Académique Documents

Professionnel Documents

Culture Documents

S52 - Research Update Testing and Analysis of LWT and SCB Properties of Asphaltic Concrete Mixtures - LTC2013

Transféré par

walaywanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

S52 - Research Update Testing and Analysis of LWT and SCB Properties of Asphaltic Concrete Mixtures - LTC2013

Transféré par

walaywanDroits d'auteur :

Formats disponibles

Testing and Analysis of LWT and SCB Properties of Asphaltic Concrete Mixtures

Samuel Cooper III

Louisiana Transportation Conference February 18 - 20, 2013 Baton Rouge, Louisiana

Acknowledgements

LTRC Asphalt Research Group

Jeremy Icenogle, Patrick Frazier, Willie Gueho, Md. Kabir, Bill King

Introduction

LADOTDs current QA/QC practice relies upon:

Gradation

AC Content VFA, VMA, % Air Voids

Moisture Susceptibility Test (Modified Lottman), and

Roadway Parameters: Density, Smoothness

But these volumetric properties are not adequate to reflect the pavement performance in the field. Must develop methods to evaluate pavement performance indicators

Introduction

New laboratory tests are required to evaluate the as-built pavement qualities. The test will screen materials prone to rutting, cracking and alternative moisture damage indicators.

Create a Balanced Mixture Design

Introduction

What is a balanced mixture design?

Process to ensure adequate resistance to rutting and cracking distress

Rutting: Loaded Wheel Tracking (LWT) Test Cracking: Semi-Circular Bend (SCB) Test

Volumetric Parameters

Two laboratory tests are proposed:

1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 0 0

Cracking Resistance

High Temperature Performance

Cracking Performance

10 15 Rutting Resistance

20

Research Objective

To implement the Loaded Wheel Tracking (LWT) test as a measure of mixture rutting resistance. To evaluate a simplified Semi-Circular Bend (SCB) tests as an end result parameter for intermediate temperature cracking resistance.

Rutting

Cracking

Laboratory Experiment: LWT Test

Performance Indicator

Resistance to Rutting and Moisture Sensitivity

Test Protocol

AASHTO T324

Temperature

50C

Loading

Wheel Diameter: 203.5 mm (8 inch) Wheel Width: 47mm (1.85 inch) Fixed Load: 703 N (158 lbs) Rolling Speed: 1.1 km/hr Passing Rate: 52 passes/min

Laboratory Experiment: LWT Test

Performance Indicators

Resistance to Rutting and Moisture Sensitivity

Rutting Indicator: Plot Rut Depth vs Number of Passes Report Rut Depth at

1000, 5000, 7500, 10000, 15000, and 20000 Passes

Moisture Sensitivity Indicator Determine Stripping Inflection Point

The point where slope of the line begins to steepen

Laboratory Experiment: SCB Test

Performance Indicator

Resistance to Crack Propagation

Test Protocol

Mohammad et al. [2004]

Temperature

25C

Loading

0.5 mm/min vertical deformation

P

The Critical Value of Fracture Resistance,

Jc 1 dU ( ) b da

a notch P 2 2s 2rd P 2 b

b = sample thickness, a = notch depth, U = strain energy to failure

SCB Sample Preparation

150mm x 57mm

Laboratory Experiment: Conventional SCB Test

Servo Hydraulic Test System Environmental Chamber Expensive Complicated Deformation

Load

Laboratory Experiment: Modified SCB Test

Load

Force (Kn)

0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 0.5 1 1.5 2 2.5 3

Original Data Max of Data set Fitted Curve Peak of Curve

Deformation

Length(mm)

J c (

1 dU ) b da

Laboratory Experiment: Modified SCB Test

Laboratory Experiment: Modified SCB Test

Laboratory Experiment: Modified SCB Test

0.7 0.6 0.5

Original Data Max of Data set Fitted Curve Peak of Curve

Force (Kn)

0.4 0.3 0.2 0.1 0 0 0.5 1 1.5 2 2.5 3

Length(mm)

J c (

1 dU ) b da

*Temperature is controlled using an external environmental chamber

Analysis: Loaded Wheel Tester

90%!

Volumetric Parameters

Level 1 Level 2

High Temperature Performance

Cracking Performance

Preliminary Analysis: Semi-Circular Bend

42%

58%

72%

0%

Volumetric Parameters

High Temperature Performance

Cracking Performance

Preliminary Analysis: Balanced Design

Level 2

Level 1

50%

Volumetric Parameters

High Temperature Performance

Cracking Performance

Preliminary Analysis: Balanced Design

Level 1

50%

Volumetric Parameters

High Temperature Performance

Cracking Performance

How do we get there?

A system to conduct mechanical property test to determine the anticipated performance of asphalt mixtures is needed LTRC has been using LWT and SCB test as forensics investigative tools and performance indicators. Incorporate tests into state specification compliance evaluation.

Develop a simplified SCB test procedure.

Adapt SCB test to a commonly used load frames

Must control TEMPERATURE!

How do we get there?

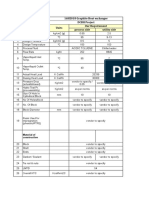

1.5 inch (37.5 Nominal Max., Size Agg. SMA mm) Incidental Wearing Base Base Type of Mix Wearing Course Binder Course Binder Course ATB Wearing Paving Course Course Course Level A 1 2 2 1 2 1 2 1 1 1 2 Asphalt Binder Table 502-2, (3% minimum for Asphalt Treated base (ATB), 6% min for SMA) Friction Rating Table 502-3 RAP, Max. % of Mix 20 15 15 15 20 20 20 20 30 30 30 0 Compacted Mix Volumetrics 4 VMA, Min. % 13.0 13.0 13.0 12.0 12.0 12.0 11.0 11.0 11.0 n/a 10.5 16.0 Air Voids, % (2.5-4.5);; (no limit for ATB) VFA, % (69-80); no limit for ATB Ninitial 90% max. (Gyrations) 7 7 7 7 7 7 7 7 7 n/a 7 7 Ndesign 96.51 % (Gyrations) 65 65 75 75 65 75 65 75 65 30 65 65 Nmax 98 % max. (Gyrations) 100 100 115 115 100 115 100 115 100 n/a 100 100 LWT, max. rut-design, mm 10 @ 10 @ 6@ 6@ 10 @ 6 @ 10 @ 6 @ 12 @ 10 12 @ 6@ @ # passes, 10,000 20,000 20,000 20,000 20,000 20,000 20,000 20,000 20,000 @10,000 20,000 20,000 @ 50 C Dust/Effective Asphalt 0.6 1.6 Ratio, % 2.01.52.0 1.52.0 2.03.0 2.54.0 2.5+ 3.0+ 4.0+ 1.5-2.0 Lift Thickness, inch (mm) (50-) (38-50) (38-50) (50-75) (65-100) (65+) (75+) (100+) (38-50) 0.5 inch (12.5 mm) 0.75 inch (19 mm) 1.0 inch (25 mm)

How do we get there?

1.5 inch (37.5 Nominal Max., Size Agg. SMA mm) Incidental Wearing Base Base Type of Mix Wearing Course Binder Course Binder Course ATB Wearing Paving Course Course Course Level A 1 2 2 1 2 1 2 1 1 1 2 Asphalt Binder Table 502-2, (3% minimum for Asphalt Treated base (ATB), 6% min for SMA) Friction Rating Table 502-3 RAP, Max. % of Mix 20 15 15 15 20 20 20 20 30 30 30 0 Compacted Mix Volumetrics 4 VMA, Min. % 13.0 13.0 13.0 12.0 12.0 12.0 11.0 11.0 11.0 n/a 10.5 16.0 Air Voids, % (2.5-4.5);; (no limit for ATB) VFA, % (69-80); no limit for ATB Ninitial 90% max. (Gyrations) 7 7 7 7 7 7 7 7 7 n/a 7 7 Ndesign 96.51 % (Gyrations) 65 65 75 75 65 75 65 75 65 30 65 65 Nmax 98 % max. (Gyrations) 100 100 115 115 100 115 100 115 100 n/a 100 100 LWT, max. rut-design, mm 10 @ 10 @ 6 @ 6@ 10 @ 6 @ 10 @ 6 @ 12 @ 10 12 @ 6@ @ # passes, 10,000 20,000 20,000 20,000 20,000 20,000 20,000 20,000 20,000 @10,000 20,000 20,000 @ 50 C Dust/Effective Asphalt 0.6 1.6 Ratio, % 2.01.52.0 1.52.0 2.03.0 2.54.0 2.5+ 3.0+ 4.0+ 1.5-2.0 Lift Thickness, inch (mm) (50-) (38-50) (38-50) (50-75) (65-100) (65+) (75+) (100+) (38-50) 0.5 inch (12.5 mm) 0.75 inch (19 mm) 1.0 inch (25 mm)

Whats Next?

Continued evaluation of the SCB test

Validate Jc criteria for mixture design

Communicate with other on-going research projects: 10-4B

Whats Next?

Thank You!

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- ASTM Pumping TestDocument125 pagesASTM Pumping TestErnesto Heinze100% (1)

- Oisd STD-141Document31 pagesOisd STD-141Jyotsana Rawat83% (6)

- LTRC Technical Summary 660 Evaluation of Asphalt Rubber and Reclaimed Tire Rubber in Chip Seal ApplicationsDocument2 pagesLTRC Technical Summary 660 Evaluation of Asphalt Rubber and Reclaimed Tire Rubber in Chip Seal ApplicationswalaywanPas encore d'évaluation

- TS - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDDocument2 pagesTS - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDwalaywanPas encore d'évaluation

- TS - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDDocument2 pagesTS - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDwalaywanPas encore d'évaluation

- FR - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDDocument184 pagesFR - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDwalaywanPas encore d'évaluation

- LTRC Technical Summary 663 Feasibility and Performance of Low-Volume Roadway Mixture DesignDocument2 pagesLTRC Technical Summary 663 Feasibility and Performance of Low-Volume Roadway Mixture DesignwalaywanPas encore d'évaluation

- FR - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDDocument184 pagesFR - 680 For LTRC 23-1ST MASH TL-4 Engineering Analyses and Detailing of 36-Inch and 42-Inch High Median Barriers For LADOTDwalaywanPas encore d'évaluation

- LTRC 22-1ST Technical Summary Investigating and Developing A MASH Compliant Contraflow Ramp Closure GateDocument2 pagesLTRC 22-1ST Technical Summary Investigating and Developing A MASH Compliant Contraflow Ramp Closure GatewalaywanPas encore d'évaluation

- LTRC 22-1ST Technical Summary Investigating and Developing A MASH Compliant Contraflow Ramp Closure GateDocument2 pagesLTRC 22-1ST Technical Summary Investigating and Developing A MASH Compliant Contraflow Ramp Closure GatewalaywanPas encore d'évaluation

- LTRC 07-1ST FR 529 Structural Health Monitoring of I-10 Twin Span BridgeDocument185 pagesLTRC 07-1ST FR 529 Structural Health Monitoring of I-10 Twin Span BridgewalaywanPas encore d'évaluation

- FR - 643 LTRC 20-2ST Skew Detection System Replacement On Vertical Lift BridgesDocument44 pagesFR - 643 LTRC 20-2ST Skew Detection System Replacement On Vertical Lift BridgeswalaywanPas encore d'évaluation

- TS - 643 LTRC 20-2ST Skew Detection System Replacement On Vertical Lift BridgesDocument2 pagesTS - 643 LTRC 20-2ST Skew Detection System Replacement On Vertical Lift BridgeswalaywanPas encore d'évaluation

- Ts 609Document2 pagesTs 609walaywanPas encore d'évaluation

- LTRC 22-1ST Final Report No. 665 Investigating and Developing A MASH Compliant Contraflow Ramp Closure GateDocument33 pagesLTRC 22-1ST Final Report No. 665 Investigating and Developing A MASH Compliant Contraflow Ramp Closure GatewalaywanPas encore d'évaluation

- Technical Summary 658 LTRC 16-1ST Retrofit of Existing Statewide Louisiana Safety Walk Bridge Barrier Railing SystemsDocument2 pagesTechnical Summary 658 LTRC 16-1ST Retrofit of Existing Statewide Louisiana Safety Walk Bridge Barrier Railing SystemswalaywanPas encore d'évaluation

- Volume04 AASHTODocument281 pagesVolume04 AASHTOsayedPas encore d'évaluation

- AASHTO Steel Bridge Design Handbook Volume 10Document18 pagesAASHTO Steel Bridge Design Handbook Volume 10walaywanPas encore d'évaluation

- LTRC 22-1ST Final Report No. 665 Investigating and Developing A MASH Compliant Contraflow Ramp Closure GateDocument33 pagesLTRC 22-1ST Final Report No. 665 Investigating and Developing A MASH Compliant Contraflow Ramp Closure GatewalaywanPas encore d'évaluation

- ASCE (06) Stringer Bridge PDFDocument33 pagesASCE (06) Stringer Bridge PDFShaileshRastogiPas encore d'évaluation

- Steel Bridge Design Handbook: Loads and Load CombinationsDocument22 pagesSteel Bridge Design Handbook: Loads and Load CombinationsmtPas encore d'évaluation

- Steel Bridge Design Handbook: Structural AnalysisDocument55 pagesSteel Bridge Design Handbook: Structural AnalysisAsgharPas encore d'évaluation

- Volume03 PDFDocument42 pagesVolume03 PDFmtPas encore d'évaluation

- Volume02 PDFDocument33 pagesVolume02 PDFmtPas encore d'évaluation

- Bridge Steels and Their Mechanical Properties PDFDocument55 pagesBridge Steels and Their Mechanical Properties PDFabou92Pas encore d'évaluation

- AASHTO Steel Bridge Design Handbook Volume 09Document23 pagesAASHTO Steel Bridge Design Handbook Volume 09walaywanPas encore d'évaluation

- AASHTO Steel Bridge Design Handbook Volume 05Document27 pagesAASHTO Steel Bridge Design Handbook Volume 05walaywanPas encore d'évaluation

- TS 619Document2 pagesTS 619walaywanPas encore d'évaluation

- FR 609 LTRC 13-2ST Live Load Monitoring of The I-10 Twin Span BridgeDocument150 pagesFR 609 LTRC 13-2ST Live Load Monitoring of The I-10 Twin Span BridgewalaywanPas encore d'évaluation

- Trenchless Rehabilitation Technologies For Storm Water CulvertsDocument28 pagesTrenchless Rehabilitation Technologies For Storm Water CulvertswalaywanPas encore d'évaluation

- FR 619 LTRC 18-5STInvestigating Available State-Of-The-Art Technology For Determining Needed Information For BridgeDocument189 pagesFR 619 LTRC 18-5STInvestigating Available State-Of-The-Art Technology For Determining Needed Information For BridgewalaywanPas encore d'évaluation

- Latest Advances in Large Span Burried StructuresDocument128 pagesLatest Advances in Large Span Burried StructureswalaywanPas encore d'évaluation

- Power GenerationDocument34 pagesPower GenerationTaufiq AkbarPas encore d'évaluation

- SPIN-Energy Efficiency & Urban Development PlanningDocument45 pagesSPIN-Energy Efficiency & Urban Development PlanningEvropski Projekti Savski VenacPas encore d'évaluation

- Texture Formats Used by CFS3Document2 pagesTexture Formats Used by CFS3Hillmen HussinPas encore d'évaluation

- Campus Invitation Letter - Sample 2Document1 pageCampus Invitation Letter - Sample 2sitaram shindePas encore d'évaluation

- The Mpeg Dash StandardDocument6 pagesThe Mpeg Dash Standard9716755397Pas encore d'évaluation

- Civil Engineering Interview QuestionsDocument12 pagesCivil Engineering Interview Questionsjadgug100% (1)

- Thinker Thought Sara HendrenDocument1 pageThinker Thought Sara HendrenNathaniel RiversPas encore d'évaluation

- Research Paper On Plate Heat Exchanger PDFDocument8 pagesResearch Paper On Plate Heat Exchanger PDFc9s9h7r7100% (1)

- Government Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesDocument18 pagesGovernment Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesVK DPas encore d'évaluation

- Based On CIRIA Report 108:1985: Formwork Load Calculator - ResultsDocument4 pagesBased On CIRIA Report 108:1985: Formwork Load Calculator - Resultsyassir dafallaPas encore d'évaluation

- BOQ Gas PipingDocument2 pagesBOQ Gas PipingAbu ZakaPas encore d'évaluation

- Instrumentation For Measurement of Roof Convergence in Coal MinesDocument9 pagesInstrumentation For Measurement of Roof Convergence in Coal MinessamratPas encore d'évaluation

- Characterization and Application of Cerium Fluoride Film in InfraredDocument4 pagesCharacterization and Application of Cerium Fluoride Film in InfrarednguyenthanhhopPas encore d'évaluation

- Grade 2 SasmoDocument8 pagesGrade 2 SasmoThích Toán HọcPas encore d'évaluation

- Casting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HDocument1 pageCasting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HCarlos Ediver Arias RestrepoPas encore d'évaluation

- 1169a AopDocument12 pages1169a AopBAYARD BernardPas encore d'évaluation

- After12th FinalDocument114 pagesAfter12th FinaltransendencePas encore d'évaluation

- TD Operation MaintenanceDocument51 pagesTD Operation MaintenanceHassam Ahmad100% (1)

- Phone Genesys ConfigurationDocument22 pagesPhone Genesys ConfigurationRodolfo TobiasPas encore d'évaluation

- Thesis FYPDocument50 pagesThesis FYPEyka ZulaikaPas encore d'évaluation

- 29 Oct. To 4 Nov. 211Document16 pages29 Oct. To 4 Nov. 211pratidinPas encore d'évaluation

- Pumps: Vane Type Single PumpsDocument2 pagesPumps: Vane Type Single PumpsFernando SabinoPas encore d'évaluation

- Comparative Analysis of Wear Rate of Coated Hss Tool and Non-Coated Hss Tool by Using Cr-Zn-NiDocument21 pagesComparative Analysis of Wear Rate of Coated Hss Tool and Non-Coated Hss Tool by Using Cr-Zn-Nithai avvaiPas encore d'évaluation

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pages16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaPas encore d'évaluation

- Artificial LightingDocument7 pagesArtificial Lightingkookie maePas encore d'évaluation

- 8bit Microprocessor Using VHDLDocument16 pages8bit Microprocessor Using VHDLTanu Newar0% (2)

- KPODocument18 pagesKPOjohnrichardjasminePas encore d'évaluation

- PowerMaxExpress V17 Eng User Guide D-303974 PDFDocument38 pagesPowerMaxExpress V17 Eng User Guide D-303974 PDFSretenPas encore d'évaluation