Académique Documents

Professionnel Documents

Culture Documents

Stabilizing Piles of Soft Cohesive Slopes, A Case History-Salem PDF

Transféré par

Anonymous Re62LKaACTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stabilizing Piles of Soft Cohesive Slopes, A Case History-Salem PDF

Transféré par

Anonymous Re62LKaACDroits d'auteur :

Formats disponibles

Stabilizing Piles of Soft Cohesive Slopes: A Case History

Tarek N. Salem1, Mohsen Mashhour2, Rana Hassan3

Prof. of soil mechanics and foundations, Zagazig University, Egypt, nageeb2@yahoo.com. 2 Prof. of soil mechanics and foundations, Zagazig University, Egypt, edecon2005@yahoo.ca. 3 Teaching assistant, Zagazig University, Egypt, roony567@yahoo.com.

1

ABSTRACT

Slope stability is one of the most important problems in geotechnical engineering because failure could cause catastrophic environmental and human disasters, in addition to large economical losses due to such failure. The purpose of this paper is to study the effect of using piles in stabilizing the embankments of Al-Salam Canal in Northern Egypt. The canal left side is a formed soft clay embankment which is mainly formed from dredging and cleaning of the bottom of the nearby AlManzala lake. Sudden and progressive failures took place in the left side embankment over years for many reasons. These failures are mainly due to the nature of the soft clay forming the slope in addition to the existence of gypsum and peat pockets and thin layers within the slope in many locations. Thus, it was suggested to use a row of reinforced concrete piles to stabilize the left side embankment of the canal. Analysis of the slope stabilized by piles is performed using finite element analysis. Although the slope stabilizing piles were able to stabilize the slope to some extent, increasing the number of pile rows was not effective in increasing the safety factor in return. Another slope stabilizing technique is studied herein using lime treatment. The proposed lime treatment technique was effective in stabilizing the slope more than the slope stabilizing piles, even in the zones containing the peat layer.

KEYWORDS: Slope Stability; Piles; Soft Clay; Peat; Lime Treatment; Numerical Analysis; Slope Stabilizing Piles.

INTRODUCTION

Slope stabilizing piles are widely used to stabilize slopes. These piles are mainly subjected to lateral pressure from the horizontal movement caused by the slope sliding mass. Many techniques have been proposed in order to analyze slopes stabilized by piles like Rowe and Poulos (1979), Ito et al., (1981), Poulos (1995, 1999), Chow (1996), Bransby and Springman (1996, 1999), Lee et al. (1995), Hassiotis et al. (1997). Cai and Ugai (2000) studied the effect of stabilizing piles on the stability of a slope by three-dimensional elasto-plastic shear strength reduction finite element method. Ausilio et al. (2001) presented a kinematic approach for the stability analysis of slopes reinforced with piles. Chen and Martin (2002) examined the existence of an arching zone around landslide stabilizing pile groups for granular and fine-grained soils. Nian et al. (2008) showed that a combination of the limit analysis kinematic approach and the strength reduction technique provides a convenient and effective approach for stability analysis of slopes in anisotropic and non-homogeneous slopes. Wei and Cheng, (2009) revealed that the critical slip surface was found - 3803 -

Vol. 17 [2012], Bund. Z

3804

to be divided into two parts when the pile spacing is small, and these two parts gradually get connected with increasing the pile spacing till a clear critical slip surface is formed. The newly formed critical slip surface is similar to that formed in the case of a slope without stabilizing piles. In the nineteen seventies, it was realized that development and construction activities must be extended to reach Sinai Peninsula at the eastern borders of Egypt. The Sinai proposed development plan was based mainly on increasing the agriculture activities. It was decided to extend the developed region to go beyond the Suez canal and to exploit the unique position of Suez canal in development of the region. Later on, it was decided to construct Al-Salam canal to provide large areas with sufficient irrigation water to reclaim an extra 620 thousand feddans along the canal length till reaching Sinai Peninsula. Al-Salam canal in Northern Egypt starts at the Nile river estuary from Damietta and transmits the excess Nile water into Sinai Peninsula. The canal embankments extend for a length of about 89.750 km from the Damietta branch till reaching the Suez Canal, as shown in Figure (1).

Figure 1: Map of Al-Salam Canal Path from Google Earth.

The studied case is the left side embankment of Al-Salam canal which was originally a formed one. Thus, the embankment is formed of dredged soft clay, organic materials, and gypsum pockets and even layers within the embankment slope. Due to the soft nature of the slope and the existence of organic layers such as peat, sudden and progressive failures took place in the left side embankment. It should be noted that the peat layer caused most of the slope failures and the gypsum pockets even caused local failures in the slope accompanied by water piping when the water level in occasions of the nearby Al-Manazala lake happen to be higher than that in Al-Salam Canal. As a part of the strategic project of developing the Sinai Peninsula, it was decided to widen the canal width, along with improving the capacity and widen the highway in the canal left side. The slope height and inclination angle of the canal will remain the same after the proposed canal widening, only the canal cross-section was increased by cutting 3.0 m from the berm in each side in order to improve the canal water flow capacity. There is an existing highway in the canal right side, with no apparent stability problems for being a cut slope in a relatively stiffer soil. So, the canal left side embankment of soft soil was not stable enough to sustain such widening along with the expected highway traffic loads, Al-Ashaal et al., (1998). Field investigations were performed to evaluate the current slope status, and

Vol. 17 [2012], Bund. Z

3805

suggest the proposed stabilizing technique including slope stabilizing piles. Of concern at that time, was the piling construction technique. CFA (Continuous Flight Auger) piles will not assure hindering the caving of the soft soil inside the bored pile. However, hammer driving will induce vibrations that will cause local or general failure in the embankment body. On the one hand, using full displacement piles will compress and consequently improve the soft soil behavior laterally, while, displacement piles remain mainly driven piles. Thus, it was decided to use steel casing in the driving to induce the displacement pile effect, and the driving process is performed using vibratory drivers. Keeping the frequency of vibrations lower than the natural frequency of the soil in which the piles are being driven, along with minimizing the driving amplitude have successfully accomplished both tasks. These tasks are employing displacement piles, and prevent caving of the soil in case of using CFA piles, while excluding the pile driving effects. The embankment stabilization using piles is initially assessed using the simplified Janbu method, followed by another assessment using the wedge method. Both solution techniques using two slope stabilizing pile rows led to safety factors of more than 1.50, satisfying the requirements of the Egyptian Code (2001). Therefore, in this study the effect of slope stabilizing piles in increasing the safety factor of the embankment is exclusively studied in this research using the finite element software Phase2.

STABILIZING AL-SALAM CANAL LEFT SIDE EMBANKMENT

The general configuration of the left embankment of Al-Salam canal is presented in Figure (2). The figure shows the typical left side embankment after widening the canal cross-section. Two extensive monitoring zones are chosen namely; from 7.700 to 7.750 km and from 8.800 to 8.850 km. These zones are mainly chosen due to the presence of the peat layer, as assured from the boreholes performed along the whole embankment length. It should be noted that a full-scale embankment load test was performed in the first extensive monitoring zone, Youssef and AlGayar, (2000).

Figure 2: Schematic Diagram of Al-Salam Canal Cross Section after Widening.

It was suggested to use a slope stabilization system that consists of two rows of reinforced concrete piles, 50 cm in diameter and 16 m in length. The pile reinforcement included twelve 22 mm diameter bars, the distance between two pile rows is 2 m, and the center to center spacing between the piles in a single row is 1.25 m. The second row of piles was constructed within a thin cutoff wall constructed of bentonite slurry and cement to prevent seepage from and into the canal, because of the high salinity of Al-Manzala lake, Figure (3). Reinforced concrete connecting beams are constructed connecting the heads of the slope stabilizing piles and assuring the fixity conditions. The head fixity provides resistance against head rotation which may decrease the bending moment along the pile length. The reinforced concrete beam has a 6060 cm cross-section and reinforced with sixteen 16 mm diameter bars in

Vol. 17 [2012], Bund. Z

3806

the longitudinal direction of the canal. Lateral tie beams having the same cross-section and reinforcement were used to connect the longitudinal connecting beams laterally. The tie beams were repeated each 3.75 m in the longitudinal direction.

Figure 3: Top View of the Stabilizing System Showing the Positions of the Two Rows of Stabilizing Piles, the Seepage Cutoff Wall, and the Sand Drains.

NUMERICAL MODELING OF THE STABILIZED SLOPE

The finite element software Phase2 is used in modeling the stabilized slope. The software is a 2-dimensional elasto-plastic finite element program for calculating stresses and displacements around underground openings, and can be used to solve a wide range of slope stability and civil engineering problems, (Phase2, V.8). The safety factor is calculated using the Shear Strength Reduction method (SSR). The failure criterion used in the slope analysis was Mohr-Coulomb because the Mohr-Coulomb criterion better represents the soil behavior in addition to the physical meaning of its parameters (Das, 1983; Bishop, 1966). It should be noted that some advanced soil models have something like twenty parameters or so. Despite being very accurate when modeling their original problems they were calibrated for, these models usually fail in modeling any other geotechnical problem for simple reasons. First, the large number of model parameters rendered the model much complexity increasing the chance of errors in modeling. In addition, the real meaning of these parameters is not usually comprehended, even for simpler models like the CamClay model, Salem (1997). In Phase2, the piles were modeled using structural elements with pile/soil interface, and the properties of the interface didn't significantly affect the model results because of the soft nature of the surrounding soil. Piezometric lines are used to model the water level in the program, as shown in Figure (4), to allow for accurate modeling of the presence of the seepage cutoff wall. The soil properties used in the slope analysis is correlated from the soil investigation reports, along with the data presented in Al-Ashaal (1998). These properties are presented in Table (1), and Figure (6) which shows the soil stratification used in the analysis of the slope. It should be noted that the first soft clay layer contains trace of sand which was represented by a small friction angle of 5o.

Vol. 17 [2012], Bund. Z

3807

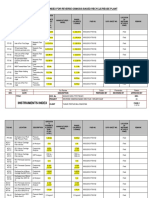

Figure 4: Finite Element Model of the Stabilized Canal Embankment. Table 1: Canal Soil Properties.

Soil Type Soft Silty Clay (1) Soft Silty Clay (2) Soft Silty Clay (3) Stiff Clay layer Peat layer Dense sand Gravel layer sat (kN/m3) 17 16 17 17 11 18 19 E (MPa) 1.70 1.40 2.00 5.90 0.30 100.0 200.0 0.45 0.45 0.45 0.45 0.45 0.30 0.30 c (kPa) 16.0 14.0 23.0 45.0 3.0 0.0 0.0 (o) 5 0.0 0.0 0.0 0.0 38 45 (o) 0.0 0.0 0.0 0.0 0.0 8 15

In which: sat : Saturated unit weight; E : Soil Young's modulus; : Poisson's ratio; c : Soil cohesion; : Angle of internal friction; and : Dilation angle, can be approximated as (-30). It should be noted that these soil properties have been obtained from several field and laboratory tests, except for the peat layer properties which are back calculated from the numerical analysis that gives the minimum applicable safety factor of 1.0, because several embankment failures took place in this zone.

ANALYSIS OF THE RESULTS

Analysis of the slope showed that the calculated safety factor before using any stabilizing system is found to be (1.03), in which case the slope is only just stable, and susceptible to failure at any point without external loading. However, using the proposed stabilizing system increased the calculated safety factor into (1.25) for a loaded slope. It should be noted that even after using the proposed slope stabilizing system the calculated safety factor has not satisfied the minimum

Vol. 17 [2012], Bund. Z

3808

safety factor required by the Egyptian Code of Practice, (2001). Moreover, using a single row of stabilizing piles instead of the proposed system containing two pile rows resulted in reducing the safety factor of the slope to (1.20), which comprises only about 5% reduction in that factor. Economically, almost doubling the cost to gain 5% increase in the safety factor is not feasible, especially if both conditions did not achieve the code requirements. The presence of the peat layer underneath such clay slope, at approximately the bed level, presents a pre-existing sliding surface that reduces the safety factor into such low values. Although using the stabilizing system has blocked such type of failure, but in return it allows for forming a new failure surface in front of the newly constructed stabilizing pile rows. Previous research indicated that the best position for such stabilizing piles is in the middle height of the embankment, in which the pile rows divide the sliding surface into two parts, Wei et al., (2009). In addition, installing the stabilizing pile rows in such position achieves the target of placing such piles in almost the middle of the peat layer sliding surface. The numerically calculated embankment maximum horizontal displacement was 34.75 cm before using the proposed stabilizing system at the slope toe, and without even applying the traffic loads. On the other hand, after using the stabilizing system and applying the surface equivalent traffic loads, which equals 33.35 kN/m2, an additional horizontal displacement of 15.15 cm and 14.30 cm took place behind and in front of the piles, respectively, as shown in Figure (5). This emphasizes that the piles have actually divided the sliding mass into two zones. The relatively large values of horizontal displacement indicate the weak nature of such soft clay and peat, which resulted in such high lateral displacement values under normal traffic loads.

Figure 5: Colored Contour Shading of the Horizontal Displacement under Equivalent Traffic Loads.

The settlement due to the embankment own weight only was found to be 24.30 cm before using the stabilizing piles. However, the calculated embankment settlement due to traffic load is found to be 23.30 cm, as presented in Figure (6). The results from the loading test performed in the extensive monitoring zone showed that the recorded total settlement at the top of the embankment was 18.0 cm, Youssef and Al-Gayar, (2000). The differences between the calculated and recorded settlement values may be due to the relative increase in the soft clay layers stiffness as caused by the loading process. Such vertical increase in soil stiffness in addition to the lateral soft clay improvement caused by using full displacement pile construction technique led to a gradual improvement in the soil properties.

Vol. 17 [2012], Bund. Z

3809

Figure 6: Settlement Contour Shading of the Stabilized Slope under Equivalent Traffic Loads.

PARAMETRIC STUDY

The canal embankments extend for a great length of about 90 km. The soil layer stratification, strength and mechanical properties, layer heights could be drastically changed. For the sake of covering up the most important parameter changes, a parametric study is performed to highlight the effect of the soil and stabilizing system parameters on the safety factors of the stabilized slope. The modeled embankment is cohesive soil containing a peat layer and followed by dense sand. Figure (7) illustrates a schematic diagram for the studied slope geometry and configurations including the followings: c: Soil cohesion ranging between 10 and 50 (kN/m2), with small effective friction angles ( ' = 5o and 10o). These parameters do cover most of the short term studied cases, and allows for studying some long term cases in which the undrained cohesion (cu) is replaced by the effective cohesion intercept (c') and () is replaced by '. H: Embankment slope height, varying from 3 to 10 meters; : Slope angle, varying from 26.57 to 70 degrees; P: Depth of 0.50 m thick peat layer, varying from 1 to 16 meters from the slope crest; N: Number of piles rows, slope studied for one and two piles rows; Hw: Height of water in the canal, varying from 0 to slope height H - 1.00 m; Other parameters included the presence of the external load; along with the concrete stabilizing pile properties such as pile length, diameter, and stiffness.

Hw

Figure 7: Slope Geometry.

Vol. 17 [2012], Bund. Z

3810

ANALYSIS AND RESULTS

Analysis of the parametric study results is presented hereinafter showing the effect of each parameter.

Effect of Soil Cohesion

There is no doubt that increasing the slope shear strength parameters will consequently increase the slope safety factor. Figure (8) shows the relation between the soil cohesion (c) and the safety factor of the slope (F.S.) for different soil effective angles of internal friction. Increasing the soil cohesion resulted in a noticeable increase in the safety factor for the loaded slope in the presence of the slope stabilizing piles. The used effective soil internal angles of friction, although small, but the actual friction angle could be higher due to the existence of sand traces, high silt content, in addition to the effect of dissipation of the pore water pressure due to using displacement piles. For soft clay soil an increase of only 5o in the friction angle, resulted in increasing the safety factor range from 20% to 36%, and for a 10o, the increase in the safety factor ranges from 39% to 71%. It is also noticed from the figure that soft clay soil with slope stabilizing system didn't reach the Egyptian Code (2001) recommended value of 1.50, but with added soil friction angle, the safety factors began to moderately increase. It should be noted that the water depth in the canal is equal (H-1.0) m, which is only 1.0 m below the full embankment height.

4.00 3.50 3.00 2.50 2.00 1.50 1.00 0.50

= 0o = 5o = 10o

F.S.

10

15

20

25

30

35

40

45

50

55

Soil Cohesion (c) kPa

Figure 8: Effect of Soil Undrained and Effective Cohesion on the F.S. (H = 5 m, Slope 2:1, One Pile Row, = 0, 5, 10).

Effect of Slope Height

The relation between the slope height and the safety factor is inversely proportional. Figure (9) shows the relation between the slope height and the slope safety factor for different undrained cohesion values (cu). Once again for purely cohesive soft soil in undrained condition, the slope stabilized with piles could not reach the recommended safety factor (1.50) even for slopes height of 3.0 m. Increasing the slope height from 3.0 to 10.0 m resulted in a decrease of about 27% for cu = 20 kN/m2, and about 24.0% for cu = 25 kN/m2. However, for medium stiff clay, the slope safety factor decreased about 30% for the same slope height range.

Vol. 17 [2012], Bund. Z

3.50

cu = 15kPa cu = 20kPa cu = 25kPa cu = 30kPa cu = 35kPa cu = 40kPa

3811

3.00

2.50

F.S.

2.00

1.50

1.00

0.50

10

12

Slope Height (H) m

Figure 9: Effect of Slope Height on F.S. (Slope 2:1, One Pile Row, cu = 15, 20, 25, 30, 35, 40 kPa).

Effect of Slope Angle

The slope angle has a small effect on the slope safety factor for cohesive slopes; the slope remains stable even for steep slopes. When the slope angle increased from gentle slope of about 27o to very steep slope of about 70o, the slope safety factor decreased by only 11.70%. This may be due to the effect of cohesion between soil particles, and the relatively large sliding surface that usually took place in cohesive soils, which in turn needs higher driving forces to overcome the cohesion forces.

Effect of Depth of the Peat Layer

The existence of the peat layer controls the shape of the failure surface. The failure surface passes through the peat layer because it is the weakest layer in the whole slope's soil profile. Figure (10) presents the relation between the depth of the peat layer and the slope safety factor for undrained cohesion, cu = 20.0 and 35.0 kPa. Existence of the peat layer within in the first meter of the slope resulted in a noticeably low safety factor value because the failure occurred in the zone of the sloped upper loaded fill behind the piles row. The piles had almost no effect on the sliding mass in such case. Increasing the depth of the peat layer within the slope resulted in a consistent reduction in the safety factor until the peat layer depth reached the slope toe. In all cases, failure took place due to the weight of the soil wedge which is increased with the increase of the peat layer depth, and the failure is planar in at the level in which the peat layer exists. The safety factor of the slope is almost constant when the peat layer is kept under the slope toe. This may be attributed to the formation of a passive soil block which resists occurrence of the failure surface through the peat layer in this case.

Vol. 17 [2012], Bund. Z

2.50

3812

2.25

cu = 20 kPa cu = 35 kPa

2.00

F.S.

1.75

1.50

1.25

1.00

10

15

20

Location of The Peat Layer (m)

Figure 10: Location of the Peat Layer Versus F.S. (H = 5 m, One Pile Row, cu = 20, 35 kPa).

Effect of Number of Pile Rows

Figure (11) shows the relation between the soil undrained cohesion and the safety factor considering the effect of one and two rows of stabilizing piles. The horizontal distance between the two pile rows is 2 m. The location of the peat layer defines the shape of the failure surface and the location of the stabilizing piles at the berm led to dividing the failure wedge into two distinctive bodies. The figure shows that using a second row of slope stabilizing piles does not result in a noticeable increase in the safety factors, assuring that the gained increase in the safety factors are not proportional to the additional cost of using the second row. By using only one pile row of stabilizing piles, and as a result of the peat layer position which controls the failure surface shape, a single pile row blocks the failed mass in front of the piles and local failure zone could be created behind the pile row due to the external loading on the slope. If an additional pile row is positioned next to the first one, only the beginning of the maximum stressed zone created after installing the first row is shifted into the second one.

3.50 one piles row two piles rows

3.00

2.50

F.S.

2.00

1.50

1.00

0.50

10

15

20

25

30

35

40

45

50

55

Soil Cohesion (cu) kPa

Figure 11: Undrained Soil Cohesion Versus F.S. (H = 5 m, cu = 20 kPa).

Effect of Water Level in the Canal

Figure (12) presents the effect of the water level in the waterway along the embankment. The presence of water in the canal provides additional lateral resisting pressure. This pressure is equal

Vol. 17 [2012], Bund. Z

3813

to (w z) where (w ) is the water unit weight and (z) is the selected water depth in the waterway. The most critical case is considered the rapid drawdown case in which a sudden emptying of the water from the waterway took place. Consequently, the water pressure triangle is suddenly removed while the embankment slope is still being fully saturated, and thus having the highest possible unit weight. For soft soils having undrained cohesion values of cu = 20 kPa or less, the embankment is not safe in the case of rapid drawdown. Thus, additional methods must be implemented to stabilize the slope if any construction activities will require sudden emptying of the canal. For higher value of undrained soil cohesion, the slope safety factor reached 1.37 in the case of rapid drawdown. Although the safety factor didn't reach the required value of 1.50 for stiffer soils, the slope will actually remain in stable condition, and failure is not predicted in such case. At cu = 20 kPa, the slope safety factor will not reach the recommended value of 1.50 even if the water depth in the canal is 4.0 m or higher. For higher undrained cohesion value at cu = 30 kPa and to ensure that the slope safety factor will reach the recommended value (1.50), the water depth in the canal shouldn't be less than 2.0 m.

2.00 cu = 20 kPa cu = 30 kPa 1.50

F.S.

1.00 0.50 0

Water Level (D) m

Figure 12: Effect of Water Level on the F.S. (H = 5 m, cu = 20, 30 kPa, One Pile Row).

Effect of the Stabilizing Pile Properties

The effect of the stabilizing piles properties on the slope such as pile diameter, stiffness, and length on the slope safety factors has been also studied. For larger and smaller pile diameters, the slope safety factor seems to be unchanged, also changing the Young's modulus of the pile material which is reinforced concrete, the slope safety factor didn't change also for higher or lower values for Young's modulus. This may be attributed to the large stiffness ratio (more than 11000 times) between the piles and the surrounding soft soils. Larger diameter piles and higher concrete quality with large values of Young's modulus did not also affect the overall stability of the embankment slope. Thus, additional costs due to larger pile diameters and higher pile material quality did not cause any additional safety benefits. Dense sand layers are encountered at different depths along Al-Salam canal embankment. Thus, stabilizing piles of different lengths starting with 6.0 m up to 17.0 m are also studied. Increasing the pile length L from 9.0 m up to 17.0 m is found to have nearly no effect on the slope safety factor as long as the pile tip is embedded at least 1.0 m in the dense sand layer. Again, the sliding surface is defined by the existence of the peat layer and the piles resist the sliding mass by the lateral earth pressure and the developed resisting pressure decreased with decreasing the pile length. The piles provided full resisting pressure against the embankment driving mass after which the pile length no longer affects the slope safety factor. Pile length less than 9.0 m resulted in slight decrease in the slope safety factor. Generally, the piles should be

Vol. 17 [2012], Bund. Z

3814

extended below the sliding surface with sufficient distance to avoid mobilizing the sliding mass. The slope safety factor also decreased when the pile tip does not end within the sand layer. This may be due to the fixity provided by relatively higher lateral sand resistance.

LIME TREATMENT OF THE CANAL LEFT SIDE EMBANKMENT

Results of the current study shows that stabilizing soft clay slopes containing peat layer with reinforced concrete piles seems to be ineffective in raising the slope safety factor to the recommended value of 1.50. Piles are very rigid elements with respect to the surrounding soft soils, and zones of local failure could be formed behind or in front of the piles reducing the safety factors even after constructing the stabilizing system. For these reasons stabilizing the slopes with chemical treatment such as lime columns is proposed herein to stabilize the left side embankment of Al-Salam canal. This method is widely used in Finland, Sweden and Japan due to the existence of peat layers and soft soils in wide areas. The method depends on mixing the in-situ soil with lime to stabilize the soft and organic soils. The lime reaction with the surrounding soft soil is presented in Figure (13). Lime columns increase the soil shear strength with time. Just after the installation of columns and within a very short period of time ranging between 0.50 - 2.0 hours, the unslaked lime absorbs the ground water from the surrounding soil, in addition water evaporation that takes place due to the high slaking temperature cause reduction in the soil water content and thus relatively increase its stiffness and strength properties. During this time ion exchange takes place causing an increase in the plastic limit and decrease in the plasticity index rendering the soil stiffer consistency. After this initial chemical reaction, an action governed the increase in the soil shear strength called the Pozzalnic reaction takes place. The lime begins to react with the surrounding clay minerals forming higher strength crystals. This reaction causes an increase in the soil shear strength over long time periods ranging from 2.0 to 5.0 years, Broms, (2003). In the pozzolanic reaction Calcium ions (Ca++) from the stabilizer continue to react with SiO2 and Al2O3 in the clay for a long time and forms CaO.SiO2.H2O, and causing the clay to gain strength, Rao (2006). In Al-Salam canal embankment case, the proposed stabilizing system consists of seven rows of lime columns of 0.80 m diameter, installed by the dry method, with center to center spacing of 2.0 m, with a length of about 9.0 m, as presented in Figure (14). Adding cement to lime columns is usually recommended in the zones with high organic contents and peat layers, Broms (2004). Depending on the column diameter, the center to center spacing is chosen to be 2 m which is equivalent to 2.5 d, where d is the column diameter and placed in the active zone of the embankment as shown in Figure (14). In the direction parallel to the waterway, the columns should be overlapped with a distance not less than 7 cm to ensure that the piles act as continuous wall which will increase the slope safety factor and reduce the lateral displacement, Broms (2003). The shear strength used in designing columns is based on estimating the shear strength after 28 days of installation. Assuming full interaction between the columns and the surrounding unstabilized soil, the undrained shear strength of the stabilized soil media is taken equal 100 kPa, Broms (2003)

Vol. 17 [2012], Bund. Z

3815

Figure 13: Reaction of Unslaked Lime with Clay, (after Broms, 2004).

Charbit (2009) mentioned that the Swedish code of practice assumed that the columns and the surrounding soil are considered composite material, and the columns are assumed to fail in shear. However, several studies showed that failures in bending are more probable, which means that the strength of the embankment might be overestimated.

Figure 14: FEM Mesh of the Distribution and Position of Lime Columns.

Broms (2004) stated that Lahtinen and Vepslinen (1983) have back calculated an average modulus of elasticity of 15 to 25 MPa for lime columns. For laboratory samples, the ratio E50/cu,col could be assumed equal 75 for lime, where E50 is the lime column modulus of elasticity at qu/2, cu,col is the undrained shear strength of the columns and qu is the unconfined compressive strength. The main properties of the lime columns that were used in the slope analysis are summarized in Table (2).

Vol. 17 [2012], Bund. Z

3816

Modeling the left side embankment stabilized with lime was performed by the same finite element program Phase2. The calculated slope safety factor after soil improvement using lime columns is equal to 1.66, for the embankment stabilized with seven columns. The slope safety factor exceeded the recommended value of 1.50, while the slope safety factor for the embankment stabilized with reinforced concrete stabilizing piles was only 1.25. The calculated maximum settlement under traffic loaded slope stabilized with piles is equal to 23.30 cm, whereas this calculated settlement value is reduced to 8.80 cm when lime columns are used, as shown in Figure (15).

Table 2: The Lime Treatment Columns Properties.

The Columns Properties Diameter (d) Length (L) Spacing between Columns The Unit Weight (c) Modulus of Elasticity (E) Poisson's Ratio () Shear Strength Parameter Value 0.80 m 9.0 m 2.00 m 18 kN/m3 7500 kN/m2 0.45 cu,col =100 kN/m2

Figure 15: Colored Contour Shading of the Lime Treated Embankment Settlement, after Lime Treatment

Figure (16) represents the lateral displacement of the embankment improved with lime columns. The maximum horizontal displacement is found to be 6.90 cm compared with 14.30 cm of the embankment stabilized with piles. Although the lime columns take relatively long time to increase the soil shear strength, but it is an effective method to treat the soft clay and organic soil with relatively lower costs compared to the reinforced concrete piles. In addition, the lime is available and relatively cheap material in Egypt. However, special industrial safety measures should be considered for the workers when installing lime columns. The permeability increases normally with lime treatment. Large differences can be expected between the permeabilities determined from laboratory samples and those obtained from field tests. This may be attributed to the cracks and fissures that took place after lime treatment in lime columns which could affect the test results, Broms (2004). Broms (2003) mentioned that "Broms and Boman, 1977a, Leminen and Rathmayer, 1979, Bengtsson and Holm, 1984, Hansbo and Torstensson, 1979, and Soyez et al., 1983, based on field tests, reported that the lime columns could function as vertical drains and succeeded in reducing

Vol. 17 [2012], Bund. Z

3817

the stabilized soil consolidation time". This is an additional stabilizing effect added to the chemical lime treatment reaction.

Figure 16: Colored Contour Shading of the Embankment Horizontal Displacement, after Lime Treatment.

It is recommended to use a permeability ratio (kcol/ksoil) equal to 40 in designing the columns, where, kcol is the columns permeability and ksoil is the permeability of the unstabilized soil. Thus, the pore water pressure should be observed during and after the column installation, Broms (2004). A decision should be taken about replacing one of the columns at the berm with a cutoff wall to block the two-way seepage from the waterway into the lake and vice versa through the embankment. The permeability of the seepage cutoff wall was chosen to be about 1.4*10-7 cm/sec, based on permeability tests that were performed by the Soil Mechanics Laboratory of Cairo University (2000). By analyzing this case with the finite element program, the slope safety factor is found to be (1.63) which is slightly lower than the case of no seepage cutoff wall is used. The values of the settlement and horizontal displacement under the equivalent traffic loads seemed to be unchanged. A critical case would arise when the rapid drawdown takes place in the canal, and the slope is still saturated with water. In such case, the slope is found to be unsafe, because the water pressure on the slope shares in resisting the slope disturbing forces. To ensure that the slope is safe and reaches about 1.50 as a safety factor, the water level in the canal beside the embankment shouldn't be less than about 2.00 m. In such case, the process of the slope widening will not require emptying the waterway. For constructing any projects in the future which could require emptying the canal, long-term analysis should be carried out on the soil and accordingly, a decision should be taken to choose other methods to stabilize the slope or to satisfy with the lime treatment columns as stabilizing system. The rapid drawdown case could be avoided by reducing the water level in the waterway over a longer period of time allowing for synchronized reduction of the water level in the waterway with consequent reduction of the water in the side slopes. The environmental impact of the lime treatment should be carefully assessed in such condition especially the pH value of the groundwater in the embankment and the nearby water in the canal. The seepage cutoff wall could function as an environmental barrier in such case.

Vol. 17 [2012], Bund. Z

3818

CONCLUSION

Based on the analysis made by the finite element program (Phase2), the following conclusions could be obtained: 1- For the very soft and soft clay slopes including peat layers through their profiles, the piles are not that effective as a stabilizing system. 2- Using two pile rows of stabilizing piles have not resulted in increasing the slope safety factor to the target value of 1.50. 3- Rapid drawdown of the water inside the waterway is not recommended to avoid slope failures as it was considered the most critical case when the canal is empty and the soil is saturated. However, if necessary it could be performed over a relatively long period of time to allow for the water level and saturation of the slopes to be reduced with time. 4- For soft clay containing organic layers, chemical soil treatment such as lime columns is considered an effective way to increase the slope safety factor and to increase the shear strength parameters in the failed region, but further parametric study, laboratory, and field tests should be performed in order to have a better view for stabilizing the soft soil with lime columns and to determine the different columns characteristics. Feasibility study should also be performed in such case.

REFERENCES

[1] Al-Ashaal, A. A., Abdel-Motaleb, A.A., and Haggag, H. A., (1998), "Stabilizing Embankment Made of and Founded Over Weak Soil Using Piles: A Case History", Soil Mechanics and Foundations, Journal of the Egyptian Geotechnical Society, Vol.9. [2] Ausilio, E., Conte, E., and Dente G., (2001), "Stability Analysis of Slopes Reinforced with Piles". Computers and Geotechnics, Vol. 28, pp.591611. [3] Bishop, A. W. (1966), "The Strength of Soils as Engineering Materials", Sixth Rankine Lecture, Geotechnique, Vol. 16, No. 2, pp.89-130. [4] Bransby, M. F. and Springman, S., (1996), "3-D Finite Element Modeling of Pile Groups Adjacent to Surcharge Loads", Computers and Geotechnics, Vol. 19, No.4, pp.301-324. [5] Bransby, M. F. and Springman, S., (1999), "Selection of Load-Transfer Functions for Passive Lateral Loading of Pile Groups", Computers and Geotechnics, Vol. 24, pp.155-184. [6] Broms, B. B., (2003), "Lectures in Deep Soil Stabilization, Design and Construction of Lime and Lime/Cement Columns", Royal Institute of Technology Stockholm, Sweden. [7] Broms, B. B., (2004), "Lime and lime/cement columns (Ch 8) - Ground Improvement", edited by Moseley M.P. and Kirsch K., Spon Press, Second Edition. [8] Cai, F., and Ugai, K., (2000), "Numerical Analysis of the stability of a slope reinforced with piles". Soils and foundations, Japanese Geotechnical Society Vol. 40, No. 1, pp.73-84. [9] Cairo University, Soil Mechanics Laboratory, (2000), "Mix Design Report of the Two Mixes of the Cut-off Wall in the Two Extensive Monitoring Zones".

Vol. 17 [2012], Bund. Z

3819

[10] Charbit, B., (2009), "Numerical Analysis of Laterally Loaded Lime/Cement Columns", M.Sc, Division of Soil and Rock Mechanics, Department of Civil and Architectural Engineering, Royal Institute of Technology (KTH), Stockholm, Sweden. [11] Chen, C. Y., Martin, G.R., (2002), "SoilStructure Interaction for Landslide Stabilizing Piles". Computers and Geotechnics, Vol. 29, pp.363386. [12] Chow, Y.K., (1996), "Analysis of Piles Used for Slope Stabilization". International Journal for Numerical and Analytical Methods in Geomechanics, Vol. 20, pp.635646. [13] Das, B. M., (1983), "Advanced Soil Mechanics", Washington: Hemisphere Pub. Corp., McGraw-Hill, New York. [14] Egyptian Code of Practice for Soil Mechanics, Design and Construction of Foundations, (2001), Part No. 8, Stability of Slopes. [15] Hassiotis, S., Chameau, J. L., and Gunaratne, M., (1997), "Design Method for Stabilization of Slopes with Piles", ASCE, Journal of Geotechnical and Geoenviromental Engineering Division, Vol. 123, No. 4, pp.314-323. [16] Holm, G., Trnk, R and Ekstrm, A., (1983a), "Improving Lime Column Strength with Gypsum", Proc. 8th European Conf. on Soil. Mech. a. Found. Engng., Helsinki, Finland, Vol. 2, No. 2, pp. 903-907. [17] Ito, T., and Matsui, T., Hong, W. P., (1981a), "Design Method for Stabilizing Piles against Landslide (One Row of Piles)". Soils and Foundations, Japanese Society of Soil mechanics and Foundation Engineering, Vol. 21, No. 1, pp. 1-13. [18] Ito, T., and Matsui, T., Hong, W. P., (1981b), "Extended Design Method for MultiRow Stabilizing Piles against Landslide". Soils and Foundations, Japanese Society of Soil Mechanics and Foundation Engineering, Vol. 22, No. 1, pp. 21-37. [19] Lee, C.Y, Hull, T.S, and Poulos H.G., (1995), "Simplified Pile Slope Stability Analysis", Computers and Geotechnics, Vol. 17, pp.1-16. [20] Nian, T.K., Chen, G.Q., Luan, M.T., Yang, Q. and Zheng D.F., (2008), "Limit Analysis of the Stability of Slopes Reinforced with Piles against Landslide in NonHomogeneous and Anisotropic Soils", Canadian Geotechnical Journal, Vol. 45, pp.10921103. [21] Poulos, H.G., (1995), "Design of Reinforcing Piles to Increase Slope Stability", Canadian Geotechnical Journal, Vol. 32, pp.808-818. [22] Poulos, H. G., (1999), "Design of Reinforcing Piles to Increase Slope Stability", Slope Stability Engineering, Yagi, Yamagami, Jiang, Editors, Balkema, Rotterdam. [23] PHASE 2, Version 8.005, (2011), "Rocscience Inc.", Ontario, Canada. [24] Rao, K. N., (2006), "Numerical Modeling and Analysis of Pile Supported Embankments", M.Sc. Thesis, the University of Texas at Arlington. [25] Rowe, R. K., and Poulos, H. G., (1979), "A Method for Predicting the Effect of Piles on Slope Behavior", Third International Conference on Numerical Methods in Geomechanics, Aachen, pp. 1073-1085. [26] Salem, T. N., (1997), "Analysis of Offshore Piles", PhD. Thesis, Department of Structural Design, Zagazig University, Zagazig, Egypt.

Vol. 17 [2012], Bund. Z

3820

[27] Wei, W.B., Cheng, Y.M., and Li, L., (2009), "Three-Dimensional Slope Failure Analysis by the Strength Reduction and Limit Equilibrium Methods". Computers and Geotechnics, Vol. 36, pp.7080. [28] Youssef, A. M., and Al-Gayar, M. S., (2000), "Technical Report of the Loading Embankment Results Performed at the Left Side Embankment of Al-Salam Canal from km 7.700 to km 7.750", Faculty of Engineering, Al-Mansoura University.

2012, EJGE

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 2011 Ifa FertigationDocument141 pages2011 Ifa Fertigationsarias355403100% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Ballast Water Management, Mepc 127Document16 pagesBallast Water Management, Mepc 127Eshwar BabuPas encore d'évaluation

- Drainage Impact Assessment Within The Environmental AreasDocument10 pagesDrainage Impact Assessment Within The Environmental AreasRonald Gomeseria y Valledor100% (1)

- Types of Pressure Relief ValvesDocument22 pagesTypes of Pressure Relief ValvesFaraz MichPas encore d'évaluation

- Jaane MaryamDocument2 pagesJaane Maryamhoney80% (5)

- Precious Metals Heap Leach Facilities Design, Closure and ReclamationDocument8 pagesPrecious Metals Heap Leach Facilities Design, Closure and ReclamationAhmed Mohamed RedaPas encore d'évaluation

- EN Folder Watersupply ILF PDFDocument12 pagesEN Folder Watersupply ILF PDFMishealPas encore d'évaluation

- CHEM 130 Lab Manual Guides Green Chemistry ExperimentsDocument64 pagesCHEM 130 Lab Manual Guides Green Chemistry ExperimentsCaledoniaHearthPipesPas encore d'évaluation

- Bromin Atau BromDocument17 pagesBromin Atau BromTria Yussanti100% (1)

- 5 Carbon Brush Technical Guide Mersen - 07Document40 pages5 Carbon Brush Technical Guide Mersen - 07Dhanraj PatilPas encore d'évaluation

- CENTROPELET-ZV ZVB-serviseri-ENG N 03 2015Document22 pagesCENTROPELET-ZV ZVB-serviseri-ENG N 03 2015Miloš Stijelja75% (4)

- Term 2 Week 5 2019Document11 pagesTerm 2 Week 5 2019Anonymous Re62LKaACPas encore d'évaluation

- Piano 6staff With ClefsDocument1 pagePiano 6staff With ClefsBen HarringtonPas encore d'évaluation

- Yates Liquid Copper How To ApplyDocument9 pagesYates Liquid Copper How To ApplyAnonymous Re62LKaACPas encore d'évaluation

- YatesDocument4 pagesYatesAnonymous Re62LKaACPas encore d'évaluation

- Piano - 4 Staff - With ClefsDocument1 pagePiano - 4 Staff - With ClefsAnonymous Re62LKaACPas encore d'évaluation

- Golden Dreams-2scan PDFDocument2 pagesGolden Dreams-2scan PDFAnonymous Re62LKaACPas encore d'évaluation

- ComoDocument1 pageComoAnonymous Re62LKaACPas encore d'évaluation

- c3 Battery Charger DL Broch 2014 Fin HRDocument2 pagesc3 Battery Charger DL Broch 2014 Fin HRAnonymous Re62LKaACPas encore d'évaluation

- c3 Manual Rbau A5 Pp33440 FaDocument8 pagesc3 Manual Rbau A5 Pp33440 FaAnonymous Re62LKaACPas encore d'évaluation

- Podešavanje Eq MontažeDocument19 pagesPodešavanje Eq MontažeArmagedon KommtPas encore d'évaluation

- Flashcards Bass Clef Notes Cheatsheet PDFDocument1 pageFlashcards Bass Clef Notes Cheatsheet PDFAnonymous Re62LKaACPas encore d'évaluation

- Equatorial Mount Instruction Manual For Reflector TelescopesDocument3 pagesEquatorial Mount Instruction Manual For Reflector TelescopesAnonymous Re62LKaACPas encore d'évaluation

- Visually Similar ResultsDocument2 pagesVisually Similar ResultsAnonymous Re62LKaACPas encore d'évaluation

- Persian Happy Birthday Sheet MusicDocument1 pagePersian Happy Birthday Sheet MusicAnonymous Re62LKaACPas encore d'évaluation

- Lisgar GardensDocument2 pagesLisgar GardensAnonymous Re62LKaACPas encore d'évaluation

- Flashcard Bass Clef Notes v2 Page3Document1 pageFlashcard Bass Clef Notes v2 Page3Anonymous Re62LKaACPas encore d'évaluation

- Middle Harbour Creek LoopDocument5 pagesMiddle Harbour Creek LoopAnonymous Re62LKaACPas encore d'évaluation

- Flashcard Bass Clef Notes v2 Page1 PDFDocument1 pageFlashcard Bass Clef Notes v2 Page1 PDFAnonymous Re62LKaACPas encore d'évaluation

- Flashcard Bass Clef Notes v2 Page1Document1 pageFlashcard Bass Clef Notes v2 Page1Anonymous Re62LKaACPas encore d'évaluation

- Flashcard Treble Clef Notes v2 Page2Document1 pageFlashcard Treble Clef Notes v2 Page2Anonymous Re62LKaACPas encore d'évaluation

- Flashcard Small PDFDocument5 pagesFlashcard Small PDFAnonymous Re62LKaACPas encore d'évaluation

- Flashcard Treble Clef Notes v2 Page2 PDFDocument1 pageFlashcard Treble Clef Notes v2 Page2 PDFAnonymous Re62LKaACPas encore d'évaluation

- Flashcards Treble Clef NotesDocument1 pageFlashcards Treble Clef NotesAnonymous Re62LKaACPas encore d'évaluation

- Flashcards Bass Clef Notes PDFDocument1 pageFlashcards Bass Clef Notes PDFAnonymous Re62LKaACPas encore d'évaluation

- Flashcards Treble Clef Notes PDFDocument1 pageFlashcards Treble Clef Notes PDFAnonymous Re62LKaACPas encore d'évaluation

- Flashcard-Big Bass Clef PDFDocument17 pagesFlashcard-Big Bass Clef PDFAnonymous Re62LKaACPas encore d'évaluation

- Colouring Competition: Name: TeamDocument7 pagesColouring Competition: Name: TeamAnonymous Re62LKaACPas encore d'évaluation

- Flashcard-Big Bass ClefDocument17 pagesFlashcard-Big Bass ClefAnonymous Re62LKaACPas encore d'évaluation

- Embankment Dam Lecture NoteDocument24 pagesEmbankment Dam Lecture NoteYosi100% (1)

- Membrane Element CPA2-4040: PerformanceDocument1 pageMembrane Element CPA2-4040: Performancecarlos pachecoPas encore d'évaluation

- Claire Typhoon21 - For MergeDocument3 pagesClaire Typhoon21 - For MergeSophia Claire SaballaPas encore d'évaluation

- Presentation To Unconventional Gas Technical Forum Victoria, BC April 4, 2008Document35 pagesPresentation To Unconventional Gas Technical Forum Victoria, BC April 4, 2008Rafi Zafar100% (1)

- Sampling and Analysis Plan for DOE Legacy SitesDocument224 pagesSampling and Analysis Plan for DOE Legacy SitesCharmi HediPas encore d'évaluation

- Tugas Alkohol 1 (3 Kelompok)Document39 pagesTugas Alkohol 1 (3 Kelompok)Galuh Eka WulandariPas encore d'évaluation

- Paper Production From Mauritian Hemp FibersDocument22 pagesPaper Production From Mauritian Hemp Fibersjitendra kumarPas encore d'évaluation

- Soil Physical Properties and Oil Palm Productivity in Peatlands with Different Water LevelsDocument8 pagesSoil Physical Properties and Oil Palm Productivity in Peatlands with Different Water LevelsTjandra LiemPas encore d'évaluation

- Soft Drink Bottling Plant Inspection Form ViolationsDocument2 pagesSoft Drink Bottling Plant Inspection Form ViolationsTanzila SiddiquiPas encore d'évaluation

- (Report) Experimental Study Crossflow Turbine Efficiency (Aziz Desai Clemson)Document52 pages(Report) Experimental Study Crossflow Turbine Efficiency (Aziz Desai Clemson)pekawwPas encore d'évaluation

- Jakarta - WikipediaDocument15 pagesJakarta - WikipediarizkisembiringPas encore d'évaluation

- Types of Pipes: Ar. Kiran PatilDocument6 pagesTypes of Pipes: Ar. Kiran PatilShweta PuriPas encore d'évaluation

- Design Assignment TU Noord: February 2012Document38 pagesDesign Assignment TU Noord: February 2012frankydadPas encore d'évaluation

- Instruments Index RO Plant YTMDocument8 pagesInstruments Index RO Plant YTMSswahyudiPas encore d'évaluation

- Soil Stabilization: With PolyurethaneDocument26 pagesSoil Stabilization: With Polyurethanedilaalvi100% (1)

- Worksheet 3 Reading ActivitiesDocument2 pagesWorksheet 3 Reading ActivitiesDella OktaviaPas encore d'évaluation

- Ashirvad Only PVC Product MRP - 1st Dec 2020Document68 pagesAshirvad Only PVC Product MRP - 1st Dec 2020Ujwal Elijah GurramPas encore d'évaluation

- Using Bufkit To Visualize Precipitation Amount and Type: WDTB Winter Weather Workshop July 23, 2003Document34 pagesUsing Bufkit To Visualize Precipitation Amount and Type: WDTB Winter Weather Workshop July 23, 2003George Tsavd100% (1)

- Executive Summery SuthaliyaDocument3 pagesExecutive Summery SuthaliyaAkash JainPas encore d'évaluation

- How To Clean A BeachDocument3 pagesHow To Clean A BeachSara AguilarPas encore d'évaluation