Académique Documents

Professionnel Documents

Culture Documents

This System Must Be Followed at All Times!

Transféré par

Mohammed Jai Sujiya KhanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

This System Must Be Followed at All Times!

Transféré par

Mohammed Jai Sujiya KhanDroits d'auteur :

Formats disponibles

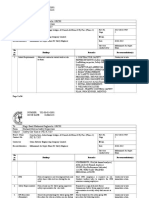

THIS SYSTEM MUST BE FOLLOWED AT ALL TIMES!

1. You must submit and RFI (Request for Inspection) before assembling the scaffolding. We will check all of the following. 2. That scaffolding materials is sufficient quality for the work to be performed. It must be in excellent condition. Scaffolding materials cannot be damaged or bent. 3. Area's around the base of the scaffolding must be clear of construction debris i.e. concrete blocks, trash, other waste materials. Good housekeeping is extremely important. 4. The ground must be as level as possible. 5. Base plates and mud sills made of 2X9 or 2X12 planking must be put in place as scaffolding foundation. If the scaffolding is level or plumb, it will be level and plumb all the way to the top. If it is not level or plumb scaffolding will lean in the direction that is not level. Mudsills and base plates also prevent settling into the soil due to the weight of the scaffolding. Should it rain it will prevent the scaffolding from eroding or washing away. 6. Scaffolding must be assembled under our supervision or that of a "Competent Person". 7. Starting with the base it must be assembled one level at a time. You do not proceed to the next level until the first level is complete. 8. Each level, except for the bottom level must be fully planked with 2X9 or 2X12 construction grade wooden planks. They cannot be warped or cracked. There can be no holes, gaps or openings! Full planking means full planking! Planks may overlap each other 6 - 12 inches. Planks must extend past the edge of the structure 6 - 12 inches to prevent them from falling or collapse should they shift. 9. Toe boards must be installed along all edges of the scaffolding to prevent workers from slipping under the guard rails and falling. They also prevent tools and other materials from accidentally being kicked over the edge causing a falling objects hazard. Toe boards must be at least 4 inches in height. 10. Hand rails, midrails and guardrails must be installed on all levels of the scaffolding especially the top level to protect workers from falling. Top rail must be at least 39 inches/1 meter in height. 11. As workers ascend to a height greater than 10 feet or 3.2 meters they must don a safety harness and lanyard and tie off to a secure anchor point to prevent them from falling while assembling the upper levels of the structure. 100 % tie off 100 % of the time. 12. As the structure reaches each level it must be secured to the building by the use of anchor bolts or other suitable fastening device. The scaffolding must be at least 14 inches from the building, no greater than 24 inches. Secure the scaffolding to the building every 30 feet or approximately 10 meters.

13. Cross braces must be attached on all levels and secured. All couplers must be tightened securely. 14. Access ladders must be installed at both ends of the scaffolding structure for workers to ascend and descend as a means of egress. Access Ladders must go all the way to the top of the structure! Access ladders must be secured in place at the base and at the top. 15. Scaffolding must be inspected upon completion and daily there after by the ALMAWRED Safety Officer to ensure it is safe to work on. A scaffolding tag must be placed at access to state that it was inspected and safe. If it found unsafe a scaffolding tag must state at access that it is unsafe and workers must not use the scaffolding under any circumstances. 16. Workers may not work from scaffolding during high winds or heavy rain. 17. Be aware of overhead power lines and electrical hazards as metal scaffolding conducts electricity. 18. Anyone working above 10 feet must be wearing fall protection and be tied off at all times! 19.Scaffolding height may not exceed 4 times its minimum base dimension unless outriggers are used to provide additional support. 20.Scaffolding must support 4 times its intended weight load.

Vous aimerez peut-être aussi

- SOP ScaffoldingDocument7 pagesSOP ScaffoldingNakkolop100% (1)

- Scaffolding Safety ChecklistDocument2 pagesScaffolding Safety Checklistpalanitharan100% (1)

- Scaffolding ProcedureDocument3 pagesScaffolding Proceduremd ruman100% (2)

- Safety in DismentallingDocument26 pagesSafety in DismentallingSubhransu MohapatraPas encore d'évaluation

- General Specification of ScaffoldingDocument5 pagesGeneral Specification of ScaffoldingAditya Hegde100% (1)

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsD'EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsÉvaluation : 3 sur 5 étoiles3/5 (8)

- Mobile Fire Extinguishers. Characteristics, Performance and Test MethodsDocument28 pagesMobile Fire Extinguishers. Characteristics, Performance and Test MethodsSawita LertsupochavanichPas encore d'évaluation

- Berger Paints - Ar-19-20 PDFDocument302 pagesBerger Paints - Ar-19-20 PDFSahil Garg100% (1)

- Procd Working at Height ScaffoldingDocument3 pagesProcd Working at Height ScaffoldingkhurramPas encore d'évaluation

- AFE Orking ON Caffolds: CaffoldingsDocument3 pagesAFE Orking ON Caffolds: Caffoldingsmd sarfaraz khanPas encore d'évaluation

- ScaffoldingDocument4 pagesScaffoldingolvernejacobs9741Pas encore d'évaluation

- Safety Lecture #9 44214387566669 PDFDocument17 pagesSafety Lecture #9 44214387566669 PDFRafi Mahmoud SulaimanPas encore d'évaluation

- Walking Work SurfacesDocument8 pagesWalking Work SurfacesSb TeoPas encore d'évaluation

- HSEP 13 8 A1 Fall Prevention System Requirement Rev 5Document5 pagesHSEP 13 8 A1 Fall Prevention System Requirement Rev 5mojgfdPas encore d'évaluation

- Construction Site PremisesDocument52 pagesConstruction Site PremisesAya AlmarioPas encore d'évaluation

- ReviewerDocument2 pagesReviewerHoney Garrovillo GacusPas encore d'évaluation

- Scaffolding GuidelinesDocument4 pagesScaffolding GuidelinesFrans ChandraPas encore d'évaluation

- Date: 10 April 2021 To: Concern To All Employees and Sub-Contractor Subject: Weekly Safety Toolbox Meeting Topic: Ladder SafetyDocument2 pagesDate: 10 April 2021 To: Concern To All Employees and Sub-Contractor Subject: Weekly Safety Toolbox Meeting Topic: Ladder SafetybryanPas encore d'évaluation

- 4 Scaffold RegulationsDocument6 pages4 Scaffold RegulationsCaron KarlosPas encore d'évaluation

- What Should You Check Before Using Scaffold?Document2 pagesWhat Should You Check Before Using Scaffold?Ange JuanPas encore d'évaluation

- Cuplock Scuffolding SOPDocument3 pagesCuplock Scuffolding SOPElangoPas encore d'évaluation

- Section 02010 - Site ClearingDocument5 pagesSection 02010 - Site ClearingMegklouie NovicioPas encore d'évaluation

- Working at Height SafetyDocument71 pagesWorking at Height SafetyAtma Prakash SinhaPas encore d'évaluation

- Ladder SafetyDocument27 pagesLadder SafetyKama Efendiyeva100% (1)

- Scaffolding Work ProcedureDocument6 pagesScaffolding Work ProcedureMuhammad Shiraz KhalidPas encore d'évaluation

- Reclamation Safety and Health Services Sec13Document25 pagesReclamation Safety and Health Services Sec13Jay BirdPas encore d'évaluation

- CH-11 PaintDocument3 pagesCH-11 Paintkim alfonsoPas encore d'évaluation

- Awareness On Working at HeightDocument3 pagesAwareness On Working at Heightsubhadipmanna8100% (1)

- 279 Falls SpecialIssueDocument8 pages279 Falls SpecialIssuesumit_b123Pas encore d'évaluation

- 7 FallPreventionSamDocument8 pages7 FallPreventionSamST ANNE GENERAL HOSPITAL INC (SAFETY DEPARTMENT)Pas encore d'évaluation

- Ladder SafetyDocument27 pagesLadder SafetySantanu Kumar Sahu100% (1)

- SOPDocument8 pagesSOPAilyn MercadoPas encore d'évaluation

- Fall Prot WWSurfacesDocument34 pagesFall Prot WWSurfacesDivakar DhandePas encore d'évaluation

- Annex 6. Working Procedures and InstructionsDocument11 pagesAnnex 6. Working Procedures and InstructionsNjiaPas encore d'évaluation

- Supported ScaffoldsDocument10 pagesSupported ScaffoldsMikaella ManzanoPas encore d'évaluation

- Ladder Safety GuidelinesDocument2 pagesLadder Safety Guidelinesneo_chemistPas encore d'évaluation

- Ladder SafetyDocument3 pagesLadder SafetyTXsafetymasters12Pas encore d'évaluation

- Scaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast NowDocument9 pagesScaffolding Safety Guideline: KAS-Scaffolding - Fast Then. Fast Nowfaizal4yaPas encore d'évaluation

- Safety Talk - ScaffoldingDocument2 pagesSafety Talk - ScaffoldingWael FathyPas encore d'évaluation

- Handout SafeworkmethodstatementsDocument8 pagesHandout SafeworkmethodstatementsHafiz SabriPas encore d'évaluation

- Site Safety ChecklistDocument5 pagesSite Safety ChecklistFAISAL RAZAPas encore d'évaluation

- TBT - AccessWork at HeightsDocument2 pagesTBT - AccessWork at HeightsMalefane Cortez TlatlanePas encore d'évaluation

- Work at HeightDocument69 pagesWork at HeightajayjanardhankaslePas encore d'évaluation

- Scaffolds ConstructionDocument34 pagesScaffolds Constructionharshal patilPas encore d'évaluation

- Working at HeightDocument30 pagesWorking at Heightmangesh.narkar638Pas encore d'évaluation

- Tool Box Talk 11 Working On RoofsDocument1 pageTool Box Talk 11 Working On RoofsRomanuSPas encore d'évaluation

- NASAC - Dos and Donts On ScaffoldsDocument1 pageNASAC - Dos and Donts On ScaffoldsHs supervisorsPas encore d'évaluation

- Class III Working AreaDocument45 pagesClass III Working AreaSaru ArjunanPas encore d'évaluation

- Saf102-Lecture 2: Good Housekeeping & Working at HeightsDocument4 pagesSaf102-Lecture 2: Good Housekeeping & Working at HeightsLin VictoriaPas encore d'évaluation

- Scaffolding HIRADocument15 pagesScaffolding HIRAlina ekawatiPas encore d'évaluation

- Vale ScaffoldsSafetyAwarenessDocument36 pagesVale ScaffoldsSafetyAwarenessGoldwin Ricky AritonangPas encore d'évaluation

- Safety, Health, and Environment Management SystemDocument1 pageSafety, Health, and Environment Management Systemmayank dataPas encore d'évaluation

- Scaffolding Safety ReportDocument6 pagesScaffolding Safety ReportRam RamirezPas encore d'évaluation

- Scaffold OverviewDocument33 pagesScaffold OverviewMohamedSaidPas encore d'évaluation

- Vcsu Safe Operating Procedures: Scaffolding SafetyDocument3 pagesVcsu Safe Operating Procedures: Scaffolding SafetyUmair RafiPas encore d'évaluation

- Scaffold TrainingDocument34 pagesScaffold TraininggilPas encore d'évaluation

- Safety While Working at HeightsDocument57 pagesSafety While Working at HeightsRísês Ãfröz100% (2)

- Office of State Human ResourcesDocument8 pagesOffice of State Human ResourcesMOHAMEDPas encore d'évaluation

- Scaffolding-Medical Cert.Document13 pagesScaffolding-Medical Cert.qoolshabiPas encore d'évaluation

- Safety Occup Lec #6 24102019229330861691598775Document12 pagesSafety Occup Lec #6 24102019229330861691598775Rafi Mahmoud SulaimanPas encore d'évaluation

- Bricklaying ChecklistDocument3 pagesBricklaying ChecklistFelipe RamalhoPas encore d'évaluation

- Mi StoreDocument1 pageMi StoreMohammed Jai Sujiya KhanPas encore d'évaluation

- FerariiiDocument1 pageFerariiiMohammed Jai Sujiya KhanPas encore d'évaluation

- Nebasulf PowderDocument1 pageNebasulf PowderMohammed Jai Sujiya KhanPas encore d'évaluation

- Mosa StoryDocument4 pagesMosa StoryMohammed Jai Sujiya KhanPas encore d'évaluation

- Don't Delete This Is The List For Drop Down Menu in Issue TypeDocument1 pageDon't Delete This Is The List For Drop Down Menu in Issue TypeMohammed Jai Sujiya KhanPas encore d'évaluation

- Meditation 12 Nov 2017Document1 pageMeditation 12 Nov 2017Mohammed Jai Sujiya KhanPas encore d'évaluation

- Ascenta Indira Appartment AddressDocument2 pagesAscenta Indira Appartment AddressMohammed Jai Sujiya KhanPas encore d'évaluation

- Radiotherapy ChemotherapyDocument17 pagesRadiotherapy ChemotherapyMohammed Jai Sujiya KhanPas encore d'évaluation

- Mi StoreDocument1 pageMi StoreMohammed Jai Sujiya KhanPas encore d'évaluation

- World GKDocument2 pagesWorld GKMohammed Jai Sujiya KhanPas encore d'évaluation

- Tgolden WordsDocument2 pagesTgolden WordsMohammed Jai Sujiya KhanPas encore d'évaluation

- Dior Shirts2016Document3 pagesDior Shirts2016Mohammed Jai Sujiya KhanPas encore d'évaluation

- Vega HELPDocument11 pagesVega HELPMohammed Jai Sujiya KhanPas encore d'évaluation

- Pic R-7513 2016.4.5.7507gac Dsir CommentsDocument5 pagesPic R-7513 2016.4.5.7507gac Dsir CommentsMohammed Jai Sujiya KhanPas encore d'évaluation

- Pic R-7507 Chec S-05hse Manager OfficerinspectorDocument1 pagePic R-7507 Chec S-05hse Manager OfficerinspectorMohammed Jai Sujiya KhanPas encore d'évaluation

- PIC R-7507 2015.30.03.5907 CHEC DSIR CommentsDocument6 pagesPIC R-7507 2015.30.03.5907 CHEC DSIR CommentsMohammed Jai Sujiya KhanPas encore d'évaluation

- DetoerDocument1 pageDetoerMohammed Jai Sujiya KhanPas encore d'évaluation

- PIC R-7507 2015.30.03.5907 CHEC DSIR CommentsDocument6 pagesPIC R-7507 2015.30.03.5907 CHEC DSIR CommentsMohammed Jai Sujiya KhanPas encore d'évaluation

- PIC R-7507 2015.30.03.5907 CHEC DSIR CommentsDocument6 pagesPIC R-7507 2015.30.03.5907 CHEC DSIR CommentsMohammed Jai Sujiya KhanPas encore d'évaluation

- Agenda Coordination Meeting No.02 Between Royal Commission (RC) and China Harbour Engineeing Arabia Co. Ltd. (Chec)Document3 pagesAgenda Coordination Meeting No.02 Between Royal Commission (RC) and China Harbour Engineeing Arabia Co. Ltd. (Chec)Mohammed Jai Sujiya KhanPas encore d'évaluation

- Pic R-7507 Chec S-05hse Manager OfficerinspectorDocument1 pagePic R-7507 Chec S-05hse Manager OfficerinspectorMohammed Jai Sujiya KhanPas encore d'évaluation

- Agenda Coordination Meeting No.02 Between Royal Commission (RC) and China Harbour Engineeing Arabia Co. Ltd. (Chec)Document3 pagesAgenda Coordination Meeting No.02 Between Royal Commission (RC) and China Harbour Engineeing Arabia Co. Ltd. (Chec)Mohammed Jai Sujiya KhanPas encore d'évaluation

- Foood Tew Mar 17Document5 pagesFoood Tew Mar 17Mohammed Jai Sujiya KhanPas encore d'évaluation

- 7507-MOM # 03 Dated 2015-05-27Document4 pages7507-MOM # 03 Dated 2015-05-27Mohammed Jai Sujiya KhanPas encore d'évaluation

- PIC R-7507 2015.30.03.5907 CHEC DSIR CommentsDocument6 pagesPIC R-7507 2015.30.03.5907 CHEC DSIR CommentsMohammed Jai Sujiya KhanPas encore d'évaluation

- Ascenta Indira Appartment AddressDocument2 pagesAscenta Indira Appartment AddressMohammed Jai Sujiya KhanPas encore d'évaluation

- Suras Dec16 GoddDocument9 pagesSuras Dec16 GoddMohammed Jai Sujiya KhanPas encore d'évaluation

- Suras Dec16 GoddDocument9 pagesSuras Dec16 GoddMohammed Jai Sujiya KhanPas encore d'évaluation

- Center Point 2016shoppingDocument3 pagesCenter Point 2016shoppingMohammed Jai Sujiya KhanPas encore d'évaluation

- Ascenta Indira Appartment AddressSDocument2 pagesAscenta Indira Appartment AddressSMohammed Jai Sujiya KhanPas encore d'évaluation

- Management and Entrepreneurship Important QuestionsDocument1 pageManagement and Entrepreneurship Important QuestionslambazPas encore d'évaluation

- q2 Long Quiz 002 EntreDocument8 pagesq2 Long Quiz 002 EntreMonn Justine Sabido0% (1)

- NOS 65-200-90x60-30KWD PDFDocument2 pagesNOS 65-200-90x60-30KWD PDFDao The ThangPas encore d'évaluation

- GGSB MibDocument4 pagesGGSB MibShrey BudhirajaPas encore d'évaluation

- Grade 5 Olympiad: Answer The QuestionsDocument14 pagesGrade 5 Olympiad: Answer The QuestionsVinieysha LoganathanPas encore d'évaluation

- AW-NB037H-SPEC - Pegatron Lucid V1.3 - BT3.0+HS Control Pin Separated - PIN5 - Pin20Document8 pagesAW-NB037H-SPEC - Pegatron Lucid V1.3 - BT3.0+HS Control Pin Separated - PIN5 - Pin20eldi_yePas encore d'évaluation

- Multiage Education in Small School SettingsDocument19 pagesMultiage Education in Small School SettingsMichelle Ronksley-PaviaPas encore d'évaluation

- TM9-238 Deepwater Fording of Ordnance Materiel PDFDocument35 pagesTM9-238 Deepwater Fording of Ordnance Materiel PDFdieudecafePas encore d'évaluation

- CRM Module 1Document58 pagesCRM Module 1Dhrupal TripathiPas encore d'évaluation

- HR Q and ADocument87 pagesHR Q and Asanjeeb88Pas encore d'évaluation

- Step Recovery DiodesDocument3 pagesStep Recovery DiodesfahkingmoronPas encore d'évaluation

- Unit 8 - Week 7: Assignment 7Document3 pagesUnit 8 - Week 7: Assignment 7Nitin MorePas encore d'évaluation

- Danais 150 ActuadoresDocument28 pagesDanais 150 Actuadoresedark2009Pas encore d'évaluation

- Scheduled Events in MySQL Load CSV Fileto MysqltabDocument11 pagesScheduled Events in MySQL Load CSV Fileto Mysqltabboil35Pas encore d'évaluation

- Organization of Brigada Eskwela Steering and Working CommitteesDocument2 pagesOrganization of Brigada Eskwela Steering and Working CommitteesCherry Lou RiofrirPas encore d'évaluation

- Longley Rice PropagationDocument11 pagesLongley Rice Propagationy_m_algbaliPas encore d'évaluation

- Q3 Week 1 Homeroom Guidance JGRDocument9 pagesQ3 Week 1 Homeroom Guidance JGRJasmin Goot Rayos50% (4)

- Transportation Problem VAMDocument16 pagesTransportation Problem VAMLia AmmuPas encore d'évaluation

- DCF ModelDocument14 pagesDCF ModelTera BytePas encore d'évaluation

- Top Ten Helicopter Checkride TipsDocument35 pagesTop Ten Helicopter Checkride TipsAbhiraj Singh SandhuPas encore d'évaluation

- KFF in OAF Page-GyanDocument4 pagesKFF in OAF Page-Gyangyan darpanPas encore d'évaluation

- Business Mathematics and Statistics: Fundamentals ofDocument468 pagesBusiness Mathematics and Statistics: Fundamentals ofSamirPas encore d'évaluation

- Guide On Multiple RegressionDocument29 pagesGuide On Multiple RegressionLucyl MendozaPas encore d'évaluation

- Techgig Open Round CompetitionDocument6 pagesTechgig Open Round CompetitionAnil Kumar GodishalaPas encore d'évaluation

- Audit Process - Performing Substantive TestDocument49 pagesAudit Process - Performing Substantive TestBooks and Stuffs100% (1)

- Pertemuan - 12 MetopenDocument40 pagesPertemuan - 12 MetopenulviaPas encore d'évaluation

- Balanza Pediatrica Health o Meter 549KL Mtto PDFDocument18 pagesBalanza Pediatrica Health o Meter 549KL Mtto PDFFix box Virrey Solís IPSPas encore d'évaluation

- 50 Hotelierstalk MinDocument16 pages50 Hotelierstalk MinPadma SanthoshPas encore d'évaluation