Académique Documents

Professionnel Documents

Culture Documents

Lifting LUG Exercise-1

Transféré par

toshicrystalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lifting LUG Exercise-1

Transféré par

toshicrystalDroits d'auteur :

Formats disponibles

E410 Design - Lifting Lug and Bracket - Prof. D.

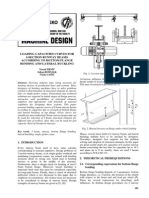

Andrews - January 2008 Introduction During manufacture it is often necessary to lift and move large objects between machining operations. Sometimes this involves an overhead crane, and a sling or lifting attachments would be employed. For safety reasons, such attachments are required to have a limit on the maximum load that can be applied (safe working load). Lifting Lug Design The large plate, shown in Figure 1 (page 2), is an example where a temporary lifting attachment is needed. The plate would ultimately be used with the attachment removed. One approach is to weld on a temporary attachment. The general form of the attachment, known as a lug, is given in Figure 1, but not dimensioned. The lug is welded to one face of the plate, half way along and centred on point A as shown in Figure 1. Lifting would be achieved by a lifting device (e.g. crane) connected to the pin inserted in the lug. Using the material data shown below, together with the plate dimensions given in Figure 1, dimension and give detailed calculations for: (a) The pin diameter (=D) (b) The lug dimensions (H, L, b) (c) The weld of the lug to the plate (A = weld area) Plate Steel Density = 7830 kg/m3 , Pin and lug Mild steel Yield stress = 200 MPa , Weld metal Yield stress = 195 MPa N.B. Other methods of lug design must not be used. Bracket Design If the plate were lifted directly from the pin through the lug then it would not hang vertically. This could make subsequent positioning of the plate for further operations more difficult. In order to avoid this inconvenient it may be important that the plate is lifted vertically. (d) Design a device (bracket) to allow vertical lifting of the plate. Detailed calculations are not required for this part of the exercise.

Stress Analysis For the shear stress in the pin, the tensile stress on the lug net section, the shear stress due to pin pull out from the lug, and the shear stress in the pin, use the following: Stress = Force / Area For pin bending: Extreme fibre stress = 32 M D 3 (2) where M is the bending moment calculated assuming that the pin is in three point bending, with the plate load applied at the centre of the lug, and reacted by the connections to the lifting device on each side of the lug, and D being the pin diameter. For the lug bending: Extreme fibre stress = 6M bd 2 (3) (1)

E410 - Exercise 1 - Deadline: 2 pm on 1st Feb. 08 - www.ucl.ac.uk/~ucemlca/E410 - 1/2

where M is the bending moment calculated using the distance from the pin centre to the plate surface, b is the lug thickness, and d is the lug height measured parallel to the plate. Hints Make the following assumptions: (a) The Tresca yield criterion is appropriate. (b) The safety factor is three. (c) The weld is a fillet weld with equal leg lengths. Use the following simplification: the plate would hang at an angle to the vertical, this makes calculations difficult. To simplify the analysis, carry out separate calculations for the two limiting cases: the full force being parallel to the plate and the full force being perpendicular to the plate. Check the following stresses in the order given. (a) In the pin. The shear stress. The extreme fibre stress due to pin bending. (b) In the lug, for the force in both directions. The tensile stress in the net section. The shear stress due to pin pull out on sections on either side of the pin from the centre line to the surface. (c) In the lug, for the force parallel to the plate. The extreme fibre stress due to lug bending. (d) In the weld connection, for the working load in both directions: perpendicular and parallel to the plate. The shear stress on the minimum area.

Figure 1 - Plate and lifting lug.

E410 - Exercise 1 - Deadline: 2 pm on 1st Feb. 08 - www.ucl.ac.uk/~ucemlca/E410 - 2/2

Vous aimerez peut-être aussi

- Eccentric ConnecctionsDocument41 pagesEccentric ConnecctionsShyam Suryawanshi100% (1)

- Design and analysis of an aerial scissor liftDocument4 pagesDesign and analysis of an aerial scissor liftBảo Toàn LêPas encore d'évaluation

- Hw1 Sol Fall 2015Document8 pagesHw1 Sol Fall 2015Ong Kok Meng100% (1)

- Knuckle Joint Design and Applications in TractorsDocument21 pagesKnuckle Joint Design and Applications in TractorsNelly Ad-apPas encore d'évaluation

- Take Home QuizDocument8 pagesTake Home QuizAshley SimmonsPas encore d'évaluation

- Me331-Design of Machine Elements Unit Iii Design of Fasteners and JointsDocument21 pagesMe331-Design of Machine Elements Unit Iii Design of Fasteners and JointsMuthuvel MPas encore d'évaluation

- MD Chap 1Document9 pagesMD Chap 1arugeetPas encore d'évaluation

- 6 Spring Back in Bending of Sheets and PlatesDocument5 pages6 Spring Back in Bending of Sheets and Platespkumar_824016Pas encore d'évaluation

- Torsion in Engineering StructuresDocument16 pagesTorsion in Engineering Structuresabouelrich188Pas encore d'évaluation

- Akshat DmeDocument38 pagesAkshat DmekartikeyPas encore d'évaluation

- Design Example of Reinforce Concrete BeamsDocument60 pagesDesign Example of Reinforce Concrete BeamsMario FrankistaPas encore d'évaluation

- Chapter09 (Shaft)Document70 pagesChapter09 (Shaft)Ganesh DongrePas encore d'évaluation

- PCI Journal Prestressed Poles JL 88 January February 3Document23 pagesPCI Journal Prestressed Poles JL 88 January February 3nagenol100% (1)

- Course Activity Sample ReportDocument10 pagesCourse Activity Sample ReporthimanshuPas encore d'évaluation

- ME302: Materials Mechanics: Chap. 1 Stress (3) Chap. 2 StrainDocument24 pagesME302: Materials Mechanics: Chap. 1 Stress (3) Chap. 2 StrainMat MatttPas encore d'évaluation

- Lecture - 3Document17 pagesLecture - 3Chala Giduma WakjiraPas encore d'évaluation

- Machine Design Lec3Document75 pagesMachine Design Lec3sam0415Pas encore d'évaluation

- Mdid Lab ManualDocument48 pagesMdid Lab Manualjaimin777Pas encore d'évaluation

- Design of Column Base Plates and Steel Anchorage to ConcreteDocument31 pagesDesign of Column Base Plates and Steel Anchorage to Concretemonther_alsalkhadiPas encore d'évaluation

- Mechanics of Solids IntroductionDocument51 pagesMechanics of Solids IntroductionSatish DhanyamrajuPas encore d'évaluation

- T Fillet WeldsDocument26 pagesT Fillet WeldsserePas encore d'évaluation

- Cad & Component DrawingDocument36 pagesCad & Component DrawingkousikkumaarPas encore d'évaluation

- Chapter 2. Tension MemberDocument12 pagesChapter 2. Tension MemberaskannancvPas encore d'évaluation

- ES 13 Mechanics of Deformable Bodies Second Departmental Examination Samplex September 28, 2017 (6:00-8:00 PM) First Semester 2017-2018Document3 pagesES 13 Mechanics of Deformable Bodies Second Departmental Examination Samplex September 28, 2017 (6:00-8:00 PM) First Semester 2017-2018Carl Justin AzucenaPas encore d'évaluation

- Design Aids For Tension Members As Per Revised Is: 800-2007Document7 pagesDesign Aids For Tension Members As Per Revised Is: 800-2007dev_1989Pas encore d'évaluation

- Guided Tour: Chapter IntroductionDocument3 pagesGuided Tour: Chapter IntroductionJenny PricePas encore d'évaluation

- Chapter 1 - STRESS AND STRAIN PDFDocument34 pagesChapter 1 - STRESS AND STRAIN PDFnurul eryn100% (1)

- Power Screws Fasteners and Rivted Joints Mech 2011Document12 pagesPower Screws Fasteners and Rivted Joints Mech 2011Eslam Mohamed SayedPas encore d'évaluation

- Dos PPT 3Document33 pagesDos PPT 3Keerthana PPas encore d'évaluation

- 8/1/13 Beam Part 2Document50 pages8/1/13 Beam Part 2Macqui MaciasPas encore d'évaluation

- SOM Lecture 03Document25 pagesSOM Lecture 03tvkbhanuprakashPas encore d'évaluation

- An Analysis of Shear Stress in Beams of Various Cross SectionsDocument10 pagesAn Analysis of Shear Stress in Beams of Various Cross SectionsGaurav KumarPas encore d'évaluation

- Simple StressDocument50 pagesSimple StressIvan Manalang50% (4)

- 4 Tension MemberDocument15 pages4 Tension Memberhari1008108Pas encore d'évaluation

- Problem Sheet - 2 Topic: Stress Submission Date: 27/08/2019Document3 pagesProblem Sheet - 2 Topic: Stress Submission Date: 27/08/2019Beesam Ramesh KumarPas encore d'évaluation

- Tension MemberDocument75 pagesTension Memberalan saeed AbdulrahmanPas encore d'évaluation

- MECH56Document4 pagesMECH56Rakesh ReddyPas encore d'évaluation

- PPSC Past Paper MCQs of Civil EngineeringDocument101 pagesPPSC Past Paper MCQs of Civil Engineeringsalman khattak80% (5)

- Base Plate LSD SubramanianDocument20 pagesBase Plate LSD SubramanianShakil AkhterPas encore d'évaluation

- Structural Analysis of Crane Hook Cross SectionsDocument4 pagesStructural Analysis of Crane Hook Cross SectionsMohankumarPas encore d'évaluation

- Unit 1Document30 pagesUnit 1balachandran143Pas encore d'évaluation

- Chapter 4 Load Tables For Flexural Members and ConnectionsDocument72 pagesChapter 4 Load Tables For Flexural Members and ConnectionsLoh Chung TatPas encore d'évaluation

- Aspects of Wire DrawingDocument6 pagesAspects of Wire DrawingAjyant SuryaPas encore d'évaluation

- "Design of Jib Crane Type Rotating Derrick System" in EOT CRANE For Easy Lifting The Spare Parts During Heavy Maintenance in Confined SpaceDocument7 pages"Design of Jib Crane Type Rotating Derrick System" in EOT CRANE For Easy Lifting The Spare Parts During Heavy Maintenance in Confined SpaceijsretPas encore d'évaluation

- 181-186 For Web PDFDocument6 pages181-186 For Web PDFdiego.peinado8856100% (1)

- 1 Screw Rivet WeldDocument26 pages1 Screw Rivet WeldWajih RaziUddin100% (1)

- Stress document with normal, shear stress problemsDocument25 pagesStress document with normal, shear stress problemsmohanadymtPas encore d'évaluation

- Machine Design: Stress Concentration FactorsDocument30 pagesMachine Design: Stress Concentration FactorsM.HPas encore d'évaluation

- IV 4 Die Casting Force CalculationsDocument15 pagesIV 4 Die Casting Force CalculationsSatishkumar Adhikesavalu100% (6)

- Springs TextDocument0 pageSprings Texter_wenPas encore d'évaluation

- بحث الميتالDocument7 pagesبحث الميتالAhmed fahmyPas encore d'évaluation

- Pressure Vessel and Stacks Field Repair ManualD'EverandPressure Vessel and Stacks Field Repair ManualÉvaluation : 4 sur 5 étoiles4/5 (4)

- Mechanical Science for Technicians: Volume 1D'EverandMechanical Science for Technicians: Volume 1Évaluation : 5 sur 5 étoiles5/5 (1)

- Fatigue of Textile and Short Fiber Reinforced CompositesD'EverandFatigue of Textile and Short Fiber Reinforced CompositesPas encore d'évaluation

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsD'EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsPas encore d'évaluation

- Architectural Concept13Document2 pagesArchitectural Concept13toshicrystalPas encore d'évaluation

- Architectural Concept12Document2 pagesArchitectural Concept12toshicrystalPas encore d'évaluation

- Architectural Concept11Document2 pagesArchitectural Concept11toshicrystalPas encore d'évaluation

- Architectural Concept5Document1 pageArchitectural Concept5toshicrystalPas encore d'évaluation

- Architectural Concept2Document2 pagesArchitectural Concept2toshicrystalPas encore d'évaluation

- Architectural Concept10Document1 pageArchitectural Concept10toshicrystalPas encore d'évaluation

- Architectural Concept9Document1 pageArchitectural Concept9toshicrystalPas encore d'évaluation

- Architectural Concept6Document1 pageArchitectural Concept6toshicrystalPas encore d'évaluation

- Architectural Concept8Document1 pageArchitectural Concept8toshicrystalPas encore d'évaluation

- Architectural Concept7Document2 pagesArchitectural Concept7toshicrystalPas encore d'évaluation

- Architectural Concept3Document2 pagesArchitectural Concept3toshicrystalPas encore d'évaluation

- Architectural Concept4Document2 pagesArchitectural Concept4toshicrystalPas encore d'évaluation

- Lion MeshDocument16 pagesLion MeshtoshicrystalPas encore d'évaluation

- My Poetry-2Document1 pageMy Poetry-2toshicrystalPas encore d'évaluation

- Architectural Concept1Document2 pagesArchitectural Concept1toshicrystalPas encore d'évaluation

- Dummy For DummyDocument1 pageDummy For DummytoshicrystalPas encore d'évaluation

- GF EulaDocument3 pagesGF EulatoshicrystalPas encore d'évaluation

- My Poetry-2Document1 pageMy Poetry-2toshicrystalPas encore d'évaluation

- Is The Virgin MaryDocument69 pagesIs The Virgin Marythinewill_bedone8055Pas encore d'évaluation

- GF EulaDocument3 pagesGF EulatoshicrystalPas encore d'évaluation

- Design Handbook Errata Sixth EditionDocument8 pagesDesign Handbook Errata Sixth Editioncezar0070% (1)

- My Poetry-1Document1 pageMy Poetry-1toshicrystalPas encore d'évaluation

- VIC Roads Design STD DWG (With AS5100)Document10 pagesVIC Roads Design STD DWG (With AS5100)toshicrystalPas encore d'évaluation

- GeotextilesDocument6 pagesGeotextilestoshicrystalPas encore d'évaluation

- Example 1-Special Moment FramesDocument16 pagesExample 1-Special Moment FramestoshicrystalPas encore d'évaluation

- Vapour BarrierDocument4 pagesVapour BarrierJeremy SenkoPas encore d'évaluation

- Is The Virgin MaryDocument69 pagesIs The Virgin Marythinewill_bedone8055Pas encore d'évaluation

- RPTP New (1) 2Document18 pagesRPTP New (1) 2toshicrystalPas encore d'évaluation

- Lifting LUG Exercise-1Document2 pagesLifting LUG Exercise-1toshicrystalPas encore d'évaluation

- Example Test (Session 11)Document3 pagesExample Test (Session 11)dhak shanPas encore d'évaluation

- Modifications of Conventional Rigid and Flexible Methods For Mat Foundation DesignDocument156 pagesModifications of Conventional Rigid and Flexible Methods For Mat Foundation Designapirakq100% (1)

- Problem 548Document14 pagesProblem 548mike jobernard f. solangonPas encore d'évaluation

- Design of Multi Storey Building Resting On Single ColumnDocument4 pagesDesign of Multi Storey Building Resting On Single Columnesatjournals100% (1)

- Ansys Explicit Dynamics Analysis GuideDocument280 pagesAnsys Explicit Dynamics Analysis GuidebuyukunludusunurPas encore d'évaluation

- Edsgn468 Section905 Syllabus sp18Document6 pagesEdsgn468 Section905 Syllabus sp18api-404403003Pas encore d'évaluation

- Solution CH1Document14 pagesSolution CH1meeraPas encore d'évaluation

- Product Brochure - 2021/2022 Edition: Delivering Global Engineered Solutions Since 1986Document10 pagesProduct Brochure - 2021/2022 Edition: Delivering Global Engineered Solutions Since 1986NisrinaFadhilaPas encore d'évaluation

- IC Engines Design Book PDFDocument19 pagesIC Engines Design Book PDFRohith FernandoPas encore d'évaluation

- How to fix STAAD.Pro warnings and errorsDocument5 pagesHow to fix STAAD.Pro warnings and errorsMohdDanishPas encore d'évaluation

- Biomechanics of Bone-Fracture Fixation by Stiffness-Graded Plates in Comparison With Stainless-Steel PlatesDocument16 pagesBiomechanics of Bone-Fracture Fixation by Stiffness-Graded Plates in Comparison With Stainless-Steel PlatesRENATO ALONSO PACHECO ROSALESPas encore d'évaluation

- Drillstring With Aluminum Alloy Pipes Design and Practices: February 2003Document13 pagesDrillstring With Aluminum Alloy Pipes Design and Practices: February 2003ام عدنانPas encore d'évaluation

- Tip ReliefDocument12 pagesTip ReliefShriyaAgarwalPas encore d'évaluation

- For Minor ProjectDocument42 pagesFor Minor ProjectSayan DasPas encore d'évaluation

- Worked Examples CompositebeamDocument9 pagesWorked Examples Compositebeamthongchai_007Pas encore d'évaluation

- Din - 4150 3 1999Document11 pagesDin - 4150 3 1999Hidelbrando Diógenes86% (7)

- Assignment 2 2021Document3 pagesAssignment 2 2021jonPas encore d'évaluation

- Steel Design Problem SetxzDocument35 pagesSteel Design Problem SetxzMiah N. PascualPas encore d'évaluation

- Aerospace Science and Technology: A. Viglietti, E. Zappino, E. CarreraDocument12 pagesAerospace Science and Technology: A. Viglietti, E. Zappino, E. CarreraAngel FajmPas encore d'évaluation

- Solid Shell Finite Elements For Quasi-Static and Dynamic Analysis of 3D Thin Structures: Application To Sheet Metal Forming ProcessesDocument218 pagesSolid Shell Finite Elements For Quasi-Static and Dynamic Analysis of 3D Thin Structures: Application To Sheet Metal Forming ProcessesHako KhechaiPas encore d'évaluation

- Design Calculations For The Dome Structure-Type 1Document6 pagesDesign Calculations For The Dome Structure-Type 1msiddiq1100% (2)

- UNIT LOAD METHOD TITLEDocument53 pagesUNIT LOAD METHOD TITLEkennypennyPas encore d'évaluation

- Lecture 9.5 - Stressed Skin DesignDocument21 pagesLecture 9.5 - Stressed Skin DesignsoulsellPas encore d'évaluation

- Short Note of SOMDocument17 pagesShort Note of SOMabrouf576Pas encore d'évaluation

- Reportbakker PDFDocument203 pagesReportbakker PDFShaileshRastogiPas encore d'évaluation

- Reinforced Concrete Design GuideDocument81 pagesReinforced Concrete Design Guidemysterium slayer100% (1)

- HDD Pipeline Design OptimizationDocument15 pagesHDD Pipeline Design Optimizationoconnorr8133% (3)

- Concrete For StartersDocument38 pagesConcrete For StartersUmpahPah75Pas encore d'évaluation

- Instant Download Ebook PDF 2018 International Building Code Illustrated Handbook by International Code PDF ScribdDocument41 pagesInstant Download Ebook PDF 2018 International Building Code Illustrated Handbook by International Code PDF Scribdfred.rivera829100% (43)