Académique Documents

Professionnel Documents

Culture Documents

OPC XML-DA Introduction DOKU v10 e

Transféré par

lue-ookDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

OPC XML-DA Introduction DOKU v10 e

Transféré par

lue-ookDroits d'auteur :

Formats disponibles

Application for Communication

Visual Basic .NET OPC Client for the XML-DA Interface of the SIMATIC NET OPC Server Introduction

Warranty, Liability and Support

Data Exchange via XML-DA

Entry-ID: 21402169

Warranty, Liability and Support

We accept no liability for information contained in this document. Any claims against us - based on whatever legal reason - resulting from the use of the examples, information, programs, engineering and performance data etc., described in this document shall be excluded. Such an exclusion shall not apply in the case of mandatory liability, e.g. under the German Product Liability Act (Produkthaftungsgesetz), in case of intent, gross negligence, or injury of life, body or health, guarantee for the quality of a product, fraudulent concealment of a deficiency or breach of a condition which goes to the root of the contract (wesentliche Vertragspflichten). However, claims arising from a breach of a condition which goes to the root of the contract shall be limited to the foreseeable damage which is intrinsic to the contract, unless caused by intent or gross negligence or based on mandatory liability for injury of life, body or health. The above provisions does not imply a change in the burden of proof to your detriment. The application examples do not purport to cover all details or variations in equipment, nor do they provide for every possible contingency. They are not customer-specific solutions. They are only intended to provide support for typical tasks. You are responsible for ensuring that the described products are used correctly. These Application Examples do not relieve you of the responsibility in safely and professionally using, installing, operating and servicing equipment. By using this application example you accept that Siemens is not liable for any damages except for those specified in the above liability clause. We reserve the right to make changes to these Application Examples at any time without prior notice. If there are any deviations between the recommendations provided in this application example and other Siemens publications e.g. Catalogs the contents of the other documents have priority. Copyright 2004 Siemens A&D. Any form of duplication or distribution of these application examples or excerpts hereof is prohibited without the expressed consent of Siemens Energy & Automation, Inc. For questions about this document please use the following e-mail address: mailto:csweb@ad.siemens.de

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

V1.0

26.04.05

2/21

Foreword

Data Exchange via XML-DA

Entry-ID: 21402169

Foreword

Objectives of the application Exchanging process data between logic controllers and computers via OPC is a core element of automation technology. The application on hand shows a possible procedure for independently generating individual OPC clients using the programming language Visual Basic .NET by Microsoft. A visualization of a mixed process is hereby realized in Visual Basic .NET. The programming paradigm ".NET by Microsoft is used here. Main contents of this application The following teaching materials are provided with this application:

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Installation and configuration of a web-server (in this example the webserver of the internet information services of Windows). This web-server is used for accessing the OPC server. Highlighting safety aspects (authentication and authorization of clients) for accessing the web-server and the OPC XML-DA web service. Demonstration in dealing with web services in .NET, especially the OPC XML-DA web service. Demonstration of the most important OPC XML-DA methods for accessing the process variables Demonstration of error handling with .NET Generating an OPC client as Windows application as well as ASP.NET web application (for calling a web browser) with similar function range.

Delimitation

This application does not contain a complete description of network safety aspects (encoded communication via SSL, application of firewalls, using VPNs) of the .NET framework, of the OPC specification as well as deeper level ASP.NET mechanisms

Basic knowledge in the area of object oriented programming is required. Further knowledge in UML (Unified Modelling Language) is an advantage.

V1.0

26.04.05

3/21

Foreword

Data Exchange via XML-DA

Entry-ID: 21402169

Structure of the document The documentation of this application is divided into the following main parts: Introduction Extension Demonstration

In addition, two setup programs (for Windows application and for ASP.NETapplication respectively), which also contain the source code of the application, as well as the STEP 7 code, are available. This first document, the Introduction, is aimed at persons who just want to gain a quick overview.

Part

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Description Provides a general overview of the contents. You will learn about the components used (standard hardware and software components and the specially created software). Discusses the detailed function processes of the involved hardware and software components, the solution structures, and where sensible the concrete implementation of this application. This part is necessary if you want to learn about the interaction of the solution components, for example in order to use them as the basis for own development. This part leads you step by step through the structure, important configuration steps, commissioning and operation of the application.

Introduction Application Description and Function Principles Extension Function Principles in detail and Program Structure

Demonstration Structure, Configuration and Operation of the Application

An additional component available is the S7 program code.

Part Setup Program of the Windows Application Setup Program of the ASP.NET Application S7 program code Description Installs the Windows application on your PC. The source code of the application is available in the program directory. Installs the ASP.NET application on your PC. The source code of the application is available in the program directory. The S7 program code contains the code and a user interface.

V1.0

26.04.05

4/21

Foreword

Data Exchange via XML-DA

Entry-ID: 21402169

Reference for Automation and Drives Service & Support This entry originates from the internet application portal of the A&D Service and Support. Clicking the link below directly displays the download page of this document. http://support.automation.siemens.com/WW/view/en/21402169

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

V1.0

26.04.05

5/21

Foreword

Data Exchange via XML-DA

Entry-ID: 21402169

Table of Contents

Table of Contents ......................................................................................................... 6 Application Description ............................................................................................... 7 1 2 2.1 2.2 3 3.1 3.2 3.3 3.4 3.5 Basic Information on OPC ............................................................................. 7 Automation Task............................................................................................. 9 Overview........................................................................................................... 9 Requirements ................................................................................................. 10 Automation Solution .................................................................................... 11 Overview of the overall solution...................................................................... 11 Description of the core functionality................................................................ 12 Required hardware and software components ............................................... 16 Basic performance data.................................................................................. 17 Alternative solutions........................................................................................ 18

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Appendix and List of Further Literature ................................................................... 20 4 5 5.1 5.2 Glossary ........................................................................................................ 20 Literature ....................................................................................................... 21 Bibliographic References................................................................................ 21 Internet links ................................................................................................... 21

V1.0

26.04.05

6/21

Application Description Basic Information on OPC

Data Exchange via XML-DA Entry-ID: 21402169

Application Description

Content Here, an overview over using the XML-DA interface of the SIMATIC NET OPC server is provided. You will learn about the components used (standard hardware and software components and the specially created software). The basic performance data show how powerful this application is.

Basic Information on OPC

further basics for the application of the XML-DA interface and on the tasks solved with this interface.

Here you will find information on

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

What is OPC? OPC serves for data exchange between hardware and software components of different producers in automation technology. OPC offers a collection of software interfaces for data exchange between PC applications and process devices. Originally based on the COM (Component Object Model) or DCOM (distributed COM) technology by Microsoft, OPC in its current specification offers a number of interfaces for different platforms. The OPC specifications are available on the internet at \3\. Data exchange via OPC occurs from an OPC server to an OPC client. Via standardized interfaces, the OPC server provides process information of a device at its interface. They can be read and described with an OPC client. What is OPC Data Access? The Data Access (abbrev. "DA") specifications of OPC define, how process data are exchanged between an OPC server and an OPC client. Data exchange is here based on the COM or DCOM technology by Microsoft and can only be applied on Microsoft Windows-based systems. This specification was the very first specification by OPC. In the mean time, there are specifications for transferring process alarms (OPC Alarms & Events), for the data exchange between OPC servers (OPC Data eXchange) and many more.

V1.0

26.04.05

7/21

Application Description Basic Information on OPC

Data Exchange via XML-DA Entry-ID: 21402169

What is the OPC XML-DA interface? OPC XML-DA (Data Access to an OPC server via XML) is, like the classic OPC Data Access, an interface for accessing process data of an OPC server. This is, however, completely platform independent (as opposed to the COM technology used for OPC Data Access V2.05) and is also supported by the development environment Visual Studio .NET. Data access by means of OPC XML-DA has a function scope based on OPC Data Access, however, only write and read services are available. Change controlled feedback messages via data changes, as for COM or DCOM OPC DA interfaces are not possible for OPC XML-DA. Data exchange via the OPC XML-DA interface is based on the open standards by XML and SOAP (see Glossary). Why should the XML-DA interface be employed?

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

The exchange of process data with OPC via a local network (LAN), an intranet or the internet is, in theory, also possible with the Data Access interface based on COM / DCOM.The XML-DA interface offers an almost equal function scope along with a much simpler configuration, parameterization and administration. The OPC XML-DA interface being based on open standards, its application is not restricted to a certain system (e.g. Microsoft Windows). Advantages and disadvantages of the interfaces

Table 1 -1 Fields of application

Interface XML-DA

Advantages Platform independent Simple administration as based on SOAP and XML Enables feedback from server to client Higher data throughput

Disadvantages Not suitable for transferring large data volumes A web server is required on the OPC server side Windows-based Not directly supported by .NET Complicated administration

Data Access via DCOM

V1.0

26.04.05

8/21

Application Description Automation Task

Data Exchange via XML-DA Entry-ID: 21402169

Automation Task

the automation task discussed in the documentation on hand.

Here you will find information on

2.1

Overview

Overview of the automation task The following figure gives an overview of the automation task.

Figure 2-1

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Description of the automation task Using the example of a simulated mixing process this application shows how this process can be visualized. The connection of the visualization station with the plant should either be made via the internet, intranet, or a local network.

V1.0

26.04.05

9/21

Application Description Automation Task

Data Exchange via XML-DA Entry-ID: 21402169

2.2

Requirements

Requirements to the visualization solution Access to the XML-DA interface of any OPC server Access to the OPC server of the head-end station via internet, intranet or a local network Symbolic addressing of process data and setpoint values Cyclic (synchronous and asynchronous) reading of process data from the controller Synchronous writing of setpoint values to the controller Realizing with programming language Visual Basic .NET Displaying and controlling process variables with a Windows application and an ASP.NET application (for calling by means of any web browser), where both versions have approximately the same function scope.

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Requirements for the head-end station Access protection for the OPC server via login Provision of symbolic address information

Requirements for the controller Saving current process values in a data block. Saving the setpoint values for the process in a data block.

V1.0

26.04.05

10/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

Automation Solution

the solution selected for the automation task, the components used, and the tasks of the individual components.

Here you will find information on

3.1

Display

Overview of the overall solution

The following figure displays the most important components of the solution:

Figure 3-1

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

V1.0

26.04.05

11/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

3.2

Description of the core functionality

User interface The following figure contains the user interface of the ASP.NET application (left) and the Windows application (right). The elements are described below.

Figure 3-2

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Description of user interface The following table explains the individual elements of the user interface.

Table 3-1

No. 1 2 3 4 5

Description Buttons for starting and terminating the visualization process. This establishes the connection to or disconnects from the OPC server. Area for entering and writing the setpoint values. Display of process values (actual values) Buttons for starting and terminating the mixing process. Graphical visualization of the mixing process (only Windows application)

V1.0

26.04.05

12/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

Process sequence of main functionality This figure shows the internal communication structure of the application on hand. It is assumed, that the connections between the components have already been established.

Figure 3-3

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Explanation of main functionality Here you will learn how the individual components of this application communicate with each other and which technologies are being used.

Table 3-2

No. 1 2

Instructions Data exchange between controller and OPC server occurs via a configured S7 connection. The OPC XML web service of SIMATIC NET will be included in the IIS Web Server (part of the Windows operating system). It provides data of the OPC server to the OPC Client. The data exchange between the OPC XML web service and the connected OPC client (in this case the Windows application and the ASP.NET application) occurs via the SOAP protocol.

Note The configuration is made with STEP 7 (NetPro).

V1.0

26.04.05

13/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

No. 4

Instructions HTTP or HTTPS (for encoded connections) is the basis for data exchange between the IIS web server and the connected clients.

Note HTTPS is not further discussed within the scope of this application.

Describing the process in the controller The S7 control program simulates a mixing process. Liquids are hereby fed into a tank via two inlet valves. If the tank is full, the liquid is mixed and heated up. After the setpoint temperature has been reached, the liquid is cooled down again and then drained via an outlet valve. The process variables for the data exchange with the OPC server are saved to three different blocks. Advantages of applying the OPC XML-DA interface

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

The application of the OPC XML-DA interface of the SIMATIC NET OPC server for plant visualization via a local network, intranet or the internet, has the following advantages: The SIMATIC NET OPC server supports all communication protocols and services provided by the communication modules. Simple transmission of process data via a local network, intranet or the internet. Simple configuration of the OPC server (as usual in STEP 7) Simple commissioning of OPC XML web service (incl. encoding and access protection) OPC clients are platform independent (due to the employed SOAP protocol being platform independent)

Advantages of the Windows application The implementation of the OPC client as Windows application using .NET has the following advantage for you: Generating user interfaces and functions of any level of complexity which can be tailored to a specific case. Simple and cost effective distribution of the visualization application

V1.0

26.04.05

14/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

Advantages of the ASP.NET application For an ASP.NET application, the entire program intelligence is located on the server (here: head-end station). In the Internet Browser of the Clients, which calls the ASP.NET application, only static information is displayed. This has the following advantages: Very cost effective solution low in maintenance, as no installation required on the client side (only Internet Browser) Minimum maintenance costs due to central software administration

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

V1.0

26.04.05

15/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

3.3

Required hardware and software components

Hardware components for visualization station and head-end station

Table 3-3

Component SIMATIC Field PG

No. 1

MLFB / Order number 6ES7 711-2BA21-3LB3

Note Incl. STEP 7 software and network card Incl. Network card and Windows XP Professional www.netgear.de

SIMATIC RACK PC IL 40 S V2 Standard HUB or Switch (e.g. NETGEAR FS105 5-Port 10/100 MBit/s) Ethernet lines

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

6AG4011-1CA21-0KX0

Depending on product

Hardware components for the controller

Table 3-4

Component PS307 5A CPU 315-2DP CP 343-1

No. 1 1 1

MLFB / Order number 6ES7307-1EA00-0AA0 6ES7315-2AG10-0AB0 6GK7343-1EX20-0XE0

Note

Standard software components

Table 3-5

Component STEP 7 V5.3 SIMATIC NET IE SOFTNET-S7 V6.2 IISLockdown Tool V2.1 (iislockd.exe)

No. 1 1 1

MLFB / Order number 6ES7 810-4CC07-0YA5 6GK1704-1CW62-3AA0 Download via www.microsoft.com

Note Contained in the above field PG Installation on head-end station Installation on head-end station. Tool for automatic protection of IIS web server On field PG and headend station

.NET Framework V1.1

Microsoft Visual Studio .NET 2003 Professional

Download via www.microsoft.com From SIMATIC NET V6.2 SP1 on included in the scope of delivery. Can be ordered via your administrator or at www.microsoft.com

Optional on field PG or head-end station

V1.0

26.04.05

16/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

Example files and projects The following list contains all files and projects used in this example.

Table 3-6

Component 21402169_OPC_XML-DA_STEP7_v10.zip 21402169_OPC_XML-DA_CODE_WIN_v10.zip

Note Contains the archived STEP 7 project. Contains the setup program for the Windows application and the source code. Contains the setup program for the ASP.NET application and the source code. Application Description and Function Principles Function Principles in detail and Program Structure Structure, Configuration and Operation

21402169_OPC_XML-DA_CODE_ASP_v10.zip

21402169_OPC_XML-DA_Introduction _DOKU_v10_e.pdf

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

21402169_OPC_XML-DA_Extension _DOKU_v10_e.pdf 21402169_OPC_XML-DA_Demonstration _DOKU_v10_e.pdf

3.4

Basic performance data

Application software Due to the combination of different components in this example it is not possible to specify concrete performance data. The following statements on the SIMATIC NET OPC server can be made: The classic Data Access interface (COM-based) is 10% 25% faster than the XML interface. The total speed also depends on the S7 communication between OPC server and S7 station. When using the internet, no general statement on transfer velocity can be made, as it may fluctuate strongly. Via the XML interface up to 10.000 OPC items can be read or written (see FAQ ID 15227599).

V1.0

26.04.05

17/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

3.5

Alternative solutions

Alternatives for using the OPC XML-DA interface of the SIMATIC NET OPC server are introduced, evaluated and compared (advantages, disadvantages, ...).

Using the OPC-DA interface of the SIMATIC NET OPC server The OPC-DA (Data Access) interface is the standard interface for exchanging process data. This interface is based on the COM technology. The implementation of the OPC-DA interface occurs with a COM-capable programming language (e.g. C++ or Visual Basic). Programming of an OPC client with C# using the OPC-DA interface is described in the following application: http://support.automation.siemens.com/WW/view/en/21043779

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Advantages and disadvantages of the OPC-DA interface

Table 3-7

Advantages High data throughput and high performance Generating user interfaces and functions of any level of complexity which can be tailored to a specific case.

Disadvantages Being based on COM, it can only be applied on Windows operating systems High implementation workload (programming with high-level language; C++, C#, Visual Basic) Setting up distributed systems is work intensive (using DCOM)

Using WinCC with Web Navigator Web Navigator is an option for WinCC for operating and monitoring plants and systems via the internet or the company intranet or LAN. The Web Navigator consists of a web server on a PC with WinCC software (singleuser, client or server version). A web client can operate and monitor a running WinCC project via an Internet browser.

V1.0

26.04.05

18/21

Application Description Automation Solution

Data Exchange via XML-DA Entry-ID: 21402169

Advantages and disadvantages of the Web Navigator

Table 3-8

Advantages Quick update rates due to event controlled communication Optimal tailored clients for Operator Control & Monitoring, Evaluation, Service & Diagnostics Taking over configuration data from an existing WinCC project for the web, generally without changes. Minimum maintenance costs due to central software administration Integrated WinCC User management

Disadvantages Based on ActiveX technology which is exclusively supported by Windows systems. License costs depending on the number of clients Installation of the WebNavigator clients necessary on client side

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Using the IT-CP On top of the functionality of an S7 communication processor (PG/OP communication, S7 communication, ...), the IT-CP (CP 343-1 IT or CP 4431 Advanced) offers the possibility of communicating via standardized protocols of the Internet world. This enables access to process data of a controller via HTTP and a web browser, access to data blocks of the controller via FTP, sending of e-mails via an integrated mail server. Using the IT-CP is described in the application "Operator Control and Monitoring with the SIMATIC IT-CP via different WAN configurations" (see link \4\). Advantages and disadvantages of the IT-CP

Table 3-9

Advantages No additional PC (head-end station) necessary, as the web server is an integral part of the CP Quick implementation of simple user interfaces Simple configuration via STEP 7 Cost effective

Disadvantages Extensive implementation of complex html-pages Currently no secure communication via https. Only suitable for small quantity frameworks (access to data of an S7-CPU via the backplane bus)

V1.0

26.04.05

19/21

Appendix and List of Further Literature Glossary

Data Exchange via XML-DA Entry-ID: 21402169

Appendix and List of Further Literature

4 Glossary

The following explanations and definitions were taken from the Internet encyclopedia "Wikipedia", see \5\. Authentication Authentication refers to the process of verifying the identity of a person or a program based on certain features. This can, for example, occur by means of a finger print, a certain user name and password, or any other legitimation. Authorization

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

Refers to the assignment and verification of access rights to data and services of a system by a user. Authorization mainly occurs after successful authentication. HTTP The Hypertext Transfer Protocol (HTTP) is a stateless data exchange protocol for transfer of data. It is one of the protocols provided by the TCP/IP protocol stack. Primarily it is used within the framework of the world wide web for transferring web-sites. SOAP SOAP is a protocol which can be used for exchanging data between systems, and calling functions on remote systems. SSL SSL (Secure Sockets Layer) refers to a transfer protocol which enables encoded communication using tunneling. TCP/IP Transmission Control Protocol / Internet Protocol. The internet protocol suite is a family of network protocols which form the basis for network communication in the internet.

V1.0

26.04.05

20/21

Appendix and List of Further Literature Literature

Data Exchange via XML-DA Entry-ID: 21402169

5

5.1

Literature

Bibliographic References

This list is by no means exhaustive and only gives a selection of appropriate sources.

Table 5-1

Topic /1/ STEP 7

Title Automatisieren mit STEP 7 in AWL und SCL (Automating with STEP7 in STL and SCL) Hans Berger published by: Publicis MCD Verlag ISBN 3-89578-113-4 SIMATIC NET, Industrielle Kommunikation mit PG/PC Band 1 Grundlagen, Systemhandbuch (auf SIMATIC NET CD)

/2/

Copyright Siemens AG 2005 All rights reserved 21402169_OPC_XML-DA_Introduction_DOKU_v10_e.doc

SIMATIC NET, Industrial communication

5.2

Internet links

This list is by no means exhaustive and only gives a selection of appropriate sources.

Table 5-2

Topic \1\ \2\ \3\ \4\ \5\ Reference to the documentation Siemens A&D Customer Support OPC Foundation WAN communication with IT-CP Internet encyclopedia Wikipedia

Title http://support.automation.siemens.com/WW/view /en/21402169 http://support.automation.siemens.com http://www.opcfoundation.org http://support.automation.siemens.com/WW/view /en/14784237 http://en.wikipedia.org

V1.0

26.04.05

21/21

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Manual CVIDocument239 pagesManual CVIjoseantonioguillenPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Installation Manual: FX - 232-BDDocument1 pageInstallation Manual: FX - 232-BDlue-ookPas encore d'évaluation

- VBAI TutorialDocument99 pagesVBAI Tutoriallue-ookPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Sensor Collection: Electronic Device Industry EditionDocument12 pagesSensor Collection: Electronic Device Industry Editionlue-ookPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- LV FPGA For Vision ApplicationsDocument26 pagesLV FPGA For Vision Applicationslue-ookPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Ignition HM I Interface To Fan Uc RobotsDocument29 pagesIgnition HM I Interface To Fan Uc RobotsAutomation BoonluePas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Basic Vision With LabVIEWDocument25 pagesBasic Vision With LabVIEWnghiepmechanPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Dell Latitude E6440 Spec SheetDocument2 pagesDell Latitude E6440 Spec Sheetlue-ookPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Cvicore1 Coursemanual English SampleDocument20 pagesCvicore1 Coursemanual English SampleArunPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Rogowski CoilsDocument7 pagesRogowski Coilslue-ookPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Voltage Transducer LV 25-600 600 VDocument3 pagesVoltage Transducer LV 25-600 600 Vlue-ookPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Process Automation Festo Product OverviewDocument20 pagesProcess Automation Festo Product Overviewlue-ookPas encore d'évaluation

- TGI Training Program 2016Document20 pagesTGI Training Program 2016lue-ookPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- FPGA Vision Using The NI LabVIEWDocument2 pagesFPGA Vision Using The NI LabVIEWlue-ookPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Usb I/oDocument8 pagesUsb I/olue-ookPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Airbus UsingRFIDDocument11 pagesAirbus UsingRFIDlue-ookPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Power Quality Monitoring and Power Metering TutorialDocument5 pagesPower Quality Monitoring and Power Metering Tutoriallue-ookPas encore d'évaluation

- Festo Process Control Sample 2015Document69 pagesFesto Process Control Sample 2015lue-ookPas encore d'évaluation

- PID ModesTrainingDocument34 pagesPID ModesTraininglue-ookPas encore d'évaluation

- S7 1200 Solar Tracker enDocument8 pagesS7 1200 Solar Tracker enlue-ook100% (1)

- Vision Builder Tutorial - 2012Document97 pagesVision Builder Tutorial - 2012lue-ookPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- uIBX 210 CV N2600 - 0421 - WebDocument1 pageuIBX 210 CV N2600 - 0421 - Weblue-ookPas encore d'évaluation

- Instrumentation Training Tutorial Part1Document6 pagesInstrumentation Training Tutorial Part1Gary8100% (1)

- 2011 Rfid Brand Report ContentsDocument3 pages2011 Rfid Brand Report Contentslue-ookPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Sales and Operations Planning Brings Balance To The Supply Chain 0Document2 pagesSales and Operations Planning Brings Balance To The Supply Chain 0lue-ookPas encore d'évaluation

- Festo Process Control - CatalogDocument3 pagesFesto Process Control - Cataloglue-ookPas encore d'évaluation

- Festo ZA Didactic Courses 2015Document36 pagesFesto ZA Didactic Courses 2015lue-ookPas encore d'évaluation

- Quick Start Up SystemQDocument52 pagesQuick Start Up SystemQlue-ookPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Electrical Relay Diagram and PID SymbolsDocument5 pagesElectrical Relay Diagram and PID SymbolsKARAM ZAKARIAPas encore d'évaluation

- Festo SCM 2013 Final PDFDocument8 pagesFesto SCM 2013 Final PDFlue-ookPas encore d'évaluation

- CMC VRTX - Start HereDocument208 pagesCMC VRTX - Start HereilirisaiPas encore d'évaluation

- The Top 10 Security Weakness (Vulnerabilities) in Web Applications (OWASP Top 10)Document33 pagesThe Top 10 Security Weakness (Vulnerabilities) in Web Applications (OWASP Top 10)Rushit D. Brahmbhatt100% (1)

- Murr Network Technology11-20Document42 pagesMurr Network Technology11-20AMPas encore d'évaluation

- Security Hardening GuideDocument21 pagesSecurity Hardening GuideDeepak ThapaPas encore d'évaluation

- Virtual Routers As A Service: The Routeflow Approach Leveraging Software-Defined NetworksDocument4 pagesVirtual Routers As A Service: The Routeflow Approach Leveraging Software-Defined NetworksIsaak ToviessiPas encore d'évaluation

- CSE Fundamental - TopologyDocument14 pagesCSE Fundamental - TopologySYED FARHAN REZAPas encore d'évaluation

- UnifyTool V1.0.1.20220311 Release NoteDocument10 pagesUnifyTool V1.0.1.20220311 Release NoteGWN techniquePas encore d'évaluation

- TCP/IP Tutorial: The IP Address and ClassesDocument11 pagesTCP/IP Tutorial: The IP Address and ClassesRajesh JainPas encore d'évaluation

- VPLEX - VPLEX Installation and Upgrade Procedures-Install Procedures - Install VPLEX Cluster-6Document28 pagesVPLEX - VPLEX Installation and Upgrade Procedures-Install Procedures - Install VPLEX Cluster-6VijayenNPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Domain RenameDocument12 pagesDomain RenameKhodor AkoumPas encore d'évaluation

- CHFI v8 Module 15 Log Capturing and Event CorrelationDocument9 pagesCHFI v8 Module 15 Log Capturing and Event CorrelationBob PoloPas encore d'évaluation

- Integritas Industrial Battery Charger: Application Industries FeaturesDocument4 pagesIntegritas Industrial Battery Charger: Application Industries Featurescelimo0710Pas encore d'évaluation

- InternetDocument24 pagesInternetPrashant SinghPas encore d'évaluation

- Activity 1.2Document3 pagesActivity 1.2Allonah Pearl RequiroPas encore d'évaluation

- Devops: For Hackers by Ralph MayDocument22 pagesDevops: For Hackers by Ralph MaySwethaPriyaPas encore d'évaluation

- GoogleCloud SlidesDocument30 pagesGoogleCloud SlidesZaeem AbbasPas encore d'évaluation

- PT Activity 2.1.7: Troubleshooting A Serial Interface: Topology DiagramDocument3 pagesPT Activity 2.1.7: Troubleshooting A Serial Interface: Topology DiagramAn LePas encore d'évaluation

- LE01 Flexi SRAN SBTS Introduction PDFDocument29 pagesLE01 Flexi SRAN SBTS Introduction PDFYoussif Mohammed Ahmed100% (1)

- LLC: Logic Link Control (IEEE 802.2)Document5 pagesLLC: Logic Link Control (IEEE 802.2)Sandip PaulPas encore d'évaluation

- Client Server ComputingDocument27 pagesClient Server Computingshriharsh123100% (1)

- HCIP-Datacom-Core Technology V1.0 Exam OutlineDocument4 pagesHCIP-Datacom-Core Technology V1.0 Exam OutlineirfanPas encore d'évaluation

- Diseño de RedesDocument7 pagesDiseño de RedesAlejandro AguilarPas encore d'évaluation

- Ethernet Oam Feature Parameter Description: SingleranDocument55 pagesEthernet Oam Feature Parameter Description: SingleranVVLPas encore d'évaluation

- Rouing ConceptsDocument211 pagesRouing ConceptsmntesnotPas encore d'évaluation

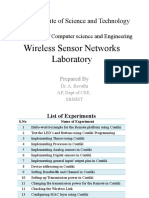

- Wireless Sensor Networks Laboratory: SRM Institute of Science and TechnologyDocument9 pagesWireless Sensor Networks Laboratory: SRM Institute of Science and TechnologyRevathi PrakashPas encore d'évaluation

- Bai Tap IPv4#1Document2 pagesBai Tap IPv4#1Truc PhanPas encore d'évaluation

- Using OpenBSD With VDSLDocument4 pagesUsing OpenBSD With VDSLtiemenwerkman3540Pas encore d'évaluation

- Compuware DCRUM Intro 2012 Version 12.00Document142 pagesCompuware DCRUM Intro 2012 Version 12.00JanPas encore d'évaluation

- Switch AT-8000S - IPconfDocument2 pagesSwitch AT-8000S - IPconfTEUKUPas encore d'évaluation

- Manage Network Synchronization: User GuideDocument52 pagesManage Network Synchronization: User GuideAndres CortezPas encore d'évaluation