Académique Documents

Professionnel Documents

Culture Documents

Unconventional Machining Processes - Model Important Questions

Transféré par

murugesan_kpmDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Unconventional Machining Processes - Model Important Questions

Transféré par

murugesan_kpmDroits d'auteur :

Formats disponibles

Department of Mechanical Engineering ME2026 UNCONVENTIONAL MACHINING PROCESSES

16. What is the working principle of operation of wirecut EDM? 17. List the process capabilities of EDM process. 18. What is the working principle of operation of wirecut EDM? 19. List the preferred characteristics of ECM electrolytes. 20. What is the self adjusting feature in ECM? 21. Give the application of electrochemical honing process. 22. What is the basic difference between electroplating and electro chemical machining? 23. What are the advantages of chemical machining? 24. What do you understand by etch factor? 25. What are the parameters that govern the performance of PAM? 26. What is meant by population inversion between energy levels with respect to laser beam machining? 27. What is the principle of PAM? 28. In electron beam machining, why is a high vacuum created in the apparatus. 29. What is the principle of PAM? 30. Can you machine electrically non-conducting materials using EBM.

PART-A

1. What are the industrial needs for UCM? 2. List down the various mechanical energy based Unconventional Machining Processes. 3. What are the different machining characteristics will respect to which the non-traditional machining processes can be analyzed? 4. Distinguish traditional & non-traditional machining processes? 5. How will you compare various non-traditional processes? 6. List the unique benefits offered by WJM process. 7. What are the applications of WJM? 8. What types of energy are employed in non-traditional machining processes? 9. What are the major elements of ultrasonic machining equipment? 10. List the process parameters of water jet machining process. 11. What type of operations can be performed in AJM? 12. What are the variables that affect the cutting phenomena in AJM? 13. What are the types of tool materials used in EDM? 14. What is the purpose of dielectric in EDM? 15. What is the working principle of EDM?

PART-B

1. What is the need for the development of UCM process? Explain with examples. 2. Make a comparison between traditional and unconventional machining processes in terms of

cost, application, scope, machining time, advantages & limitations. 3. For different non-conventional processes, present in the form of a table, various process parameters recommended. 4. Make a comparison among various non-traditional machining processes in terms of the following. Presentation in the form of a table is preferred. a.Pocketing operation b.Contouring a surface. 5. What exactly are the items that can be considered with respect to the analysis of economics of various non-traditional machining process? Briefly explain. 6. With a neat sketch explain the process of AJM? Write its advantages and applications. 7. Write about various types of feed mechanism used in USM process. 8. List the various types of tool holders and transducers used in ultrasonic machining and explain them briefly. 9. Discuss the effects of the following parameters on the material removal and surface finish in ultrasonic machining: a. Amplitude and frequency b. Abrasive size c. Concentration of abrasives d. Material hardness 10. Explain process parameters of EDM process. State the application of EDM. 11. Explain the servo system used to control the feed rate in EDM process. 12. List out the three types of spark generators used in EDM. Describe them. 13. What are the factors influencing the selection of maskants in chemical machining process?

14. Explain the reasons for the development of UCM process. Discuss about the criteria recommended in selection of these processes. 15. With a neat sketch explain the process of water-jet machining. 16. Explain the different types of control circuits used in EDM process. 17. Explain the process of Electro chemical machining with a neat sketch and discuss about influences of process parameters in machining output. 18. Describe the chemistry involved in ECM process & briefly discuss about the effect of high temperature and pressure of electrolyte on the ECM process. 19. Compare the USM, WJM, and AJM in terms of process capabilities and limitations. 20. Discuss in detail, the electric discharge machining process and its principle of operation with the help of a neat diagram. Also discuss the operating process parameters and their effects. 21. Explain the working principle, elements and characteristics of wire EDM. 22. Why is Electron Beam Machining (EBM) carried out in vacuum? Explain the process with a neat sketch. 23. Discuss about the process parameters PAM and its influence in machining quality. 24. With a neat sketch explain the principle of electro chemical grinding. State the process capabilities and applications. 25. Describe the working principle and elements of chemical machining. What are the factors on which the selection of a resist for us in chemical machining?

26. Describe the Plasma Arc Machining (PAM)

process with a simple sketch and write about its parameters, advantages and applications. 27. What is meant by optical pumping. Briefly explain the population inversion between energy levels with respect to laser beam machining. 28. List out the three types of spark generators used in EDM. Describe them. 29. Explain the servo system used to control the feed rate in EDM process. 30. Describe the ECH and ECG equipment with neat sketches and list their applications and advantages.

Vous aimerez peut-être aussi

- UNCONVENTIONAL MACHINING PROCESSES - Model Important Questions - CompressedDocument2 pagesUNCONVENTIONAL MACHINING PROCESSES - Model Important Questions - CompressedMuralee DharanPas encore d'évaluation

- Ucmp NotesDocument46 pagesUcmp NotesAnonymous fowICTKPas encore d'évaluation

- Unconventional Machining Processes - Lecture Notes, Study Material and Important Questions, AnswersDocument3 pagesUnconventional Machining Processes - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVPas encore d'évaluation

- Engineering Mechanics 2 MarksDocument2 pagesEngineering Mechanics 2 MarksMohanraj Subramani0% (1)

- MCQ Ucmp Unit I Introduction and Mechanical Energy Based ProcessesDocument30 pagesMCQ Ucmp Unit I Introduction and Mechanical Energy Based ProcessesBollu SatyanarayanaPas encore d'évaluation

- Magnetic Abrasive FinishingDocument9 pagesMagnetic Abrasive FinishingMohamed OmarPas encore d'évaluation

- MIST MSC-ME SyllabusDocument30 pagesMIST MSC-ME SyllabusSajidPas encore d'évaluation

- Me 6603 - Finite Element Analysis: Part A Questions With Answers Unit 1Document14 pagesMe 6603 - Finite Element Analysis: Part A Questions With Answers Unit 1Karthik SubramaniPas encore d'évaluation

- EDMDocument36 pagesEDMshifas 558Pas encore d'évaluation

- Assignment Question Set On Modern Manufacturing ProcessDocument1 pageAssignment Question Set On Modern Manufacturing ProcessSagar KhanPas encore d'évaluation

- Viva QuestionDocument4 pagesViva QuestionBarathkannan Lakshmi PalanichamyPas encore d'évaluation

- Delhi Eee Nba Ppt-02!5!19Document42 pagesDelhi Eee Nba Ppt-02!5!19i sai ramPas encore d'évaluation

- GovernorsDocument69 pagesGovernorsBiswajyoti Dutta100% (1)

- Gate FormulaDocument121 pagesGate FormulaJosh Manohar0% (1)

- Chapter 3 MFG IIDocument145 pagesChapter 3 MFG IITiliksew Wudie Assabe100% (1)

- Engineering Materials and Metallurgy QBDocument13 pagesEngineering Materials and Metallurgy QBAnand Jayakumar ArumughamPas encore d'évaluation

- Strength of Materials/Mechanics of Solids (CE-303/DCE-303) - Short Answer Questions-UIT-RGPV BHOPALDocument4 pagesStrength of Materials/Mechanics of Solids (CE-303/DCE-303) - Short Answer Questions-UIT-RGPV BHOPALSantosh Kumar0% (1)

- Simulation Lab ManualDocument60 pagesSimulation Lab Manualvensesfrank100% (1)

- Unit 1 Dynamics of MachineryDocument17 pagesUnit 1 Dynamics of MachineryNAVEENPas encore d'évaluation

- DME Lesson Plan As Per NBADocument3 pagesDME Lesson Plan As Per NBASabareesan Subramanian0% (1)

- Engineering Workshop Notes Viva Questions PDFDocument12 pagesEngineering Workshop Notes Viva Questions PDFMbogi TokaPas encore d'évaluation

- Auto Cad 1Document30 pagesAuto Cad 1balamuraliPas encore d'évaluation

- MOdrobs - Mech 2017Document6 pagesMOdrobs - Mech 2017Anbalagan GuruPas encore d'évaluation

- Department of Mechanical Engineering: Welcome The Chairman & Members of The NBA Peer TeamDocument106 pagesDepartment of Mechanical Engineering: Welcome The Chairman & Members of The NBA Peer TeamAnonymous p8bHAAx75% (4)

- Chapter3 GovernorDocument16 pagesChapter3 GovernorBazli Faiq Zaini100% (1)

- Two Mark Unit IIIDocument7 pagesTwo Mark Unit IIIhariharanbookPas encore d'évaluation

- ME 2354 Automobile Engineering 2009 6th Semester Anna UniversityDocument2 pagesME 2354 Automobile Engineering 2009 6th Semester Anna UniversityParanthaman GanapathyPas encore d'évaluation

- Modrob (NDT) Dec 2013Document6 pagesModrob (NDT) Dec 2013Sanjay Tiwari100% (2)

- Plasma Arc MachiningDocument12 pagesPlasma Arc MachiningAfsarShaikhPas encore d'évaluation

- Uncinventional Machining Process Interview QuestionsDocument14 pagesUncinventional Machining Process Interview QuestionsimsaiyathPas encore d'évaluation

- Mtech Thermal Engineering 2021 1-1 Sem Question Papers (Thermal Engineering)Document8 pagesMtech Thermal Engineering 2021 1-1 Sem Question Papers (Thermal Engineering)ganesh ghuttsPas encore d'évaluation

- Unit-4 Advanced Machining ProcessesDocument61 pagesUnit-4 Advanced Machining ProcessesHarshalPatilPas encore d'évaluation

- Strength of MaterialsDocument34 pagesStrength of Materialssatish44850% (2)

- Mtech. Finite Element AnalysisDocument11 pagesMtech. Finite Element Analysissimalaravi100% (2)

- Ce 8381som Lab ManualDocument31 pagesCe 8381som Lab ManualAERO JPR50% (2)

- ME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusDocument2 pagesME8073 - UNCONVENTIONAL MACHINING PROCESSES SyllabusP.N. MohankumarPas encore d'évaluation

- Practice Problems For Autocad 2011Document122 pagesPractice Problems For Autocad 2011Mandi Masood AsferPas encore d'évaluation

- Ashok LeylandDocument8 pagesAshok LeylandNaveen KumarPas encore d'évaluation

- Tom New SyllabusDocument13 pagesTom New SyllabusshekhadPas encore d'évaluation

- Non Traditional Machining Techniques - NotesDocument63 pagesNon Traditional Machining Techniques - Notesjayabalaji_7759100% (1)

- Sudharsan Engineering College: Department of Mechanical EngineeringDocument34 pagesSudharsan Engineering College: Department of Mechanical EngineeringOmar BouledrouaPas encore d'évaluation

- Chapter 3Document31 pagesChapter 3BoucharebKarimPas encore d'évaluation

- Models - Heat.shell and Tube Heat ExchangerDocument26 pagesModels - Heat.shell and Tube Heat ExchangerLuis Esteban Vela DonosoPas encore d'évaluation

- SDQADocument4 pagesSDQAyaadhaviPas encore d'évaluation

- Virtual LaboratoryDocument14 pagesVirtual LaboratoryArie Febry Fardheny, MTPas encore d'évaluation

- Project ProposalDocument6 pagesProject ProposalMuhammad Asad SaeedPas encore d'évaluation

- MCQs On SCBDocument9 pagesMCQs On SCBjigardesai100% (1)

- ECDMDocument9 pagesECDMRobert NayakPas encore d'évaluation

- Manufacturing Process Point Vise Syllabus From RaghuvanshiDocument3 pagesManufacturing Process Point Vise Syllabus From RaghuvanshiRAMAKANT RANAPas encore d'évaluation

- Unit 3 One Marks QuestionsDocument6 pagesUnit 3 One Marks QuestionsRahulPas encore d'évaluation

- ME 2035 Entrepreneurship Development Question BankDocument4 pagesME 2035 Entrepreneurship Development Question BankLiNu100% (2)

- Satyabhama MechDocument97 pagesSatyabhama MechRahul Kumar KPas encore d'évaluation

- Unit-I Two Marks Questions and Answers 1. Explain CIMDocument4 pagesUnit-I Two Marks Questions and Answers 1. Explain CIMKailashPas encore d'évaluation

- Unit-4-Computer Aided DesignDocument15 pagesUnit-4-Computer Aided DesignMuthuvel M100% (2)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsD'EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsPas encore d'évaluation

- Differential Transformation Method for Mechanical Engineering ProblemsD'EverandDifferential Transformation Method for Mechanical Engineering ProblemsPas encore d'évaluation

- Parallel Computational Fluid Dynamics '99: Towards Teraflops, Optimization and Novel FormulationsD'EverandParallel Computational Fluid Dynamics '99: Towards Teraflops, Optimization and Novel FormulationsPas encore d'évaluation

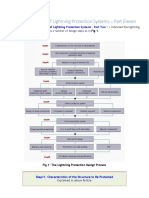

- Design Calculations of Lightning Protection Systems - Part ElevenDocument37 pagesDesign Calculations of Lightning Protection Systems - Part ElevenHansika RajapakshaPas encore d'évaluation

- Rapeepat Ratasuk NokiaDocument21 pagesRapeepat Ratasuk NokiaSudhir MPas encore d'évaluation

- Ats 380 Manual enDocument30 pagesAts 380 Manual enMuhammad Yasir IqbalPas encore d'évaluation

- Lightning Model For HVDC Transmission Lines: M. You, B. H. Zhang, L. Y. Cheng, Z. Q. Bo, A. KlimekDocument5 pagesLightning Model For HVDC Transmission Lines: M. You, B. H. Zhang, L. Y. Cheng, Z. Q. Bo, A. Klimekqais652002Pas encore d'évaluation

- MOS TransistorDocument21 pagesMOS TransistorAbhishek Singh100% (1)

- Ex60 Ex90 User Guide tc63Document72 pagesEx60 Ex90 User Guide tc63Wael AliPas encore d'évaluation

- Panasonic 10th Gen PDP TV Training ManualDocument100 pagesPanasonic 10th Gen PDP TV Training Manualenforcer2008Pas encore d'évaluation

- Trends in MultimediaDocument10 pagesTrends in MultimediaFrancis Gutierrez BalazonPas encore d'évaluation

- SA288 ARTICLE 23 Ultrasonic StandardsDocument10 pagesSA288 ARTICLE 23 Ultrasonic StandardsSean LavergnePas encore d'évaluation

- High Frequency Modeling of Transformer Using Black Box Frequency Response AnalysisDocument7 pagesHigh Frequency Modeling of Transformer Using Black Box Frequency Response AnalysisJosPas encore d'évaluation

- ch8 12eDocument103 pagesch8 12eareej.fatima1298Pas encore d'évaluation

- Thermal Profiler HC-40 60 80 12 ChannelDocument4 pagesThermal Profiler HC-40 60 80 12 ChannelWade DyerPas encore d'évaluation

- Dxdiag FilesDocument23 pagesDxdiag FilesAnonymous P0MH7SdgqPas encore d'évaluation

- Ece-V-Information Theory & Coding (10ec55) - AssignmentDocument10 pagesEce-V-Information Theory & Coding (10ec55) - AssignmentLavanya Vaishnavi D.A.Pas encore d'évaluation

- Operating Manual: Signal Converter SSI - Analog / SerialDocument30 pagesOperating Manual: Signal Converter SSI - Analog / SerialDiana MIND AmayaPas encore d'évaluation

- Lg+29ln450b,+450u,+457b,+457u+ch +la31r+led+tvDocument35 pagesLg+29ln450b,+450u,+457b,+457u+ch +la31r+led+tvСтоян ДимитровPas encore d'évaluation

- Damien Elite C-7Document3 pagesDamien Elite C-7m43238Pas encore d'évaluation

- Kirisun PT8100-Service-ManualDocument35 pagesKirisun PT8100-Service-ManualRobertino100% (1)

- Manual: Installation & UserDocument39 pagesManual: Installation & UserAthan CruzPas encore d'évaluation

- Fx5u Pid Control Function PDFDocument38 pagesFx5u Pid Control Function PDFNutchaiSaengsurathamPas encore d'évaluation

- MKT053 Fa22-2300 MadrasDocument2 pagesMKT053 Fa22-2300 MadrasrawassatPas encore d'évaluation

- A 77 GHZ Cmos Low Noise Amplifier For Automotive Radar ReceiverDocument3 pagesA 77 GHZ Cmos Low Noise Amplifier For Automotive Radar ReceiverJeong-geun KimPas encore d'évaluation

- May 2003 Ray Marston - Understanding and Using OTA OP-AmpsDocument5 pagesMay 2003 Ray Marston - Understanding and Using OTA OP-AmpsFederico CirelliPas encore d'évaluation

- 27011054-Wall Mount Antenna Datasheet (HADA-07091827-N-586-O) DatasheetDocument1 page27011054-Wall Mount Antenna Datasheet (HADA-07091827-N-586-O) DatasheetСергей МирошниченкоPas encore d'évaluation

- THX Design Process2Document3 pagesTHX Design Process2Christian Ivan PolloPas encore d'évaluation

- ISC 2013 Physics Paper 1 Theory Solved Paper PDFDocument30 pagesISC 2013 Physics Paper 1 Theory Solved Paper PDFeltytanPas encore d'évaluation

- Sony CDX-G3100UE, G3100UV, G3150UP, G3150UV PDFDocument38 pagesSony CDX-G3100UE, G3100UV, G3150UP, G3150UV PDFboroda2410Pas encore d'évaluation

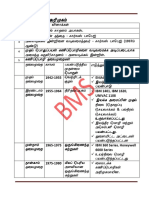

- 11th Computer Science Question Bank Volume 1 Tamil MediumDocument49 pages11th Computer Science Question Bank Volume 1 Tamil MediumSathish Julius100% (1)

- Belden Fieldbus CablesDocument4 pagesBelden Fieldbus CablesprogradePas encore d'évaluation

- CSS 8 Hazard and RiskDocument56 pagesCSS 8 Hazard and RiskPEMAR ACOSTA0% (1)