total amount of solar radiation energy is expressed in hours of full sunlight per m, or Peak Sun Hours. This term, Peak Sun Hours, represents the average amount of sun available per day throughout the year. It is presumed that at "peak sun", 1000 W/m of power reaches the surface of the earth. One hour of full sun provides 1000 Wh per m = 1 kWh/m - representing the solar energy received in one hour on a cloudless summer day on a one-square meter surface directed towards the sun. To put this in some other perspective, the

United States Department of Energy indicates the amount of solar energy that hits the surface of the earth every +/- hour is greater than the total amount of energy that the entire human population requires in a year. Another perspective is that roughly 100 square miles of solar panels placed in the southwestern U.S. could power the country. The daily average of Peak Sun Hours, based on either full year statistics, or average worst month of the year statistics, for example, is used for calculation purposes in the design of the system. To see the average Peak Sun Hours for your area in the United States, you can click the following link which will open a new window - just close it [X] when you're done to return here; U.S.-Solar Insolation Choose the area closest to your location for a good indication of your average Peak Sun Hours. For a view of global solar insolation values (peak sun-hours) use this link: Global Peak Sun-hour Maps , then, you can use [back] or [previous] on your browser to return right here if you want to. So it can be concluded that the power of a system varies, depending on the intended geographical location. Folks in the northeastern U.S. will need more solar panels in their system to produce the same overall power as those living in Arizona. We can advise you on this if you have any doubts about your area. Components used to provide solar power: The four primary components for producing electricity using solar power, which provides common 120 volt AC power for daily use are: Solar panels, charge controller, battery and inverter. Solar panels charge the battery, and the charge regulator insures proper charging of the battery. The battery provides DC voltage to the inverter, and the inverter converts the DC voltage to normal AC voltage. If 240 volts AC is needed, then either a transformer is added or two identical inverters are series-stacked to produce the 240 volts.

Solar Panels: The output of a solar panel is usually stated in watts, and the wattage is determined by multiplying the rated voltage by the rated amperage. The formula for wattage is VOLTS times AMPS equals WATTS. So for example, a 12 volt 60 watt solar panel measuring about 20 X 44 inches has a rated voltage of 17.1 and a rated 3.5 amperage. VxA=W 17.1 volts times 3.5 amps equals 60 watts If an average of 6 hours of peak sun per day is available in an area, then the above solar panel can produce an average 360 watt hours of power per day; 60w times 6

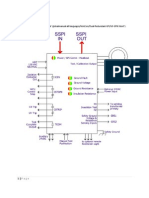

hrs. = 360 watt-hours. Since the intensity of sunlight contacting the solar panel varies throughout the day, we use the term "peak sun hours" as a method to smooth out the variations into a daily average. Early morning and late-in-the-day sunlight produces less power than the mid-day sun. Naturally, cloudy days will produce less power than bright sunny days as well. When planning a system your geographical area is rated in average peak sun hours per day based on yearly sun data. Average peak sun hours for various geographical areas is listed in the above section. Solar panels can be wired in series or in parallel to increase voltage or amperage respectively, and they can be wired both in series and in parallel to increase both volts and amps. Series wiring refers to connecting the positive terminal of one panel to the negative terminal of another. The resulting outer positive and negative terminals will produce voltage the sum of the two panels, but the amperage stays the same as one panel. So two 12 volt/3.5 amp panels wired in series produces 24 volts at 3.5 amps. Four of these wired in series would produce 48 volts at 3.5 amps. Parallel wiring refers to connecting positive terminals to positive terminals and negative to negative. The result is that voltage stays the same, but amperage becomes the sum of the number of panels. So two 12 volt/3.5 amp panels wired in parallel would produce 12 volts at 7 amps. Four panels would produce 12 volts at 14 amps. Series/parallel wiring refers to doing both of the above - increasing volts and amps to achieve the desired voltage as in 24 or 48 volt systems. The following diagram reflects this. In addition, the four panels below can then be wired in parallel to another four and so on to make a larger array.

Charge Controller: A charge controller monitors the battery's state-of-charge to insure that when the battery needs charge-current it gets it, and also insures the battery isn't overcharged. Connecting a solar panel to a battery without a regulator seriously risks damaging the battery and potentially causing a safety concern. Charge controllers (or often called charge regulator) are rated based on the amount of amperage they can process from a solar array. If a controller is rated at 20 amps it means that you can connect up to 20 amps of solar panel output current to this one controller. The most advanced charge controllers utilize a charging principal referred to as Pulse-Width-Modulation (PWM) - which insures the most efficient battery charging and extends the life of the battery. Even more advanced controllers also include Maximum Power Point Tracking (MPPT) which maximizes the amount of current going into the battery from the solar array by lowering the panel's output voltage, which increases the charging amps to the battery - because if a panel can produce 60 watts with 17.2 volts and 3.5 amps, then if the voltage is lowered to say

14 volts then the amperage increases to 4.28 (14v X 4.28 amps = 60 watts) resulting in a 19% increase in charging amps for this example. Many charge controllers also offer Low Voltage Disconnect (LVD) and Battery Temperature Compensation (BTC) as an optional feature. The LVD feature permits connecting loads to the LVD terminals which are then voltage sensitive. If the battery voltage drops too far the loads are disconnected - preventing potential damage to both the battery and the loads. BTC adjusts the charge rate based on the temperature of the battery since batteries are sensitive to temperature variations above and below about 75 F degrees. Battery: The Deep Cycle batteries used are designed to be discharged and then re-charged hundreds or thousands of times. These batteries are rated in Amp Hours (ah) usually at 20 hours and 100 hours. Simply stated, amp hours refers to the amount of current - in amps - which can be supplied by the battery over the period of hours. For example, a 350ah battery could supply 17.5 continuous amps over 20 hours or 35 continuous amps for 10 hours. To quickly express the total watts potentially available in a 6 volt 360ah battery; 360ah times the nominal 6 volts equals 2160 watts or 2.16kWh (kilowatt-hours). Like solar panels, batteries are wired in series and/or parallel to increase voltage to the desired level and increase amp hours. The battery should have sufficient amp hour capacity to supply needed power during the longest expected period "no sun" or extremely cloudy conditions. A lead-acid battery should be sized at least 20% larger than this amount. If there is a source of back-up power, such as a standby generator along with a battery charger, the battery bank does not have to be sized for worst case weather conditions. The size of the battery bank required will depend on the storage capacity required, the maximum discharge rate, the maximum charge rate, and the minimum temperature at which the batteries will be used. During planning, all of these factors are looked at, and the one requiring the largest capacity will dictate the battery size. One of the biggest mistakes made by those just starting out is not understanding the relationship between amps and amp-hour requirements of 120 volt AC items versus the effects on their DC low voltage batteries. For example, say you have a 24 volt nominal system and an inverter powering a load of 3 amps, 120VAC, which has a duty cycle of 4 hours per day. You would have a 12 amp hour load (3A X 4 hrs=12 ah). However, in order to determine the true drain on your batteries you have to divide your nominal battery voltage (24v) into the voltage of the load (120v), which is 5, and then multiply this times your 120vac amp hours (5 x 12 ah). So in this case the calculation would be 60 amp hours drained from your batteries - not the 12 ah. Another simple way is to take the total watt-hours of your 120VAC device and divide by nominal system voltage. Using the above example; 3 amps x 120 volts x 4 hours = 1440 watt-hours divided by 24 DC volts = 60 amp hours. Lead-acid batteries are the most common in PV systems because their initial cost is lower and because they are readily available nearly everywhere in the world. There are many different sizes and designs of lead-acid batteries, but the most important designation is that they are deep cycle batteries. Lead-acid batteries are available in both wet-cell (requires maintenance) and sealed no-maintenance versions. AGM and

Gel-cell deep-cycle batteries are also popular because they are maintenance free and they last a lot longer. Using an Inverter: An inverter is a device which changes DC power stored in a battery to standard 120/240 VAC electricity (also referred to as 110/220). Most solar power systems generate DC current which is stored in batteries. Nearly all lighting, appliances, motors, etc., are designed to use ac power, so it takes an inverter to make the switch from battery-stored DC to standard power (120 VAC, 60 Hz). In an inverter, direct current (DC) is switched back and forth to produce alternating current (AC). Then it is transformed, filtered, stepped, etc. to get it to an acceptable output waveform. The more processing, the cleaner and quieter the output, but the lower the efficiency of the conversion. The goal becomes to produce a waveform that is acceptable to all loads without sacrificing too much power into the conversion process. Inverters come in two basic output designs - sine wave and modified sine wave. Most 120VAC devices can use the modified sine wave, but there are some notable exceptions. Devices such as laser printers which use triacs and/or silicon controlled rectifiers are damaged when provided mod-sine wave power. Motors and power supplies usually run warmer and less efficiently on mod-sine wave power. Some things, like fans, amplifiers, and cheap fluorescent lights, give off an audible buzz on modified sine wave power. However, modified sine wave inverters make the conversion from DC to AC very efficiently. They are relatively inexpensive, and many of the electrical devices we use every day work fine on them. Sine wave inverters can virtually operate anything. Your utility company provides sine wave power, so a sine wave inverter is equal to or even better than utility supplied power. A sine wave inverter can "clean up" utility or generator supplied power because of its internal processing. Inverters are made with various internal features and many permit external equipment interface. Common internal features are internal battery chargers which can rapidly charge batteries when an AC source such as a generator or utility power is connected to the inverter's INPUT terminals. Auto-transfer switching is also a common internal feature which enables switching from either one AC source to another and/or from utility power to inverter power for designated loads. Battery temperature compensation, internal relays to control loads, automatic remote generator starting/stopping and many other programmable features are available. Most inverters produce 120VAC, but can be equipped with a step-up transformer to produce 120/240VAC. Some inverters can be series or parallel "stacked-interfaced" to produce 120/240VAC or to increase the available amperage. Efficiency Losses: In all systems there are losses due to such things as voltage losses as the electricity is carried across the wires, batteries and inverters not being 100 percent efficient, and other factors. These efficiency losses vary from component to component, and from system to system and can be as high as 25 percent. That's why it's a good idea to speak to someone who has extensive design experience - like us! - to properly configure the right equipment for you.

CONGRATULATIONS! IF YOU HAVE READ AND BASICALLY UNDERSTAND ALL THE SECTIONS ABOVE, THEN YOU CAN BEGIN PLANNING OF A POWER SYSTEM USING SOLAR POWER. The next section you can review is: Solar power system sizing Check out our low cost High-Tech Portable Solar Power and back up power system

Determining your solar power requirements and planning the number of components.

Quick links to view or print calculation areas below 1. Load 2. Inverter 3. Solar Array 4. Battery Calculations Selection Sizing Sizing Important Initial Considerations The following information is a general guide for sizing, but not intended for more critical applications or remote sites requiring very high reliability. These types of systems require extensive analysis of regional climate history, site specific data, expert understanding and selection of system components and should be designed by professionals. For example, among other things we use highly proprietary performance analysis software and climate histories of 30 or more years when planning for applications requiring very high or no-fail reliability.

GENERAL SIZING FOR SOLAR POWER In sizing an electric system using solar power the first two factors we consider are the sunlight levels (insolation values) from your area and the daily power consumption of your electrical loads. Orientation of a solar array is best at true south. True south is slightly different than a magnetic reference or compass south. The more an array is situated off of true south the less the total insolation value. A quick way to determine solar south is to divide the span of time between sunrise and sunset in half. The position of the sun at the resulting time would be true solar south. The angle of the solar array can be anywhere from your latitude plus 15 degrees to latitude minus 15 degrees for a yearly fixed mount position. Your latitude offers the best year-round position. By biasing the array "latitude plus 15 degrees" you will get slightly more insolation during winter months. A "latitude minus 15 degrees" will bias the array to summer months. Insolation Insolation, or sunlight intensity is measured in equivalent full sun hours. One hour of maximum, or 100% sunshine received by a solar panel equals one equivalent full sun hour. Even though the sun may be above the horizon for 14 hours a day, this may only result in six hours of equivalent full sun. There are two main reasons. One is reflection due to a high angle of the sun in relationship to your solar array. The second is also due to the high angle and the amount of the earth's atmosphere the light is passing through. When the sun is straight overhead the light is passing through the least amount of atmosphere. Early or late in the day the sunlight is

passing through much more of the atmosphere due to its position in the sky. Sun tracking devices are available and can help reduce reflectance, but cannot help with the increased atmosphere in the sun's path. Because of these factors the most productive hours of sunlight are from 9:00 a.m. to 3:00 p.m. around solar noon (solar south). This is different than 12:00 noon. Before and after these times power is being produced, but at much lower levels. When we size solar panels for a solar power system, we take these equivalent full sun hour figures per day and average them over a given period. You can quickly refer to Solar for U.S. Major Cities, and then come right back here. Just close the new window that appears. For a view of global solar insolation values (peak sun-hours) use this link: Global Peak Sun-hour Maps Then, you can use [back] or [previous] on your browser to return right here if you want to. In most locations in the United States winter produces the least sunlight because of shorter days and increased cloud cover, as well as the sun's lower position in the sky. Usually, we work with a yearly average, a June - July average when insolation is highest, and a December - January average when insolation is lowest.

The diagram above illustrates the path of the sun over varying seasons. Remember when selecting a site for your solar power panels to pick a spot that is clear of shade from a minimum of 10 A.M. to 2 P.M. on December 21st. Even a limb from a deciduous tree will substantially reduce power output. Many solar sites are quite uncomplicated in terms of shading and aspect. You may already have a good idea of where the sun appears in the morning and disappears in the evening, as well as how low it swings in the winter sky. If your site is partially shaded, it may be necessary to determine exactly where the best placement of solar panels will be. If you need a more sophisticated site analysis, please contact us. We also have world-wide insolation data as well as more local data that can be useful for your particular location. Nominal DC System Voltage Since solar panels charge your battery and these are both typically low voltage DC items, it's best to decide up-front what your nominal DC voltage will be. The decision of which DC voltage to use is often dictated by the distance between the various components. For example, with solar panels wired at 12 volts charging a 12 volt

battery it is difficult to "push" the 12 volts very far, so if the solar array is going to be more than 75 -100 feet from the batteries it would be advisable to have 24 volt nominal charging since 24 volts will push farther than 12 volts over the same wire size. Rather than increase the wire size to the thickness of your thumb as in a AWG#0000 (4 ought) cable to carry the 12 volts efficiently, it's usually advisable to use 24 or 48 volts and keep the wire sizes between components much smaller. For further reference click the link below or contact us for assistance. Wire Loss and Ampacity Tables - to determine voltage drop and wire size for various distances

1. Load Calculation Work Form

This worksheet determines the total amp hours per day used by all the AC and DC loads in your system. CLICK HERE - Print out a form to apply your own data. Step 1 Calculate your AC and DC loads. List wattage and hours of use per week (or other period) for all loads in the spaces provided. Multiply Watts by Hours/Week to get Watt-Hours per Week (WH/Wk.) for each load. Then add up all the watt hours per week to determine total Watt Hours Per Week. For total home systems that have a grid-connected electrical history you can simply use the kWh per month from your bill and convert this into a weekly figure, where the monthly kWh (X) divided by 4.3 times 1000 equals your average weekly watt-hours per week. The form requests weekly totals, but you can change weekly watt-hours to daily or any period which applies to your particular situation by simply modifying the time period that you're working with...as long as you establish Ah/day in Line #10. Note: Wattage of appliances can usually be determined from tags on the back of the appliance or from the owner's manual. If an item is rated in amps, multiply amps by operating voltage to find the watts. Another way to more accurately calculate your AC loads is to use a power meter. We sell various power meters that simply "plug in" and you read the actual wattage. These are very handy for planning a solar power electric system, but also very useful to have around after you get your system up and running. These power meters start at $99, but can often save you by more accurately calculating your actual loads for specific items. Contact us for more information on the power meter.

Wire Loss and Ampacity Tables - to determine voltage drop and wire size for various distances.

2. INVERTER SELECTION

Inverters are rated in continuous wattage and surge watts. Continuous watts is the total watts the inverter can support indefinitely. So a 4000 watt inverter can power up to 4000 watts continuously. Surge watts is how much power the inverter can support for a very brief period, usually momentary. So a 4000 watt inverter rated at 7000 surge watts can handle up to 7000 watts momentarily while starting such loads as motors - which usually require more than normal power to get started. Go to Inverter Terminology to better understand equipment specifications (opens a new window - use [X] to close) To select the appropriate inverter size, refer back to the LOAD CALCULATION WORK FORM and add up the wattage of your specific items which will (or potentially can) operate simultaneously to determine the minimum continuous watts you need. Then, also look at the potential surge of the specific items to determine the minimum surge wattage you'll need. Usually, you'll need 1.5 to 2 times the continuous rating. Some deep well submersible pumps can require 3 times the surge protection. We can assist you with this if you have any problems determining either continuous or surge requirements. Finally, if any of your specific items operate at 220-240 volts you'll need either a step-up transformer - which will also give you the 220-240 volts for one or more items, or you can "stack-interface" two inverters to produce both 120 and 240 volts. We can assist you with this if you're not sure which way is better for you.

3. Solar Array Sizing Work Form

This type worksheet helps figure the total number of solar modules required for your system. CLICK HERE - Print out a form to apply your own data. To find average sun hours per day in your area (line 3), check local weather data, or go to the Solar Energy Maps page. If you want year-round reliability, it's best to use the lowest of the figures or "smooth" the data. The peak amperage of the module you will be using can be found in the module specifications. You can also get close enough for this basic understanding if you divide the modules wattage by the peak power point voltage, usually (17 to 18.5.

4. Battery Size Work Form

This type of worksheet helps determine what size batteries are required for your system. CLICK HERE - Print out a form to apply your own data. Battery size is measured in AMP-HOURS. This is a measure of battery capacity. All lead-acid batteries have a nominal output of 2 volts per cell. Actual cell voltage varies from about 1.7 volts at full discharge to 2.4 volts at full charge. 12 volt leadacid batteries are made of 6 separate cells in one case. 6 volt batteries are made of 3 cells in one case. Industrial 2 volt single-cell batteries are also used in a series for larger applications. Series connections are where the positive terminal of one battery is connected to the negative terminal of another, resulting in increased voltage.

Putting battery cells in parallel (positive to positive and negative to negative) increases (amps) amp-hour capacity, but does not affect voltage.

Batteries

Battery Size The size of the battery bank required will depend on the storage capacity required, the maximum discharge rate, the maximum charge rate, and the minimum temperature at which the batteries will be used. When designing a power system, all of these factors are looked at, and the one requiring the largest capacity will dictate battery size. Our System Sizing work forms take many of these factors into account. One of the biggest mistakes made by those just starting out is not understanding the relationship between amps and amp-hour requirements of 120 volt AC items versus the effects on their DC low voltage batteries. For example, say you have a 24 volt nominal system powering a load of 3 amps, 120VAC, which has a duty cycle of 4 hours per day. You would have a 12 amp hour load (3A X 4 hrs=12 ah). However, in order to determine the true drain on your batteries you have to divide your nominal battery voltage (24v) into the voltage of the load (120v), which is 5, and then multiply this times your amp hours (12 ah). So in this case the calculation would be 60 amp hours drained from your batteries - not the 12 ah. The easiest way to quickly determine the total battery amp hours required is to first determine total watt-hours required by all loads, and then divide by the nominal DC system voltage. This resulting number will indicate the amount of amp hours needed to operate all loads for a given period. However, additional amp hour capacity would typically be added for more "reserve" capacity or to prevent complete discharge. Using the above example, 3 amps x 120 VAC x 4 hours = 1440 watt-hours divided by 24 VDC battery environment equals 60 amp-hours; the same answer as before, but another way to get it. There are other factors for determining the full extent of the battery drain, such as temperature, start-up factors, etc., but this should help you get a more complete picture on how to size your low DC voltage batteries when powering 120/240 volt loads using an inverter. Our System Sizing work forms take many of these factors into account. Temperature has a significant effect on lead-acid batteries. At 40F they will have about 75% of rated capacity, and at 0F their capacity drops to about 50%. An exception to this general rule would be the Concorde PVX battery, which is not as sensitive to these temperature extremes. The storage capacity of a battery, the amount of electrical energy it can hold, is usually expressed in amp hours. If one amp is used for 100 hours, then 100 amphours have been used. A battery in a solar power system should have sufficient amp hour capacity to supply needed power during the longest expected period "no sun" or extremely cloudy conditions. In wind systems allowance for "no wind" days should be included. A lead-battery should be sized at least 20% larger than this amount. If there is a source of back-up power, such as a standby generator along with a battery charger, the battery bank does not have to be sized for worst-case weather conditions.

Series Wiring Series wiring refers to connecting batteries to increase volts, but not amps. If you have two 6 volt batteries like the Trojan L16 rated at 350 amp hours, for example, by connecting the positive terminal of one battery to the negative terminal of the other, then you have series wired the two together. In this case, you now have a 12 volt battery and the rated 350 amps does not change. If you were to series wire four L16's you'd have 24 volts at 350 amps, and so on. Parallel Wiring Parallel wiring refers to connecting batteries to increase amps, but not volts. If you have two 6 volt batteries like the Trojan L16 rated at 350 amp hours, for example, by connecting the positive terminal of one battery to the positive terminal of the other, and the same with the negative terminal, then you have parallel wired the two together. In this case, you now have a 6 volt battery and the rated 350 amps increases to 700 amp hours. If you were to series wire four L16's you'd have 24 volts at 350 amps, and then parallel wire these four to the four other that are in series, then you'd have a 24 volt battery at 700 amps.

Five basic wiring types Using these wiring examples a complete battery bank might have any number of total batteries to achieve required reserve capacity. Lead-Acid Batteries Lead-acid batteries are the most common in PV systems because their initial cost is lower and because they are readily available nearly everywhere in the world. There are many different sizes and designs of lead-acid batteries, but the most important designation is whether they are deep cycle batteries or shallow cycle batteries. Shallow cycle batteries, like the type used as starting batteries in automobiles, are designed to supply a large amount of current for a short time and stand mild overcharge without losing electrolyte. Unfortunately, they cannot tolerate being deeply discharged. If they are repeatedly discharged more than 20 percent, their life will be very short. These batteries are not a good choice for a PV system.

Deep cycle batteries are designed to be repeatedly discharged by as much as 80 percent of their capacity so they are a good choice for power systems. Even though they are designed to withstand deep cycling, these batteries will have a longer life if the cycles are shallower. All lead-acid batteries will fail prematurely if they are not recharged completely after each cycle. Letting a lead-acid battery stay in a discharged condition for many days at a time will cause sulfation of the positive plate and a permanent loss of capacity. Sealed deep-cycle lead-acid batteries are maintenance free. They never need watering or an equalization charge. They cannot freeze or spill, so they can be mounted in any position. We especially recommend sealed batteries for remote, unattended power systems, but also for any client who wants the maintenance free feature and doesn't mind the extra cost associated with these batteries. The Concorde PVX series (Sun-Xtender) is an excellent choice. Sealed Gel Cell (gelled-electrolyte) batteries are relatively maintenance free, however unlike a high quality sealed lead-acid battery like the Concorde PVX extra care must be taken to insure a Gel Cell battery is not charged above 14.1 volts for a 12 volt battery, for example. Over charging a Gel Cell even once for a sustained period can really shorten it's life and even ruin it. Any charge source or charge regulator used must have user adjustable settings for sealed Gel Cell batteries to insure charge voltage does not exceed a safe limit. If your application dictates a sealed, gelled battery the Deka-East Penn MK series is an excellent choice. Caring For Wet Cell Lead-Acid Batteries Wet cell lead acid batteries like the high quality Surrette require periodic watering and equalization. Always use extreme caution when handling batteries and electrolyte. Wear gloves, goggles and old clothes. "Battery acid" will burn skin and eyes and destroy cotton and wool clothing. The quickest way to ruin lead-acid batteries is to discharge them deeply and leave them stand "dead" for an extended period of time. When they discharge, there is a chemical change in the positive plates of the battery. They change from lead oxide when charged to lead sulfate when discharged. If they remain in the lead sulfate state for a few days, some part of the plate does not return to lead oxide when the battery is recharged. If the battery remains discharged longer, a greater amount of the positive plate will remain lead sulfate. The parts of the plates that become "sulfated" no longer store energy. Batteries that are deeply discharged, and then charged partially on a regular basis can fail in less than one year. Check your batteries on a regular basis to be sure they are getting charged. Use a hydrometer to check the specific gravity of your lead acid batteries. If batteries are cycled very deeply and then recharged quickly, the specific gravity reading will be lower than it should because the electrolyte at the top of the battery may not have mixed with the "charged" electrolyte. Check the electrolyte level in wet-cell batteries at least four times a year and top each cell off with distilled water. Do not add water to discharged batteries. Electrolyte is absorbed when batteries are very discharged. If you add water at this time, and then recharge the battery, electrolyte will overflow and make a mess.

Keep the tops of your batteries clean and check that cables are tight. Do not tighten or remove cables while charging or discharging. Any spark around batteries can cause a hydrogen explosion inside and ruin one of the cells, and possibly you too. It is a good idea to do an equalizing charge when some cells show a variation of 0.05 specific gravity from each other. This is a long steady overcharge, bringing the battery to a gassing or bubbling state. Typically, we'll recommend an equalization charge at least once a month. Do not equalize sealed or gell type batteries. With proper care, lead-acid batteries will have a long service life and work very well in almost any power system. Measuring battery condition Connect a voltmeter and measure the voltage across the battery terminals with the battery at rest (no input, no output) for at least three hours. These readings are best taken in the early morning, at or before sunrise, or in late evening. Take the reading while all loads are off and no charging sources are producing power. The following table will allow conversion of the voltage readings obtained to an estimate of state of charge. The table is good for batteries at 77F that have been at rest for 3 hours or more. If the batteries are at a lower temperature you can expect lower voltage readings. You can see that when your voltage reading is about equal to the battery "nominal voltage" your battery is about 60% discharged. Battery State of Charge Voltage Table

Percent of Full 12 Volt DC Charge System 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 12.7 12.6 12.5 12.3 12.2 12.1 12.0 11.8 11.7 11.6 <11.6

24 Volt DC System 25.4 25.2 25 24.6 24.4 24.2 24 23.6 23.4 23.2 <23.2

48 Volts DC System 50.8 50.4 50 49.2 48.8 48.4 48 47.2 46.8 46.4 <46.4

The following chart reflects state of charge vs. specific gravity of the electrolyte in each cell. A hydrometer is used to determine specific gravity. State of Charge 100% Charged 75% Charged 50% Charged 25% Charged Fully Discharged Specific Gravity 1.265 1.239 1.200 1.170 1.110

These readings are correct at 75F

Solar Insolation for U.S. Major Cities This chart shows solar insolation in kilowatt-hours per square meter per day in many US locations. For simplicity, we call this figure "Sun Hours / Day". To find average sun hours per day in your area (column 5), check local weather data, look at the maps at the bottom of this page, or find a city in the table below that has similar weather to your location. If you want year-round autonomy, use the lowest figure. If you want only 100% autonomy in summer, use the highest figure. State City AK AK AL AR AR AZ AZ AZ CA CA CA CA CA CA CA CA CO CO CO CO DC FL FL FL Fairbanks Matanuska Montgomery Bethel Little Rock Tuscon Page Pheonix Santa Maria Riverside Davis Fresno Los Angeles Soda Springs La Jolla Inyokern Grandby Grand Lake Grand Junction Boulder Washington Apalachicola Belie Is. Miami High Low Avg 5.87 5.24 4.69 6.29 5.29 7.42 7.30 7.13 6.52 6.35 6.09 6.19 6.14 6.47 5.24 8.70 7.47 5.86 6.34 5.72 4.69 5.98 5.31 6.26 2.12 3.99 1.74 3.55 3.37 4.23 2.37 3.81 3.88 4.69 6.01 6.57 5.65 6.36 5.78 6.58 5.42 5.94 5.35 5.87 3.31 5.10 3.42 5.38 5.03 5.62 4.40 5.60 4.29 4.77 6.87 7.66 5.15 5.69 3.56 5.08 5.23 5.85 4.44 4.87 3.37 4.23 4.92 5.49 4.58 4.99 5.05 5.62 State City MO MO MS MT MT MT NM NB NB NC NC ND NJ NV NV NY NY NY NY NY OH OH OK OK Columbia St. Louis Meridian Glasgow Great Falls Summit Albuquerque Lincoln N. Omaha Cape Hatteras Greensboro Bismark Sea Brook Las Vegas Ely Binghamton Ithaca Schenectady Rochester New York City Columbus Cleveland Stillwater High Low Avg 5.50 4.87 4.86 5.97 5.70 5.17 7.16 5.40 5.28 5.81 5.05 5.48 4.76 7.13 6.48 3.93 4.57 3.92 4.22 4.97 5.26 4.79 5.52 3.97 4.73 3.24 4.38 3.64 4.43 4.09 5.15 3.66 4.93 2.36 3.99 6.21 6.77 4.38 4.79 4.26 4.90 4.69 5.31 4.00 4.71 3.97 5.01 3.20 4.21 5.84 6.41 5.49 5.98 1.62 3.16 2.29 3.79 2.53 3.55 1.58 3.31 3.03 4.08 2.66 4.15 2.69 3.94 4.22 4.99 4.98 5.59

Oklahoma City 6.26

FL FL GA GA HI IA ID ID IL IN KS KS KY LA LA LA MA MA MA MA MA MD ME ME MI MI MN

Gainsville Tampa Atlanta Griffin Honolulu Ames Boise Twin Falls Chicago Indianapolis Manhattan Dodge City Lexington Lake Charles New Orleans Shreveport E. Wareham Boston Blue Hill Natick Lynn Silver Hill Caribou Portland E. Lansing St. Cloud

5.81 6.16 5.16 5.41 6.71 4.80 5.83 5.42 4.08 5.02 5.08 4.14 5.97 5.73 5.71 4.99 4.48 4.27 4.38 4.62 4.60 4.71 5.62 5.23 4.71 5.43

4.71 5.27 5.26 5.67 4.09 4.74 4.26 4.99 5.59 6.02 3.73 4.40 3.33 4.92 3.42 4.70 1.47 3.14 2.55 4.21 3.62 4.57 5.28 5.79 3.60 4.94 4.29 4.93 3.63 4.92 3.87 4.63 3.06 3.99 2.99 3.84 3.33 4.05 3.09 4.10 2.33 3.79 3.84 4.47 2.57 4.19 3.56 4.51 2.33 4.20 2.70 4.00 3.53 4.53

OR OR OR PA PA RI SC SD TN TN TX TX TX TX TX UT UT VA WA WA WA WA WA WI WV WY

Astoria Corvallis Medford Pittsburg State College Newport Charleston Rapid City Nashville Oak Ridge San Antonio Brownsville El Paso Midland Fort Worth Salt Lake City Richmond Seattle Richland Pullman Spokane Prosser Madison Charleston Lander

4.76 5.71 5.84 4.19 4.44 4.69 5.72 5.91 5.20 5.06 5.88 5.49 7.42 6.33 6.00 6.09 4.50 4.83 6.13 6.07 5.53 6.21 4.85 4.12 6.81

1.99 3.72 1.90 4.03 2.02 4.51 1.45 3.28 2.79 3.91 3.58 4.23 4.23 5.06 4.56 5.23 3.14 4.45 3.22 4.37 4.65 5.30 4.42 4.92 5.87 6.72 5.23 5.83 4.80 5.43 3.78 5.26 5.48 5.83 3.37 4.13 1.60 3.57 2.01 4.44 2.90 4.73 1.16 4.48 3.06 5.03 3.28 4.29 2.47 3.65 5.50 6.06

Flaming Gorge 6.63

Sault Ste. Marie 4.83

Wire Loss and Ampacity Tables 2% Voltage Drop Chart For 12 volt Systems Maximum distance in feet of various gauge two conductor copper wire from power source to load for 2% voltage drop in a 12 volt system. Do not exceed the 2% drop for wire between PV modules and batteries. A 4 to 5% loss is acceptable between batteries and lighting circuits in most cases, however the cost of the next larger wire size is usually insignificant and increases efficiency. Amps 1 2 4 6 8 10 15 20 25 30 40 50 100 150 200 #14 45 22.5 10 7.5 5.5 4.5 3 2 1.8 1.5 . . . . . #12 70 35 17.5 12 8.5 7 4.5 3.5 2.8 2.4 . . . . . #10 115 57.5 27.5 17.5 11.5 11.5 7 5.5 4.5 3.5 2.8 2.3 . . . #8 180 90 45 30 22.5 18 12 9 7 6 4.5 3.6 . . . #6 290 145 72.5 47.5 35.5 28.5 19 14.5 11.5 9.5 7 5.5 2.9 . . #4 456 228 114 75 57 45.5 30 22.5 18 15 11.5 9 4.6 . . #2 720 360 180 120 90 72.5 48 36 29 24 18 14.5 7.2 4.8 3.6 #1/0 . 580 290 193 145 115 76.5 57.5 46 38.5 29 23 11.5 7.7 5.8 #2/0 . 720 360 243 180 145 96 72.5 58 48.5 36 29 14.5 9.7 7.3 #4/0 . 1060 580 380 290 230 150 116 92 77 56 46 23 15 11

Top of Page

5% Voltage Drop Table The following tables represent the maximum one-way distance for various wire gauge, voltage and current combinations based upon a 5% voltage loss for 120v and 24v. Five percent is acceptable in most low voltage systems, except 12 volt (see above). NOTE: To obtain a 2% figure from these tables, divide the given distance shown in the table by 2.5. For calculating distances for 48 volt systems, multiply the 24 volt distances by 2. For 240 volt systems, multiply the 120 volt distances by 2. Below stepped lines check ampacity. The (=) indicates over 1000 feet. Top table = 120/240 volts; Lower table = 24/48 volts; or slide page to view voltage -------------------->

Below stepped lines check ampacity. The (=) indicates over 1000 feet. To achieve maximum efficiency from your power system you do not want to undersize your wire between various components. If in doubt use a larger wire size than the charts suggest. We will generally size the wire to maintain no more than a 2 - 3 percent voltage drop regardless of the system voltage, however this factor is more critical on low voltages. For 120/240 volts a maximum of five percent loss is acceptable unless specific equipment dictates otherwise. The difference in cost of the next larger-size wire is usually insignificant to the overall costs, where performance may be affected over the life of the system. In addition, improperly sized wire can shorten the life of your components. **IMPORTANT** Before using these tables, some calculations must first be performed by the system designer to insure accurate current ratings and safety factors are used. For solar modules, the UL-1703 standard requires the short circuit current (lsc) rating of the PV module be multiplied by 125% before other factors are applied. This is because the PV module electrical performance can increase above the factory rating due to the combination of increased operating temperatures and enhanced irradiances over 1000W/M2 (such as edge-of-cloud effect).

NOTE The "edge-of-cloud effect" is also a consideration when sizing a charge/voltage controller for solar modules. Use the short-circuit current rating to determine the controller - see below. The NEC requires the short circuit current ratings of the PV module or array be multiplied by 125% before calculating ampacities of any cable or over-current device. This is in addition to the UL required 125%! This yields a multiplier of (125%x125%=156%) or 1.56. Although this may seem redundant, good design practice dictates both factors should be used when determining wire size from the solar array to the battery. Example A 24V solar array of four Solarex MSX-120 modules, 2 in series by 2 parallel modules located 30 ft. from the battery; lsc=7.60 A (two modules); 7.60 x 2 = 15.2A (four modules); 15.2A x 1.56 = 23.71A. Using the 24 volt table, locate a value equal to or greater than 24 amps from the left column, follow a line to the right until a distance at or above 30 ft. is found. For this example, using the 24 volt table, we find 25 amps at 36 feet to be the best selection (for not more than 5% loss) indicating a wire size of #8 AWG. For the controller, a minimum 20A would be needed - 15.2A x 125% = 19A, and the nearest available size controller is a 20A unit.

Top of Page

Maximum Ampacity for Copper and Aluminum Wire Wire Size 14 12 10 8 6 4 2 Copper 25 30 40 55 75 95 130 Aluminum . 25 35 45 60 75 100

1 1/0 2/0 4/0

150 170 265 360

115 135 150 205

NEC allows rounding up cable ampacity to next standard fuse or breaker.

General Construction Considerations Here we discuss solar power energy considerations prior to new construction or when remodeling an existing structure. Passive solar (solar thermal) makes use of the sun's heat energy and compliments solar power electric - photovoltaics. Energy efficiency can be maximized if certain features are incorporated into the design of your home, office or other utility building. Passive solar features are used to keep a building warmer in the winter, and if planned properly, the same features will also keep the building cooler in the summer. There are numerous considerations. Here's a few important ones. Some Important Energy Considerations When building an energy efficient structure it's not what you do, but what you do and how you do it. Solar power & Passive Solar: If you're considering an alternative form of electrical production using solar power or other resources, the following items can be very useful to minimize overall energy requirements when designing a building. However, even if you don't utilize an alternative electrical system you can still benefit by considering these features in your construction design. Enough sunlight falls on the Earth's surface each minute to meet world energy demands for an entire year. The sun is a fusion reactor delivering 1.52 x 1018 kWh/year to earth. All of mankind's energy needs total less than 0.1% of this amount. The United States receives more energy in the form of sunlight in less than 40 minutes than from all the fossil fuels we burn every year? Source: Solar Energy Research and Education Foundation The average American family spends over $1,500 per year on utility bills. This expense can be reduced by 10% to as much as 90% percent depending on how aggressive you want to be about getting more efficient. Figures for businesses are much harder to quantify due to varying sizes and types. Heating and cooling your home uses more energy and drains more energy dollars than any other system in your home. Typically, 44% of your utility bill goes for heating and cooling. What's more, heating and cooling systems together in the United States emit over a half billion tons of carbon dioxide into the atmosphere each year, adding to global warming & other health issues. They also generate about 24% of the nation's sulfur dioxide and 12% of the nitrogen oxides. Using the sun to heat your home through passive solar design can be environmentally friendly and cost effective. In many cases, you can cut your heating costs by more than 50% compared to the cost of heating the same house that does not include passive solar design. Solar Orientation Simple, but confusing? Lattitude 50.00 North. The sun really only rises exactly in the east and sets exactly in the west on two days of the year - the first day of spring and the first day of fall. The sun rises in a direction north of east and sets in a

direction north of west during the spring and summer months (northerly latitudes). The sun rises in a direction south of east and sets in a direction south of west during the fall and winter months (northerly latitudes). The sun reaches its peak (zenith) at a point due south of the observer (northerly latitudes). The time this occurs is defined as solar noon. The sun's zenith is closer to the horizon during fall and winter months, and is higher in the sky during spring and summer months. The sun rises earlier and sets later during the spring and summer months, with the opposite being true during the fall & winter months. Most energy-sensitive architects and builders understand that a south facing orientation tends to increase solar heat during winter months. However, it can also produce extreme heat on the west facing sides of the structure in the summer, thus negating any overall benefit. In fact, sometimes there's an overall decline in efficiency. As the illustration below shows you, in the winter months the sun arcs much lower in the sky and the path is much shorter than in the summer. A building project should be evaluated for orientation, but don't automatically assume that facing true south is the best. It can be, but only when other features are incorporated. Your building can be angled as much as 15 east or west of true south and still be energy efficient. The southern orientation of the building could vary by up to 30 from true south without significantly harming its heating season performance, but because such a large variance could seriously reduce cooling performance, it is recommended that the orientation should not vary by more than 15 either to the east or west of true south.

Eave Projection: The eaves or soffit width can make a big difference. By using the proper projection off the main structure for your particular location, your building can be mostly in the shade by 10:30AM in the summer, keeping it cooler, and be kept out of the shade during winter months, which keeps it warmer. Proper eave projections can also enable you to use more glass surfaces since they'll permit winter solar heat, but also shade the same windows in the summer.

For example, in June - July when the summer sun is moving from about 65 to 75 degrees overhead between 10:30AM & noon, a south facing building with only a 36" eave or soffit on the south side will be virtually in the shade on the south side, will have little or no east side solar heat (deflection is also occurring), and of course will not have any solar heat on the west or north. With a more typical 12" to 16" soffit, the south

side is absorbing a lot of heat, thus increasing cooling costs. Conversely, in December - January the winter sun arcs at about 22-25 degrees in the sky, and the solar heat can help warm the south exterior and pass through the windows to warm the interior.Graphic courtesy of North Carolina Solar Center. Landscape Features: Trees can be very helpful or very restrictive in passive solar designs depending on how close they are to the structure and what type of tree it is. Evergreen trees should ideally be kept on the west, north and northeast if they are close to the building. Deciduous trees which lose their leaves in the fall are usually best on the south side, but if you will be using rooftop solar photovoltaics you wouldn't want them too close or too high. For passive solar energy, during the summer they can provide additional shading, and after losing their leaves in the fall they will permit winter sun to warm the building. Taking full advantage of trees and shrubs can provide shading, wind break and other benefits. Window Glass: Energy efficient window glass can really help to keep summer heat from penetrating your windows, especially on the west side, but also allow winter solar heat to keep your structure warmer - without ruining your furnishings. Besides normal consideration of double or triple pane for heat & cooling losses, depending on window size and compass orientation, we recommend using inexpensive transparent, Low-E coatings (Low Emissivity) applied by the window manufacturer when ordering your windows. Particularly on west facing windows, the Low-E coating dramatically reduces the amount of solar heat passing through to your interior in the summer. When it's combined with sealed gases like Argon in double or triple pane, Low E coatings can either keep heat in or out, and reduce ultraviolet ray penetration by up to 84%. What Low-E does (see graphic): 1. The Low-E allows most natural light to enter freely, but absorbs a significant portion of short-wave heat energy. 2. In the summer, long-wave heat energy is reflected back outside, lowering cooling cost. 3. In winter, internal long-wave heat energy is reflected back inside, lowering heating cost. Unlike other insulating features of the home, the efficiency of windows is typically expressed in terms of an U-value. U-value measures the conductivity of the window (this is the inverse of R-value.) Therefore, the lower the U-value the better. Using a lot of glass material may be aesthetically desirable, but balance should be maintained. Plain glass has a very high U value. Even high performance double and triple pane windows will still cause relevant losses, so this is a factor to consider. Too much glass on a particular side of a building can be very costly in lost energy efficiency. The idea should be to use enough glass material to keep the structure light and reasonably bright, but to understand that for every square foot of glass there is some relevant loss of heating & cooling efficiency. Windows on the north side should be few in number and small in size, to reduce heat loss from this exposure. The eave or soffit projections can be sized to enable the use of more glass, more efficiently. Wind Barriers: The proper use of "wrap" or a wind barrier prior to final siding will help restrict unwanted air flow in the wall and ceiling cavities, but unless it's installed properly, it's a waste of money. Tyvek is a brand name familiar in most parts of the

country. We often see this material applied using only a staple gun. This method is a big waste of your money. This material can be very helpful, but all edge seams, cut ends and window/door openings must be sealed properly - not just stapled. Absorption Materials: The use of stone, brick or tile in the interior can absorb winter solar heat during the day through window openings, and then slowly release it throughout the evening. Decorative water columns are also used. However, unless it is also kept shaded in summer months, it's effect is negated or worse. There are many interior features which can be utilized to store heat during the day in the winter to reduce overall heating costs. The same holds true for keeping cooling costs down, but it makes little sense to gain in one respect and then lose it in another. Solar angles throughout the year, window sizes, eave projections and total mass of the absorption material are all considerations. Insulation & Caulking: Proper insulation and caulking during construction is obviously very important. One of the most important factors is to be certain the insulation is properly sized, but equally important is that it be installed correctly. We often see buildings with the correct thickness of material, but the installation is inferior. Many construction companies use low-cost labor to install the insulation, and the building owner ends up paying for it, over and over again in higher heating/cooling costs. The required thickness of wall and ceiling insulation varies from area to area, but as a general rule, using fiberglass as a basis; 6" in the walls and 12" in the ceiling is the minimum. This generally means the outside frame walls will be made using a nominal 6" thick dimension. However, unless other construction practices are kept to the highest standards, the insulation properties are seriously diminished. Proper installation of insulation materials is critical. For even a small home we'll usually recommend $300 in caulking alone, but in the coldest periods you can walk around in your bare feet without drafts. This isn't a reflection of using caulking to make-up for lousy carpentry. The intent is to compliment good carpentry. It's a matter of properly sealing joints and other areas so air penetration into your interior from the sill areas, corners, etc. is minimized. Those that say you shouldn't make a building too tight usually do not understand how to build a truly energy efficient home. It is true you can make a building too tight, but through the proper use and installation of certain construction products, your energy efficiency can be increased dramatically. When building an energy efficient structure it's not what you do, but what you do and how you do it. Fresh air exchange is important in any residential or commercial building. However, compared to typical construction which usually results in a fresh air exchange ratio of about 8 to 1 or even 10 to 1, a really energy efficient building will have about a 2.5 - 3 to 1 exchange ratio. A building should also have sufficient exhausting in kitchens, baths, etc. This is important to keep the air quality fresh and healthy. In contrast, a 10 to 1 ratio means you're literally just blowing in the wind wasting all kinds of heat and cooling. A home does have to breathe, but there's a difference between enabling a home to breathe and inefficient construction which causes undesirable air flow.

Gas vs. Electric: It's more efficient to "heat" with gas than electricity. Electricity does well on inductive loads like motors and such, but resistive loads (heat elements) are better heated with natural or propane gas. You're far better to use gas for central heating, hot water, your kitchen range/oven and even your clothes dryer. Maytag, for example makes an excellent gas clothes dryer in case you weren't aware you could even buy one. Most newer modern gas appliances are now 99+% emissions efficient, also making them desirable over electrical units which require more energy derived from fossil fuels. Note: In a forced air heating system, extreme care should be taken to insure all ducts are thoroughly sealed at joints and well insulated to insure maximum efficiency. High Efficiency Appliances: High efficiency refrigerators, water heaters, furnaces, air conditioners, etc. are available. Efficient appliances save resources and money, reduce environmental impacts, and keep your home cooler in the summer by eliminating the heat wasted by inefficient appliances. They do cost more up front, and sometimes the pay back for the extra cost takes 5, 7 or 10 years depending on the appliance and the amount of use. However, if you can afford the extra up-front cost, and you intend to own the structure a long time, they are definitely worth it. They are especially helpful and recommended if you produce your own electricity (being off the grid) with alternative energy. Geothermal Energy: Using relatively stable underground temperatures to assist heating in the winter and cooling a structure in the summer is very viable. A yearround average underground temperature of say, 50-55 deg. is sufficient to pre-warm fluid systems when outside temperatures may be hovering below freezing. The colder the outside air the more viable these systems are - if sized accordingly. Conversely, that same average underground temperature can cool fluids and be used to provide "air conditioning". The geothermal system uses the earth as a heat/cooling source and "sink". The heat is exchanged with the earth via a system of buried plastic pipes called the ground heat exchanger. In the winter, the fluid within the pipes extracts heat from the earth, carries it through the system and into the building. In the summer, the system reverses itself. Heat is pulled from the building, carried through the system and deposited in the cool earth. In addition waste heat from the system can be used to provide domestic hot water at no cost in the summer and at a substantial savings in the winter. The graphic image illustrates a "closed loop" system. Caution is advised to used established industry methods and equipment for geothermal energy. Attempts at "home built" versions may not function efficiently although this is not to say you can't build your own system. One key point to remember is that "air" is a poor conductor by itself. Air space is an insulator because air does not conduct well. So just forcing a whole lot of air through an underground trench loop isn't effective. Plus air can absorb unhealthy Radon gases, etc. If air is used (not recommended), there must be an "exchanger" of some type for the circulated air to pass through, much like the heat exchanger in a forced hot air

heating system or the exchanger in an air conditioning system. It's better to use a fluid to absorb ground temperature. If sized & built properly, a geothermal system can be extremely energy efficient. Compact Fluorescent Lighting: A regular light bulb produces about 5-7 times more heat energy than it does light. That's why they're very hot when you touch them. A compact fluorescent bulb is just the opposite, producing 5 times more light than heat. They're barely warm to the touch. In addition, while most regular bulbs have an average life of about 800 - 1000 hours of use, a C.F. may have a life of 810,000 hours, or ten times as long. Also, it takes a lot less electrical energy to produce the same light output. C.F.'s cost more, about 8-10 times as much as a regular bulb of equal light output, but over the life of the bulb they save enough electrical energy to pay for themselves. Here's an example. A regular 100w bulb costs about $1.50 and lasts 1000 hours. It will consume about $8 in electricity at $.08/kWh. So that's a total of $9.50 per 1000 hours. Now multiply this by 10, or $95. An equivalent 100w C.F. lasting 10,000 hours costs about $16 and will use only 27 watts to produce 100w of light. The C.F. will consume about $22 at $.08/kWh. The total for the C.F. is $38. The difference is about $57 per bulb over a period of 10,000 hours of use. If you have say, 30 light bulbs in your building, then the potential savings is $1,710. If you figure this over a ten year period you will save about $171 per year by using C.F.'s for 30 light bulbs. C.F.'s make sense, however some lighting fixtures will not accommodate the larger bulb size since C.F.'s are a little bigger in size. Also, some fixtures are intended to be flood or spot lights, and C.F.'s aren't as good for this purpose. We usually recommend them for any fixture they'll fit into nicely, unless the fixture is intended for occasional decorator purposes as a flood lamp. Color & Materials: Exposed surfaces affected by summer/winter solar heat is a factor. The total surface areas and their color or material should be considered. Darker colors absorb more heat in the winter, but also in the summer. The top four absorbing colors are black, red, brown & navy blue. Balance of the type of materials and color can make a difference in overall efficiency, although with the proper insulation & other design features there's plenty of room for decorative colors. Brief Summary These are just some of the considerations which should go into the design of a truly energy efficient building. The more the better. You don't have to dig a hole in the side of a south facing hill to achieve high efficiency. You also don't have to ruin a beautiful architectural concept just to make it efficient. But a little compromising on some key issues may make all the difference in the world. However, never compromise on the quality of workmanship going into your project. Each & every phase must be completed according to exact specifications if you are to really benefit from all the planning. Proper instruction and supervision of construction personnel can not be stressed enough. Do not permit transient labor or untrained personnel to perform certain functions in your project. Too many

areas of construction get covered over by the next phase, and you may not see or feel the affects until after they've been paid and gone.

Glossary of Related Solar Power Terms

absorbers--Dark-colored objects that soak up heat in thermal solar power collectors used to produce heat energy. active solar heater--A solar water or space-heating system that moves heated air or water using pumps or fans. AGM -- Absorbed Glass Mat, a newer type of battery construction that uses saturated absorbant glass mats rather than gelled or liquid electrolyte. Somewhat more expensive than flooded (liquid), but offers very good reliability. alternating current--Electric current in which the direction of flow is reversed at frequent intervals--usually 100 or 120 times per second (50 or 60 cycles per second or 50//60 Hz). amorphous semiconductor--A non-crystalline semiconductor material. Easier and cheaper to make than crystalline, but less efficient and slowly degrades over time. Also called thin film. ampere (A) or amp--The unit for the electric current; the flow of electrons. One amp is 1 coulomb passing in one second. One amp is produced by an electric force of 1 volt acting across a resistance of 1 ohm. ampere-hour (Ah)--Quantity of electricity or measure of charge. How many amps of flow or which can be provided over a one hour period. Deep cycle batteries used in solar power systems are rated in Ah (amp-hour). angle of incidence--Angle between the normal to a surface and the direction of incident radiation; applies to the aperture plane of a solar collector. Most modern solar panels have only minor reductions in power output within plus/minus 15 degrees. antireflection coating--A thin coating of a material, which reduces the light reflection and increases light transmission, applied to a photovoltaic cell surface. array--Any number of photovoltaic modules connected together to provide a single electrical output. Arrays are often designed to produce significant amounts of electricity. autonomous system--A stand-alone PV system that has no back-up generating source. May or may not include storage batteries. Most battery systems are designed for a certain minimum "days of autonomy" - which means that the batteries can supply sufficient power with no sunlight to charge the batteries. This varies from 3-5 days in the sunbelt, to 5 to 10 days elsewhere. AWG -- American Wire Gauge, a standard system for designating the size of electrical wire. The higher the number, the smaller the wire. Most house wiring is #12 or 14. In most other countries, wire is specified by the size in millimeters.

azimuth--Angle between the north direction and the projection of the surface normal into the horizontal plane; measured clockwise from north. As applied to the PV array, 180 degree azimuth means the array faces due south. balance of system (BOS)--Represents all components and costs other than the PV modules. It includes design costs, land, site preparation, system installation, support structures, power conditioning, operation and maintenance costs, batteries, indirect storage, and related costs. baseline performance value--Initial values of Isc, Voc, Pmp, Imp measured by the accredited laboratory and corrected to Standard Test Conditions, used to validate the manufacturer's performance measurements provided with the qualification modules per IEEE 1262. blocking diode--A diode used to restrict or block reverse current from flowing backward through a module. [UL 1703] Alternatively, diode connected in series to a PV string; it protects its modules from a reverse power flow and, thus, against the risk of thermal destruction of solar cells. British thermal unit (BTU)--The amount of heat energy required to raise the temperature of one pound of water from 60 degrees F to 61 degrees F at one atmosphere pressure. bypass diode--A diode connected across one or more solar cells in a photovoltaic module such that the diode will conduct if the cell(s) become reverse biased. [UL 1703] Alternatively, diode connected anti-parallel across a part of the solar cells of a PV module. It protects these solar cells from thermal destruction in case of total or partial shading, broken cells, or cell string failures of individual solar cells while other cells are exposed to full light. cathodic protection--A method of preventing oxidation (rusting) of exposed metal structures, such as bridges and pipelines, by imposing a small electrical voltage that opposes the flow of electrons between the structure and the ground that is greater than the voltage present during oxidation. cell--The basic unit of a photovoltaic panel or battery. cell barrier--A very thin region of static electric charge along the interface of the positive and negative layers in a photovoltaic cell. The barrier inhibits the movement of electrons from one layer to the other, so that higher-energy electrons from one side diffuse preferentially through it in one direction, creating a current and thus a voltage across the cell. Also called depletion zone, cell junction, or space charge. cell junction--The area of immediate contact between two layers (positive and negative) of a photovoltaic cell. The junction lies at the center of the cell barrier or depletion zone. charge controller--An electronic device which regulates the voltage applied to the battery system from the PV array. Essential for ensuring that batteries obtain maximum state of charge and longest life.

combined collector--A photovoltaic device or module that provides useful heat energy in addition to electricity. concentrator--A PV module that uses optical elements to increase the amount of sunlight incident on a PV cell. Concentrating arrays must track the sun and use only the direct sunlight because the diffuse portion cannot be focused onto the PV cells. Efficiency is increased, but lifespan is usually decreased due to the high heat. concentrator (module, array, or collector)--An arrangement of photovoltaic cells that includes a lens to concentrate sunlight onto small-area cells. Concentrators can increase the power flux of sunlight hundreds of times. conversion efficiency (cell or module)--The ratio of the electric energy produced by a photovoltaic device (under one-sun conditions) to the energy from sunlight incident upon the cell. current at maximum power (Imp)--The current at which maximum power is available from a module. [UL 1703] cycle life--Number of discharge-charge cycles that a battery can tolerate under specified conditions before it fails to meet specified criteria as to performance (e.g., capacity decreases to 80-percent of the nominal capacity). dc to dc converter--Electronic circuit to convert dc voltages (e.g., PV module voltage) into other levels (e.g., load voltage). Can be part of a maximum power point tracker (MPPT). deep discharge--Discharging a battery to 20-percent or less of its full charge. diffuse insolation--Sunlight received indirectly as a result of scattering due to clouds, fog, haze, dust, or other obstructions in the atmosphere. Opposite of direct insolation. direct current (dc)--Electric current in which electrons flow in one direction only. Opposite of alternating current. direct insolation--Sunlight falling directly upon a collector. Opposite of diffuse insolation. discharge rate--The rate, usually expressed in amperes or time, at which electrical current is taken from the battery. distributed systems--Systems that are installed at or near the location where the electricity is used, as opposed to central systems that supply electricity to grids. A residential photovoltaic system is a distributed system. DOD--'Depth of Discharge,' from 100-percent state of charge (SOC), in a battery or battery system.

electric circuit--Path followed by electrons from a power source (generator or battery) through an external line (including devices that use the electricity) and returning through another line to the source. electric current--A flow of electrons; electricity, amps. electrical grid--An integrated system of electricity distribution, usually covering a large area. As in "off the grid". electrolyte--A liquid conductor of electricity. In batteries, usualy H2SO4, sulfuric acid, but may be any number of things. Seawater is the mostcommon electrolyte in the world - and by suspending a zinc and a steel sheet in it, you can get a little electricity. energy--The ability to do work. Stored energy becomes working energy when we use it. energy density--The ratio of energy available from a battery to its volume (Wh/1) or mass (Wh/kg). "watts to weight" ratio. energy payback time--The time required for any energy producing system or device to produce as much energy as was required in its manufacture. For solar electric panels, this is about 16-20 months. EVA--(ETHYLENE VINYL ACETATE) An encapsulant used between the glass cover and the solar cells in PV modules. It is durable, transparent,resistant to corrosion, and flame retardant. flat-plate PV--Refers to a PV array or module that consists of nonconcentrating elements. Flat-plate arrays and modules use direct and diffuse sunlight, but if the array is fixed in position, some portion of the direct sunlight is lost because of oblique sun-angles in relation to the array. float charge--Float charge is the voltage required to counteract the self-discharge of the battery at a certain temperature. float life--Number of years that a battery can keep its stated capacity when it is kept at float charge (see float charge). fuel cell--A device that converts the energy of a fuel directly to electricity and heat, without combustion. Because there is no combustion, fuel cells give off few emissions; because there are no moving parts, fuel cells are quiet. gel-type battery--Lead-acid battery in which the electrolyte is composed of a silica gel matrix. grid-connected (PV system)--A PV system in which the PV array acts like a central generating plant, supplying power to the grid.

ground loop--An undesirable feedback condition caused by two or more circuits sharing a common electrical line, usually a grounded conductor. hot spot--An undesirable phenomenon of PV device operation whereby one or more cells within a PV module or array act as a resistive load, resulting in local overheating or melting of the cell(s). hybrid system--A PV system that includes other sources of electricity generation, such as wind or fossil fuel generators. incident light--Light that shines onto the face of a solar cell or module. insolation--Sunlight, direct or diffuse; from 'incident solar radiation.' Not to be confused with 'insulation.' Equal to about 1000 watts per square meter at high noon. interconnect--A conductor within a module or other means of connection which provides an electrical interconnection between the solar cells. [UL 1703] inverters--Devices that convert dc electricity into ac electricity (single or multiphase), either for stand-alone systems (not connected to the grid) or for utility-interactive systems. I-V curve--A graphical presentation of the current versus the voltage from a photovoltaic device as the load is increased from the short circuit (no load) condition to the open circuit (maximum voltage) condition. The shape of the curve characterized cell performance. I-V data--The relationship between current and voltage of a photovoltaic device in the power-producing quadrant, as a set of ordered pairs of current and voltage readings in a table, or as a curve plotted in a suitable coordinate system (i.e., Cartesian). [ASTM E 1036] junction box--A PV generator junction box is an enclosure on the module where PV strings are electrically connected and where protection devices can be located, if necessary. junction diode--A semiconductor device with a junction and a built-in potential that passes current better in one direction than the other. All solar cells are junction diodes. kilowatt (kW)--1000 watts. kilowatt-hour (kWh)--One thousand watts acting over a period of 1 hour. The kWh is a unit of energy. 1 kWh=3600 kJ. light-induced defects--Defects, such as dangling bonds, induced in an amorphous silicon semiconductor upon initial exposure to light. light trapping--The trapping of light inside a semiconductor material by refracting and reflecting the light at critical angles; trapped light will travel further in the

material, greatly increasing the probability of absorption and hence of producing charge carriers. line-commutated inverter--An inverter that is tied to a power grid or line. The commutation of power (conversion from dc to ac) is controlled by the power line, so that, if there is a failure in the power grid, the PV system cannot feed power into the line. load--Anything in an electrical circuit that, when the circuit is turned on, draws power from that circuit. maximum power point (MPP)--The point on the current-voltage (I-V) curve of a module under illumination, where the product of current and voltage is maximum. [UL 1703] For a typical silicon cell panel, this is about 17 volts for a 36 cell configuration. maximum power point tracker (MPPT)--A power conditioning unit that automatically operates the PV-generator at its MPP under all conditions. An MPPT will typically increase power delivered to the system by 10% to 40%, depending on climate conditions and battery state of charge. microgroove--A small groove scribed into the surface of a cell which is filled with metal for contacts. module--A number of PV cells connected together,sealed with an encapsulant, and having a standard size and output power; the smallest building block of the power generating part of a PV array. Also called panel. monolithic--Fabricated as a single structure. multicrystalline--Material that is solidified at such as rate that many small crystals (crystallites) form. The atoms within a single crystallite are symmetrically arranged, whereas crystallites are jumbled together. These numerous grain boundaries reduce the device efficiency. A material composed of variously oriented, small individual crystals. (Sometimes referred to as polycrystalline or semicrystalline). multijunction device--A photovoltaic device containing two or more cell junctions, each of which is optimized for a particular part of the solar spectrum, to achieve greater overall efficiency. n-type semiconductor--A semiconductor produced by doping an intrinsic semiconductor with an electron-donor impurity (e.g., phosphorous in silicon). NOCT--Nominal Operating Cell Temperature. The solar cell temperature at a reference environment defined as 800 W/m2 irradiance, 20C ambient air temperature, and 1 m/s wind speed with the cell or module in an electrically open circuit state. ohm--The unit of resistance to the flow of an electric current. one-axis tracking--A system capable of rotating about one axis.