Académique Documents

Professionnel Documents

Culture Documents

Computational and Experimental Study of Engine Characteristics Using N-Butanol

Transféré par

IAEME PublicationCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Computational and Experimental Study of Engine Characteristics Using N-Butanol

Transféré par

IAEME PublicationDroits d'auteur :

Formats disponibles

International Journal of JOURNAL OF MECHANICAL ENGINEERING INTERNATIONALMechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976

6 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME AND TECHNOLOGY (IJMET)

ISSN 0976 6340 (Print) ISSN 0976 6359 (Online) Volume 4, Issue 1, January- February (2013), pp. 209-221 IAEME: www.iaeme.com/ijmet.asp Journal Impact Factor (2012): 3.8071 (Calculated by GISI) www.jifactor.com

IJMET

IAEME

COMPUTATIONAL AND EXPERIMENTAL STUDY OF ENGINE CHARACTERISTICS USING N-BUTANOL GASOLINE BLENDS

S Raviteja1, Shashank S N1 and Kumar G N2

1

Student, Department of Mechanical Engineering, National Institute of Technology Karnataka Surathkal, Mangalore, India- 575025 2 Assistant Professor, Department of Mechanical Engineering, National Institute of Technology Karnataka Surathkal, Mangalore, India- 575025

ABSTRACT This study investigates the effect of blending of n-butanol with gasoline in a fourstroke spark ignited MPI engine. AVL BOOST was used as a computational fluid dynamics (CFD) simulation tool to analyze the performance and emission characteristics for different blends of n-butanol and gasoline (0%, 10%, 20% and 30% of butanol by volume). The study was carried out at full load conditions for different engine speeds. CFD results are always approximate due to truncation errors. An experiment was conducted on a four-cylinder spark ignited MPI engine to validate the results obtained from AVL Boost. AVL simulation and experimental results showed a considerable decrease in Hydro-Carbon (HC) Emissions and the percentage of Carbon Monoxide (CO) emitted remained constant. However, an increase in emissions of Oxides of Nitrogen (NOx) was observed in both cases. Keywords: AVL Boost, CFD, Emissions, n-Butanol blends, Variable speed 1. INTRODUCTION

The Dwindling crude oil reserves and the long lead times in creating these fuels have brought in the fear of fuel crisis in the near future. The known worldwide reserves of petroleum are about 1000 billion barrels and these petroleum reserves are predicted to be consumed in about 30 years. Increasing Air pollution is one of the other major problems being faced by the world today. This has led to a debate on usage of alternate fuels which have the potential to replace gasoline. Alcohols are advocated as the prospective fuels because they can be manufactured from natural products or waste materials, unlike gasoline which is a non renewable energy resource. Alcohols can be used directly without requiring

209

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

any major changes in the structure of the engine. Ethanol was the first fuel among the alcohols used to power vehicles in the 1880s and 1890s [1]. However, economic reasons still limit its usage on a large-scale. Butanol has a 4-carbon structure with a hydroxyl group (-OH) attached to one of the carbon atoms. There exist different isomers of butanol based on their molecular structure. n-Butanol has a straight chain structure. Various properties of n-Butanol in comparison with fossil fuels and few other alcohols have been presented in the TABLE 1. Studies have shown that n-butanol is more advantageous over the lighter alcohols like ethanol and methanol. n-Butanol has higher energy content when compared to ethanol, which reduces the Specific Fuel Consumption. n-Butanol is also less prone to water contamination and is less volatile in comparison to ethanol. As a result it could be distributed and stored using the same infrastructure used for gasoline. n-Butanol has a higher heat of evaporation. n-Butanol has lower volatility, which reduces the tendency of cavitation and vapour lock. n-Butanol has a lesser heat of vaporization, which enables easy cold start. n-Butanol has a very low vapour pressure and high flash point, which makes it a safe fuel [2]. n-Butanol can be produced from both petrochemicals as well as from renewable resources like agricultural waste. Historically, n-Butanol was produced by biological fermentation processes. The advent of biotechnology has made possible many new advanced chemical and biological ways of butanol production [3]. Butanol production from fermentation process of agricultural feedstock by cellulosic enzymes has the potential to cut its production cost [4]. However the studies investigating the use of Butanol in internal combustion engines are very limited. This study investigates the effect of n- Butanol gasoline blends in a Spark Ignited Internal Combustion Engine. Table 1: Property of different fuels Molecular formula Octane Number Oxygen content(% weight) Density(g/mL) at 20oC Auto-ignition Temperature(oC) Lower Heating Value(MJ/kg) Latent Heating (kJ/kg) at 25oC Stoichiometric ratio Boiling Point(oC) Gasoline C4-C12 80-99 0.720.78 300 42.7 380-500 14.7 25-215 Methanol Ethanol CH3OH C2H5OH 111 108 50 34.8 0.796 470 19.9 1109 31.69 64.5 0.790 434 26.8 904 13.8 78.4 n-Butanol C4H9OH 96 21.6 0.808 385 33.1 582 2.27 117.7

The advent of high-speed digital computers and advances in Computational methods has made it possible for the researchers to simulate and analyse complex physiological processes. The huge amount of results that are obtained by simulation studies are rather very difficult to be obtained experimentally. The use of Computational Fluid Dynamics (CFD) further saves upon the manpower, material and financial resources.CFD has been looked

210

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

upon as a high-technology research and design tool by the automobile researchers. The ability to analyse not only the external flows but also the flows in the manifolds and engine cylinders has made the use of CFD essential before actual experimentation. Advances in Computational algorithms have helped researchers to even simulate the combustion process happening within the cylinder [5]. The present study uses CFD to simulate the combustion process of butanol blends in IC Engine. 2. BACKGROUND

Investigation of butanol usage as an engine fuel has been conducted by several research groups. Alasfour reported that there was an increase in first and second-law efficiencies in the lean regions for the butanol-gasoline blend; also investigations were made on the effect of spark timing on the NOx production for a engine running on 30% iso-butanolgasoline engine [6, 7]. J. Dernotte et al assessed influence of butanol addition on the emission of unburned hydrocarbons, carbon monoxide, and nitrogen oxide using different butanolgasoline blends in a port fuel-injection, spark-ignition engine. The studies reported that 40% butanol/60% gasoline blend by volume (B40) minimized HC emissions, no significant change in NOx emissions except B80,which showed lower emission levels due to combustion deterioration [8]. Studies by S. Szwaja and J.D. Naber reported that Combustion stability at the part-load condition as measured by the COV of IMEP was slightly lower for nbutanol in comparison to gasoline using blends of n -butanol to gasoline with ratios of 0%, 20%, and 60% in a single cylinder Waukesha Cooperative Fuels Research engine (CFR) SI engine with variable compression ratio [4]. Xiaolei Gu et al analysed the effect of spark timing, blend ratio and EGR rate on the emission characteristics. Results showed that the blends of gasoline and n-butanol decrease engine specific HC, CO and NOx emissions compared to those of gasoline. It was also examined that EGR reduces engine specific NOx emissions and particle number concentration simultaneously in spark-ignition engine fuelled with gasoline and n -butanol blends [9]. Experimental tests were carried out by G. Broustail et al on a single-cylinder port-fuel injection SI engine to quantify the potential of butanol/isooctane blends to reduce regulated pollutants (CO, CO2, NOx and HC), and nonregulated pollutants (methane, acetylene, ethylene, benzene, acetaldehyde and formaldehyde), without deteriorating the engine performance. It was reported that there was an increase of the fuel consumption of about 30% with butanol and 60% with ethanol, but only a slight increase (about 2%) in CO2 emissions. A strong decrease in HC and NOx emissions was obtained for both alcohols [10]. Adrian Irimescu investigated the effect of fuelling a port injection engine with iso-butanol, as compared to gasoline operation. Fuel conversion efficiency decreased when the engine was fueled with iso-butanol by up to 9% at full load and by up to 11% at part load. He cited incomplete fuel evaporation as the reason for the drop in engine efficiency [11]. In his additional investigations, it was found that Isobutanol can be blended with gasoline in much higher concentrations compared to ethanol, without any modifications to the fuel system or other engine components [12]. 3. PRESENT WORK

AVL Boost is a package of computer codes which enables the user to model and simulate the various processes of an Internal Combustion Engine. In the current investigation AVL BOOST has been used to analyze effect the blending of n-Butanol (C4H10O) with

211

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

gasoline at different concentrations. Blends of n-Butanol to gasoline with ratios of 0%, 10%, 20%, and 30% by volume were used in the simulation for various speed conditions. Due to the fact that CFD results are always approximate, Engine Test bed experiments were conducted to validate the results obtained from the simulations. One of the purposes of this paper is to analyze the computed results and their deviation from the experimental results. 4. SIMULATION MODELLING

The pre-processing steps of AVL Boost enables the user to model a 1-Dimensional engine test bench setup using the predefined elements provided in the software toolbox. The various elements are joined by the desired connectors to establish the complete engine model using pipelines. In Fig.1, E1 represents the engine C1, C2, C3, C4 represent the four cylinders of the engine. MP1 to MP14 represent the measuring points, PL1, PL2 represent the plenum.SB1, SB2 are for the system boundary and the flow pipes are numbered 1 to 32. CL1 represents the cleaner and R1 to R10 represent flow restrictions.

Figure 1: AVL BOOST 1D Engine model The various configurations and parameters are set for each element. The system boundary conditions are specified. It is important to make a correct estimate of the boundary conditions as it directly affects the accuracy of the results. For the current study Vibe two zone model was selected for the combustion analysis. This model divides the combustion chamber into unburned and burned gas regions [13]. The first law of thermodynamics is applied to each of the zones to predict the rate of fuel consumed with respect to crank angle.

212

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

The following equations (1, 2) govern the Vibe two zone model [14]: (1)

(2) Where

Denotes change of the internal energy in the cylinder Denotes piston work Denotes fuel heat input Denotes wall heat losses Denotes enthalpy flow from the unburned to the burned zone Denotes enthalpy due to blow by u and b in the subscripts denote unburned and burned gas Prediction of NOx generated by combustion was based on the model by Pattas and Hfner which incorporates the well known Zeldovich mechanism [15].The rate of NOx production was estimated by using the following equation (3): (3)

Where Denotes Post Processing Multiplier Denotes Kinetic Multiplier Denotes molar concentration in equilibrium Denotes reactions rates of Zeldovich mechanism

213

c ri

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

The amount of CO emissions was predicted using the following equation (4) which was taken from a model presented by Onorati et al[16].

(4)

Where c ri Denotes molar concentration in equilibrium Denotes reactions rates based on the model

The process of formation of unburned hydrocarbons in the crevices is described by assuming that, the pressure in the cylinder and in the crevices is the same and that the temperature of the mass in the crevice volumes is equal to the piston temperature [17]. The mass in the crevices at any time period is given by equation (5): (5) Where mcrevice p Vcrevice M R Tpiston Denotes mass of unburned charge in the crevices [kg] Denotes cylinder pressure [Pa] Denotes total crevice volume [m3] Denotes unburned molecular weight [kg/kmol] Denotes gas constant [J/( kmol K)] Denotes piston temperature [K]

Butanol properties are not pre-defined in AVL BOOST. Hence coefficients for calculating thermodynamic properties of Butanol were taken from NASA Technical Memorandum [18] and were added to the BOOST fuel database to simulate the engine fuelled with the blends. 5. EXPERIMENTAL SETUP AND EXPERIMENTS

The engine setup consists of a four-stroke, four cylinder, SI engine as shown in the Fig. 2. The setup had stand-alone panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air and fuel flow measurements, process indicator and engine indicator. Rotameters were provided for cooling water and calorimeter water flow measurement. The setup enables study of engine performance for brake power, indicated power, frictional power, BMEP, IMEP, brake thermal efficiency, indicated thermal efficiency, mechanical efficiency, volumetric efficiency, specific fuel consumption, air-fuel ratio (A/F) and heat balance. Windows based engine performance analysis software package Engine Soft is provided for on-line performance evaluation.

214

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

Figure 2: Schematic Diagram of Experimental set up

AVL 5 gas exhaust analyser was used to obtain the emission characteristics. TABLE.2 gives the range and resolution of the analyser. TABLE 3 gives the technical specifications of the engine used for the experiments.

Table 2: Range and Resolution of the AVL exhaust gas analyser Measured Parameters CO HC CO2 O2 NO Measured Range 0-10% Vol. 0-20000 ppm 0-20% Vol. 0-22% Vol. 0-5000 ppm Resolution 0.01% Vol. 10 ppm 0.1% Vol. 0.01% Vol. 1 ppm

Table 3: Specifications of the Engine Make Model Type Capacity Cooling Max. Power Max. Torque Stroke Bore Compression Ratio Suzuki Zen MPFI 4 Cylinder, 4 stroke 993 cc Water Cooled 44.5kW @ 6000rpm 59Nm @ 2500rpm 61mm 72mm 9.4:1

215

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

6.

RESULTS AND DISCUSSION

The present study concentrated on the emission and performance characteristics of the n- butanol-gasoline blends. Different concentrations of the blends (10% n-Butanol (B10), 20% n-Butanol(B20) and 30% n-Butanol(B30) by volume) were analysed using AVL BOOST codes and were validated experimentally at full load conditions for the speeds ranging from 2000-4000 rpm in the steps of 500rpm. The results are divided into different subsections based on the parameter analysed. 6.1 Brake Power Brake power is one of the important factors that determine the performance of an engine. The variation of brake power with Speed was obtained at full load conditions for B10, B20, B30 and pure gasoline using the CFD results. The results were also validated experimentally and it was found that there was a very small deviation in CFD results from the experimental results. This can be clearly seen in Fig. 3 to Fig. 6

Figure 3: Variation of Brake Power with speed for pure Gasoline

Figure 4: Variation of Brake Power with speed for case of B10

Figure 5: Variation of Brake Power with speed for B20

Figure 6: Variation of Brake Power with speed for B30

216

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

The deviation noted in all the four cases is very small and occurs due to the assumptions made during the CFD analysis as well as the human errors made during the experiments. The results show that the brake power increases in the cases of B10 and B20 compared to Pure Gasoline. However there was a decrease in case of B30. This factor can be acknowledged to the lower heating value of n-Butanol compared to Gasoline. 6.2 CO Emissions Carbon Monoxide (CO) emission is a strong function of equivalence ratio. The influence of other parameters on the emissions of CO is very low and the percentage of CO emitted from the engine was almost constant with increasing speed at full load condition. The variation of CO emissions with respect to speed for different blends is shown below in Fig. 7 to Fig.10. Both CFD and experimental results show that the change in percentage of CO emissions with varying speed is constant at full load conditions for all the cases.

Figure 7: Variation of CO with speed for pure Gasoline

Figure 8: Variation of CO with speed for B10

Figure 9: Variation of CO with speed for B20

Figure 10: Variation of CO with speed for B30

217

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

The emission of CO increases for B10 and drastically decreases for B20 and B30. This decrease can be attributed for the presence of extra oxygen molecule in n-Butanol which helps in more complete combustion and thus decrease in amount of CO. 6.3 NOx Emissions NOx emissions are mainly affected by the equivalence ratio, peak temperature, ignition timing and oxygen concentration in the fuel. In the present study, NOx emissions were obtained from CFD analysis and the results were validated experimentally. Both the results have shown that there was increase in NOx emissions with increase in speed. B10, B20, B30 showed an increase in NOx emissions because of the increase in oxygen concentration. The CFD and Experimental results are shown for various cases in Fig. 11 to Fig.14.

Figure 11: Variation of NOx with speed for gasoline

Figure 12: Variation of NOx with speed for B10

Figure 13: Variation of NOx with speed for B20

Figure 14: Variation of NOx with speed for B30

218

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

6.4 HC Emissions The origin of unburned hydrocarbons (HC) in SI Engines is due to incomplete combustion of charge. Major source of HC emission is the charge in the crevice volume which is not burned due to flame quenching at the entrance and fuel vapours absorbed by the oil layers are not burned during the combustion process. Variations of HC emitted with respect to speed are shown Fig.15 to Fig.18.

Figure 15: Variation of HC with speed for pure gasoline

Figure 16: Variation of HC with speed for B10

Figure 17: Variation of HC with speed for B20

Figure 18: Variation of HC with speed for B30

From the results obtained, it is clear that HC emissions decrease with increase in percentage of n-butanol. However experimentally obtained results showed a considerable deviation from CFD results. This is due to the fact that a complete description of the HC formation process cannot yet be simulated and the achievement of a reliable predictive model within a thermodynamic approach is prevented by the fundamental assumptions and the requirement of reduced computational times [14]. AVL BOOST code predicts the formation of HC based on G. D'Errico model. n-Butanol is not readily available in the AVL database and considers

219

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

only thermodynamic and transport properties for the prediction of combustion. However fuel specific properties are not considered. Laminar flame speeds of alcohols are higher compared to gasoline. Hence this leads to better combustion at higher engine speeds and decrease in HC emissions which are not accounted by the software. 7. CONCLUSIONS

CFD and experimental analysis was carried out successfully on SI Engine and the following conclusions are made based on the results.

8.

CFD and experimental results complement each other for the performance characteristics at full load conditions for all blends. CO emissions remained constant experimentally for all blends as predicted by the CFD simulations. NO emissions were estimated to increase with the increase in butanol concentration by AVL BOOST and were successfully validated by the experiments. CFD results showed a considerable deviation in forecasting HC emissions when compared to the experiments. ACKNOWLEDGEMENTS

The authors would like to acknowledge AVL-AST, Graz, Austria for granted use of AVL-BOOST under the university partnership program. We are also eternally grateful to staff members of NITK Surathkal for their immense support. REFERENCES [1] M. Al-Hasan, Effect of ethanolunleaded gasoline blends on engine performance and exhaust emission. Energy Conversion and Management, 44(9), 2003, 1547-1561. [2] C. Jin, M. Yao, H. Liu, C. F. F Lee, and J. Ji. Progress in the production and application of n-butanol as a biofuel, Renewable and Sustainable Energy Reviews, 15(8), 2011, 4080-4106 [3] S. Y. Lee, J. H. Park, S. H. Jang, L. K. Nielsen, J. Kim and K. S. Jung, Fermentative butanol production by clostridia. Biotechnology and bioengineering, 101(2), 2008, 209-228 [4] S. Szwaja, and J. D. Naber, Combustion of n butanol in a spark-ignition IC engine. Fuel, 89(7), 2010, 1573-1582 [5] J. D. Anderson, Computational fluid dynamics (Vol. 206, McGraw-Hill, 1995). [6] F. N. Alasfour, Butanola single-cylinder engine study: availability analysis. Applied Thermal Engineering, 17(6),1997, 537-549 [7] F. N. Alasfour, , NOx Emission from a spark ignition engine using 30% Iso-butanol gasoline blend: Part 2-Ignition Timing, Applied thermal engineering, 18(8), 1998, 609-618 [8] J. Dernotte, C. Mounaim-Rousselle, F. Halter and P. Seers, Evaluation of butanol gasoline blends in a port fuel-injection, spark-ignition engine. Oil & Gas Science and TechnologyRevue de lInstitut Franais du Ptrole, 65(2), 2009, 345-351. [9] X. Gu, Z. Huang, J. Cai, J. Gong, X. Wu and C. F. Lee, Emission characteristics of a spark-ignition engine fuelled with gasoline n-butanol blends in combination with EGR. Fuel, 2011.

220

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 6340(Print), ISSN 0976 6359(Online) Volume 4, Issue 1, January - February (2013) IAEME

[10] G. Broustail, F.Halter, P. Seers, G. Morac and C. Mounaim-Rousselle, Comparison of regulated and non-regulated pollutants with iso-octane/butanol and iso-octane/ethanol blends in a port-fuel injection Spark-Ignition engine, Fuel, 2011 [11] A. Irimescu, Performance and fuel conversion efficiency of a spark ignition engine fueled with iso-butanol. Applied Energy. 2012. [12] A. Irimescu Study of cold start airfuel mixture parameters for spark ignition engines fueled with gasolineisobutanol blends. International Communications in Heat and Mass Transfer, 37(9), 2010, 1203-1207. [13] J. B. Heywood, Internal combustion engine fundamentals, 1988. [14] AVL List Gmbh, AVL Boost Theory, 2009 [15] C. T. Bowman, Kinetics of pollutant formation and destruction in combustion. Progress in energy and combustion science, 1(1), 1975, 33-45 [16] A. Onorati, G. Ferrari, G.DErrico, 1D Unsteady Flows with Chemical Reactions in the Exhaust Duct-System of S.I. Engines: Predictions and Experiments, SAE Paper No. 200101-0939. [17] G. D'Errico, G. Ferrari, A. Onorati, and T. Cerri, Modeling the Pollutant Emissions from a S.I. Engine, SAE Paper No. 2002-01-0006 [18] B. J. McBride, S. Gordon and M.A. Reno, Coefficients for calculating thermodynamic and transport properties of individual species, 1993. [19] K. D. Sapate and Dr. A. N. Tikekar, Design and Development Gasoline Direct Injection (Gdi) System for Small Two-Stroke Engine International Journal of Mechanical Engineering & Technology (IJMET), Volume 3, Issue 2, 2012, pp. 346 - 353, ISSN Print: 0976 6340, ISSN Online: 0976 6359, Published by IAEME. [20] Shri. N.V. Hargude and Dr. S.M. Sawant, Experimental Investigation of Four Stroke S.I. Engine using Fuel Energizer for Improved Performance and Reduced Emissions International Journal of Mechanical Engineering & Technology (IJMET), Volume 3, Issue 1, 2012, pp. 244 - 257, ISSN Print: 0976 6340, ISSN Online: 0976 6359, Published by IAEME. [21] S.H. Choi, Y.T. Oh and J. Azjargal, Lard Biodiesel Engine Performance and Emissions Characteristics with EGR Method International Journal of Mechanical Engineering & Technology (IJMET), Volume 3, Issue 2, 2012, pp. 397 - 409, ISSN Print: 0976 6340, ISSN Online: 0976 6359, Published by IAEME. [22] S M Lawankar and Dr L P Dhamande, Comparative Study of Performance of LPG Fuelled SI Engine at Different Compression Ratio and Ignition Timing International Journal of Mechanical Engineering & Technology (IJMET), Volume 3, Issue 3, 2012, pp. 337 - 343, ISSN Print: 0976 6340, ISSN Online: 0976 6359, Published by IAEME.

221

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- VentilationDocument92 pagesVentilationRobert Nixon100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Motive Journal (3rd Edition)Document42 pagesThe Motive Journal (3rd Edition)Shubham Sharma0% (1)

- Objection HandlingDocument3 pagesObjection HandlingNabin GaraiPas encore d'évaluation

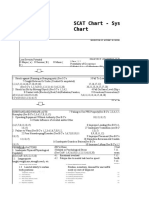

- SCAT Chart - Systematic Cause Analysis Technique - SCAT ChartDocument6 pagesSCAT Chart - Systematic Cause Analysis Technique - SCAT ChartSalman Alfarisi100% (1)

- Healthcare Financing in IndiADocument86 pagesHealthcare Financing in IndiAGeet Sheil67% (3)

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationPas encore d'évaluation

- 5 S Principles ExplainedDocument30 pages5 S Principles Explainedamaresh nkPas encore d'évaluation

- Holy Cross Academy Quarterly Cookery ExamDocument4 pagesHoly Cross Academy Quarterly Cookery ExamAlle Eiram Padillo95% (21)

- Accredited Meat Processing Plant (MPP) PDFDocument14 pagesAccredited Meat Processing Plant (MPP) PDFClayton PanghulanPas encore d'évaluation

- A Study On The Reasons For Transgender To Become EntrepreneursDocument7 pagesA Study On The Reasons For Transgender To Become EntrepreneursIAEME PublicationPas encore d'évaluation

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationPas encore d'évaluation

- Determinants Affecting The User's Intention To Use Mobile Banking ApplicationsDocument8 pagesDeterminants Affecting The User's Intention To Use Mobile Banking ApplicationsIAEME PublicationPas encore d'évaluation

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationPas encore d'évaluation

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationPas encore d'évaluation

- Analyse The User Predilection On Gpay and Phonepe For Digital TransactionsDocument7 pagesAnalyse The User Predilection On Gpay and Phonepe For Digital TransactionsIAEME PublicationPas encore d'évaluation

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationPas encore d'évaluation

- Gandhi On Non-Violent PoliceDocument8 pagesGandhi On Non-Violent PoliceIAEME PublicationPas encore d'évaluation

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationPas encore d'évaluation

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationPas encore d'évaluation

- Visualising Aging Parents & Their Close Carers Life Journey in Aging EconomyDocument4 pagesVisualising Aging Parents & Their Close Carers Life Journey in Aging EconomyIAEME PublicationPas encore d'évaluation

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationPas encore d'évaluation

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationPas encore d'évaluation

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationPas encore d'évaluation

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationPas encore d'évaluation

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationPas encore d'évaluation

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationPas encore d'évaluation

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationPas encore d'évaluation

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationPas encore d'évaluation

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationPas encore d'évaluation

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationPas encore d'évaluation

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationPas encore d'évaluation

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationPas encore d'évaluation

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationPas encore d'évaluation

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationPas encore d'évaluation

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationPas encore d'évaluation

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationPas encore d'évaluation

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationPas encore d'évaluation

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationPas encore d'évaluation

- Afforestation in Arid and Semi Arid RegionsDocument68 pagesAfforestation in Arid and Semi Arid RegionsMilian Marian SanduPas encore d'évaluation

- Concept PaperDocument6 pagesConcept Paperapple amantePas encore d'évaluation

- Khatr Khola ISP District RatesDocument56 pagesKhatr Khola ISP District RatesCivil EngineeringPas encore d'évaluation

- 670W Bifacial Mono PERC ModuleDocument2 pages670W Bifacial Mono PERC Modulemabrouk adouanePas encore d'évaluation

- Ielts Band Score 7Document2 pagesIelts Band Score 7Subhan Iain IIPas encore d'évaluation

- Understanding Anxiety Disorders and Abnormal PsychologyDocument7 pagesUnderstanding Anxiety Disorders and Abnormal PsychologyLeonardo YsaiahPas encore d'évaluation

- Morningstar Bakery: Business PlanDocument14 pagesMorningstar Bakery: Business PlanbakhtawarPas encore d'évaluation

- Specialized Connective TissueDocument15 pagesSpecialized Connective TissueSebPas encore d'évaluation

- VERALLIA WHITE-BOOK EN March2022 PDFDocument48 pagesVERALLIA WHITE-BOOK EN March2022 PDFEugenio94Pas encore d'évaluation

- SAP Technical Consultant resumeDocument11 pagesSAP Technical Consultant resumeKallol BhowmickPas encore d'évaluation

- Batson Et All - 2007 - Anger and Unfairness - Is It Moral Outrage?Document15 pagesBatson Et All - 2007 - Anger and Unfairness - Is It Moral Outrage?Julia GonzalezPas encore d'évaluation

- Steroids ActivityDocument1 pageSteroids Activityfaqed ilzakiraPas encore d'évaluation

- Darnell's Father Goes StrictDocument2 pagesDarnell's Father Goes StrictDavid Theodore Richardson IIIPas encore d'évaluation

- DSUSJRC01161350 Corail ST-Total Hip SystemDocument20 pagesDSUSJRC01161350 Corail ST-Total Hip SystemXeniaPas encore d'évaluation

- Experiment 4 (Group 1)Document4 pagesExperiment 4 (Group 1)Webster Kevin John Dela CruzPas encore d'évaluation

- Compensation and BenefitsDocument8 pagesCompensation and BenefitsOthman FaroussiPas encore d'évaluation

- Training and Supervision of Health Care WorkersDocument12 pagesTraining and Supervision of Health Care WorkerspriyankaPas encore d'évaluation

- Solucionario. Advanced Level.Document68 pagesSolucionario. Advanced Level.Christian Delgado RamosPas encore d'évaluation

- SSMT ConplanDocument2 pagesSSMT ConplanJeffrey VillangcaPas encore d'évaluation

- ĐỀ THI THU TNTHPT SỐ 17Document4 pagesĐỀ THI THU TNTHPT SỐ 17Nguyên Hà NguyễnPas encore d'évaluation

- Myofascial Release for Piriformis MyalgiaDocument14 pagesMyofascial Release for Piriformis MyalgiaApoorvPas encore d'évaluation

- Report Experiment 5 STK1211Document9 pagesReport Experiment 5 STK1211NurAkila Mohd YasirPas encore d'évaluation