Académique Documents

Professionnel Documents

Culture Documents

Magnesium Oxide Board

Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Magnesium Oxide Board

Droits d'auteur :

Formats disponibles

I

N D U S T

I A L

FavorSea Magnesium Oxide Board

Serial No.:FSMO2013.1.1

H A

N E

History

three yesrs Mgo board established its good reputation From then on Mgo borad has repeated its success story in other Magnesium oxide boards are a type of inorganic-bonded oversea markets. Now mgo boards have been exported in composite, Inorganic-bonded composites are those that large volumes of Mgo boards have been exported into contain a mineral or mineral mix as binder system, the three Europe Japan and North America. most common inorganic binder systems are magnesium oxide. Gypsum, and portland cement, The products produced from these binder systems are magnesium oxide boards, Magnesium oxide (MGO) Board is a building product with the gypsum boards and fiber cement boards. Gypsum products, the most common of which is drywall following charactenstics board, have a long history, Conventional drywall board is a Appearance: gypsum panel is wrapped with paper, the paper wrap gives Mgo boards are white in color. Standard production is square edge or bevel edge boards with one smoother side and one the gypsum panel much of its strength. Another form of inorganic-bonded composites, rougher side cement-bonded wood composites, or as they are more commonly called, Cement boards, have a long history in Europe. The Philippines, Japan, and the United States were Square edge starting to use this material from 1980/1990s, Enforcement of stricter building codes accelerated the use of cement board, It is likely that there may have been less damage caused by the fires if fire-resistant roofing slates and cement-bond exterior panels had used earlier Cement board is a mixture of Bevel edge cement and wood or other lignocelluloses fiber, Cement-bonded wood composites are used in a wide range of building types. Compared with Gypsum boards and cement boards. Mgo (magnesium oxide) boards Is relatively unknown to most board users. There are two reasons. Firstly: Magnesium oxide (Mgo) boards are manufactured in Mainland China, as China has the suitable raw materials of good quality, in large volume at low cost. Secondly: Mgo boards have only 10 years of successful commercial history. Back in the 1950 the first generation of Mgo boards appeared on the market. The first generation Mgo boards were made by unskilled labor with rudimentary tools and the quality was low. The boards were easily broken Size: and of variable thickness. Soon the first Generation Mgo Standard production is 4x8.3x6 and 3x7. Maximum width is boards lost much of its market due to low quality. However 4a Maximum length is 8, widths and lengths less than the technical experts of Mgo boards worked hard to improve maximum can be custom produced on special order the quality with various technical innovations. In 1990, the ThicknessStandard stock thickness is metric. From 3mm quality of Mgo board was improved considerably with the to 12mm introduction of two layers of fiber glass mesh put into the Mgo board. As the market for Mgo board increased, concurrently with the gradual introduction of more sophisticated technology. From 1994, Mgo board begin to be exported to the world market. The first oversea market was Tainwan. In only about

Characteristics

http//www.FavorSea.com 1

info@favorsea.com

H A

N E

Mineral based. The main ingredient is magnesium oxide. Environmentally friendly. It does not contain asbestos or any other known toxic material Fire Resistant. A similar material is used in some parts of the world to line industrial blast furnaces Test results Combustibility Non-combustible Fire- resistant limit (min) >180 Fire and smoke development 0 Heated size shrinkage ratio (%) 1.0 Water Resistant: And does not leach. Test results Moisture deformability%0.25 Water drip-though 0 Flexible, Does not break or crack easily. Wastage is therefore reduced. Flexibility is enhanced when wet. Test results: Dry-state bending strength (Mpa) 15 Water-absorbing state bending strength 22 Impact Resistant: 3mm mgo boards are at the same level with 9mm gypsum boards. Thicker mgo boards 6-12mm are mucsh tronger Dampens sound. Can be used where sound insulation is required Lightweight. Considerably Lighter than fiber cement board Test results: Density (g/cm3) 900kg/M3 to 1100kg/m3 (56lbs/Ft3 to 68lbs/Ft3)

Favorsea Mgo boards can be used wherever fire safety. Moisture, bug/fungus/moid resistance, and impact resistance, and impact resistance are primary considerations. These could be commercial high rise building s, single family home , multiple dwelling apartments, theaters, museums, schools, hospitals, malls, shopping centers , hotels, restaurants, night clubs, airports, subway stations, tunnels, fire separations, etc. Favorsea Mgo Board is now being introduced to the world market, you may wish to consider the advantages this revolutionary product offers over the materials you are now using, You might be able to save injury, breakage, time, and money, and at the same time deliver a better and safer finished product.

Horizontal pallet

Vertical pallet

Installs easily

Competitively priced

like gypsum board and fiber cement boards using stud, grid, nails or screws. The type of tape and mud used will depend on the application, I. e: fireproof or waterproof

This combination of characteristics, unique among building materials .makes Mgo Board suitable for a wide range of applications: Partition walls Substrate for laminated panels Backer board for tile installation Wrapping for steel structures Sub floors in framed structures Exterior sub walls Exterior signage (road, advertising) Construction site enclosure FavorSea Industrial Channel Limited 2307 First Building No.6 Dacheng StreetBeijing China Tel: +86 10 8817 7742 Fax: +86 10 8817 7443

Applications

compared to existing fireproof and waterproof material Favorsea warehouse

Mgo boards is being loaded into Container http//www.FavorSea.com 2 info@favorsea.com

Vous aimerez peut-être aussi

- Using Magnesium Oxide Wallboard As An Alternative Building Façade CladdingDocument9 pagesUsing Magnesium Oxide Wallboard As An Alternative Building Façade Claddingrenjisrs100% (1)

- Autoclaved Aerated Concrete: A Sustainable Alternate of Clay Brick Masonry in Form of Light Weight ConcreteDocument6 pagesAutoclaved Aerated Concrete: A Sustainable Alternate of Clay Brick Masonry in Form of Light Weight ConcreteGRD JournalsPas encore d'évaluation

- Global Fibre Cement MarketDocument19 pagesGlobal Fibre Cement MarketSanjay MatthewsPas encore d'évaluation

- Auto Aerated ConcreteDocument6 pagesAuto Aerated ConcreteLeo GohPas encore d'évaluation

- Study and Experimentation of Autoclaved Aerated Concrete by Using Fly AshDocument5 pagesStudy and Experimentation of Autoclaved Aerated Concrete by Using Fly AshInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Calcium Silicate MsdsDocument3 pagesCalcium Silicate MsdsHaniff RahimPas encore d'évaluation

- HempShive PresentationDocument11 pagesHempShive PresentationNabeelAhmedPas encore d'évaluation

- Anti Carbonation PaintDocument4 pagesAnti Carbonation Paintptk94287Pas encore d'évaluation

- The Fly Ash Brick Production TechnologyDocument18 pagesThe Fly Ash Brick Production TechnologyVishal KedarPas encore d'évaluation

- HDF High Density Fiber BoardsDocument75 pagesHDF High Density Fiber BoardssennimalaiPas encore d'évaluation

- UAC Fibre Cement BoardDocument9 pagesUAC Fibre Cement BoardescapelizaPas encore d'évaluation

- Global Autoclaved Aerated Concrete AAC Market, 2020-2027Document202 pagesGlobal Autoclaved Aerated Concrete AAC Market, 2020-2027pazuzu100% (1)

- DurraWallSystem 050606Document1 pageDurraWallSystem 050606tallerautorepPas encore d'évaluation

- EPS Vs XPSDocument2 pagesEPS Vs XPSminsara madtPas encore d'évaluation

- Fibre Cement BoardsDocument30 pagesFibre Cement Boardsandrefaccindasilva100% (1)

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsPas encore d'évaluation

- (BS en 1936-1999) - Natural Stone Test Methods. Determination of Real Density and Apparent Density and of Total and Open Porosity.Document8 pages(BS en 1936-1999) - Natural Stone Test Methods. Determination of Real Density and Apparent Density and of Total and Open Porosity.Jod JDPas encore d'évaluation

- Fiber Cement BoardDocument4 pagesFiber Cement Boardfrozenfatty139956100% (1)

- 2010 Natural Stone EU Market SurveyDocument40 pages2010 Natural Stone EU Market SurveyMohamed SalahPas encore d'évaluation

- CLC CostingDocument34 pagesCLC CostingpipestressPas encore d'évaluation

- Specification CS-A-F10 B Brick Block WallingDocument26 pagesSpecification CS-A-F10 B Brick Block WallingKasun Chathuranga0% (1)

- Plastics in Construction: A Guide For Architects and SpecifiersDocument16 pagesPlastics in Construction: A Guide For Architects and SpecifiersHaroun EdressPas encore d'évaluation

- Coconut Wood Processing PDFDocument48 pagesCoconut Wood Processing PDFZoebairPas encore d'évaluation

- Enhancing White and Colored Concrete With MetaMaxDocument3 pagesEnhancing White and Colored Concrete With MetaMaxm.shahbaghiPas encore d'évaluation

- Aluminium Composite Panels Article: History of ACPDocument7 pagesAluminium Composite Panels Article: History of ACPsales7099Pas encore d'évaluation

- To Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao DeshmukhDocument11 pagesTo Modify The Properties of Concrete by Using Rubber Crumb & Ceramic Waste, Prof. Manish Sudhakarrao Deshmukhmukesh poundekarPas encore d'évaluation

- Ar Bricks-21Document34 pagesAr Bricks-21ManishaChary100% (1)

- Life Cycle Inventory of Techniques For Stone Quarrying, Cutting and Finishing Contribution To Fill Data Gaps (Bianco-Italia-2019)Document27 pagesLife Cycle Inventory of Techniques For Stone Quarrying, Cutting and Finishing Contribution To Fill Data Gaps (Bianco-Italia-2019)juan diazPas encore d'évaluation

- Foam Concrete - Experimental Investigation of Its PropertiesDocument7 pagesFoam Concrete - Experimental Investigation of Its PropertiesIJASRETPas encore d'évaluation

- Fly Ash Based Geopolymer MortarDocument9 pagesFly Ash Based Geopolymer MortarRama Arul SakthiPas encore d'évaluation

- An Gypsum Modern Building Material - enDocument19 pagesAn Gypsum Modern Building Material - enprofmgaPas encore d'évaluation

- Green ConcreteDocument22 pagesGreen ConcreteQseem Khan100% (1)

- Admixture Brochure PDFDocument16 pagesAdmixture Brochure PDFFrancois-Pas encore d'évaluation

- Difference Between Aac and CLC - Foam Generator Suppliers in Pune, CLC Block Making Plant in Mumbai, Pune, Gujarat, Nashik, Akola, Nellore - Foam Generator Manfacturer IndiaDocument2 pagesDifference Between Aac and CLC - Foam Generator Suppliers in Pune, CLC Block Making Plant in Mumbai, Pune, Gujarat, Nashik, Akola, Nellore - Foam Generator Manfacturer IndiaGitesh Gaurav0% (1)

- Project Design Document (PDD) : CDM - Executive BoardDocument84 pagesProject Design Document (PDD) : CDM - Executive BoardParakh AgrawalPas encore d'évaluation

- Green Buildings and Cities: - The Challenges AheadDocument84 pagesGreen Buildings and Cities: - The Challenges AheadPham Trung KienPas encore d'évaluation

- Wall PannelsDocument5 pagesWall PannelsGaurav MallaPas encore d'évaluation

- Durock Cement Board Msds en 14090001Document9 pagesDurock Cement Board Msds en 14090001joelbeckerPas encore d'évaluation

- Recent Progress in Concrete-Polymer CompositesDocument10 pagesRecent Progress in Concrete-Polymer Compositesswathi1105Pas encore d'évaluation

- BP Marble QuarryingDocument19 pagesBP Marble QuarryingMusaab Saadat JanjuaPas encore d'évaluation

- ASTM C28C28M (2015) Standard Specification For Gypsum PlastersDocument5 pagesASTM C28C28M (2015) Standard Specification For Gypsum PlastersKatherine CarabaliPas encore d'évaluation

- FOAMING PresentationDocument15 pagesFOAMING PresentationWe'am almasri0% (1)

- Cement Board Specs-123Document4 pagesCement Board Specs-123realchicPas encore d'évaluation

- Fire Test ComparisonDocument20 pagesFire Test ComparisonMasahiko HiganePas encore d'évaluation

- Non-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialDocument5 pagesNon-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialIJRASETPublicationsPas encore d'évaluation

- Presentation Foamed Concrete 2009Document25 pagesPresentation Foamed Concrete 2009Mukut DasPas encore d'évaluation

- A TO Z of TILESDocument10 pagesA TO Z of TILESuffshezy4Pas encore d'évaluation

- CLC Block PresentationDocument14 pagesCLC Block PresentationNikhilesh KadukarPas encore d'évaluation

- Contemporary Building MaterialsDocument37 pagesContemporary Building MaterialsShif renPas encore d'évaluation

- Raimondi - Presentazione Large Format Tiles Tools DEF Update Oct-2016Document63 pagesRaimondi - Presentazione Large Format Tiles Tools DEF Update Oct-2016Antuan KourosPas encore d'évaluation

- Bio-Renewable Asphalt Modifiers and Asphalt SubstitutesDocument27 pagesBio-Renewable Asphalt Modifiers and Asphalt Substitutesadina100% (1)

- Introduction of Cement: When Was Cement Begin?Document11 pagesIntroduction of Cement: When Was Cement Begin?مايف سعدونPas encore d'évaluation

- Alc CatalogDocument63 pagesAlc Catalogapi-274480886Pas encore d'évaluation

- CLC Brick ProductionDocument14 pagesCLC Brick ProductionKrishna YarlagaddaPas encore d'évaluation

- Waste Management: Maciej Sienkiewicz, Justyna Kucinska-Lipka, Helena Janik, Adolf BalasDocument10 pagesWaste Management: Maciej Sienkiewicz, Justyna Kucinska-Lipka, Helena Janik, Adolf BalasGina MoraPas encore d'évaluation

- AAC Blocks-Introducers of Green Building Concept in IndiaDocument6 pagesAAC Blocks-Introducers of Green Building Concept in IndiaBibek BhattaraiPas encore d'évaluation

- CLC Plant DetailDocument17 pagesCLC Plant DetailSibiyarasu Rock RiderPas encore d'évaluation

- Thermal Insulation Materials Made of Rigid Polyurethane Foam (PURDocument33 pagesThermal Insulation Materials Made of Rigid Polyurethane Foam (PURvtintin2006Pas encore d'évaluation

- Green Building Materials Supplier - Guangzhou RYMAX eCatalogue-201202ADocument81 pagesGreen Building Materials Supplier - Guangzhou RYMAX eCatalogue-201202AMilind RamaniPas encore d'évaluation

- DI-NOC™ Architectural Finishes: Product Bulletin D1Document6 pagesDI-NOC™ Architectural Finishes: Product Bulletin D1Giannhs BairamidisPas encore d'évaluation

- Tangshan Branch of CCTEGDocument51 pagesTangshan Branch of CCTEGFavorSea Industrial Channel Limited, Building Materials DivisionPas encore d'évaluation

- 扬州Document37 pages扬州FavorSea Industrial Channel Limited, Building Materials DivisionPas encore d'évaluation

- Gypsum BoardDocument11 pagesGypsum BoardFavorSea Industrial Channel Limited, Building Materials DivisionPas encore d'évaluation

- Fiber Cement BoardDocument6 pagesFiber Cement BoardFavorSea Industrial Channel Limited, Building Materials DivisionPas encore d'évaluation

- DoorDocument11 pagesDoorFavorSea Industrial Channel Limited, Building Materials DivisionPas encore d'évaluation

- BS 759-1 PDFDocument20 pagesBS 759-1 PDFlaythPas encore d'évaluation

- 84 Tank Ss Distilled Water StorageDocument1 page84 Tank Ss Distilled Water Storagezulfadli zainalPas encore d'évaluation

- DEKMaster Fast CatDocument20 pagesDEKMaster Fast CatmangeshshingotePas encore d'évaluation

- Box & Shutter Price ListDocument2 pagesBox & Shutter Price Listsandeep vermaPas encore d'évaluation

- P.W.D Electrical SR 10-11Document60 pagesP.W.D Electrical SR 10-11uday.sachin PandithPas encore d'évaluation

- Department of Aeronautical Engineering: Answer All The Questions: Part - A (10 X 2 20 MARKS)Document2 pagesDepartment of Aeronautical Engineering: Answer All The Questions: Part - A (10 X 2 20 MARKS)RajakumariPas encore d'évaluation

- 2209 EutecTrodeDocument1 page2209 EutecTrodeSimelemon TolomeoPas encore d'évaluation

- SSPC SP Cab 1Document5 pagesSSPC SP Cab 1mithileshPas encore d'évaluation

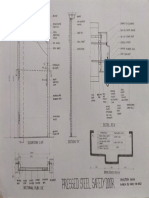

- Pressed Steel Safety DoorDocument1 pagePressed Steel Safety DoorAshutosh SinghPas encore d'évaluation

- White Book C08 Finishes SectionDocument32 pagesWhite Book C08 Finishes SectionPavaloaie Marian ConstantinPas encore d'évaluation

- Nobel 2022 - CabinetDocument10 pagesNobel 2022 - CabinetLynn ChiaPas encore d'évaluation

- Sliding Thermal BreakDocument64 pagesSliding Thermal BreakSaud AffanPas encore d'évaluation

- Nitobond Ec (Epoxy Adhesive)Document3 pagesNitobond Ec (Epoxy Adhesive)Kris SiregarPas encore d'évaluation

- Development of Sawdust As An Admixture in Production of Hollow BlocksDocument11 pagesDevelopment of Sawdust As An Admixture in Production of Hollow BlocksJonniel De GuzmanPas encore d'évaluation

- 7 SteelDocument6 pages7 SteelIssaPas encore d'évaluation

- Prestressed Concrete Structures - AssignmentDocument11 pagesPrestressed Concrete Structures - AssignmentAlbinPSunnyPas encore d'évaluation

- Construction Technology MCQDocument16 pagesConstruction Technology MCQvignesh rulzPas encore d'évaluation

- CHB Back-Up ComputationDocument36 pagesCHB Back-Up Computationkhim tugasPas encore d'évaluation

- Astm B 505 PDFDocument8 pagesAstm B 505 PDFRio WitcandraPas encore d'évaluation

- REO Range CatalogueDocument8 pagesREO Range CatalogueSURAJ PratapPas encore d'évaluation

- Private Majlis: Corsair Wall Mounted WC Pan White BDS-COR-602011-B-WHDocument57 pagesPrivate Majlis: Corsair Wall Mounted WC Pan White BDS-COR-602011-B-WHmohammadPas encore d'évaluation

- MB Evo/Evo Spare PartsDocument1 pageMB Evo/Evo Spare PartsBranko FerenčakPas encore d'évaluation

- C38 Mpa Type-IDocument17 pagesC38 Mpa Type-IshahulPas encore d'évaluation

- Rebar Drawing Check ListDocument1 pageRebar Drawing Check Listalok100% (1)

- TDS Cat Tembok Altex Naturetone PDFDocument1 pageTDS Cat Tembok Altex Naturetone PDFMunafri HairilPas encore d'évaluation

- Machine Design Final Coaching ShuffledDocument385 pagesMachine Design Final Coaching Shuffledkristan7Pas encore d'évaluation

- Method Statement Secant Pile: Page 1 of 12Document12 pagesMethod Statement Secant Pile: Page 1 of 12J. Kumar Infraprojects LtdPas encore d'évaluation

- BS 729 1971 Hot Ip Galvanized Coatings On Iron and Steel ArticlespdfDocument15 pagesBS 729 1971 Hot Ip Galvanized Coatings On Iron and Steel ArticlespdfAvinash LalPas encore d'évaluation

- SOP-PVC FlooringDocument7 pagesSOP-PVC FlooringNitish Singh (Monty)Pas encore d'évaluation