Académique Documents

Professionnel Documents

Culture Documents

MV 20 N 021992 P 67

Transféré par

ahmed_eng_1500Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MV 20 N 021992 P 67

Transféré par

ahmed_eng_1500Droits d'auteur :

Formats disponibles

67

Research on Methano1-fueled Marine Diesel Engine*

By Yoichi Nakamura'hk, Tadahiro Ozu**, Hisashi YanLashita***, Nobuyoshi Nakayamab'< and Tatsuo Fujii** Nowadays concerns about methanol has increased from the viewpoints of environrnental protection and versatility of fuels at a global scale. Desire for saving of maintenance cost and lobour prevails as well as the environmental problems in the field of marine engines. From these rnotives we have carried out research and development of a methanol fueled marine diesel engine which is quite different from automobile en9ines in the size, main particulars, working condition and durability.Although we have made a great use of invaluable knowledge from automotive techno1ogy, sorne special studies were neccessary due to these differences. Ignition method is a typical one. Dual fuel injection system was tried for trouble-free ignition of methanol fuel. This system is thought to be the most favourable ignition method for marine diesel engines which have to withstand quick load change and accept no mis-firing. Under the leadership of Ministry of Transportation and with the aid from The Japan Shipbuilding Industries Foundation and The Japan Marine Machinery Developrnent Association the work has proceeded from elementary studies of injection and tribo1ogy to the running test. In this article the effects of configurations as to fuel injection system on the engine perforrnance are described. Fundamental running test with a single cylindered 4-stroke test engine reveals that the marine deisel engine can afford to have such a good performance as an original diesel engine has, when suitable reconditioning of fuel injection-and governing systems being applied to. 1. Introduction Kawasaki -cho, Akashi, 673 Japan) However, IM0 (International Maritime 0rgan-ization) is now investigating to include exhaust gas from ships in the objects to be controlled from the viewpoint of environmental protection on a worldwide scale that has been loudly emphasized recentlyl). In case clean methanol is used as fuel,work for handling complicated machines such as centrifuges for heavy fuel oil and for treating sludge discharged from them can be avoided, and further it can be expected to lessen frequent engine maintenance work. It has therefore been strongly desired to use methanol on marine diesel engines from main1y the viewpoint of pursuing ec0nomy. Though knowledge which has been gained with automobile engines can be used in principle,many subjects to be so1ved still remain, since marine diesel engines have large bores and mean effective pressures of more than two times as much, their operating conditions are extremely severe and they need high reliability and durability in comparison with automobile engines. The authors have conducted the above captioned R&D for the purpose of gaining knowledge which can so1ve these issues and contribute to engine

Energetic research on methano1-fueled automobile engines has been forwarded from the viewpoints of low environmental pollution and the use of alternate fuel since the oil crisis, and they are now being tested on vehicles in various Countries in the world. Various technical issues have already been solved or the prospect is bright for them. It can be said that this type of engine is very c1ose to completion at present. On the other hand, it is an actual situation in the marine engine field that the research on this type of engine has hardly been tested so far, since it has seldom been evaluated from the viewpoint of environmental pollution control because it is used at sea and the idea tO use methano1 on marine engines is not established yet. * Translated from Journal of MESJ Vo1.26, No.9 (manuscript received June 7, 1991) Lectured May 16, 1991 **KAWASAKI Heavy Industries, Ltd. (3-1-1, Higashi-kawasaki-cho, Chuo-ku, Kobe, 650 Japan) ***KAWASAKI Heavy Industries, Ltd. (1-1,

October 1992

(1)

68

Yoichi Nakamura, Tadahiro Ozu, Hisashi Yamashita, Nobuyoshi Nakayama, Tatsuo Fujii

design. Methano1 has a cetane number of threeh and,consequently, extremely low ignitability. For automobile engines, ordinary technologies can cope with the issues on ignition, since ignition plugs have actual service results over prolonged periods on Otto engines and starting plugs have also been used to date on. diesel engines. On the other hand, rnarine engines with spark ignition can not exhibit mean effective pressures as high as those of ordinary diesel engines because of the high rate of pressure rise during ignition and they can not perrnit misfiring because of the large volume of their exhaust systems. The dual fuel injection system which has actual service results on large-sized gas engines has therefore been selected as the ignition system for this research. Since methanol is not only corrosive but also insufficient in lubricating ability, elemental resea-rch has been neededto so1ve these issues.However, elemental research will be explained at another opportunity and this paper describes the operating performance of a methanol diesel engine without touching elemental research. 2. Experimental Engine

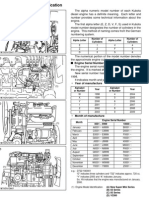

Fig.1 Schematic Drawing of Experimental Engine The combustion system of the experimental engine is of a dual fuel injection type such that the main fuel injection valve (methano1) is 1ocated at the center of the combustion chamber and atomized fuel from this va1ve is ignited by the pilot oil injection frorn the secondary injection valve (oil) 1ocated on the cylinder head near the periphery of the combustion space. This system has been adopted from the reasons that it has the high stability of ignition, good low load perform-ance and high reliability, and that it serves as a rneasure to prevent corrosion, since combustion deposits made by pilot oil injection cover the inside surface of the combustion chamber. The rnethanol injection pump is of a forced lubrication type to prevent lubrication troubles. Since metha-nol is highly vo1ati1e, the auxiliary equipment of

A single-,cylinder, four-stroke, direct-injection type diese1 engine having a cylinder bore of 250mrn has been modified so as to be suitable for this experiment. The rated speed of this experim-ental engine has been set lower than that of the original type so that the results of this research can be utilized as widely as possible. Table l and Fig.1 show the principal particulars of the expeimental engine and the schematic drawing

(2) Bulletin of the M.E.S.J., Vo1. 20, No.2

Research on Methano1-fueled Marine Diesel Engine

69

Fig. 3

Schematic Drawing of Fuel Regulating Linkage of E xperimental Engine

the methano1 system such as the fuel tank, strainer, supply pump and valves have been installed in an enclosed chamber (a fuel supply unit) as shown in Fig.2. A fan and a gas detector have been installed to sufficiently ventilate the inside of the unit for safety. Pipe joints are also of speciaI structure to prevent fueI leakage. Though the dual fuel injection system invo1-ves such a demerit that its fuel system becomes complicated, auxiliary machinery such as generat-ing engines and a boiler burn fuel oil on board in case of a ship, and large gain can not be expected even though only the main engine adopts a system of burning only methanol unless these auxiliary machines also burn only methano1. The dual fuel system is therefore considered proper. Fig.3 shows the schematic drawing of the fuel regulating linkage of the experimental engine. In this drawing, l is the methanol injecti-on pump, 2 is the pilot oil injection pump, 5 is the governor and 31 is the actuator necessary for controlling the ratio of the quantity of methanol and pilot oil to be injected. To grasp the condition of deposits in the combustion chamber, methanol with purity of 99.9% and JIS No.2 gas oil for pilot injection have been used. 3. Operation Test under Normal Condition Under the full 1oad condition of the above-m-entioned experimental engine (mean effective pressure Pe : 16.13kgf/cm), influence on engine performance, the contamination condition of engine inside and Iubricating oil, and the propert-ies of exhaust gas have been investigated by changing the specifications of the pilot oil injecti-on nozzle, main fuel injection nozzle and main fuel injection pump, fuel injection timing and the quantity of pilot oil. 3.I Influence of Pilot Oil Injection Nozzle The effect of the pilot oil injection nozzle has been confirmed by changing the nurnber and diameter of nozzle holes and the direCtion of injection in the range shown in Fig.4. As a result, the one-hole nozzle I s the best in terms of fuel consumption, the stability of cylin-der pressure and the reduction in the quantity of pilot oil. However, the difference in perf0rmance among various types of nozzles is not remarkable. As mentioned later, when priority is given to the issues of startability, accelerating ability and sudden load change like the engagement of a clutch, or to the problem when the pilot oil injection nozzle ho1es have been c1osed, it can be said that the three-hole nozzle is the best and the

October 1992

(3)

69

Yoichi Nakamura, Tadahiro Ozu, Hisashi Yamashita, Nobuyoshi Nakayama, Tatsuo Fujii

Fig.5

Engine Performance vs Nu mber of Pilot Oil Nozzle Holes 1argest possible nozzle hole diameter is desirable.Though the influence of the direction of the pilot oil injection nozzle in relation to the main fuel injection nozzle has also been confirmed, no improvement has been found. It is conjectured that the reasons for the above are that swirls in the combustion chamber of the experimental engine are not strong and the quantity of pilot oil is enough. Fig.5 shows engine performance when the total nozzle hole area of the pilot oil injection valve has been kept constant (35% of the total nozzle hole area of the injection valve for burning only oil) and the number of nozzle holes has been changed. The two-hole nozzle shows slightly better fuel consumption. However, it is not preferable from the viewpoint of ignition stability,since the variation of maximum cylinder pressure (Pmax) is large. Fig.6 shows engine performance when the total nozzle hole area of the pilot oil injection valve has been changed. It has turned out that,

Fig.6

Engine Performance vs Total Pi1ot Nozzle Hole Area when the total area is made too sma11, it becomes difficult to start the engine, and that it is also difficult to continue the operation of the engine on methano1/oil even if it could be started and the engine finally stops, since the quantity of pilot oil necessary for causing perfect ignition can not be supplied. However, when keeping the quantity of pilot oil constant, smaller total nozzle hole area gives the better stability of pilot injection. 3.2 Influence of Methanol Injection Nozzle Engine performance has been confirrned using methanol injection nozzles of which the number of nozzle holes are 8, 9, 10 and 12, and nozzle hole diameters have been selected in the range from 0.39mm to 0.48mm (90% to 200% of the nozzle

(4)

Bulletin of the M.E.S.J., Vo1. 20, No.2

Research on Methano1-fueled Marine Diesel Engine

71

Fig. 7

Engine Performance vs Number Methano1 Injection Nozzle Holes

of Liner Temperature vs the Number of Methano1 Injection Nozzle Holes inner surface of the cylinder liner (above TDC position of the top ring). It shows that temperatu-res for the 8-hole nozzle are higher by nearly 401C than those for other nozzles and the abovementio-ned conjecture is correct. When considering the ignition characteristic of methanol burning from the periphery of a spray, issues remain from the viewpoint of reliability including sliding conditions, since the quantity of atomized fue1 reaching the surface of the cylinder liner is estimated to be more. The 12-hole nozzle shows slightly worse fuel consump-tion probably due to the interference of sprays.According to the research by WAKURI et al.u, the spray angle in this case becomes 17 or 18 degrees and sprays do not directly touch each other.However, when taking account of the behavior of sprays after impinging on the surface of the liner and the entrainment of air into sprays, it is thought that the limit of the number of nozzle holes is 12 or so. Fig.9 shows test results in the case where the nozzle diameters of the 10-hole and the 12-hole methanol injection nozzles have been changed. No large change of characteristics has been found Fig. 8

area of the injection nozzle for burning only oil).As a result, it has turned out that, in case of the experimental engine, the injection nozzle which has ten nozzle holes of 0.46mm in diameter, i.e.150% of the nozzle area of the injection nozzle for burning only oil, shows the best fuel consumption. Fig.7 shows engine performance against the number of injection nozzle holes using intake air pressure as a parameter when using injection nozzles of which areas have been kept constant (130% of the nozzle area of the injection nozzle for burning only oil) and the number of nozzle holes has been 8, 10 and 12. Though the 8-hole nozzle shows the specific fuel consumption on almost the same level as that for the lO-hole nozzle, the former shows better performance, since both Pmax and exhaust temperature are 1ower. However, it is considered in this case that thermal 1oads on the combustion chamber components become high due to the longer fuel spray travel by about 7% than that for gas oil according to the calculation using the experimental formula of YAMASHITA etal.y,since the nozzle diameter of the 8-hole nozzle is larger. Fig.8 shows measured temperatures on the

October 1992

(5)

72

Yoichi Nakamura, Tadahiro Ozu, Hisashi Yamashita, Nobuyoshi Nakayama, Tatsuo Fujii

Fig.9 Engine Performance vs Methano1 Injection Nozzle Hole Diameter even though the diameters of nozzle holes have been changed except injection pressure. In order to obtain sprays similar to those of gas oil, it is necessary to use a methanol injection nozzle with the number of holes of l.5 to 2 times and a hole diameter of 1.l to 1.2 times of those of a gas oi1 injection nozzle, taking account of the spray characteristic of methanol having a shorter fuel travel and a difference in calorific value between gas oil and methano1. However, the number of holes is limited to 12 or so in terms of the machining of injection nozzles in practice and injection duration for methanol becomes relatively longer than that for gas oil. It is likely that this characteristic is cancelled out by the high combu-stion speed of methanol and does not badly influence the heat release periOd of a running engine so much. 3.3 lnfluence of P1unger Diameter of Methano1 Injection Pump Fig.10 case where shows engine performance the plunger diameter of in the

methanol injection pump has been changed in the range from 22mm to 28mm. The test has been carried out with injection timing being set at 23 degrees before TDC (statically) for pumps having plunger diameters from 22mm to 27mm and at 20 degrees before TDC (statically)for the pump having plunger diameter of 28mm, since maximum cylinder pressure has been predicted to exceed an al1ow-able limit in this case. As seen in this figure, the

(6)

Bulletin of the M.E.S.J., Vo1. 20, No.2

Research on Methano1-fueled Marine Diesel Engine

73

injection duration and the specific fuel consumpti-on are almost constant in the range of plunger diameter from 26mm to 28mm. Since Pmax has an allowable limit and injection timing must be changed when the rate of injection is increased,the improvement in fuel consumption is small even though the plunger diameter of the metha-nol injection pump is made too large. It can therefore be said that the limit to the plunger diameter is about l.3 times of that for only oil burning. It can be seen from Figs.11 and 12 that the influence of the plunger diameter on the distribut-ion of heat release rates and on injection pressure and the lift pattern of the needle valve becomes smal1. 3.4 Influence of Injection Timing Fig.13 shows engine performance in case where the injection timing for methanol has been kept constant and that for pilot oil has been changed. As seen in this figure, the engine

performance becomes better in case where pilot oil is injected earlier by two degrees than metha-no1. Though the test where pilot oil is injeCted later than methanol has also been carried out,combustion has not stabilized and continuous running has been difficult. Another test has also been carried out, where the relative difference in injection timing between methanol and pilot oil has been fixed and the timing for both fuels has been advanced in parallel. However it haS turned out that the improvement in fuel consumption is smal1. 3.5 Influence of the Quantity of pilot Oi1 Fig.14 shows engine performance in case where the quantity of pilot oil has been changed for each pilot oil injection nozzle. It can be seen from this figure that the lowest points of specific fuel consumption differ with the specifications of pilot oil injection valves. That is, the percentage of pilot oil in total consumed fuel for the lowest point of specific fuel consumption is between l1 and 12% for the one-hole nozzle and that is near 15% for the three-hole nozzle. Thus, the lowest point shifts toward the larger percentage of pilot oil. Though the quanttty ot piLot aiL can be decreased down to about 4% by making the pilot oil injection nozzle area smaller, proper quantity.is

October

1992

(7)

73

Yoichi Nakamura, Tadahiro Ozu, Hisashi Yamashita, Nobuyoshi Nakayama, Tatsuo Fujii

necessary in addition to normal running torque. For this reason, starting tests have been carried out under the fol1owing conditions. a) Constant quantity of methano1 (full 1oad) and varying quantity of pilot oi1 b) Constant quantity of pilot oil and varying quantity of methano1 c) Operation on only pilot oi1 d) Starting on pilot oil and injection of methanol after that e) Constant quantity of methano1 (50%) and varying quantity of pilot oi1 For al1 conditions except e), cold conditions of intake air temperature ts # 191C , cooling water temperature tw t 191C , 1ubricating oil temperatu-re to # 201C and liner temperature tL # 201C have been adopted. For a part of e) condition,warm conditions of ts t 301C , tw # 58 C , to # 50 t and tL # 391C have been adopted. 4.2 Test Results Fig.15 shows the summaries of test results

considered to be 12-15% in practice, since the startability of an engine must be considered as mentioned later. Smoke density and NOx have also been measured during these tests. Though detailed results will be explained later, the results can be summarized as fol1ows. Compared with a diese1 engine being operated on gas oil, the smoke density is 1ower by one order by Bosch scale and NOx is sbout half under the same load condition.Thus, exhaust gas characteristics have been confirmed to be superior. Furthermore, overhaul inspection and the results of lubricating oil analysis after tests have shown less contamination of the engine inside. As mentioned above, it has been confirmed that the possibility of lowering environmental pollution and decreasing maintenan-ce work for diesel engines is large. 4. Starting Test 4.l Test Method The stable combustion of dual fuel engines under normal operation can be ensured by pilot oil of several percent of total fuel which is injected under full 1oad condition. However, a considerably large quantity of fuel is needed when starting engines, since accelerating torque is

(8)

Bulletin of the M.E.S.J., Vo1. 20, No.2

Research on Methano1-fueled Marine Diesel Engine

75

taking the quantity of pilot oil on the abscissa and that of methanol1 on the ordinate. . mark shows that no ignition has been detected. } and J marks show that, though ignition has been detected, it has not been continued and torque has not been generated. > and O marks show that ignition has been detected and continued stably and engine speed has risen up to its set speed. Suffixes show test numbers. As can be seen from this figure, under the cold condition (0 J .), ignition has not been detected at all like Test Nos. 1-5 in case where a large quantity of methanol has been injected together with oil. On the other hand, under the warm condition (O }) like engines just after operation, starting has been possible like Test Nos. 21, 22 and 13. However, there has been an example such as Test No.12 where operation could not be continued due to pilot oilless by few percent than that of Test No.13. When pilot oil is plenty, starting even under the cold condition is

possible like Test No.25 even though a considera-bly 1arge quantity of methanol is injected. Test Nos.8, 9 and l0 have been carried out in such a way that the engine has been started on only pilot oil and methanol has been injected after detecting ignition. These are examples where the engine has misfired and not generated effective torque and operatiOn could not be continued because of much methanol and less pilot oil. It has turned out that, since pilot flames are blown out by the injection of meth1no1, energy necessary for starting can not be made up by methanol and a necessary quantity of pilot oil must be inj:?cted under the cold condition. Fig.16 shows the transition of engine speed for Test Nos.3, 7, 11 and 13 which have been carried out under typical starting conditions. Test No.3 shows the case where methano1 of the quantity corresponding to the limit of the injection pump rack has been injected under the cold condition. Engine speed rises up to only that by starting air. Test No.7 shows that accelerating torque is not generated though slight ignition is detected, because the quantity of methanol has been decreased to 30%. Test No.11 shows the case where only pilot oil is injected. Though the rate of speed increase is smal1, engine speed rises up to the set speed.Test No.13 shows the case where methanol of the quantity of 50% has been injected under the warm condition. It can be seen that engine speed quickly rises by the combustion of methano1.Fig.17 summarizes the results of starting tests using accelerating time and mean effective pressure (Pmi) obtained from indicator diagrams as coordinates. O and X marks show cases where starting has succeeded and failed respectively.The solid line shows the relationship between minimum mean effective pressure necessary for accelerating engine speed which has been calcula-ted from mean accelerating torque and accelerat-ing time. It can be seen from this figure that,apart from the length of accelerating time related to inertial mass, Pmi of at least 4 or 5 kgf/cm2 must be generated for starting engines. 5. Quick Load Throw -in Test 5.l Test Method Tests simulating the condition of engaging clutches which are often installed on medium to

October 1992

(9)

76

Yoichi Nakamura, Tadahiro Ozu, Hisashi Yamashita, Nobuyoshi Nakayama, Tatsuo Fujii

The governor of this engine is Woodward UG8 type with a torque limiter. The test has been carried out by controlling the quantity of pilot oil with the lever 34 and that of methanol by limiting the output of the lever 6 with the torque limiter of the governor in Fig.3. 5.2 Test Results Fig.19 shows the test results of the quick load throw-in test. Measured points are p1otted by selecting Pmi, which has been converted from a dynamometer load, for the abscissa and the percentage of methanol injected, which has been calculated from the rack position of the injection pump, for the ordinate. In this figure, ^ , O , O , and O' marks show cases where engine speed has returned to its set values after quickly imposing loads ; ^ ,., . and .' marks show cases where the engine has stalled and could not carry loads ; and J , J' and > show cases where the engine had not sta1led but the engine speed has not returned to its set values. Suffixes show test numbers. The magnitude of load which can be thrown-in is effective only in the hatched range under naturally aspirated condition and the engine output is limited to Pmi = 9-1Okgf/cm2. Since this limit can not be raised even under the warm condition, it is not influenced by the phenomenon of blowing out pilot flames by methanol as

Fig. 18 Procedure8 of Quick Load Throw -in Test

high speed engines have been carried out by quickly throwing-in 1oads on the dynamometer (eddy current type) according to the procedures shown in Fig.18. Rotating mass is added between the engine shown in Fig.l and the dynamometer to be able to simulate a shafting of a marine engine. The engine has been imposed with a load during four or five seconds after changing over from oil operation to methano1/oil operation under no lobd condition, and engine speed and pressure in the cylinder have been recorded.Supposing the loaded condition of an engine after engaging a clutch, 1oads (40-150 kgf ) correspondi-ng to 20-70% of the load at full engine output and also the quantity of fuel to be injected corresponding to these loads have been selected.For intake air pressure, two cases of naturally aspirated and supercharged (0.35 kgf/cm) conditions have been selected. Since intake air of this experimental engine is supplied by an indep-endent motor driven blower, the transient chara-cteristics of a turbocharged engine can not be simulated exactly. However, it is considered that engine characteristics can qualitatively be grasped by this test.

(10)

Bulletin of the M.E.S.J., Vo1. 20, No.2

Research on Methano1-fueled 4arine Diesel Engine

77

Both Test Nos.19 and 25 have this tendency, and engine speed lowers halfway and can not recover. Under supercharged condition, the engine generates Pmi # 15kgf/cm2 and engine speed quickly returns to the set value, since a conside-rably large quantity of air, i.e. specific air consu-mption 4kgf/PSh, is supplied to the engine. Test Nos.41 and 42 show the cases where the engine can not develop enough output because of too little quantity of injected methanol against the thrown-in engine load. As mentioned before, the experimental engine does not represent the dynamic characteristics of actual turbocharged engines, since the experimental engine is not equipped with an exhaust turbocharger. However,it is expected that the above-mentioned load throw-in test can offer matters to be considered when methanol is applied to diesel engines. 6. Conclusion Tests have been carried out under static and dynamic conditions in order to grasp engine performance when methanol is applied to marine detailed under the section of starting test, and it is thought that output can not be increased due to the shortage of intake air even though the quantity of methanol is increased. It can be seen from examples marked with O' that the limit of output can considerably be increased by d small degree of supercharging and Pmi of 12.5kgf/cm2 can be developed. It means that the magnitude of load which can be thrown-in, i.e. the speed of engaging the c1utch (the rising speed of oil pressure for operating the clutch), depends on the accelerating ability of the turbocharger and it can be said that the clutch must be operated linking with intake air pressHre. The quantity of pilot oil has almost no influence on the limit of output in the range shown in Fig.19. Fig.20 and 21 show the transitions of engine performance after load throw-in under naturally aspirated condition and under supercharged condition wiht the intake air pressure of 0.35kgf/cm2 respectively. Though Pmi # 1Okgf/cm2 can be obtained just after load acceptance in every case under naturally aspirated condition, the balance between generated engine torque and load can not be maintained due to the shortage of air (small air/fuel ratio) and the cooling effect by the latent heat of vaporization of methanol when the quantity of injected methanol is much.

October 1992

(11)

78

Yoichi Nakamura, Tadahiro Ozu, Hisashi Yamashita, Nobuyoshi Nakayama, Tatsuo Fujii

diesel engines. As a result, it has turned out that the performance of a methano1/oil burning engine can be improved near to the performance level of an oil burning engine by optimizing the fuel injection sysytem and the combustion chamb-er geometry and by adapting the fuel regualting system and tbe intake air system of the former. 7. Acknowledgements This research has been carried out in co-op-eration with KOKKA SANGYO, coastal Shipping company, and HANSHIN Diesel Works, engine manufacturer for coasters. The authors wish to express our deep gratitude to people concerned. Discussion Yasuhiro Ito (NIICATA ENGINEERING CO.,LTD.) I pay my respects to you for your presentation of valuable research. I am happy if you give me your answers to the fol1owing two questions. 1. How do you evaluate the properties of exhaust gas from the viewpoint of low environmental pollution ? To what extent does NOx in particular decrease in comparison with diesel engin-es ? I think soot is more or less influenced by pilot injection. How do you think about this matter ? 2. Please let me know if there is any point to be particularly noted in the respect of d urability. Author'8 reply 1. Though exhaust emissions which are problematical are formaldehyde and unbur-ned methano1, they are not so much probl-ematical in marine engines compared with automobile engines. NOx was from 2/3 to 1/2 of that of gas oil burning engines,since the combustion temperature of met-hanol was 1ow. Soot was so little that it could hardly be measured by a Bosch smoke meter in spite of pilot injection. 2. Though we were worried about the occurrence of piston ring scuffing, we could confirm that no problem would occur by selecting proper lubricating oil. However,for the durability of the methanol injection system, we experienced the stick of the plunger and the corrosion and breakage of the spring.

On these troubles, we are scheduled to present in detail at the autumn lecture meeting. Pleae see this paper. Keijiro Shiode (SHIP RESEARCH INSTITU -TE ) I pay my respects to you for your presentation of very valuable experimental data. Please let me know if you have experienced any trouble on the fue1 injection valve when alcohol fuel has been used. Author's reply On the trouble of the methanol injection system, we are scheduled to present in detail. Please see this paper. Though we experienced the wear of the needle valve and the corrosion and breakage of the spring due to the low viscosity and corrosiveness of methano1, we could solve these troubles by changing their shapes and materials. Hiromi Kondo (DAIHATSU DIESELMFG.CO., LTD.) I pay my respects to you for your valuable research on the combustion of methano1. Please give me your answers to the fol1owing questions. 1. What phenomenon can I think about by the description "In case the quantity of injected oil is the same, smaller area of nozzle holes is ..." on Page 70 in the text ? 2. Please tell me the locations of measuring points for liner temperature and of the pilot oil nozzle in Fig.6. 3. Please tell me the process of calculating Pmi from mean accelerating torque shown in Fig.6 on Page 70. 4. How should I consider compression ratios for methanol engines ? I should be obliged if you would tell me the compression ratio used in this experiment. Author's reply l. The pilot injection system actually has considerably larger capacity than that necessary for normal operation, taking account of engine starting and the engag-ement of a clutch. Consequently, injection characteristics under normal operation tend to deteriorate. It is therefore necessary to throttle nozzle area to maintain necessary

(12)

Bulletin of the M.E.S.J., Vo1. 20, No.2

Research on Methano1-fueled Marine Diesel Engine

79

injection pressure. 2. Eight sensors for measuring liner temperature are inserted on the periphery of the liner at intervals of 45 degrees and the pilot oil injection nozzle is located near the periphery of the combustion chamber. The difference in liner temperature which was thought to be due to pilot flame was not observed . 3. Though the rate of engine speed increase after starting is not uniform, this minimum Pmi curve has been made by the way of thinking of the mean rate of acceleration for the sake of simplification to investigate its tendency. Friction torque has been made constant. 4. Though tests with various compression ratios were not conducted, we think the compression ratios for engines with pilot injection can be considered in the same way as those of oil burning engines. Tho-ugh the compression ratio of the experimental engine is

the same as that for the case of burning only oil ( E = 13), the effective compression ratio becomes higher than that for the case of burning only oil,since the timing of intake valve c1osing is advanced a little. References (1) Yonebayashi A., "Activities of IMO MEPC regarding exhaust enlission fron-1 ships", Pre-text of the 47th M.E.S.J-Conference, p.l44,199l. (2) Hikino K., et al, "Recent trends of ignitability improvements on methanoI diesel en9ines", Journal of S.A.E.J, vo1.44, No.8,p.92, 1990. (3) Yamashita H., et aI, Journal of M.E.S.J,vo1.26, No.9, 1991. (4) Wakuri Y., et al, Transaction of J.S.M.E,256-156 (24-8), p.820.

October 1992

(13)

Vous aimerez peut-être aussi

- Internal Combustion EnginesD'EverandInternal Combustion EnginesConstantine ArcoumanisÉvaluation : 4 sur 5 étoiles4/5 (4)

- Methanol Fueled Marine Diesel Engine Seminar ReportDocument24 pagesMethanol Fueled Marine Diesel Engine Seminar ReportDixit RPas encore d'évaluation

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyD'EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyPas encore d'évaluation

- Methanol Fueled Marine Diesel EngineDocument24 pagesMethanol Fueled Marine Diesel EngineSanket ThoratPas encore d'évaluation

- Methanol Fueled Marine Diesel EngineDocument24 pagesMethanol Fueled Marine Diesel EngineMayurMahajanPas encore d'évaluation

- Methanol Fueled Marine Diesel EngineDocument27 pagesMethanol Fueled Marine Diesel EngineDevender NathPas encore d'évaluation

- The Influence of Oil Pressure in The Engine Lubrication System On Friction LossesDocument6 pagesThe Influence of Oil Pressure in The Engine Lubrication System On Friction LossesAmr ShebanPas encore d'évaluation

- Problem in Steam Turbine LubricationDocument8 pagesProblem in Steam Turbine LubricationmishraenggPas encore d'évaluation

- Report On Cylinder DeactivationDocument7 pagesReport On Cylinder Deactivationsanchit333Pas encore d'évaluation

- Lotus Omnivore Initial ResultsDocument6 pagesLotus Omnivore Initial ResultsPaulPas encore d'évaluation

- Engineering Seminar Paper on Methanol-Fueled Marine Diesel EngineDocument12 pagesEngineering Seminar Paper on Methanol-Fueled Marine Diesel Enginenacer zidiPas encore d'évaluation

- Eccentric SleeveDocument20 pagesEccentric SleeveSenthil KumarPas encore d'évaluation

- Paper 17Document9 pagesPaper 17Faitar CatalinPas encore d'évaluation

- Development of CNG Injection EngineDocument8 pagesDevelopment of CNG Injection EngineShasahank JoshiPas encore d'évaluation

- Air Flow and Camshaft Stress Analysis of VariableDocument10 pagesAir Flow and Camshaft Stress Analysis of VariableAditya Nur IlyasaPas encore d'évaluation

- Mechanical Final 2 PDFDocument16 pagesMechanical Final 2 PDFMbalekelwa MpembePas encore d'évaluation

- EFI Two StrokeDocument6 pagesEFI Two StrokegkarthikeyanPas encore d'évaluation

- CE 2016 405 PublikacjaDocument6 pagesCE 2016 405 PublikacjaPrathmesh KuranePas encore d'évaluation

- In Uence of Fuel Injector Position of Port-Fuel Injection Retrofit-Kit To The Performances of Small Gasoline En..Document9 pagesIn Uence of Fuel Injector Position of Port-Fuel Injection Retrofit-Kit To The Performances of Small Gasoline En..Aasif SheikhPas encore d'évaluation

- Paper 17Document8 pagesPaper 17Faitar CatalinPas encore d'évaluation

- Energy Conversion and Management: M.A. Ceviz, M. AkınDocument6 pagesEnergy Conversion and Management: M.A. Ceviz, M. AkınMartinito MacraméPas encore d'évaluation

- Pulse Fuel Pump Maintenance and TroubleshootingDocument5 pagesPulse Fuel Pump Maintenance and TroubleshootingdiegoPas encore d'évaluation

- Matecconf EaaicDocument10 pagesMatecconf EaaicPablo EscobarPas encore d'évaluation

- Machines: Monitoring The Oil of Wind-Turbine Gearboxes: Main Degradation Indicators and Detection MethodsDocument24 pagesMachines: Monitoring The Oil of Wind-Turbine Gearboxes: Main Degradation Indicators and Detection MethodsGuilherme Souza GomesPas encore d'évaluation

- Lubricants: Analysis of The Journal Bearing Friction Losses in A Heavy-Duty Diesel EngineDocument13 pagesLubricants: Analysis of The Journal Bearing Friction Losses in A Heavy-Duty Diesel EngineKah KiatPas encore d'évaluation

- Engine Friction Losses InvestigationDocument33 pagesEngine Friction Losses Investigationbosse ekisdePas encore d'évaluation

- Stepped PistfonDocument12 pagesStepped PistfonSrikanth DesaiPas encore d'évaluation

- Increasing IC Engine Efficiency Using Turbocharging and Waste Heat RecoveryDocument7 pagesIncreasing IC Engine Efficiency Using Turbocharging and Waste Heat RecoveryHarsh PatelPas encore d'évaluation

- Estructura de ProyectoDocument12 pagesEstructura de ProyectoCidit DescartesPas encore d'évaluation

- Operation Strategy of A Dual Fuel HCCI Engine With VGT: Carl Wilhelmsson, Per Tunest Al and Bengt JohanssonDocument9 pagesOperation Strategy of A Dual Fuel HCCI Engine With VGT: Carl Wilhelmsson, Per Tunest Al and Bengt JohanssonSantosh TrimbakePas encore d'évaluation

- Ue60ls IiDocument5 pagesUe60ls IiHaziq IsmailPas encore d'évaluation

- Study On Air Intake and Cooling System For MarineDocument7 pagesStudy On Air Intake and Cooling System For MarineSyed Sdik Siddique Roll twenty four Batch eighteenPas encore d'évaluation

- I C EngineDocument9 pagesI C Enginesubhromondal2017Pas encore d'évaluation

- Temperature Pressure Ls Diesel EnginesDocument8 pagesTemperature Pressure Ls Diesel EnginesCvita CvitićPas encore d'évaluation

- 4stroke 4 Cylinder PetrolDocument4 pages4stroke 4 Cylinder PetrolEric CookPas encore d'évaluation

- Wear Procces DieselsDocument6 pagesWear Procces Dieselsargentum19619692Pas encore d'évaluation

- Gasoline FAQ 4Document25 pagesGasoline FAQ 4Claudia MmsPas encore d'évaluation

- Performance Analysis of Compression Ignition (Ci) Engine Using Bio FuelsDocument8 pagesPerformance Analysis of Compression Ignition (Ci) Engine Using Bio FuelsTJPRC PublicationsPas encore d'évaluation

- Study ExpDocument41 pagesStudy ExpNishant Nagle100% (1)

- Tribological Properties of Vegetable Based Universal Tractor Transmission OilDocument7 pagesTribological Properties of Vegetable Based Universal Tractor Transmission Oilradu2000vPas encore d'évaluation

- Frank Atzler PDFDocument11 pagesFrank Atzler PDFlongtrandang5867Pas encore d'évaluation

- Likhanov 2020 IOP Conf. Ser. - Mater. Sci. Eng. 734 012208Document6 pagesLikhanov 2020 IOP Conf. Ser. - Mater. Sci. Eng. 734 012208Ammar AhmadPas encore d'évaluation

- Effect of Air Intake Pressure on Diesel Engine PerformanceDocument8 pagesEffect of Air Intake Pressure on Diesel Engine Performancebrijesh kinkhabPas encore d'évaluation

- Lubricator HistoryDocument8 pagesLubricator Historymaninder_khasriaPas encore d'évaluation

- Investigating The Effects of Variable Valve Timing On Spark Ignition Engine PerformanceDocument13 pagesInvestigating The Effects of Variable Valve Timing On Spark Ignition Engine PerformanceFlaviano CavalcantiPas encore d'évaluation

- GR 07Document6 pagesGR 07tovinny14159Pas encore d'évaluation

- Development of Engine Oil Using Palm Oil As A Base Stock For Four-Stroke EnginesDocument5 pagesDevelopment of Engine Oil Using Palm Oil As A Base Stock For Four-Stroke EnginesShahabuddin SuzanPas encore d'évaluation

- A Practical Study of Using Hydrogen in Dual - Fuel Compression Ignition EngineDocument10 pagesA Practical Study of Using Hydrogen in Dual - Fuel Compression Ignition EngineInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Effect of Piston Bowl Geometry On The Performance of ADocument9 pagesEffect of Piston Bowl Geometry On The Performance of AMuhammad RonaldoPas encore d'évaluation

- Engine Modelling of A Single Cylinder Diesel EnginDocument14 pagesEngine Modelling of A Single Cylinder Diesel Enginmr.htetwaiaung.mechPas encore d'évaluation

- Application of Variable Geometry Turbine Turbochargers To Gasoline Engines-A ReviewDocument16 pagesApplication of Variable Geometry Turbine Turbochargers To Gasoline Engines-A ReviewTugulschi NichitaPas encore d'évaluation

- Acta 12 003Document15 pagesActa 12 003Andras NagyPas encore d'évaluation

- Enhancement of Gasoline Fuel Quality WithDocument12 pagesEnhancement of Gasoline Fuel Quality WithRawezh Muhtasim MustafaPas encore d'évaluation

- Testing Modern Fuel Injection PumpsDocument5 pagesTesting Modern Fuel Injection PumpsTendai AlfacePas encore d'évaluation

- Lube Oil Maintenance BasicsDocument13 pagesLube Oil Maintenance BasicsMaintenance Circle100% (2)

- Full Paper Template by KPI USUDocument5 pagesFull Paper Template by KPI USUHendrik V SihombingPas encore d'évaluation

- Tribology International: Vicente Macián, Bernardo Tormos, Santiago Ruiz, Guillermo MiróDocument9 pagesTribology International: Vicente Macián, Bernardo Tormos, Santiago Ruiz, Guillermo MiróMauricio R Morales100% (1)

- Keywords: Diesel Engine, System of Injection, Fuel ChargingDocument5 pagesKeywords: Diesel Engine, System of Injection, Fuel ChargingNikola PetrovicPas encore d'évaluation

- Bahirdar University Bahirdar Institute of ThecnologyDocument6 pagesBahirdar University Bahirdar Institute of ThecnologyKaleab EndalePas encore d'évaluation

- Artificial Neural Network Optimization Modeling OnDocument16 pagesArtificial Neural Network Optimization Modeling OnWan NurdyanaPas encore d'évaluation

- Diesel CFDocument2 pagesDiesel CFahmed_eng_1500Pas encore d'évaluation

- Fleet Av Advisory Carb FlyerDocument4 pagesFleet Av Advisory Carb Flyerahmed_eng_1500Pas encore d'évaluation

- Online: Monographs See HTTP:// Monograph Working Group MembersDocument2 pagesOnline: Monographs See HTTP:// Monograph Working Group Membersahmed_eng_1500Pas encore d'évaluation

- Research On Methano1-Fueled Marine Diesel EngineDocument13 pagesResearch On Methano1-Fueled Marine Diesel Engineahmed_eng_1500Pas encore d'évaluation

- Volume 46Document27 pagesVolume 46ahmed_eng_1500Pas encore d'évaluation

- SCRDocument81 pagesSCRLaurentiu StefanPas encore d'évaluation

- Stationary Engine Diesel Retrofit Case Studies 1109finalDocument16 pagesStationary Engine Diesel Retrofit Case Studies 1109finalahmed_eng_1500Pas encore d'évaluation

- SisuDiesel 6cylengDocument2 pagesSisuDiesel 6cylengahmed_eng_1500Pas encore d'évaluation

- Stationary Engine Diesel Retrofit Case Studies 1109finalDocument16 pagesStationary Engine Diesel Retrofit Case Studies 1109finalahmed_eng_1500Pas encore d'évaluation

- SisuDiesel 6cylengDocument2 pagesSisuDiesel 6cylengahmed_eng_1500Pas encore d'évaluation

- p365 377Document13 pagesp365 377ahmed_eng_1500Pas encore d'évaluation

- Rapport Fra IARC Om DieselosDocument4 pagesRapport Fra IARC Om Dieselosredaktion6657Pas encore d'évaluation

- Combustion Control of Diesel Engines Using Injection TimingDocument12 pagesCombustion Control of Diesel Engines Using Injection TimingAhmad ElsheemyPas encore d'évaluation

- Research On Methano1-Fueled Marine Diesel EngineDocument13 pagesResearch On Methano1-Fueled Marine Diesel Engineahmed_eng_1500Pas encore d'évaluation

- InTech-Effect of Injector Nozzle Holes On Diesel Engine PerformanceDocument13 pagesInTech-Effect of Injector Nozzle Holes On Diesel Engine Performanceahmed_eng_1500Pas encore d'évaluation

- Kubota Engine ModelDocument1 pageKubota Engine Modelahmed_eng_1500100% (1)

- Four Stroke Diesel EngineDocument4 pagesFour Stroke Diesel EngineSwati SutarPas encore d'évaluation

- MB 10033Document8 pagesMB 10033Vinod YbPas encore d'évaluation

- Four Stroke Diesel EngineDocument4 pagesFour Stroke Diesel EngineSwati SutarPas encore d'évaluation

- Final Reg 2011Document52 pagesFinal Reg 2011ahmed_eng_1500Pas encore d'évaluation

- Engineering Software: Diesel Cycle AnalysisDocument18 pagesEngineering Software: Diesel Cycle Analysisesakkiraj05Pas encore d'évaluation

- Diesel CFDocument2 pagesDiesel CFahmed_eng_1500Pas encore d'évaluation

- Diesel Engine ProblemsDocument4 pagesDiesel Engine ProblemsArvind Sangeeta KothariPas encore d'évaluation

- Diesel Generator TroubleshootingDocument7 pagesDiesel Generator TroubleshootingChandra Vinoth Senthilnathan100% (4)

- Mesin DieselDocument6 pagesMesin DieselWilman BhiguPas encore d'évaluation

- DieselDocument6 pagesDieselahmed_eng_1500Pas encore d'évaluation

- Diesel 4Document11 pagesDiesel 4ahmed_eng_1500Pas encore d'évaluation

- Replace diesel pump engine with electric motor to save 70% on energy costsDocument3 pagesReplace diesel pump engine with electric motor to save 70% on energy costsahmed_eng_1500Pas encore d'évaluation

- Diesel Engine Converted For Gas OperationDocument9 pagesDiesel Engine Converted For Gas Operationsonu_cadPas encore d'évaluation

- Caterpillar EMCPDocument40 pagesCaterpillar EMCPrealwild93% (59)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseD'EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseÉvaluation : 4.5 sur 5 étoiles4.5/5 (50)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionD'EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsD'EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsD'EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsPas encore d'évaluation

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationD'EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationÉvaluation : 4 sur 5 étoiles4/5 (18)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedD'EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Laws of Thermodynamics: A Very Short IntroductionD'EverandThe Laws of Thermodynamics: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Handbook of Mechanical and Materials EngineeringD'EverandHandbook of Mechanical and Materials EngineeringÉvaluation : 5 sur 5 étoiles5/5 (4)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionD'EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionÉvaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Aerodynamics for Engineering StudentsD'EverandAerodynamics for Engineering StudentsÉvaluation : 5 sur 5 étoiles5/5 (5)

- Oil and Gas Pipelines: Integrity and Safety HandbookD'EverandOil and Gas Pipelines: Integrity and Safety HandbookPas encore d'évaluation

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationD'EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationÉvaluation : 1 sur 5 étoiles1/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsPas encore d'évaluation

- Waves and Beaches: The Powerful Dynamics of Sea and CoastD'EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastÉvaluation : 4 sur 5 étoiles4/5 (1)

- Albert Einstein's Theory Of Relativity Explained SimplyD'EverandAlbert Einstein's Theory Of Relativity Explained SimplyPas encore d'évaluation

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideD'Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeD'EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeÉvaluation : 3.5 sur 5 étoiles3.5/5 (4)

- Operational Amplifier Circuits: Analysis and DesignD'EverandOperational Amplifier Circuits: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)