Académique Documents

Professionnel Documents

Culture Documents

A Laboratory Facility For Testing Cemented

Transféré par

rannscribdDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A Laboratory Facility For Testing Cemented

Transféré par

rannscribdDroits d'auteur :

Formats disponibles

A LABORATORY FACILITY FOR TESTING CEMENTED

FILLS

By

R. C. FLANN

ABSTRACT while the test is in progre'ss.

This case study describes various Also described are controlled

aspects of establishing a laboratory environment curing facilities which

facility for testing chemically-cemented allow samples to be cured or weathered

fill materials. Th. applicability of under different temperature or humidity

data obtained from such a facility conditions to simulate long-term ageing

related to mine conditions depends on and in place conditions.

many factors: kind of data, type of INTRODUCTION

testing facility, sample parameters DefOrmation studies are

selected following an extensive study of

equipment available for testing materials

in the fields of rock mechanics and

testing 'facility incorporates Linear

Variable Transformers for

monitoring both lateral and axial

displacements during sample compression.

The output from these and from other

related instrumentation can be recorded

or fed direct to a computer, enabling

stress-strain data to be printed out

(composition, geometry, size, etc.).

The equipment employed must be adaptable,

to accommodate variations in sample size

and properties.

The design, construction and

operation of the testing facility is

described, and its application to fill

samples prepared from sulphides and

oxides both chemically and naturally

construction materials.

Such studies are conducted

both in the laboratory and in the field.

Tests range from crude to very

sophisticated, and the facility described

falls between these extremes, to provide

a number of test routines that are both

practical and meaningful.

The most common direct technique

used in construction materials

is uniaxial compression which is a

special case of the triaxial technique

and allows both laboratory and field

testing without the need for an

extensive range of ancillary equipment.

The object of determining these

mechanical properties is to find those

representative of a good mine fill,

using accepted practices. The facility

allows the stress-strain characteristics

of the material to be obtained and the

determination of elastic constants or

to evaluate the stability of structural

materialS.

The strength

The present system was cemented.

Experimental Officer, CSIRO,

Division of Mineral Chemistry,

Victoria. Melbourne.

moduli (see Appendix I).

Use can be made of this information by

applying theoretical engineering

concepts.

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

MS received at The Institute - 18.6.73 105

106 R. C. Flann

The monitoring facility was designed

for uniaxial test conditions and cannot

in its present form be used for triaxial

testing. Similar systems "have been

selecting the Shimadzu was the table

size (50 cm x 50 cm) and space between

the table and crosshead (50 cm x 70 cm)

This allowed monitoring equipment to be

designed, using transducers in a fitted into the sample area. The load-

the clamp-on type, in which the sample

is located inside a mUlti-ring system,

containing electronic transducers with

electronic amplification (Protodyakonov,

M.M., 1961, Singh, D.P. et aI, 1967,

Hardy, H.R. et aI, 1970, Horino, F.G.

et aI, 1972), or the extensometer type

(Leeman, E.R. et aI, 1957(b)), using

mechanical and electronic amplification

techniques improve resolution of the

deformation patterns of the test sample.

A similar system to the one

described was used to establish the time

dependent properties of rocks (Singh,

D.P., 1970), employing electronic

transducers for both lateral and axial

"cm diameter using a common 20.32 cm base

recording facility provided was a

mechanically operated arm and rotating

drum, of limited resolution, which is

incorporated with a high tolerance

potentiometer attached directly to the

dynamometer indicator drive shaft.

This allows direct calibration and

A new system has been

These platens were designed to

no longer used.

s<;lat.

recording.

Platens

The loading platens of the Shimadzu

RH-lO supplied with the machine were

85 mm, limiting the sample diameter.

A further set of platens was designed

and constructed with 20.32 cm and 30.48

Most of these are of variety of ways.

minimize surface deflection on pressure

application, and reduce the effect of

tension in the sample caps induced by

function of the spherical seats is to

correct for any nature of

the sample ends, and to apply pressur,e

uniformly over the total end area.

The spherical seats are used in a

lightly lubricated state and function as

if fixed after initial seating has

sensing.

Bonded strain gauges have been used

extensively in both uniaxial and triaxial

systems (Leeman, E.R. 1957(a), Hardy,

H.R. 1966, Rough, R.L. et aI, 1971).

Although relatively inexpensive,

type of gauge is difficult to calibrate

directly, can suffer damage when sample

failure occurs, and cannot be bonded

easily to wet samples when saturated

samples are tested.

platen deformation. The primary

TESTI'NG FACILITY occurred. " Their radius of operation

Loading System

The basic unit of the loading system

consists of a five range (5, 10, 25, 50

and 100KN) hydraulically operated

Shimadzu RH-lO Universal Testing Machine.

During operation, steady load application

is maintained using a load pacer built

lies on the sample-platen interface, as

recommended by the American Society for

Testing of Materials (ASTM), (Schuyler,

the platens should be the same as that

of the test sample, (Sigvaldason, a.T.

1966), but the required variation in

sample size and type that has to be into the machine. A reason for

M., 1913). Ideally, the diameter of

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.l.M.M.

R. C. Flann

107

should then be minimized over the elastic

section of the deformation curve

used for these end-pieces should have

the same lateral expansion as that of

the specimen, i.e. the same ~ / E ratio

alternative is to provide the specimen

with metal end-pieces of the same cross-

section, thereby eliminating effects of

tested make t h ~ s impractical.

These

The main body

and probe rods of brass.

of the assembly and the transducer

holder is made of aluminium, the guide

rods of silver steel, the slip coupling

shown in Figs. 2 and 3.

LVDTs were chosen for the system

because of their low cost, high stability,

high sensitivity (displacements of

4 x 10-

5

mm can be measured), and

resistance to damage.

The lateral LVDTs were mounted as

An

The material

The end effects (see Appendix, I).

diameter differences.

(Jaeger, J.C. et al 1969).

Transducers

materials were selected for their low

weight factors and non-magnetic

the probe, which passes through a low

friction teflon bush held in position

The sensing elements employed for

monitoring axial and lateral sample

deformation are DC-DC Linear Variable

properties. The core is attached to

is placed in contact with the sample it

is pushed into the assembly and the core

Differential Transformers (LVDTs).

Two types of LVDT were used in the

construction of the axial/lateral strain

by the spring shown. When the probe

transducer; Schaevitz lOO-HR DC (axial) is moved further into the LVDT. The

LVDT is positioned using the micrometer

head which is attached to the holder by

and the 050-HR DC (lateral).

integrated units with DC-AC-DC

conversion circuits (Fig. 1).

Both are

a slip coupling. The Mitutoyo series

150-190 micrometer heads measure to

0.001 mm, and allow accurate positioning

of the core within the LVDT. silver

steel rods are used to locate and

support the LVDT holder, which moves

that the core stays free within the

LVDT and can move during test,

irrespective of the LVDT position.

Axial LVDTs are similarly mounted

in aluminium holders and allow the

They ensure laterally along them.

Fig. 1 Cross-section of

DC-DC LVDT

and phase of the output voltage depends

on the position of the iron core in the

transducer body (Schaevitz, H., 1947),

being zero at the centre (null).

As the core is displaced in either

direction, the output voltage increases

as a function of core displacement.

flexibility required, depending on the

is attached to a brass rod and adheres

to the top platen or machine crosshead

rod is threaded British standard Fine

(BSF) allowing fine adjustment of the

core position to null within the LVDT.

The brass

In each case the core

by means of a pot magnet.

sample size.

that the magnitude The design is such

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

108

R. C. Flann

MIc. itOHLTE 12.

HE-A C.

SLIP

COUPLlN cr.

LY.b.T.

I{Ol.ceil

Fig. 2

Cross section of Lateral Transducer

recorded with the lateral transducers

set on orthogonal axes at the sample

centre and the axials mounted on

This design allows rapid relocation of

the transducers when testing a'range of

samples.

The transducer assemblies are

commonly used. Deformations are

deployed as shown in Fig. 4 to

accommodate samples of varying sizes

from 2.54 cm - 25.4 cm diameter and

5.08 cm - 50.3 cm in height, the

configuration shown being the one most

opposite sides, parallel with the

specimen's longitudinal axis.

Fig. 3 Lateral Linear Variable

Differential Transformer

Assembly

Fig. 4 Transducer Assemblies

Arranged to Test Aluminium

Sample.

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

R. C. Flann 109

In this arrangement the lateral

deformation can be recorded in several

deployed and oriented as required, to

suit the geometry and properties of the

ways: sample tested. For a given size of

the signals from the opposing

By individual recording of

deformation at 90

0

in the

horizontal plane normal to the

compression axis on the

orthogonal axes.

By summing or averaging

opposing LVDTs, reducing the

effects of sample movement

other than deformation because

sample the transducers are accurately

positioned for the first "settling in"

and can subsequently be re-zeroed with-

out relocating, for repeat compressive

test cycles.

Calibration

The transducers are calibrated in

Individually, using a separate

micrometer aligned on the

transducer axis and positioned

1.

two ways:

Allowing LVDTs will cancel.

2.

1.

sample deformation can then be

recorded.

other types of movement, i.e.

flexure, to be observed.

By summing or averaging all

four lateral LVDTs together,

obtaining a total or average

deformation at four points of

transducer probe can then be

moved gradually into the LVDT

and the displacement graphed

against voltage output.

As a complete assembly, using

a load ring with an axially

mounted dial gauge to measure

The lateral

The

deformation.

against the probe.

2.

The mean of the the sample.

3.

The advantage of this type of

transducer system configuration (which

can be extended to strain gauges if

necessary) is its ability to detect

non-uniform (asymmetric) deformation in

test samples, expected in anisotropic

or non-uniformly bedded samples, but

sometimes encountered in apparently

transducers are paired and

positioned on the horizontal

axis of the ring allowing the

calibration to be checked by

summation or averaging of

diagonal transducers (Fig. 5)

The axial transducers can be

calibrated directly against

homogenous specimens. Summing the the dial gauge. This

outputs of the LVDTs has the advantage

that lower amplifications can be used to

record outputs, improving signal to

arrangement allows the load-

axial and load-lateral

deformation curves to be

the axial and lateral transducers to be

alternatives in recording modes increase

the system's analytical capability.

The transducer support frame fits

around the lower platen and rests on

the machine table.

plotted (Fig. 6).

The linearity and reproducibility

of the calibration was very

The linear good.

relationship was evaluated by

least squares on a computer.

for future use in automatic

test data evaluation.

This system allows

The sum and/or average noise ratio.

Jubilee Symposium on Mine Filling. Mount Isa. August. 1973

North West Queensland Branch. The Aus.I.M.M.

110 R. C. Flann

Fig. 5 Transducers Arranged in

Calibration positions on Load Ring

Recording

A block diagram (Fig. 7) shows the

main components of the sensing and

recording systems.

RE.c..o!21J 16: X-Y, )(-7; .lJntrL04t.

1.6

2.0

E

oS 1.2

...

z

w

~

t: 0.8

..

it

III

o 0.4

Calibration cf LVDT using a

Soiltest Load Ring

This allows

six

Electronic

Buffer amplifiers

Block Diagram of Electrical

system

1. Rikadenki, KA 60 - A

Fig. 7

The balancing networks were

adjusted to give the LVDTs the same

from the recording.

direct comparison and extraction of data

output-displacement ratios.

multi-channel recording.

are used for matching to give a low

impedence output for simultaneous

networks which allow the LVDTs' outputs

to be summed or averaged are used to

mix signals before recording.

The recording systems currently

available are:

25 20 10 15

LOAD Cl\NJ.

5

-----

NIAL. ~ /

/

l/

./

/

L TERAL.

I------ --

./

/ - ~

~ . -

~

p/! ~

6

o

Fig.

3. Steel and aluminium samples of

known physical constants have

been used to calibrate the

2.

channel X-T recorder.

Hewlett Packard Moseley, 7050A

X-Y recorder.

assembly, subject to

limitations imposed by lateral

flexing of the particular

specimens used.

3. Data logging system based on a

PDP 8/e computer, with memory

storage capacity.

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

R. C. Flann III

Sample Geometry

Sample geometry is a major factor

which influences deformation and

compressive strength. The optimum

SAMPLE TESTING

Samples so far tested with the

facility have included the following

types:

sample shape has been the subject of

considerable research and discussion,

(Gonnerman, H.F., 1925, Hansen, H. et

~ , 1962, Grosvenor, N.E., 1963,

standard shape, the cylinder is

preferred to the cube, and is the

accepted form in Australia.

Requirements for the size and shape

of the test specimen should be based on

the following criteria:

Sigvaldason, O. T., 1966).

sulphides.

The samples exhibited the following

behaviour:

fine particulate

8 (a), (b).

cemented with

The porous agglomerated

materials underwent granulation,

then fractured in shear Fig.

bonded sulphide agglomerates.

Fine particulate, highly

consolidated sulphide

agglomerates.

Various types of aggregate

Porous, coarse grained, weakly

2.

3.

1.

1.

As a

The shape should allow the

greatest reproducibility, with

a minimum spread in ultimate

1.

2.

3.

2.

3.

strength.

The size should accommodate the

maximum aggregate size without

causing any marked difference

in ultimate strength, (ASTM.

1969) specifies that for a

coarse aggregate the largest

fragment dimension to lateral

dimension of the test specimen

shall not exceed 1:3.

Samples should be easy to

prepare, handle and finish for

testing, e.g. easy to cap so as

to provide smooth parallel

faces.

The fine particulate highly

consolidated specimens exhibited

high strength, fractured

axially and showed no detectable

granulation Fig. 9(a), (b).

The different sulphide cemented

samples showed properties

rang ing be tween (l) and (2)

depending on the constituents

present in the mix and their

relative proportions.

Cycling these samples

to approximately 40% of their estimated

ultimate compressive strength allows

them to "bed in" and eliminates some of

the initial differences observed, e.g.

high axial deformation when the samples

various research workers (Gonnerman,

H.F., 1925, Hansen, H. et ~ , 1962,

Grosvenor, N.E., 1963) agree that test are tested without cycling. This is

also the region in which reversible

deformation occurs, and provides the

data necessary for the calculation of

specimens with a circular cross section

and a height-to-diameter ratio of

between 2 and 3 give a more uniform

stress distribution in uniaxial

compression.

elasticity constants and moduli

Appendix, I).

(see

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

112 R. C. Flann

A

1

X14L. I

/

l--

__CJ

/

b-e

I r-

II

LATERAL

0-

0 ,

_..<---!- -

._--_.-

0.5

0.4

0.3

....

z

'"

;r

'" 0.2

-'

A.

o

0.1

o

0.5 1.0 1.5

LOAt)(KN).

2.0 25

Fig. Sea) Porous Agglomerated Sample

that has undergone Shear Failure

(b) Load Displacement Curves for Sample

showing granulation

15 10

LOAD tKNl.

5

I

AXIAJ t

V

V

I /

./

../'

1/

---

IL

.-?

---

--

---

o

0.1

--'- O.l

E

E

'"

;r

'"

u

-<

er 0.2

l/l

Cl

0.5

Fig. 9(a) Fine Particulate Sample that

has undergone axial fracture

(b) Load Displacement Curves for Sample

showing no granulation.

available which can be programmed to

cycle over a temperature and relative

humidity range from -lOoC to 1000C and

SAMPLE PREPARATION

In addition to the above, systems

have been established for mixing,

curing and finishing (capping) of test 0% to 100% R.H. to cure samples. This

of two cubic meters capacity is

specimens. An environmental cabinet can be used to simulate any environment

and hence study its effects on sample

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

------ ---------

R. C. Flann 113

pp. 31-33.

Research Laboratory, Chicago)

proportion. Min. Engineering, Jan.

properties. A room of 50 cubic meters

which operates at 253

0

C and 505% R.H.

is also available for large samples.

Both facilities allow simulation of

Grosvenor, N.E., 1963. Specimen

long term curing and in-place conditions. Hansen, H., Kielland, A., Nielsen, K.E.C.

CONCLUSION and Thaulow, S., 1962. Compressive

rhe transducer assembly allows the

accurate recording of deformation in

complex samples undergoing

strength of Concrete - Cube or

Cylinder?, Bulletin Rilem No. 17,

compression. Future modifications can

Dec. 1962, pp.

Hardy, H.R., 1959..

23-30.

Time-dE;lpendent

extend the capacity of the system to Deformation and Failure of Geologic

triaxial compressive testing. Further Materials. Colorado Schl. of Mines

test work on a wider range of materials

will be required before a quantitative

interpretation of results can be made,

and the applicability of the data to

practical mining conditions can be

Qtrly. 54:135-75.

Hardy, H.R. 1966. A Loading System for

the Investigation of the Inelastic

Properties of Geologic Materials

Testing Techniques for Rock Mechanics,

REFERENCES

(ASTM), Standard C192, 1969, Section

American Society for Testing of Materials

allows an effective comparison to be

made in fundamental properties between

different materials.

A

Clamp-on Strain Transducer for use

on Geologic Materials. Soc. of

Petroleum Engnrs. J., March 1970,

pp. 41-50.

pp. 138-139 (Methuen: London).

Leeman, E.R. and Grobbelaar, C., 1957(a)

A Compressometer for obtaining

stress-strain Curves of Rock

Horino, F.G., Brady, B.T., Duvall, W.I.

and Hooker, y.E., 1972. A J'housand-

ton Capacity stiff Testing Machine,

U.S. Bur. Mines. Report of

Inv:estigations 76.24 (Washington)

Jaeger, J.C. and Cook, N.G.W., 1969,

Fundamentals of Rock Mechanics.

ASTM STP 402, pp. 232-271.

Hardy, H.R. and Kim, Y.S., 1970.

However, the present system

Mineral Chemistry for frequent advice

and assistance in editing this paper, as'

well as to the Workshop staff of the

Division of Mineral Chemistry for their

help in construction of apparatus.

assessed.

ACKNOWLEDGEMENTS

The author would like' to express

,his appreciation to Mr. W.E. Bamford of

the University of Melbourne and Dr. G.M.

Lukaszewski of the CSIRO Division of

34. Making and Curing Concrete specimens up to Fracture. J.

Test specimens in the Laboratory. Scientific Instruments Vol. 34:

Coates, D.F., 1970. Rock Mechanics 279-281.

(Mines Branch, Canada).

Principles. 3rd. Ed. App. B 1-24, Leeman, E_R. and Grobbelaar, C., 1957(b)

A Lateral Extensometer for the

Gonnerman, H.F., 1925. Effect of Size Determination of Poisson's Ratio of

and Shape of Test Specimen on Rock. J. Scientific Instruments

Compressive Strength of Concrete, Vol. 34: 503-505.

Pp. 1-2 (Structural Materials

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

L. -

114 R. C. Flann

Protodyakonov, M.M., Methods of MODULUS OF ELASTICITY, E. (Modulus of

studying the strength of Rocks,

Used in the Int. Symp. on

Mining Resources. Vol. 2: 649-668.

(Univ. of Missouri, Permagon).

Rough, R.L., and Lambert, W.G., 1971.

In Situ Strain Orientations:

Comparison of Three Measuring

Report of Investigations 7575

(Washington) .

U.S. Bur. Mines.

numerically

(Young's Modulus) deformation)

The ratio of normal stress to

normal strain for a material under

defined loading conditions;

equal to the slope of the

<tangent modulus) or secant (secant

modulus) of the stress-strain curve.

The term Modulus of Elasticity is

normally applied to materials conforming

to Hooke's Law and Modulus of Deformation

for materials that deform otherwise.

A

The Linear

Techniques.

Schaevitz, H., 1947.

Variable Differential Transformer. MODULUS OF RIGIDITY, G. (Shear Modulus)

Soc. for Exp. Stress Anal. Proc.

Vol. 4, 2 : 79-88.

Schuy;Ler, M. , 1913. Spherical Bearings.

Amer. Soc. for Testing Materials,

The ratio of shear stress to shear

strain for a material determined either

from the slope of the tangent or of the

secant of a stress-strain curve.

13: 1004-1018. POISSON'S RATIO,

of Testing Machine Characteristics

upon the Cube and Cylinder strength

Mag. Concrete Res.,

Sigvaldason, O.T., 1966.

of Concrete.

The Influence The ratio of the transverse normal

strain to the longitudinal normal strain

of a body under uniaxial stress.

POISSON'S NUMBER, m.

Dec., 1966, Vol. 18, 57: 197-206. The reciprocal of Poisson's Ratio.

Singh, D.P., 1970. Time Dependent PROPORTIONAL LIMIT

properties of Ph.D. Thesis

(unpublished), university of

Melbourne.

Singh, M.M. and Kim, Y.S., 1967.

Lateral Extensometer for Brittle

The greatest stress that a material

is capable of developing without any

deviation from proportionality of stress

to strain (Hooke's Law).

REFERENCE

Materials. Rev. Scientific Coates, D.F., 1970. Rock Mechanics

Instruments, Vol. 38, 6:769-771. Principles. 3rd. Ed. App. B 1-24,

APPENDIX I

(Mines Branch, Canada).

BULK MODULUS, MODULUS OF COMPRESSION, K.

The ratio of the change in average

stress to the change in unit volume.

PLASTIC LIMIT

The maximum stress that a specimen

can withstand without undergoing

permanent deformation either by solid

flow or by rupture.

point.

Also called yield

Jubilee Symposium on Mine Filling, Mount Isa, August, 1973

North West Queensland Branch, The Aus.I.M.M.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Music Frequency Cheat SheetDocument1 pageMusic Frequency Cheat SheetLeonel Molina AlvaradoPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Construction Schedule Template 05Document7 pagesConstruction Schedule Template 05bharat gadaraPas encore d'évaluation

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Gasoline Direct InjectionDocument21 pagesGasoline Direct InjectionhoangPas encore d'évaluation

- Charpy Impact Test - STP 1072Document219 pagesCharpy Impact Test - STP 1072biancogallazzi100% (3)

- Top 100 IT Companies (Rank-Wise List)Document3 pagesTop 100 IT Companies (Rank-Wise List)Somesh100% (1)

- List of Companies and E-Mail Id SL - No Company E-MailDocument4 pagesList of Companies and E-Mail Id SL - No Company E-MailRadheshyam Kushwaha75% (4)

- Business Dynamics and Diversification PlanningDocument6 pagesBusiness Dynamics and Diversification PlanningrannscribdPas encore d'évaluation

- ATX Specification - Revision 1.1, February 1996Document15 pagesATX Specification - Revision 1.1, February 1996ivanagui2Pas encore d'évaluation

- Jar Test Lab Report Environmental EngineeringDocument7 pagesJar Test Lab Report Environmental EngineeringNur Hazimah100% (1)

- Limestone Mining Reserves and ValuationDocument5 pagesLimestone Mining Reserves and ValuationrannscribdPas encore d'évaluation

- Cat 772 Catálogo de Peças PDFDocument937 pagesCat 772 Catálogo de Peças PDFTom Souza100% (1)

- Mechanized Excavability Rating For Hard-Rock MiningDocument10 pagesMechanized Excavability Rating For Hard-Rock MiningrannscribdPas encore d'évaluation

- TunelDocument10 pagesTunelrannscribdPas encore d'évaluation

- A Methodology To Determine in Situ Rock Mass FailureDocument8 pagesA Methodology To Determine in Situ Rock Mass FailurerannscribdPas encore d'évaluation

- Pit To Plant - Current TrendsDocument11 pagesPit To Plant - Current TrendsrannscribdPas encore d'évaluation

- Determination and IT Supported Evaluation of Rock Mechanical Parameters and Thir Utilization During Application of Roof Bolting TechniquesDocument10 pagesDetermination and IT Supported Evaluation of Rock Mechanical Parameters and Thir Utilization During Application of Roof Bolting TechniquesrannscribdPas encore d'évaluation

- Two-Point Estimates in ProbabilitiesDocument7 pagesTwo-Point Estimates in ProbabilitiesrannscribdPas encore d'évaluation

- 35 NL Web3Document30 pages35 NL Web3rannscribdPas encore d'évaluation

- Velocity EquipmentDocument8 pagesVelocity EquipmentrannscribdPas encore d'évaluation

- Erich NeugebauerDocument18 pagesErich NeugebauerrannscribdPas encore d'évaluation

- TT-196 FinalDocument10 pagesTT-196 FinalrannscribdPas encore d'évaluation

- Mining Practices and Their Effect On Mobile Equipment CostsDocument4 pagesMining Practices and Their Effect On Mobile Equipment CostsrannscribdPas encore d'évaluation

- TT-193 FinalDocument10 pagesTT-193 FinalrannscribdPas encore d'évaluation

- Chapter 2. Protected AreasDocument18 pagesChapter 2. Protected AreasrannscribdPas encore d'évaluation

- TT-197 FinalDocument2 pagesTT-197 FinalFabian Sedano MangualayaPas encore d'évaluation

- Three-Dimensional Finite Element Stress Analysis Applied To Two Problems in Rock MechanicsDocument6 pagesThree-Dimensional Finite Element Stress Analysis Applied To Two Problems in Rock MechanicsrannscribdPas encore d'évaluation

- TT-197 FinalDocument2 pagesTT-197 FinalFabian Sedano MangualayaPas encore d'évaluation

- Assessment of Rock Slope Stability Using The Rock Mass Rating (RMR) SystemDocument5 pagesAssessment of Rock Slope Stability Using The Rock Mass Rating (RMR) SystemrannscribdPas encore d'évaluation

- Design and Support of Excavations Subjected To High Horizontal StressDocument22 pagesDesign and Support of Excavations Subjected To High Horizontal StressrannscribdPas encore d'évaluation

- Determination and IT Supported Evaluation of Rock Mechanical Parameters and Thir Utilization During Application of Roof Bolting TechniquesDocument10 pagesDetermination and IT Supported Evaluation of Rock Mechanical Parameters and Thir Utilization During Application of Roof Bolting TechniquesrannscribdPas encore d'évaluation

- Breakage and Fragmentation Modelling ForDocument22 pagesBreakage and Fragmentation Modelling ForrannscribdPas encore d'évaluation

- Velocity EquipmentDocument8 pagesVelocity EquipmentrannscribdPas encore d'évaluation

- Underground Mined Type LGP StorangeDocument13 pagesUnderground Mined Type LGP StorangerannscribdPas encore d'évaluation

- Mining Geotechnical BenchmarkingDocument4 pagesMining Geotechnical BenchmarkingrannscribdPas encore d'évaluation

- Comparison of Multiple and Single Entry Roadways For Highly Stressed LongwallsDocument4 pagesComparison of Multiple and Single Entry Roadways For Highly Stressed LongwallsrannscribdPas encore d'évaluation

- Combined Approach For Surface Mine Short Term Planning OptimizationDocument8 pagesCombined Approach For Surface Mine Short Term Planning OptimizationrannscribdPas encore d'évaluation

- Rpta.: 2 Rpta.: 168Document3 pagesRpta.: 2 Rpta.: 168rannscribdPas encore d'évaluation

- Comparison of Multiple and Single Entry Roadways For Highly Stressed LongwallsDocument4 pagesComparison of Multiple and Single Entry Roadways For Highly Stressed LongwallsrannscribdPas encore d'évaluation

- Australian Longwall Geomechanics - A Recent StudyDocument9 pagesAustralian Longwall Geomechanics - A Recent StudyrannscribdPas encore d'évaluation

- PM 2.5 Sampler Model Aas-127: Advantages: FeaturesDocument1 pagePM 2.5 Sampler Model Aas-127: Advantages: FeaturesRajesh MishraPas encore d'évaluation

- Phy 109 PDFDocument1 pagePhy 109 PDFsohamPas encore d'évaluation

- Sonali MondalDocument2 pagesSonali MondalSonali MondalPas encore d'évaluation

- Composite For Innovative Wind TurbineDocument25 pagesComposite For Innovative Wind TurbineSuraj MoodPas encore d'évaluation

- Grundfosliterature 5439530Document244 pagesGrundfosliterature 5439530Dien HuynhPas encore d'évaluation

- PVsyst Simulation ReportDocument7 pagesPVsyst Simulation ReportRandu Satria PutraPas encore d'évaluation

- The Cunard Building, LiverpoolDocument2 pagesThe Cunard Building, LiverpoolIbrahim FawwazPas encore d'évaluation

- Advanced Vibration Chapter03Document130 pagesAdvanced Vibration Chapter03Alooy MohamedPas encore d'évaluation

- JSP BasicsDocument41 pagesJSP BasicsSandeep KavuriPas encore d'évaluation

- Computer Science With Java by Sumita Arora Pdf. TutorialDocument3 pagesComputer Science With Java by Sumita Arora Pdf. TutorialSouryadeep MazumderPas encore d'évaluation

- Oncell 5004/5104-Hspa Series: Industrial Five-Band Gsm/Gprs/Edge/Umts/Hspa Cellular RoutersDocument2 pagesOncell 5004/5104-Hspa Series: Industrial Five-Band Gsm/Gprs/Edge/Umts/Hspa Cellular Routersudaya kumarPas encore d'évaluation

- Sizing Columns in HysysDocument4 pagesSizing Columns in HysysemebusamuelPas encore d'évaluation

- Market Consumer Perception Mahindra ThesisDocument95 pagesMarket Consumer Perception Mahindra ThesisHarmeet singh100% (1)

- Sika MonoTop 615 PDS (CE)Document6 pagesSika MonoTop 615 PDS (CE)Virah Sammy ChandraPas encore d'évaluation

- Titus Slot DiffuserDocument4 pagesTitus Slot Diffuservico1982Pas encore d'évaluation

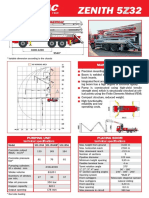

- Sermac SCL130ADocument2 pagesSermac SCL130AVasiliy PavliukPas encore d'évaluation

- The Wire and Cable Technical Information HandbookDocument313 pagesThe Wire and Cable Technical Information Handbookdannyalarconm64718100% (5)

- Aim Algorithm ResultDocument10 pagesAim Algorithm ResultSuraj Ramakrishnan100% (1)

- BB Session - Me132p - Lecture 2 KD and DofDocument31 pagesBB Session - Me132p - Lecture 2 KD and Dofkris garciaPas encore d'évaluation

- Stainless Steel Wire Mesh and Wire ClothDocument3 pagesStainless Steel Wire Mesh and Wire ClothStela LjevarPas encore d'évaluation