Académique Documents

Professionnel Documents

Culture Documents

ACI Mix-Design Summary Sheet

Transféré par

Jesus Perez Rosa0 évaluation0% ont trouvé ce document utile (0 vote)

263 vues3 pagesACI Mix Design - Summary Sheet calculates the required cement content Based on water / cement ratio, slump and aggregate size. The fine aggregate must occupy a volume of: ACI Mix Design equations x 27 ft. Value from table 4 The OD weight of the coarse aggregate CAOD CA dryrodded lb. Dry-rodded unit weight.

Description originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentACI Mix Design - Summary Sheet calculates the required cement content Based on water / cement ratio, slump and aggregate size. The fine aggregate must occupy a volume of: ACI Mix Design equations x 27 ft. Value from table 4 The OD weight of the coarse aggregate CAOD CA dryrodded lb. Dry-rodded unit weight.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

263 vues3 pagesACI Mix-Design Summary Sheet

Transféré par

Jesus Perez RosaACI Mix Design - Summary Sheet calculates the required cement content Based on water / cement ratio, slump and aggregate size. The fine aggregate must occupy a volume of: ACI Mix Design equations x 27 ft. Value from table 4 The OD weight of the coarse aggregate CAOD CA dryrodded lb. Dry-rodded unit weight.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

CIVL 1112

ACI Mix Design - Summary Sheet

1/3

ACI Mix Design Equations

Step 1. Required material information (already given). Step 2. Choice of slump. The slump is given, consistent with Table 1.

Slump(in) 1 to 2 3 to 4 6 to 7 Air Content Mild Moderate Extreme

ACI Mix Design Equations

Step 4. Estimation of mixing water and air content.

Maximum aggregate size (in.) 0.75 1 1.5 280 270 250 305 295 275 325 310 290 3.5% 5.0% 6.0% 3.0% 4.5% 6.0% 2.5% 4.5% 5.5%

0.375 305 340 365 4.5% 6.0% 7.5%

0.5 295 325 345 4.0% 5.5% 7.0%

2 240 265 280 2.0% 4.0% 5.0%

3 225 250 270 1.5% 3.5% 4.5%

6 180 200 1.0% 3.0% 4.0%

Step 3. Maximum aggregate size.

ACI Mix Design Equations

Step 4. If the concrete were non air entrained then you would use the following table to estimate the mixing water.

Maximum aggregate size (in.) 0.75 1 1.5 315 300 275 340 325 300 360 340 315 2.0% 1.5% 1.0%

ACI Mix Design Equations

Step 5. Water/cement ratio.

Slump(in) 1 to 2 3 to 4 6 to 7 Air Content

0.375 350 385 410 3.0%

0.5 335 365 385 2.5%

2 260 285 300 0.5%

3 220 245 270 0.3%

6 190 210 0.2%

28-day Compressive Non-AE Strength (psi) 2,000 0.82 3,000 0.68 4,000 0.57 5,000 0.48 6,000 0.41 7,000 0.33

AE 0.74 0.59 0.48 0.40 0.32 ---

ACI Mix Design Equations

Step 6. Calculation of cement content. Based on steps 4 and 5, the required cement content is:

ACI Mix Design Equations

Step 7. Estimation of coarse aggregate content.

Fineness Modulus 2.6 2.7 0.48 0.47 0.57 0.56 0.64 0.63 0.69 0.68 0.73 0.72 0.76 0.75 0.80 0.79 0.85 0.84

weight of water weight of cement w c

Max Aggregate (in.) 0.375 0.500 0.750 1.000 1.500 2.000 3.000 6.000

2.4 0.50 0.59 0.66 0.71 0.75 0.78 0.82 0.87

2.5 0.49 0.58 0.65 0.70 0.74 0.77 0.81 0.86

2.8 0.46 0.55 0.62 0.67 0.71 0.74 0.78 0.83

2.9 0.45 0.54 0.61 0.66 0.70 0.73 0.77 0.82

3 0.44 0.53 0.60 0.65 0.69 0.72 0.76 0.81

CIVL 1112

ACI Mix Design - Summary Sheet

2/3

ACI Mix Design Equations

The coarse aggregate will occupy:

3

ACI Mix Design Equations

Step 8. Estimation of fine aggregate content by the absolute volume method.

CA %coarse aggregate 27 ft.

Value from Table 4

yd.3

Water: Cement: Coarse Aggregate: Air:

water/62.4 lb./ft.3 cement/(3.15 x 62.4 lb./ft.3) CAOD/(SGCA x 62.4 lb./ft.3) air content x 27ft.3/yd3

The OD weight of the coarse aggregate

CAOD CA dryrodded lb.

Dry-Rodded Unit Weight

ft.

ACI Mix Design Equations

Therefore, the fine aggregate must occupy a volume of:

ACI Mix Design Equations

Step 9. Adjustment for moisture in the aggregate.

Since the moisture level of the fine aggregate in our storage bins can vary, we will apply a simple rule to adjust the water required. Decrease the amount of water required by surface moisture content of the weight of the fine aggregate

FAvolume 27 ft.3 volume

The SSD weight of the fine aggregate is:

FAOD FAvolume SGFA 62.4 lb.

Specific Gravity of Fine Aggregate

ft.3

Increase the amount of aggregate by the amount equal to the surface moisture

Unit Weight of Water

ACI Mix Design Equations

Mix Design Procedures

9. Adjustment for moisture in the aggregate -- The water content of the concrete will be affected by the moisture content of the aggregate.

ACI Mix Design Equations

Mix Design Procedures

9. Adjustment for moisture in the aggregate -- The water content of the concrete will be affected by the moisture content of the aggregate.

AC

SM

Moisturecontent (MC ) AC SM

CIVL 1112

ACI Mix Design - Summary Sheet

3/3

ACI Mix Design Equations

Step 9. Stockpile adjustment for moisture in the aggregate. Stockpile fine aggregate required is: FA stockpile = FAOD (1 + MCFA)

ACI Mix Design Equations

Step 9. Adjustment of required water

SM = MC - AC

The water required is: Require water = water - FA OD (SM) CA OD (SM)

Moisture Content

Stockpile coarse aggregate required is: CA stockpile = CAOD (1 + MCCA)

Moisture Content

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

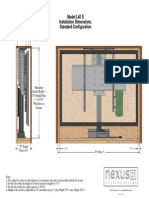

- Model L40 S Installation Dimensions: Standard Configuration: © 2013, Nexus 21, Inc. All Rights ReservedDocument1 pageModel L40 S Installation Dimensions: Standard Configuration: © 2013, Nexus 21, Inc. All Rights ReservedJesus Perez RosaPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- QuickStartGuideWin AR MEDIADocument18 pagesQuickStartGuideWin AR MEDIAJesus Perez RosaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Windsor Shade ShelterDocument2 pagesWindsor Shade ShelterJesus Perez RosaPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Ar Media PluginfDocument10 pagesAr Media PluginfJesus Perez RosaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- S M W C: ASTM C 1602/C 1602M-04 - Standard Specification For Mixing Water Used in The Production ofDocument6 pagesS M W C: ASTM C 1602/C 1602M-04 - Standard Specification For Mixing Water Used in The Production ofsaurimoPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Pat Student CIVL 1101 - Civil Engineering Measurements Assignment #6Document1 pagePat Student CIVL 1101 - Civil Engineering Measurements Assignment #6Jesus Perez RosaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Concrete Mix DesignDocument3 pagesConcrete Mix DesignZain Saeed75% (4)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Flexural Behavior of Circular Hollow Columns With A Single Layer of Reinforcement Under Seismic LoadingDocument92 pagesFlexural Behavior of Circular Hollow Columns With A Single Layer of Reinforcement Under Seismic LoadingArnold TunduliPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Graphs in Physics PDFDocument2 pagesGraphs in Physics PDFVishalPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Odd Magnus Faltinsen cv2015Document45 pagesOdd Magnus Faltinsen cv2015eВаскесPas encore d'évaluation

- TechNote - B008-20-Basic C-Shaped Wall Stud Behavior-WEBFINALDocument6 pagesTechNote - B008-20-Basic C-Shaped Wall Stud Behavior-WEBFINALsahanPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Chemical Technician Review GasesDocument53 pagesChemical Technician Review GasesJasonTenebrosoPas encore d'évaluation

- Bda31203notes 28studentversion Printable 29semii2020 2021Document192 pagesBda31203notes 28studentversion Printable 29semii2020 2021Praven KumarPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- AbstractDocument5 pagesAbstractkanzPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Moving Charge in A Magnetic FieldDocument3 pagesMoving Charge in A Magnetic FieldEntertainmentPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- SSC JE Mechanical Study Material Strength of Materials PDFDocument13 pagesSSC JE Mechanical Study Material Strength of Materials PDFSameer ShahPas encore d'évaluation

- SCORE300 Test Series-2024 - T02 (Code-A) - SolutionDocument17 pagesSCORE300 Test Series-2024 - T02 (Code-A) - Solutiondummymail6383Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Chemical Reaction Engineering (CRE) Is TheDocument24 pagesChemical Reaction Engineering (CRE) Is TheVaibhav GuptaPas encore d'évaluation

- Simulation of Particle Flows and Breakage in Crushers Using DEM Part 1 - Compression CrushersDocument20 pagesSimulation of Particle Flows and Breakage in Crushers Using DEM Part 1 - Compression Crushersthe requiem LastPas encore d'évaluation

- As-NZS 1554.1 Testing RequirementsDocument2 pagesAs-NZS 1554.1 Testing RequirementsSyed Mahmud Habibur RahmanPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Thin Wall Pressure VesselsDocument20 pagesThin Wall Pressure VesselsTare Er KshitijPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Fluid DynamicsDocument18 pagesFluid DynamicsAngelica Losares100% (1)

- Design of Automotive DifferentialDocument8 pagesDesign of Automotive DifferentialDeepak ChachraPas encore d'évaluation

- CLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Document8 pagesCLS Aipmt 16 17 XII Che Study Package 5 SET 1 Chapter 2Kareena Gupta100% (3)

- College Physics Quiz 2Document2 pagesCollege Physics Quiz 2jisoo rabbitPas encore d'évaluation

- Einstein and The Photoelectric Effect: H. J. Carmichael University of AucklandDocument29 pagesEinstein and The Photoelectric Effect: H. J. Carmichael University of AucklandBrahmanand TiwariPas encore d'évaluation

- Head Loss Calculator by Fadi YasinDocument8 pagesHead Loss Calculator by Fadi YasinYasser ShehataPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Introduction To Joining Processes: ObjectiveDocument5 pagesIntroduction To Joining Processes: ObjectiveSubhasis BiswalPas encore d'évaluation

- Organograma ASME IX Art. I PDFDocument4 pagesOrganograma ASME IX Art. I PDFfabiocorreasilvaPas encore d'évaluation

- Exhaust System DesignDocument9 pagesExhaust System Designbernard alcorizaPas encore d'évaluation

- CT LastDocument3 pagesCT LastJerick JusayPas encore d'évaluation

- Biomes of The EarthDocument273 pagesBiomes of The Earthbruiatu100% (1)

- R.N. Swamy (Editor) - B. Barr (Editor) - Fibre Reinforced Cement and Concretes - Recent developments-CRC Press (1990)Document715 pagesR.N. Swamy (Editor) - B. Barr (Editor) - Fibre Reinforced Cement and Concretes - Recent developments-CRC Press (1990)Gardener Ayu0% (1)

- 340P PDFDocument2 pages340P PDFBujar DalipiPas encore d'évaluation

- CH 1 Solid State SsnotesDocument29 pagesCH 1 Solid State SsnotesAnonymous 8VJhV1eI2yPas encore d'évaluation

- Study On The Diaphragm Fracture in A Diaphragm Compressor For A Hydrogen Refueling StationDocument10 pagesStudy On The Diaphragm Fracture in A Diaphragm Compressor For A Hydrogen Refueling StationMateusPas encore d'évaluation

- SolidsNotes6 ElutriationDocument7 pagesSolidsNotes6 ElutriationRoberta BelazPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)