Académique Documents

Professionnel Documents

Culture Documents

API Flange Bolting Torque Chart

Transféré par

Cristian Alfredo OyarzunDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

API Flange Bolting Torque Chart

Transféré par

Cristian Alfredo OyarzunDroits d'auteur :

Formats disponibles

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

Sigma Fasteners Custom ASTM Bolting to Print Toll Free: (866) 378-3044 Phone: (281) 214-8800 Fax: (281) 214-8801

Home About Custom Coated Standard Quality Catalog International Contact Get Quote You are here: Home / Archives for PTFE Coated Bolts

Flouropolymer Coated Bolt Torque

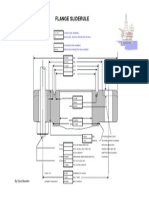

March 19, 2010 by Sigma Fasteners Leave a Comment API 6A is an International Standard which specifies requirements and gives recommendations for the performance, dimensional and functional interchangeability, design, materials, testing, inspection, welding, marking, handling, storing, shipment, purchasing, repair and re-manufacture of wellhead and well tree equipment for use in the petroleum and natural gas industries.

Download Torque Value Chart

1 de 8

19-07-2012 17:56

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

Covering bolts on Wellhead Equipment, Valves and chokes, and loose flanged connectors.

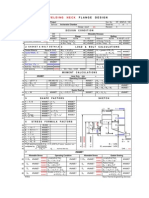

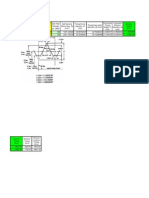

TORQUE FOR FLANGE BOLTING (B7/L7 STUDS)*

ANSI / API 6A / ISO 10423:2003 Feb. 1, 2005

ASTM A193 Grade B7 Tensile and Yield Strength 2 1/2 and under tensile 125 ksi; yield strength 105 ksi Over 2 1/2 to 4 tensile 115 ksi; yield 95 ksi Over 4 to 7 tensile 100; yield 75 ksi ASTM A320 L7 Tensile and Yield Strength Only covers 2 1/2 and under - tensile 125 ksi; yield strength 105 ksi

Source: API 6-A, 19th Appendix D, Table D1 & D2

Stud Diameter Size Inch

Tension Ibf

PTFE Coated Bolt coefficient of Friction

Plain Bolt coefficient of Friction

Torque Nm f=0.07

Torque Ft. lbs f=0.07 35 68 118 188 279 401 553 739 962 1226 1534 1890 2297 3276 4500 4716 5424 7047 8965 13782 15208

Torque Nm f=0.13 80 155 270 429 639 925 1285 1727 2261 2894 3636 4493 5476 7851 10828 11429 13168 17156 21878 33766 37293

Torque Ft. lbs f=0.13 59 115 200 319 474 686 953 1281 1677 2146 2696 3332 4061 5822 8030 8430 9712 12654 16136 24905 27506

1/2 5/8 3/4 7/8 1 1 1/8 1 1/4 1 3/8 1 1/2 1 5/8 1 3/4 1 7/8 2 2 1/4 2 1/2 2 5/8 2 3/4 3 3 1/4 3 3/4 3 7/8

7450 11865 17559 24241 31802 41499 52484 64759 78322 93173 109313 126741 145458 186758 233212 233765 257694 309050 365070 491099 525521

48 92 160 253 376 540 745 996 1297 1653 2069 2549 3097 4418 6068 6394 7354 9555 12154 18685 20620

2 de 8

19-07-2012 17:56

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

561108

22683

16730

41057

30282

*This chart is for general practice purposes only and should not be in the engineering or design of any products. The most current edition of the API specification may be obtained on the API Standards website to make sure you have the most current edition of API 6A. For most the accurate references in critical situations torque values should be replaced with field measured tension values. Accurate stud tension is difficult to attain using torque, because friction has a significant effect on the torquetension relationship. Any thread damage (however minor), additional lubrication, or standard deviations within the range can change friction and thereby the expected outcome. Filed under Coated Bolts, Stud Bolts Tagged with Coated Bolt Torque Values, Coated Bolts, PTFE Coated Bolts, Teflon Coated Bolts, Xylan Coated Bolts

Xylan Coated Bolts

February 19, 2010 by Sigma Fasteners Leave a Comment

Coated Stud Bolts Xylan Coated Stud Bolts Xylan 1010, 1070, 1014, 1052 and now 1424 have been used as bolt coatings for almost a quarter century now. Most major Oil and Chemical Companies recognizing that maintenance is a huge issue have made coated bolt specifications for bolted high pressure flange connections. The various properties on the Xylan give excellent make up and brake out torque and reduce the need for high risk cutting torches or high cost bolt cutting when maintenance is required. Xylan 1014 in bolt coatings used for its good lubricity, chemical and abrasion resistance. Xylan 1052 for coated bolts used for its excellent lubricity. Xylan 1070 and 1010 where the pioneers in the field used for the lubricity and chemical inertness. With VOCs an ever present issue these days Whitford has made a low VOC version 1424 which Sigma applies to achieve the results need in a coated bolt connection and to stay complaint in a green economy.

3 de 8

19-07-2012 17:56

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

Xylan coated bolts come in many tints and the coated bolts are often coordinated with standard corporate color branding schemes. While very light shades are possible most of the popular hues range from a Dark Yellow to black with Reds and Blues and greens being the most widespread. Filed under Coated Bolts, Custom Bolts, Stud Bolts Tagged with Bolt Coatings, Coated Bolt, Coated Bolts, PTFE Coated Bolts, Xylan Coated Bolt, Xylan Coated Bolts, Xylan Coating

Xylan Coating

February 6, 2010 by Sigma Fasteners Leave a Comment

Xylan Industrial Coating Service

Xylan coating prevents leaks past thread Pressure vessels, valves, pipe unions, storage tanks, reactors, pipelines and other fluid containment equipment are often fitted with threaded plugs for inspection, pressure relief, filling or tapping. Coatings on pipe plugs not only improve their performance and reliability but also make them easier to use. A thin film of Xylan eliminates the PTFE tape normally wrapped around the threads to seal them. In addition, the corrosion protection and low-friction properties of the coating greatly reduce breakout torques, enabling users to remove the plugs at a later date without destroying them. In most instances, the pipe plugs may be re-used without difficulty. Xylan coatings are also available in many colors, enabling users to color-code particular plug sizes and alloys.

Xylan 1014

Main Properties: High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Dry film lubricant. Thermoset. Wide use temperature. Typical Applications: Any mating surface which requires lubrication. Hinge pins. Piston casing. Compressors. Fasteners. Description: Resin-bonded, thermosetting, dry-film lubricant which, when compared to Xylan 1010 contains significantly more bonding resin relative to its content of PTFE lubricant. Altering the formula in this manner produces finishes which are harder, more abrasion resistant, glossier, and less porous. Frictional values remain low and very predictable. Working temp. range (continuous) -195C/-320F to 260/500F Working temp. range (intermittent) -195C/-320F to 285C/545F

Xylan 1052

Main Properties: High temperature resistant. High load carrying capacity. Abrasion / wear resistant. Thermoset.

4 de 8 19-07-2012 17:56

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

Typical Applications: Applications to prevent wear of mating surfaces under extreme load such as bearings, sealing rings, and valve springs. Main Properties: High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Thermoset. Wide use temperature. Corrosion resistant. Controlled torque. Typical Applications: Threaded fasteners. Description: Resin-bonded, thermosetting, dry film lubricant. It is formulated for high-pressure, low-speed wear applications and provides long-term lubrication for bearing surfaces subjected to extreme pressures, up to 150,000 psi (10,500 kg/cm2). The coating utilizes a unique dual lubrication system of PTFE and MoS2 and is superior to moly greases which wash away and PTFE coatings which cold flow. Resin-bonded lubricants in Xylan 1052 stay on the job, even in harsh chemical environments. Working temp. range (continuous) -195C/-320F to 260C/500F Working temp. range (intermittent) -195C/-320F to 285C/545F

Xylan 1070

Main Properties: High temperature resistant. Low coefficient of friction. Abrasion / wear resistant. Thermoset. Wide use temperature. Corrosion resistant. Controlled torque. Typical Applications: Threaded fasteners. Description: Resin-bonded, thermosetting, PTFE based, dry-film lubricant. It has extra corrosion protection and issued to coat large studs (B7), nuts, flanges, and related hardware for sub-sea and splash-zone service. Because of its predictable, low-friction properties, less make-up torque is required to produce the specified tension. During assembly, clamp loads are increased; scatter is reduced. In fact, the frictional characteristics are the most predictable of any lubricant, coating, or plating used on bolting. The low friction properties also reduce break-out torque, which allows removal of bolting with a wrench instead of a blowtorch. Application: Conventional spray. Working temp. range (continuous) -195C/-320F to 260C/500F Working temp. range (intermittent) -195C/-320F to 285C/545F

Xylan 1400

Main Properties: Corrosion resistant. Chemical resistant. Weathering resistant. Acid rain resistant. Typical Applications: Threaded fasteners for the building, chemical process, oil and off shore industries. Description: A recoatable RC coating developed to protect large fasteners and chemical processing equipment from chemical exposure (especially those with high pH). Although it contains a small percentage of PTFE lubricant to facilitate installation and prevent galling, it is considered a barrier coating rather than a dry film lubricant.

5 de 8

19-07-2012 17:56

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

Working temp. range (continuous) -50C/-58F to 175C/350F

Xylan 1424

Main Properties: Dry film lubricant. Corrosion resistant. Typical Applications: Any mating surface which requires lubrication. Hinge pins. Piston casing. Compressors. Threaded fasteners. Description: This VOC compliant*, resin-bonded, PTFE based coating is primarily formulated for use on fasteners to prevent corrosion and facilitate make-up torque. Working temp. range (continuous) -50C/-58F to 175C/347F Working temp. range (intermittent) -50C/-58F to 200C/392F More Xylan Inforamation Filed under Industrial Coating Service Tagged with Coated Bolts, PTFE Coated Bolts, Teflon Coated Bolts, Xylan, Xylan 1014, Xylan 1052, Xylan 1070, Xylan 1400, Xylan 1424, Xylan Coated Bolts, Xylan Coating

Coated Bolts

February 6, 2010 by Sigma Fasteners Leave a Comment Sigma Fasteners manufacturers coated studs to meet major Chemical and Oil Company standards. Sizes range from 1/2 inch 3 1/2 and larger.

Coated Stud Bolts Sigma coated bolts have a two-layer structure of special pretreatment polymer film and under-treatment layer. Phosphate Pre-treatment technique insures the physical performance of product without changing and fluropolymer top coating results in a better performance in resisting chemical and seawater corrosion. SermaGard coating is different from PTFE because of their strong corrosion resistant ability. Xylan can be different per customers request to meet various environmental working conditions.

6 de 8

19-07-2012 17:56

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

Xylan SermaGard Teflon PTFE Moly Xyan combined with an advanced treatment technology; the film is thin but is excellent in corrosion resistance which prolongs the lifespan of the product. Non-stick and low friction properties can make-up the torque coefficient which is easy to install and disassembling. Property of chemical & weather resistance make it suitable to various severe environments. Xyaln and SermaGard coatings are the best choice in offshore, oilfield and petrochemical precision equipment against corrosion. Its properties are particularly suitable for surface corrosion prevention of underwater precision equipment including Christmas tree, BOP and pipelines and other parts. Xylan coating properties: Low friction ( as low as 0.055) Remarkable adhesion Unusual resistance to wear and abrasion Excellent resistance to corrosion Resistance to chipping Resistance to the elements: weather, sunlight, salt water Working temperature range from: -190 to + 260 C Available in a wide range of colors Filed under Custom Bolts Tagged with Coated Bolts, Moly Coated Bolts, PTFE Coated Bolts, Teflon Coated Bolts, Xylan Coated Bolts, Zinc Plated Bolts Produts and Services Coated Bolts Custom Bolts Fasteners Industrial Coating Service Stainless Bolts Standard Bolts Stud Bolts Nuts and Bolts

304 Stainless Bolts 316 Stainless Bolt 316 Stainless Steel Bolt 660 ASTM Bolt Bolts Stud Coated

Bolts Custom Bolts Custom Fasteners Double End Studs

Pressure Bolting Inconel Bolt Inconel Bolts Metric

Duplex Stainless Flange Bolting High

7 de 8

19-07-2012 17:56

API Flange Bolting Torque Chart

http://www.sigmafasteners.com/tag/ptfe-coated-bolts

Stainless Bolt

Molybdenum Disulfide Moly

Coated Bolts Monel Bolt Monel Bolts Nitronic

60 PTFE

Coated Bolts SermaGard 1105 SermaGard 1280 SermaGard Coated Bolts

Bolt Specialty Bolts Stainless Bolt Stainless Bolting Stainless

SermaGard Coating Specialty

Carriage Bolt Stainless Carriage Bolts Stainless Hex Bolt Stainless Nuts and Bolts Stainless Steel Carriage Bolt Stainless Steel Carriage Bolts Stainless Steel Hex Bolts Stainless Steel Metric Bolts Stainless Steel Nuts and Bolts Stainless U Bolt

Stud Bolts Teflon

Coated Bolts Xylan

Coated Bolts Xylan Coating Zinc Plated Bolts

PostsComments Subscribe Log in Copyright 2012 All Rights Reserved Sigma Fasteners, Inc Return to top of page

Me gusta

A 23 personas les gusta esto. S el primero de tus amigos.

Tweet

8 de 8

19-07-2012 17:56

Vous aimerez peut-être aussi

- PCC-1-2010 Bolt Torque by FLG SizeDocument1 pagePCC-1-2010 Bolt Torque by FLG SizeemaanazeemPas encore d'évaluation

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- Bolt Stress and Torque Values for Standard FlangesDocument1 pageBolt Stress and Torque Values for Standard FlangesMaung SheinPas encore d'évaluation

- Bolt Torque ASME B16.5 Flanges - Sheet Gaskets 02Document26 pagesBolt Torque ASME B16.5 Flanges - Sheet Gaskets 02bakelly100% (7)

- Torque Coefficient and Axial Tension RelationshipDocument12 pagesTorque Coefficient and Axial Tension Relationshiplwin_oo2435100% (3)

- Bolt TorqueDocument20 pagesBolt TorqueArjun Singh AroraPas encore d'évaluation

- BOLTRIGHT Tightening Procedure 20-900Document2 pagesBOLTRIGHT Tightening Procedure 20-900zeids100% (4)

- GF - Installation Instructions For FlangesDocument6 pagesGF - Installation Instructions For FlangesHafiz KamalPas encore d'évaluation

- Body Flange Bolt TorqueDocument1 pageBody Flange Bolt TorqueLcm Tnl100% (1)

- Bolt Torque ASME B16 5 Flanges Spiral Wound GasketsDocument29 pagesBolt Torque ASME B16 5 Flanges Spiral Wound Gasketssaiful anwar100% (1)

- Flange Hydraulic Torque Tightening Procedure PDFDocument18 pagesFlange Hydraulic Torque Tightening Procedure PDFInzi100% (2)

- Torque Values RTJ (B16.5)Document3 pagesTorque Values RTJ (B16.5)ariyamanjulaPas encore d'évaluation

- Spiral Wound GasketsDocument3 pagesSpiral Wound GasketsHarish GundaPas encore d'évaluation

- Flange Leakage CheckingDocument3 pagesFlange Leakage CheckingKumar RPas encore d'évaluation

- Smooth Finish FlangesDocument4 pagesSmooth Finish FlangessanoopvkPas encore d'évaluation

- Bolt Torque ProcedureDocument5 pagesBolt Torque Procedurezeids100% (5)

- Flange CalculationsDocument5 pagesFlange CalculationsswapnavattemPas encore d'évaluation

- SAEP-351 Bolted Flange Joint AssemblyDocument12 pagesSAEP-351 Bolted Flange Joint AssemblyBebin Mathew75% (8)

- Assembling Flanged Joints Procedure1Document34 pagesAssembling Flanged Joints Procedure1Ndomadu100% (3)

- Loads On FlangesDocument16 pagesLoads On Flangesccoollest100% (3)

- Analysis of Bolt TorquingDocument7 pagesAnalysis of Bolt TorquingAlessandro Serafini100% (1)

- Working Philosophy of A Gasket To Prevent LeakageDocument4 pagesWorking Philosophy of A Gasket To Prevent LeakageAlfonPas encore d'évaluation

- Torque Wrench Tightening Torque CalculationDocument2 pagesTorque Wrench Tightening Torque CalculationAlupole_AlbertLim100% (1)

- Bolt Torque CalculationDocument3 pagesBolt Torque Calculationshazan100% (1)

- Flang ManegmentDocument12 pagesFlang ManegmentYasser Abd El Fattah100% (1)

- Bolt Torque Calculation For FlangeDocument1 pageBolt Torque Calculation For FlangeSaravanan Koomidi AnnaduraiPas encore d'évaluation

- Flange Bolt Tightening ProcedureDocument5 pagesFlange Bolt Tightening ProcedureArya100% (1)

- BOLT TORQUING, GASKET INSTALLATION AND VERIFICATION Rev.00 PDFDocument26 pagesBOLT TORQUING, GASKET INSTALLATION AND VERIFICATION Rev.00 PDFFlorante NoblezaPas encore d'évaluation

- Bolt Tensioning and Torquing SpecificationDocument11 pagesBolt Tensioning and Torquing Specificationpower12580% (5)

- Training Ver7.1 Calculate Flange - General ExampleDocument12 pagesTraining Ver7.1 Calculate Flange - General ExamplevantayusdPas encore d'évaluation

- Flange Management GuideDocument8 pagesFlange Management GuidekeronsPas encore d'évaluation

- What Is The Impact of Flange Finish On Gasket PerformanceDocument2 pagesWhat Is The Impact of Flange Finish On Gasket Performancem_stasys9939100% (2)

- Flange bolt size and spanner size chartDocument6 pagesFlange bolt size and spanner size chartŠhiññ ŠóhäïPas encore d'évaluation

- Hydrogen Compressor Flange Bolts FailureDocument8 pagesHydrogen Compressor Flange Bolts FailurePablo ScottPas encore d'évaluation

- Flangemanagementpresentation 160911122834Document83 pagesFlangemanagementpresentation 160911122834Yusuf Alfathony100% (2)

- How Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedDocument2 pagesHow Can Spiral Wound Gasket Selection and Installation Problems Be AvoidedTay Hua SetPas encore d'évaluation

- FLANGEDocument1 pageFLANGEscrbdgharavi50% (2)

- Smith Gasket BrochureDocument29 pagesSmith Gasket BrochureJeesan MathewPas encore d'évaluation

- Flange Calculation Sheet..Document2 pagesFlange Calculation Sheet..nguyenquoc198850% (2)

- Garlock Metal - Gaskets TorqueDocument48 pagesGarlock Metal - Gaskets TorqueakenathorPas encore d'évaluation

- Controlled Bolting ProcedureDocument18 pagesControlled Bolting ProcedureRafiqKuPas encore d'évaluation

- Hastelloy C-276 WeldingDocument4 pagesHastelloy C-276 WeldingClaudia MmsPas encore d'évaluation

- Example Calculation TorqueDocument8 pagesExample Calculation TorquePenchalaiah PodalakuruPas encore d'évaluation

- Bolt Torque DeterminationDocument11 pagesBolt Torque DeterminationRatna Giridhar Kavali100% (1)

- OEUP-InT1000-SOP-OPS-0031 PE Flange Assembly Bolt and Nut TighteningDocument16 pagesOEUP-InT1000-SOP-OPS-0031 PE Flange Assembly Bolt and Nut TighteningHasan Sevim100% (2)

- Torque-Tension Chart For B7Document1 pageTorque-Tension Chart For B7Ramón C. Silva H.Pas encore d'évaluation

- O Ring BrochureDocument36 pagesO Ring BrochureJesus N RodriguezPas encore d'évaluation

- Protech Seal BrochureDocument10 pagesProtech Seal BrochureRodrigo Jechéla Barrios0% (1)

- CSTR Oring Catalog Or2009Document48 pagesCSTR Oring Catalog Or2009roccandradoPas encore d'évaluation

- Rotary Seal Design GuideDocument434 pagesRotary Seal Design GuideBhargav Suvagiya100% (3)

- Castrol Longtime PD1 & PD2 Product Data SheetDocument3 pagesCastrol Longtime PD1 & PD2 Product Data SheetAmit NaikPas encore d'évaluation

- Molub Alloy 860Document3 pagesMolub Alloy 860akshatmalhotraPas encore d'évaluation

- Seal Cat PDFDocument44 pagesSeal Cat PDFkarinaerojasPas encore d'évaluation

- AGS Gaskets TrainingDocument31 pagesAGS Gaskets TrainingMee WinPas encore d'évaluation

- MRO Product Range From Project Sales Corp, IndiaDocument43 pagesMRO Product Range From Project Sales Corp, IndiaProject Sales CorpPas encore d'évaluation

- PDS - Mobilgrease XHP 460 SeriesDocument3 pagesPDS - Mobilgrease XHP 460 SeriesJuanSantillanPas encore d'évaluation

- Gasket RefDocument21 pagesGasket Refjun_bucayuPas encore d'évaluation

- Rotary Seals VringsDocument25 pagesRotary Seals VringsPatrick BaridonPas encore d'évaluation

- Hidrolik SilindirlerDocument20 pagesHidrolik SilindirlerEnver AtamanPas encore d'évaluation

- Bollhoff Armstrong HeliCoilDocument28 pagesBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- Information Sheet-CHS NCIIDocument9 pagesInformation Sheet-CHS NCIIRenel CuaresmaPas encore d'évaluation

- Lista 04-09-19Document6 pagesLista 04-09-19comunik1977Pas encore d'évaluation

- Definition of UMA: Basis For Comparison UMA NumaDocument10 pagesDefinition of UMA: Basis For Comparison UMA NumaaagamPas encore d'évaluation

- ABC Corp ProjectDocument32 pagesABC Corp Projectratnabpatel9700Pas encore d'évaluation

- Robotics Lab Session Covers Drive Mechanisms, Payloads, Sensors (MECH 4002YDocument12 pagesRobotics Lab Session Covers Drive Mechanisms, Payloads, Sensors (MECH 4002Ysanjiv0909Pas encore d'évaluation

- VtrisdocDocument145 pagesVtrisdocElmaz RexhepiPas encore d'évaluation

- Sacombank Success Story Dcc3354 SacomBank CS v4Document2 pagesSacombank Success Story Dcc3354 SacomBank CS v4thanh-truong-8011Pas encore d'évaluation

- 8086/8088 Microprocessor's: Registers and Their Role in MicroprocessorDocument18 pages8086/8088 Microprocessor's: Registers and Their Role in MicroprocessorHafsaAsgharPas encore d'évaluation

- Lab 5 Dig and NslookupDocument4 pagesLab 5 Dig and NslookupbripradPas encore d'évaluation

- Operator's Manual for SSAS Alert SystemDocument36 pagesOperator's Manual for SSAS Alert Systemgenaro guzmanPas encore d'évaluation

- JETCAS-CfP-0501-v1 - 1 PDFDocument2 pagesJETCAS-CfP-0501-v1 - 1 PDFersan turkmanPas encore d'évaluation

- BOLT! Mobile WiFi MF90 Update Tool v1.1 Manual Instruction For WindowsDocument7 pagesBOLT! Mobile WiFi MF90 Update Tool v1.1 Manual Instruction For WindowsSonia LimousPas encore d'évaluation

- ODA X4-2 TechDocument23 pagesODA X4-2 TechjaccehPas encore d'évaluation

- Virtualization EnablingDocument5 pagesVirtualization EnablingSaishiva SukkalaPas encore d'évaluation

- OSS ReferenceDocument336 pagesOSS ReferenceMonish R Nath50% (2)

- 1102 - Chapter 14 Maintaining and Optimizing Operating Systems - Slide HandoutsDocument28 pages1102 - Chapter 14 Maintaining and Optimizing Operating Systems - Slide HandoutsManuel ZambranoPas encore d'évaluation

- Microcontrollers and ApplicationsDocument228 pagesMicrocontrollers and ApplicationsGovinda Prasad AcharyaPas encore d'évaluation

- Clock SpeedDocument3 pagesClock Speedtironeschaska615Pas encore d'évaluation

- ECE Mnemonics 2014Document83 pagesECE Mnemonics 2014Jigs GarciaPas encore d'évaluation

- Swisspac Resources Hardware Price ListDocument4 pagesSwisspac Resources Hardware Price ListlipsinPas encore d'évaluation

- Guide To Load Share System Design and CommissioningDocument35 pagesGuide To Load Share System Design and CommissioningpeefincaPas encore d'évaluation

- Scanner Av 121Document2 pagesScanner Av 121myrudykuPas encore d'évaluation

- TE Aluminum Cable Clamp DatasheetDocument2 pagesTE Aluminum Cable Clamp Datasheetbrayan colorado tobonPas encore d'évaluation

- Computer Types Advantages and Disadvantages, I.TDocument6 pagesComputer Types Advantages and Disadvantages, I.TMilana Andrew100% (3)

- Computer ArchitectDocument194 pagesComputer Architectksu2006Pas encore d'évaluation

- Windows Support For HDD More Than 2TBDocument2 pagesWindows Support For HDD More Than 2TBNOWHERE-MANPas encore d'évaluation

- Tap Position Indicator Technical DetailsDocument4 pagesTap Position Indicator Technical DetailsS. M. Touhidur RahmanPas encore d'évaluation

- Serial Port Control Through A Shell Script - Stack OverflowDocument2 pagesSerial Port Control Through A Shell Script - Stack OverflowAntonio DxPas encore d'évaluation

- 1757 In092b en PDocument20 pages1757 In092b en PnmnicolauPas encore d'évaluation