Académique Documents

Professionnel Documents

Culture Documents

DSSV SDM

Transféré par

vishnunair27Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DSSV SDM

Transféré par

vishnunair27Droits d'auteur :

Formats disponibles

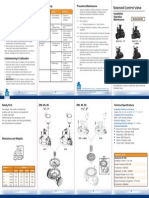

INTRODUCTION : At Reliance Jamnagar Model 1815/1830, Daniel make digital set stop valves have been used for

r loading operation control and accurate product filling in truck tankers and wagons. Digital set stop valve has many benefits compared to normal on/off or plug type control valves. These are, FEATURE Positive shut off Smooth transition Adjustable opening speed Adjustable closing speed Low pressure drop Tight piston seal All seals PTFE ( Teflon ) Bonnet can be rotated Piston cylinder fill and drain port Seal cleaning integral strainer Easy service Fail safe operation Internal thermal relief BENEFIT Prevents leaks, product loss From closed to initial flow or vice versa prevents slamming and low flow chatter With rampup prevents static charge buildup as flow starts With rampdown prevents hydraulic line shock ( water hammer effect ) save energy, allows using a smaller pump means valve will hold position without electrical signals for maximum wear protection and wide application of the valve to match flow direction and wide application of the valve allows collected water, air and debries to be flushed out no maintenance, uses aerodynamic shape for total cleaning because design allows access to internals without removing valve from line Internal spring assures that valve will cose if line pressure and/or electrical power is lost, or for emergency shutdown ( ESD ) service Valve design provides inherent downstream thermal relied to upstream at no extra cost.

Typical Applications : Typical applications include : Loading / Unloading at terminals truck, rail, pipeline, storage, tankers/barges Pipeline flow control hydrocarbons, paints, resins, solvents, breweries, power plants, paper, marine and other industries Skid mounted metering/control units Blending and mixing Emergency shutdown (ESD ) Hi- level shutdown to prevent overfill Material of construction : DESCRIPTION Valve body Valve cover Valve seat Spring, stem, stem nut Poppet, poppet guide Poppet seal MATERIAL Cast steel Cast steel Cast steel Stainless steel Aluminium Graphic impregnated Teflon ( PTFE )

Model 1815/1830 Valve Operation : The Daniel Model 1815/1830 valve is intended for use with liquids only ( no gases ) . It must be hydraulically packed at all times with positive pressure at the upstream inlet; it is not designed to operate on the suction or negative pressure side of the pump. It should be installed on the discharge side of a pump for proper operation and/or downstream of a meter so that the meter will be kept full of product for best metering accuracy. For maintenance and safety, manual isolation valves should be installed upstream and downstream of the model 1815/1830 valve, strainer, air eliminator, and/or meter. All equipment must be installed and used in accordance with all applicable codes and regulations, including NFPA # 30 and 70. The valve closes securely when a Teflon valve disc seals against the seat machined in the valve body. A tapered cone extending below the sealing surface has scooped out scallops which alter the flow pattern just as the valve closes or initially opens. They provide a smooth transition between flowing and non flowing conditions and eliminate chatter of the valve at very low flow rates. Balanced Piston Operation : Pl. refer Model 1815/1830 Digital flow control valve manual section 2.1. Spring loaded piston seal operation : Pl. refer Model 1815/1830 Digital flow control valve manual section 2.2. Automatic Internal Thermal relief : Pl. refer Model 1815/1830 Digital flow control valve manual section 2.3. Pressure Drop across the valve Calculation : refer Model 1815/1830 Digital flow control valve manual section 2.4. Digital control : Pl. refer Model 1815/1830 Digital flow control valve manual section 6.2. Back pressure control ( LPG service ) : Pl. refer Model 1815/1830 Digital flow control valve manual section 6.3. Two stage control valve operation : Pl. refer Model 1815/1830 Digital flow control valve manual section 6.4.

Installation : In order to insure safe, accurate and efficient operation of the DSSV, the following list of checkpoints and procedures should be followed when installing the valve. 1. Make a careful visual inspection of the valve to insure that there has been no damage to the external piping, fittings or controls. Check that all fittings are tight. 2. Thoroughly flush all interconnection piping of chips, scale and foreign matter prior to mounting the valve. 3. Install the valve in line according to the flow arrow marked on the inlet flange. The arrow should point downstream flow direction. 4. Allow sufficient room around the valve for ease of adjustment and maintenance. 5. Both needle valve should be in fully open position.

Maintenance : The DSSV requires no lubrication and minimum maintenance. However a peridic inspection should be established to determine how the fluid being handled is affecting the efficiency of the valve. Valve interior inspection is recommended to check the foreign patricals on valve seat anf PTFE gasket. This may lead to leakage through valve piston. In all case this warn out parts should be replaced with new one. Pl. refer Maintenance check sheet for checking all the valve accessories.

Troubleshooting : PROBLEM Valve opens too slowly,or will not open SOLUTION DSSV needle valve adjustment 1. Counter clockwise will speed valve opening 2. Clockwise will slow down the valve opening 3. Needle valve in fully closed condition will not allow valve to open. DSSV needle valve adjustment 1. Counter clockwise will speed valve opening 2. Clockwise will slow down the valve opening 3. Needle valve in fully closed condition will not allow valve to open. Recommended spares required before opening the valve No clicks form the solenoids Ball seal damaged or wore Check highflow, lowflow parameters Down stream Normally closed SOV not holding Close downstream needle valve and check if leak stops Teflon disc on poppet bottom is damaged Ball seal, valve disc, Teflon seal Body top gasket Check connections Check the resistance values of SOVs.

Valve closing too fast, or will not close

Solenoid valve chattering Valve will not seal

Vous aimerez peut-être aussi

- CROWN Esd Brochure Usa 3 2Document4 pagesCROWN Esd Brochure Usa 3 2Ahmed Ayman Yassin100% (1)

- Training Valves FAINAL 2013 AugustDocument6 pagesTraining Valves FAINAL 2013 Augustwidada007Pas encore d'évaluation

- Control Valve CharacteristicsDocument9 pagesControl Valve CharacteristicsSiddhartha SharmaPas encore d'évaluation

- Valves Gate DamperDocument54 pagesValves Gate DamperLalit MeenaPas encore d'évaluation

- Fluidtecq: Operation and Maintenance ManualDocument18 pagesFluidtecq: Operation and Maintenance ManualmehtahemalPas encore d'évaluation

- Rev F AvantaPure Logix 268 Owners Manual 3-31-09Document46 pagesRev F AvantaPure Logix 268 Owners Manual 3-31-09intermountainwaterPas encore d'évaluation

- Penguin - Magnetic Drive Pump M SeiresDocument4 pagesPenguin - Magnetic Drive Pump M SeiresMiguel Angel LòpezPas encore d'évaluation

- Claval PRV TM-90-01Document30 pagesClaval PRV TM-90-01DuxToyPas encore d'évaluation

- 278 Manual de Operaciones 764Document40 pages278 Manual de Operaciones 764AntonioDanielHernandezEspinoPas encore d'évaluation

- Water Distribution ValvesDocument35 pagesWater Distribution ValvesAbdullah ObeidatPas encore d'évaluation

- Standard Gate Valves ManualDocument8 pagesStandard Gate Valves ManualmechanikyPas encore d'évaluation

- DTC Marcopolo ManualDocument51 pagesDTC Marcopolo ManualAnurag SharmaPas encore d'évaluation

- 3B - Inst - Control ValveDocument31 pages3B - Inst - Control ValveMystic AamirPas encore d'évaluation

- In-Line Hydraulic TesterDocument5 pagesIn-Line Hydraulic TesterMasterrPas encore d'évaluation

- Control Valve - Theory & SizingDocument32 pagesControl Valve - Theory & SizingAmanda Porter100% (1)

- ValvesDocument44 pagesValvesأحمد محمد قدريPas encore d'évaluation

- CV Training InstDocument21 pagesCV Training Instxentrer100% (1)

- Control Valve PresentDocument120 pagesControl Valve PresentShoeb Ali KhanPas encore d'évaluation

- 1063 Forged Brass Spring Check ValveDocument5 pages1063 Forged Brass Spring Check ValveSyed FazluPas encore d'évaluation

- Ball Valve BrochureDocument6 pagesBall Valve BrochureRohith GrandhiPas encore d'évaluation

- Thermo Valves Corporation: Scuba Diving Valves Maintenance ManualDocument24 pagesThermo Valves Corporation: Scuba Diving Valves Maintenance ManualCarlos Arturo Martinez SalcedoPas encore d'évaluation

- Atmospheric Relief Valve ManualDocument12 pagesAtmospheric Relief Valve ManualTarun ChandraPas encore d'évaluation

- Typical Module Maintenance Schedule - Turbine MeteredDocument1 pageTypical Module Maintenance Schedule - Turbine MeteredRindu Putra AmbaritaPas encore d'évaluation

- Trainer GuideDocument16 pagesTrainer GuideCrystal DavisPas encore d'évaluation

- Control ValveDocument39 pagesControl Valveryukyu100% (1)

- Sur - Flo Turbine MeterDocument40 pagesSur - Flo Turbine MeterCheng HuangPas encore d'évaluation

- Operating Manual: Altronic Gas Control Valve, 690210Document12 pagesOperating Manual: Altronic Gas Control Valve, 690210Esau Jose PabloPas encore d'évaluation

- Safety Valves For Power PlantDocument56 pagesSafety Valves For Power Planttek_surinder100% (1)

- Contorl ValvesDocument8 pagesContorl ValvesGaurav MishraPas encore d'évaluation

- Es Acv M115F M1115FDocument4 pagesEs Acv M115F M1115FWattsPas encore d'évaluation

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 pagesInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasPas encore d'évaluation

- Valves Details and UsageDocument72 pagesValves Details and UsageKagira Drawing Soltuion100% (1)

- LPG MultivalvesDocument55 pagesLPG MultivalvesAPIPas encore d'évaluation

- Automatic Recirculation Valve BrochureDocument12 pagesAutomatic Recirculation Valve BrochureYuvaraj NithyanandamPas encore d'évaluation

- Anupam Catalouge Check Valve SelectionDocument7 pagesAnupam Catalouge Check Valve Selectionsunil bajpaiPas encore d'évaluation

- Control ValvesDocument38 pagesControl ValvesAmol PawarPas encore d'évaluation

- CSeal - DBBV Catalogue PDFDocument16 pagesCSeal - DBBV Catalogue PDFkentchoyPas encore d'évaluation

- Vane Presiune DN40 - DN250Document28 pagesVane Presiune DN40 - DN250iza66bellPas encore d'évaluation

- VAAS Fig 740 and 730 Series IOMDocument9 pagesVAAS Fig 740 and 730 Series IOMCarlos GutierrezPas encore d'évaluation

- Resol FlowSol B Installation ManualDocument8 pagesResol FlowSol B Installation ManualDan JungPas encore d'évaluation

- Super Choke BasicsDocument10 pagesSuper Choke BasicsTg TarroPas encore d'évaluation

- Smith MN 01011Document8 pagesSmith MN 01011John UrdanetaPas encore d'évaluation

- l3070 e 0Document128 pagesl3070 e 0Riki NurzamanPas encore d'évaluation

- KBR T407-3 Manual PDFDocument12 pagesKBR T407-3 Manual PDFgiulian2009Pas encore d'évaluation

- Alarm ValveDocument6 pagesAlarm ValveAnonymous ZPTCAz9Pas encore d'évaluation

- Hopkinson Valves IOM Manual PDFDocument7 pagesHopkinson Valves IOM Manual PDFGiorgiana RosuPas encore d'évaluation

- Parker PV SeriesDocument20 pagesParker PV SeriesPedro Piñero Cebrian0% (1)

- Control Valve - Theory & SizingDocument29 pagesControl Valve - Theory & SizingSandeep KulathapallilPas encore d'évaluation

- Operating InstructionDocument2 pagesOperating InstructionÖmer KarahanPas encore d'évaluation

- Uob Control ValvesDocument30 pagesUob Control ValvesBAHRAIN1967100% (1)

- Millipore Reservoir ManualDocument13 pagesMillipore Reservoir ManualLucian BuhalteanuPas encore d'évaluation

- Pressure Seal Valves-GateDocument24 pagesPressure Seal Valves-GateHieu NguyenPas encore d'évaluation

- HD 247 Alarm Valve Model-HDocument16 pagesHD 247 Alarm Valve Model-HAjjuParmarPas encore d'évaluation

- HD 102 Alarm Valve Model ADocument9 pagesHD 102 Alarm Valve Model AjabbanPas encore d'évaluation

- Instrumentation Course 2.Document67 pagesInstrumentation Course 2.FACE BOOK100% (1)

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistPas encore d'évaluation

- Manual de Filtro AutolimpianteDocument29 pagesManual de Filtro AutolimpianteMegan PiercePas encore d'évaluation

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDocument14 pagesFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalPas encore d'évaluation

- Valves Used in Pipelines: Valve Specification Siemens Energy Gas Turbine Inlet FiltersDocument13 pagesValves Used in Pipelines: Valve Specification Siemens Energy Gas Turbine Inlet Filtersravikumar_jamiPas encore d'évaluation

- Eja Hart Im 08Document31 pagesEja Hart Im 08vishnunair27Pas encore d'évaluation

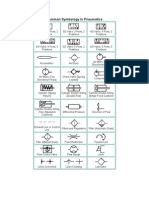

- Common Symbology in PneumaticsDocument3 pagesCommon Symbology in Pneumaticsvishnunair27Pas encore d'évaluation

- Automatic Tank GaugingDocument4 pagesAutomatic Tank Gaugingvishnunair27Pas encore d'évaluation

- Control Valve DatasheetDocument1 pageControl Valve Datasheetvishnunair27Pas encore d'évaluation

- Case Stydy 1Document2 pagesCase Stydy 1vishnunair27Pas encore d'évaluation

- Circuflow 5200 Operating InstructionsDocument24 pagesCircuflow 5200 Operating InstructionsalexPas encore d'évaluation

- DAA NotesDocument97 pagesDAA Notesanish.t.pPas encore d'évaluation

- How To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentDocument19 pagesHow To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentClaudiu Stefan HaiduPas encore d'évaluation

- Omb ValvesDocument52 pagesOmb ValvesCesar SotoPas encore d'évaluation

- Recap For Inset 03-16-2021Document1 pageRecap For Inset 03-16-2021Melicia LimboPas encore d'évaluation

- ARIMI Et Al-2010-Journal of Texture Studies PDFDocument21 pagesARIMI Et Al-2010-Journal of Texture Studies PDFRomaric OuetchehouPas encore d'évaluation

- 4UIE - AB - Nov 23Document2 pages4UIE - AB - Nov 23aaaPas encore d'évaluation

- The Influence of Social Media On Crowd Behavior and The Operational EnvironmentDocument78 pagesThe Influence of Social Media On Crowd Behavior and The Operational EnvironmentangryTXPas encore d'évaluation

- Find The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inDocument4 pagesFind The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inGeoffrey GolbequePas encore d'évaluation

- Types of Speeches and Speech StyleDocument1 pageTypes of Speeches and Speech StyleSai RiveraPas encore d'évaluation

- Revo Uninstaller Pro HelpDocument61 pagesRevo Uninstaller Pro HelpGuy Sinclaire OmbePas encore d'évaluation

- CDI1Document40 pagesCDI1Leonino Angelica Aiko S.Pas encore d'évaluation

- Motorola Pt4 - VHF - WWW - Manualesderadios.com - ArDocument24 pagesMotorola Pt4 - VHF - WWW - Manualesderadios.com - Arpisy74Pas encore d'évaluation

- Cambridge O Level: PHYSICS 5054/42Document16 pagesCambridge O Level: PHYSICS 5054/42Lapu LapuPas encore d'évaluation

- Practical Research 2 Module 1: Characteristics, Strengths, Weaknesses, and Kinds of Quantitative ResearchDocument6 pagesPractical Research 2 Module 1: Characteristics, Strengths, Weaknesses, and Kinds of Quantitative Research306947 Bancal Pugad ISPas encore d'évaluation

- Quiz7 1Document6 pagesQuiz7 1rizqi joeniPas encore d'évaluation

- The Psychometrician Licensure Examinations (Pmle) : Impact To The Behavioral Science CurriculumDocument21 pagesThe Psychometrician Licensure Examinations (Pmle) : Impact To The Behavioral Science CurriculumghPas encore d'évaluation

- Dwnload Full Business Research Methods 9th Edition Zikmund Solutions Manual PDFDocument35 pagesDwnload Full Business Research Methods 9th Edition Zikmund Solutions Manual PDFerichuel33a100% (14)

- Letter B Lesson PlanDocument3 pagesLetter B Lesson Planapi-300212612100% (1)

- LGIT CatalogueDocument11 pagesLGIT CatalogueArjun SharmaPas encore d'évaluation

- GasLink - Development of GLIADocument24 pagesGasLink - Development of GLIAOribuyaku DamiPas encore d'évaluation

- A Detailed Lesson Plan in Mathematics 10: Measures-Of-Position-Ungrouped-DataDocument6 pagesA Detailed Lesson Plan in Mathematics 10: Measures-Of-Position-Ungrouped-DataJIMERSON RAMPOLAPas encore d'évaluation

- QCBS RFP For Gweir SHPP PMC PDFDocument125 pagesQCBS RFP For Gweir SHPP PMC PDFjayant pathakPas encore d'évaluation

- PMRC Mar Va 115Document11 pagesPMRC Mar Va 115adamsaufimahmud1988Pas encore d'évaluation

- Slide Topic 2 - PR TheoriesDocument26 pagesSlide Topic 2 - PR TheoriesJeneesh RajendranPas encore d'évaluation

- Battista Mondin, Saint Thomas Aquinas' Philosophy. in The Commentary To The Sentences (Inglés) PDFDocument134 pagesBattista Mondin, Saint Thomas Aquinas' Philosophy. in The Commentary To The Sentences (Inglés) PDFFray Daniel Sisa NiñoPas encore d'évaluation

- AMME4710 Chap5 ColourIPDocument56 pagesAMME4710 Chap5 ColourIPrajeevrajkumarPas encore d'évaluation

- Executive Leadership: Artificial Intelligence Primer For 2021Document10 pagesExecutive Leadership: Artificial Intelligence Primer For 2021ranga.raman100% (1)

- 제8차 전력수급기본계획Document51 pages제8차 전력수급기본계획김명근Pas encore d'évaluation