Académique Documents

Professionnel Documents

Culture Documents

Current Limiting MCCB's

Transféré par

jannumitsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Current Limiting MCCB's

Transféré par

jannumitsDroits d'auteur :

Formats disponibles

Current Limiting MCCBs*

* Current Limiting Molded Case Circuit Breakers

Current Limiting MCCBs

Some of todays high performance molded case circuit breakers have had the qualifier current limiting added to their description in recent years. Current generation design technology has resulted in these products offering customer solutions based on additional features and benefits beyond traditional overcurrent protection capabilities. This paper will discuss the design, construction and application of current limiting molded case circuit breakers. Current limiting overcurrent protective devices have been available in the marketplace for many years. The age old competition between fuses and circuit breakers has reached a new level with the introduction of these fast acting, high performing current limiting circuit breakers. Current limiting fuse applications require compromises by the end user, especially in 3-phase applications. It is not unusual for at least one of the three fuses in the circuit not to open during an overcurrent event. This could create a single phasing situation on the system which could result in equipment damage, especially in motor applications. To assure that all three phases are open prior to inspection, maintenance or fuse replacement, the switching device in which the fuses are installed must either be manually opened or have supplemental means to automatically open the switch, which is common only above 800 amperes. Although these switches always include safety interlocking to assure that the clips or clamps are de-energized, local codes may still require that service technicians wear protective clothing during this replacement process. Market dynamics have encouraged other current limiting solutions. This has led to the demand for circuit breaker-based current limiting devices in recent years. We will examine what current limiting means in the context of circuit breaker applications, what technical design hurdles were overcome, and discuss numerous benefits of circuit breaker-based solutions.

Current limiting when applied to circuit breakers describes a unique capability that extends beyond the normal tripping features of a circuit breaker.

Current Limiting Defined

Current limiting when applied to circuit breakers describes a unique capability that extends beyond the normal tripping features of a circuit breaker. Although all circuit breakers could be said to limit current by opening during an overload or fault current condition, current limiting circuit breakers are special versions that provide additional protection. This current limiting protection is provided typically beyond the calibration of the instantaneous trip system that would typically respond to fault current. But first, we need to fully understand the need for current limitation in electrical systems and how the standards define current limiting. During a fault current event, usually referred to as a short circuit, one or more of the electrical conductors make accidental contact with ground or an adjacent phase. This can be compared to a broken water main. The electric current in the circuit, like the water in the pipe, wants to take the shortest path out. At that moment when there is a phase to phase or phase to ground failure, all of the electric current available rushes to that short circuit pushed by the system voltage, much like the pressurized water in that main rushes to the area of the break. Unlike our water main example, however, engineers have designed fast-acting protective devices to minimize the damage that can occur during a short circuit. These circuit breakers operate very rapidly to limit the short circuit current flow before it reaches a level that damages electrical conductors in the equipment, as well as the downstream load. The standard for molded case circuit breakers, UL 489 (and its current twin, IEC 60947-2), defines a current limiting circuit breaker as one that does not employ a fusible element and, when operating within its current-limiting range, limits the let-through I2t to a value less than the I2t of

2

Compliments of ABB Inc., Wichita Falls, TX 888-385-1221

Current Limiting MCCBs

a 1/2-cycle wave of the symmetrical prospective current. 1 Furthermore, I2t is defined as an expression related to the circuit energy as a result of current flow. With respect to circuit breakers, the I2t is expressed for the current flow between the initiation of the fault current and the clearing of the circuit. 2 Expressed graphically, the energy in the circuit, I2t, is represented as the area under the curve. For a circuit breaker to be current limiting, it must interrupt the short circuit energy in one half cycle or less. It should be noted that an electrical short that lasts just three cycles adds six times the energy of one lasting just one-half cycle. In 60 Hz systems, half cycle

Figure 1

For a circuit breaker to be current limiting, it must interrupt the short circuit energy in one half cycle or less.

tripping means that the circuit breaker must sense the short circuit current, trigger the tripping mechanism, part the electrical contacts, and interrupt the subsequent arc in no more than 8.3 milliseconds. However, this interruption is performed only when the short circuit current is in the current limiting range of the trip device. This range is typically above the 10X to 15X instantaneous trip element calibration in these high-end molded case circuit breakers (MCCBs). To perform these functions at the speeds required to be current limiting requires fast acting current sensing, a special mechanism, customized electrical contacts, and unique arc chute construction. We will examine these features in the next section.

Current Limiting Design Features

Current limiting capability has been made possible in part due to advancements in molding compounds for MCCBs. Because modern insulating materials tolerate high temperatures, withstand significant mechanical stress, and provide higher dielectric integrity, circuit breaker designers have been able to exploit these features in their designs. Although the newer plastics enabled the creation of these breakers, many other design elements had to converge to create the complete package. In earlier generations of circuit breakers, the electrical contact assemblies, including the moving insulated parts that isolated them, were hefty designs that had to be set in motion to open the circuit. These designs do not allow the high speed movement that true current limiting capability requires. Engineers have developed designs that maintain the continuous current capability of previous designs, while decreasing the mass of the various current carrying parts. They have also positioned internal current carrying parts so that current is flowing in parallel but opposite directions, thus creating a repulsive electromagnetic force which acts upon the movable contact arm, causing the contacts to separate rapidly. This reverse current flow is another design feature that differentiates a conventional molded case circuit breaker from a circuit breaker with current limiting performance. In the current limiting ABB Tmax design, the arcing contacts close immediately as the main contacts part, transferring the energy to the arcing contacts. At the moment of arcing contact separation, there is an instantaneous formation of a voltage arc from the contacts

1 2

This reverse current flow is another design feature that differentiates a conventional molded case circuit breaker from a circuit breaker with current limiting performance

from UL 489, paragraph 2.25, April 25, 2002 from UL 489, paragraph 2.50, April 25, 2002

3

Compliments of ABB Inc., Wichita Falls, TX 888-385-1221

Current Limiting MCCBs

ABB Tmax Series Circuit Breakers

Tmax T2

Tmax T4

Tmax T5

The ABB molded case current limiting circuit breakers contain and dissipate ionized gases within the case of the circuit breaker.

as they part. Specially shaped arcing contacts pull the arc up rapidly into the arc chute plates. The general shape of the main contacts, arcing contacts and the area adjacent to the contacts contribute to a magnetic effect that encourages the arc to move in the direction of the arcing chute plates. As the current carrying parts were downsized, operating mechanisms were simplified to allow rapid operation. Coupled with the repulsive electromagnetic force generated by the contacts themselves, contact parting takes place early enough in the current half cycle to allow full arc extinction in the arc chutes. Perhaps the hardest working part of the current limiting molded case circuit breaker, the arc chutes, have also been optimized for current limitation. Featuring designs similar to conventional arc chutes, the arc chute has multiple parallel steel plates. Note, however, that the steel arc chute plates inside the arc chute are electrically separated from one another. During the initiation of the high energy arc, an electrical potential is generated between each of the arc chute plates. This arc chute voltage opposes the electrical system voltage driving the short circuit current. This further acts to elongate and snuff out the arc in the general proximity of the arc chute plates. To further stretch the arc, alternate plates differ in general shape so that the arc is forced to zigzag from plate to plate. This segmentation of the arc allows it to be rapidly extinguished. Hot ionized gases are by-products as the high energy arc is created. These gases must have a path of escape through the arc chute and its baffles. If these ionized gases happen to contact grounded steel components adjacent to the arc chute inside or above the circuit breaker, they will create a path to ground for the arc. At that point, control of the arc is lost and significant damage can result. It is for this reason, The ABB molded case current limiting circuit breakers contain and dissipate ionized gases within the case of the circuit breaker. There is one final component that provides a key role in current limiting molded case circuit breaker performance, the trip system. Current limiting molded case circuit breaker trip systems fall into two categories: electro-mechanical and electronic. Traditional electro-mechanical trip systems use a magnetic trip assembly, which acts as a simple solenoid when a magnetic field is created in

4

Compliments of ABB Inc., Wichita Falls, TX 888-385-1221

Current Limiting MCCBs

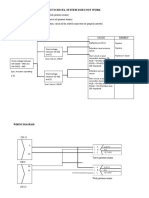

the breaker due to high current flow. This triggers immediate circuit breaker opening. Electronic trip systems have allowed extremely fast recognition of high fault current events, surpassing electro-mechanical trip systems for speed. Using current sensors in each phase of a three pole circuit breaker, electronic trip systems derive both their control power and current magnitude from these sensors. Employing a microprocessor with embedded software, electronic trip systems monitor the current magnitude for overload, short circuit and high energy trip conditions. It is the third condition, high energy trips, that provide the current limiting performance. With the ability to sense the rate-of-rise of the current, di/dt as it is called; electronic trip systems allow end users to customize the current limiting performance of the circuit breaker according to fault current rate-of-rise. In Figure 1, two trip currents are shown; curve 1 is a high energy fault current, curve 3 is a lower level fault current. For the circuit breaker to respond within the first half cycle, the rateof-rise, di/dt1 is calculated. This is compared to the programming of the trip system; if the rate-of-rise meets the current limiting trip criteria, the circuit breaker flux shifter is energized to trip the opening mechanism. The other fault condition, signified by curve 3 would not meet the criteria for high speed instantaneous tripping; its rate-of-rise di/dt2 is much lower. Curve 2 represents the letthrough current allowed by the current limiting circuit breaker prior to complete interruption. Obviously the I2t, the area under that curve, is much less than that of curve 1. The potential damage that could have resulted in downstream devices served by a current limiting circuit breaker is, therefore, significantly reduced. That capability plays a key role in the short circuit current ratings of industrial control panels.

...the SCCR represents the maximum short circuit current level that the ICP can safely withstand without compromising safety of the building or personnel.

Current Limiting Circuit Breakers and Short Circuit Current Ratings

Resulting from revisions in the 2005 National Fire Protection Association (NFPA) 70, better known as the National Electrical Code, industrial control panels are now required to have a short circuit current rating (SCCR) appear on their nameplate. Article 409 was added to the NEC to focus on safe design, application, and inspection of industrial control panels. Rising out of concern for the misapplication of industrial control panels, the NEC requires that consideration be given for short circuit current rating of the entire assemblycircuit breaker, contactor, overload relay, and terminal blocks. The short circuit current rating, by definition is the maximum RMS symmetrical current that the industrial control panel (ICP) can withstand for a minimum of three ac cycles (50 milliseconds) or until a circuit breaker clears this circuit. In other words, the SCCR represents the maximum short circuit current level that the ICP can safely withstand without compromising safety of the building or personnel. To assist design engineers, UL 508A, Supplement SB, was issued to define the process for determining the SCCR of an ICP. With regard to current limiting circuit breakers, 508A supplement SB4.3.2 states that for branch circuit breakers . marked current limiting in the feeder circuit, the short circuit current rating on the line side of the circuit breaker shall be ..(a) the short circuit current rating of the feeder circuit breaker when all of the components in the branch circuit have a short circuit current rating not less than the published peak let-through current of the circuit breaker. The SCCR of the ICP is not to be confused with interrupting ratingsthese ratings are associated with overcurrent protective devices, like circuit breakers. A circuit breaker interrupts a short circuit at its rated interrupting rating. Although a circuit breaker is included in the ICP, the SCCR of the ICP is usually not the interrupting rating of that circuit breaker. Other devices with lower short circuit current ratings inside the ICP will tend to lower the

5

Compliments of ABB Inc., Wichita Falls, TX 888-385-1221

Current Limiting MCCBs

Figure 2

Circuit Breaker Type Circuit Breaker Range 15 30 50 100 100 250 600 250 600 10 kA Let Through Energy (I2t [106 A2s]) 0.21 0.26 0.26 0.31 0.30 0.54 1.30 0.52 1.00 Let Through Peak (Ip 103) 480 V T2 Thermal Magnetic Trip T2 Electronic Trip T4 T5 T4 T5 8.7 13 11 11 11 16 16 600 V 14 16 1.30 2.70 30 36 1.4 3.0 37 43 0.31 0.40 0.45 0.49 0.48 1.30 2.40 15 17 21 21 21 35 41 1.5 2.4 41 48 50 kA Let Through Energy (I2t [106 A2s]) Let Through Peak (Ip 103) 100 kA Let Through Energy (I2t [106 A2s]) Let Through Peak (Ip 103)

short circuit current rating of the overall assembly. But the proper application of current limiting molded case circuit breakers, like the ABB Tmax line, reduces the let-through energy to these vulnerable components. These current limiting circuit breakers, therefore, allow higher short circuit current ratings to be posted on industrial control panels. This concept can best be illustrated using an ABB MCCB Combination Starter example. As shown by the values in Tables 1 and 2 above, the combination kA rating improves from 22kA to 50kA when a current limiting device is applied in place of a standard breaker. In Table 2, the peak let through current, IP, and the clearing, I2t, are shown for various ABB Tmax circuit breakers at selected interrupting ratings. When determining the SCCR of an industrial control panel that has a Tmax circuit breaker installed, Table 1 provides a quick reference for circuits with prospective short circuit currents of 10kA, 50kA or 100KA. In this example, when the components of the industrial control panel meet the criteria outlined in UL 508A, SB4.3.2 above, then that panel will have the short circuit current rating of the feeder.

In Summary

To achieve the half cycle interruption required to be truly current limiting, the current limiting circuit breaker will have the following design features: Special main and arcing contacts that part quickly and transfer arc energy to the arc chute effectively Instantaneous development of arc voltage that opposes the system voltage driving the short circuit current. Arc chamber design that controls the arc, dissipates and exhausts the ionized gases, and contains the spray of molten material from the arcing contacts Fast acting instantaneous sensing and trip system

6

Compliments of ABB Inc., Wichita Falls, TX 888-385-1221

Current Limiting MCCBs

Achieving true current limitation in MCCBs is the combination of specialized internal circuit breaker components all configured to sense and interrupt a rapidly rising short circuit current in the first quarter cycle so that interruption is complete within the first half-cycle. The benefits of current limitation have a significant economic impact. For downstream equipment that cannot withstand the effects of the full short circuit current, damage will occur in conductors and the equipment being fed. By designing systems with current limiting protection in the system, this costly damage can be minimized. Current limiting breakers in new power systems have another beneficial attribute. Because they can limit current to the downstream components, in some cases equipment designers are able to re-size their downstream components. In addition, compared to the equipment costs of fused low voltage circuit breakers, modern current limiting circuit breaker avoid upfront costs as well as maintenance and surveillance costs for the future. Although current limiting circuit breakers have many clear benefits, they are not able to completely limit the arc flash to the point that unprotected individuals would not be at risk. Even when limiting the current and energy to a much smaller let-through, that let through is still capable of exposing personnel to a significant number or calories per square centimeter. Service personnel must still plan to wear layers of PPE when performing service on live equipment. Unlike fused equipment that must necessarily be serviced through the open door of its enclosure, circuit breaker-based current limiting devices can be reset and re-closed with the door closed, after the original short circuit condition has been cleared. Arc flash detection relays like ABBs Arc Guard or REA101 relays provide a rapid response to the light flash; main circuit breakers connected to these relays can trip much faster than their usual current sensing components can provide. Use of current limiting relays, in addition to these arc flash detection relays, provide comprehensive arc flash mitigation. Current limiting molded case circuit breakers should be part of any comprehensive power distribution system or control panel design.

7

Compliments of ABB Inc., Wichita Falls, TX 888-385-1221

ABB Inc. 1206 Hatton Road Wichita Falls, TX 76302 Telephone 888-385-1221; 940-397-7000 Fax 940-397-7085 www.abb.us/lowvoltage

Publication No. LV127 1SXU210127G0201 Printed in USA, March 2009

Vous aimerez peut-être aussi

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringD'EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringPas encore d'évaluation

- Insulation Co-ordination in High-voltage Electric Power SystemsD'EverandInsulation Co-ordination in High-voltage Electric Power SystemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Voltage Transformers Type UMZDocument25 pagesVoltage Transformers Type UMZpattarawatPas encore d'évaluation

- K Rating of Transformers Supplying Harmonic Rich LoadsDocument33 pagesK Rating of Transformers Supplying Harmonic Rich LoadsJonas Abilio Sestrem JuniorPas encore d'évaluation

- Internal Arc TestingDocument5 pagesInternal Arc Testinggosalhs9395Pas encore d'évaluation

- Earth Potential Rise ManualDocument25 pagesEarth Potential Rise Manualparas99Pas encore d'évaluation

- IEC60183 Cable-HV Cable Selection Guide-1990Document19 pagesIEC60183 Cable-HV Cable Selection Guide-1990Mohammad Husain100% (1)

- MCCBDocument80 pagesMCCBSomnath Das100% (1)

- BEF Calculation - Part 2 PDFDocument8 pagesBEF Calculation - Part 2 PDFLin HengPas encore d'évaluation

- Impedance Correction FactorDocument7 pagesImpedance Correction FactorEngr Fahimuddin QureshiPas encore d'évaluation

- CT154 (Anglais)Document31 pagesCT154 (Anglais)kamlzPas encore d'évaluation

- Medium Voltage Capacitor Bank SpecificationsDocument4 pagesMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaPas encore d'évaluation

- MV Power CablesDocument32 pagesMV Power CablesMuhammad AlshafiPas encore d'évaluation

- SPE Earthing Presentation 1Document33 pagesSPE Earthing Presentation 1Azad RahmanPas encore d'évaluation

- CT152 - Harmonic Disturbances in Networks and Their TreatmentDocument31 pagesCT152 - Harmonic Disturbances in Networks and Their TreatmentlcatelaniPas encore d'évaluation

- Ect129 Uninterruptible Static Power Supplies and The Protection of PersonsDocument44 pagesEct129 Uninterruptible Static Power Supplies and The Protection of PersonsMarko VujicaPas encore d'évaluation

- Littelfuse Arc-Flash Hazards White PaperDocument8 pagesLittelfuse Arc-Flash Hazards White PaperVigneshwaran KandaswamyPas encore d'évaluation

- Coordination of LV Protection DevicesDocument44 pagesCoordination of LV Protection Deviceslsanchezorjuela100% (1)

- Underground Power Cables: Jatinder Singh 1241084 B.Tech Ee-7 Ctiemt, Shahpur, JalandharDocument42 pagesUnderground Power Cables: Jatinder Singh 1241084 B.Tech Ee-7 Ctiemt, Shahpur, JalandharGopinath B L NaiduPas encore d'évaluation

- 1MRG012769 en Application Note Injection Based 100 Stator Earth Fault Protection in REG670 PDFDocument9 pages1MRG012769 en Application Note Injection Based 100 Stator Earth Fault Protection in REG670 PDFRajendra Prasad ShuklaPas encore d'évaluation

- Calculation of Induced Sheath Voltage For Transposed and Untransposed Cable ConductorsDocument6 pagesCalculation of Induced Sheath Voltage For Transposed and Untransposed Cable ConductorsPradeep PooNoorPas encore d'évaluation

- Whitepaper Ground Potential Rise ExplainedDocument17 pagesWhitepaper Ground Potential Rise ExplainedHaresh RenkutlaPas encore d'évaluation

- Auxiliary System Protection DesignDocument26 pagesAuxiliary System Protection DesignPreetham100% (1)

- Voltage Sags.... 2020Document13 pagesVoltage Sags.... 2020Dr Hafiz Mudassir Munir - Assistant ProfessorPas encore d'évaluation

- LV Network Calculations and Use of AmtechDocument38 pagesLV Network Calculations and Use of AmtechAbraham JyothimonPas encore d'évaluation

- HV Sheath Voltage Calculation - SampleDocument8 pagesHV Sheath Voltage Calculation - SampleOliver HermosaPas encore d'évaluation

- Presenation ON: Insulation Cordination AND Insualtion Level of Substation EquipmentDocument16 pagesPresenation ON: Insulation Cordination AND Insualtion Level of Substation EquipmentshreyaPas encore d'évaluation

- Page 1 of 4 Why Your Capacitor Bank Should Be Left UngroundedDocument4 pagesPage 1 of 4 Why Your Capacitor Bank Should Be Left UngroundedArunava BasakPas encore d'évaluation

- Transformer Tech TestingDocument60 pagesTransformer Tech TestingCiel Aire100% (1)

- Battery Sizing: From Open ElectricalDocument11 pagesBattery Sizing: From Open ElectricalBADRI VENKATESHPas encore d'évaluation

- Technical User Guide HV XLPE Cable Systems enDocument21 pagesTechnical User Guide HV XLPE Cable Systems enTaner ErtürkPas encore d'évaluation

- Bus ReactorDocument6 pagesBus Reactorbibhoo100% (1)

- Fast Bus Transfer Systems For Critical Process ContinuityDocument11 pagesFast Bus Transfer Systems For Critical Process ContinuityamdatiPas encore d'évaluation

- Current Carrying Capacity of Underground CableDocument7 pagesCurrent Carrying Capacity of Underground CableSathit Buapanommas0% (1)

- Technical Report - Internal Arc - OrmazabalDocument10 pagesTechnical Report - Internal Arc - OrmazabalAshish RanjanPas encore d'évaluation

- Earthing and Lightning Protection Systems PDFDocument88 pagesEarthing and Lightning Protection Systems PDFSky LightPas encore d'évaluation

- HV Cable Sheath EarthingDocument15 pagesHV Cable Sheath EarthingjuliancansenPas encore d'évaluation

- Benefits of Using IEC 61439 Standard in Electrical Busbar SystemsDocument9 pagesBenefits of Using IEC 61439 Standard in Electrical Busbar SystemsMessung Power Distribution SystemsPas encore d'évaluation

- Internal Insulation Failure of HV EquipmentDocument6 pagesInternal Insulation Failure of HV EquipmentashawishPas encore d'évaluation

- Major Factors Affecting Cable AmpacityDocument6 pagesMajor Factors Affecting Cable AmpacityfvicunaePas encore d'évaluation

- STATCOMDocument5 pagesSTATCOMVenkateshPas encore d'évaluation

- Cable Termination KitDocument17 pagesCable Termination KitAshutosh Sharma100% (1)

- ArresterFacts 032 The Sheath Voltage LimiterDocument9 pagesArresterFacts 032 The Sheath Voltage Limiterdwas1314Pas encore d'évaluation

- 35-sdms-01 Rev.01Document14 pages35-sdms-01 Rev.01Mohammad FathiPas encore d'évaluation

- As 61800.6-2007 Adjustable Speed Electrical Power Drive Systems Guide For Determination of Types of Load DutyDocument8 pagesAs 61800.6-2007 Adjustable Speed Electrical Power Drive Systems Guide For Determination of Types of Load DutySAI Global - APACPas encore d'évaluation

- 7pg21 Solkor R RF Catalogue SheetDocument26 pages7pg21 Solkor R RF Catalogue SheetsmcraftPas encore d'évaluation

- Y Vs Delta - IEC 60076-8Document1 pageY Vs Delta - IEC 60076-8Krishna VenkataramanPas encore d'évaluation

- Grounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal PradeshDocument7 pagesGrounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal Pradeshostojic007Pas encore d'évaluation

- Cleveland Cable Catlaogue 2012 PDFDocument140 pagesCleveland Cable Catlaogue 2012 PDFjaliscoruedaPas encore d'évaluation

- Article Ultrasonic or TevDocument2 pagesArticle Ultrasonic or Tevanchak99Pas encore d'évaluation

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsD'EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsPas encore d'évaluation

- The Dangers of DC High Voltage Test For XLPE Cables at SiteDocument4 pagesThe Dangers of DC High Voltage Test For XLPE Cables at SiteLTE002Pas encore d'évaluation

- Medium Voltage Capacitor SwitchingDocument52 pagesMedium Voltage Capacitor Switchinganand_girgaonkarPas encore d'évaluation

- DC Arc Flash Calculation Example: Test Project: DC DemoDocument8 pagesDC Arc Flash Calculation Example: Test Project: DC DemomiguelpaltinoPas encore d'évaluation

- Manual UG ZS1 2016 11Document116 pagesManual UG ZS1 2016 11maruf048100% (1)

- Resistance Grounded Systems: PurposeDocument6 pagesResistance Grounded Systems: Purposerenjithas2005Pas encore d'évaluation

- System Earthing: Technical InstituteDocument70 pagesSystem Earthing: Technical InstituteBasudev PatraPas encore d'évaluation

- L V P C C: Phelps Dodge Conductor Type CVDocument2 pagesL V P C C: Phelps Dodge Conductor Type CVgari_monsantoPas encore d'évaluation

- Knowledge is "Real Power": Introduction to Power QualityD'EverandKnowledge is "Real Power": Introduction to Power QualityPas encore d'évaluation

- AP Bets Big On Renewable Energy - Business LineDocument1 pageAP Bets Big On Renewable Energy - Business LinejannumitsPas encore d'évaluation

- 21 5 10 1978wiremenDocument5 pages21 5 10 1978wiremenjannumitsPas encore d'évaluation

- System Integration DepartmentDocument1 pageSystem Integration DepartmentjannumitsPas encore d'évaluation

- StartupIndia ActionPlan 16january2016Document40 pagesStartupIndia ActionPlan 16january2016Kaushik RudraPas encore d'évaluation

- The Make in India Opportunity in Five Charts - Print View - LivemintDocument1 pageThe Make in India Opportunity in Five Charts - Print View - LivemintjannumitsPas encore d'évaluation

- Storage ContainerDocument1 pageStorage ContainerjannumitsPas encore d'évaluation

- Croatia's Capital Zagreb - The City With A Million HeartsDocument1 pageCroatia's Capital Zagreb - The City With A Million HeartsjannumitsPas encore d'évaluation

- l359 14my SpecsDocument2 pagesl359 14my SpecsjannumitsPas encore d'évaluation

- 11 Traits That All SucceDocument2 pages11 Traits That All SuccejannumitsPas encore d'évaluation

- 2014 in TeluguDocument1 page2014 in TelugujannumitsPas encore d'évaluation

- NotificationDocument16 pagesNotificationjannumitsPas encore d'évaluation

- Economics of Renewable Energy Power PlantsDocument4 pagesEconomics of Renewable Energy Power PlantsjannumitsPas encore d'évaluation

- RegistDocument1 pageRegistjannumitsPas encore d'évaluation

- Annual Maintenance Contract (Form)Document1 pageAnnual Maintenance Contract (Form)jannumitsPas encore d'évaluation

- Worldwide Smartphone Sales Hit 267 Million in Q1 2014Document1 pageWorldwide Smartphone Sales Hit 267 Million in Q1 2014jannumitsPas encore d'évaluation

- ISD Tariff RevisionDocument11 pagesISD Tariff RevisionjannumitsPas encore d'évaluation

- English Grammar TensesDocument38 pagesEnglish Grammar Tensesapi-283719185Pas encore d'évaluation

- WSG01 01 CapacityDocument3 pagesWSG01 01 CapacityjannumitsPas encore d'évaluation

- Future Seven Rules To Stop Your Phone Taking Over Your LifeDocument4 pagesFuture Seven Rules To Stop Your Phone Taking Over Your LifejannumitsPas encore d'évaluation

- Delhi MetroDocument6 pagesDelhi MetroShafaqueAlamPas encore d'évaluation

- Good Experience and Relieving CertificateDocument3 pagesGood Experience and Relieving CertificatejannumitsPas encore d'évaluation

- ISD Tariff RevisionDocument11 pagesISD Tariff RevisionjannumitsPas encore d'évaluation

- OLClipper - 2014 04 17Document7 pagesOLClipper - 2014 04 17jannumitsPas encore d'évaluation

- Cost ComparisionDocument1 pageCost ComparisionjannumitsPas encore d'évaluation

- Statement of PurposeDocument2 pagesStatement of PurposejannumitsPas encore d'évaluation

- OLClipper - 2014 03 26Document26 pagesOLClipper - 2014 03 26jannumitsPas encore d'évaluation

- What Does Language Level A1, A2, B1, B2, C1 and C2 MeanDocument1 pageWhat Does Language Level A1, A2, B1, B2, C1 and C2 MeanjannumitsPas encore d'évaluation

- ELECTRICAL Reading Electrical PlansDocument8 pagesELECTRICAL Reading Electrical PlansShereen AliPas encore d'évaluation

- An 9609Document3 pagesAn 9609jannumitsPas encore d'évaluation

- Future Seven Rules To Stop Your Phone Taking Over Your LifeDocument4 pagesFuture Seven Rules To Stop Your Phone Taking Over Your LifejannumitsPas encore d'évaluation

- Gipam ManualDocument123 pagesGipam Manualgiau richkyPas encore d'évaluation

- rt11 Elegant Home With Power Saving, Security, Safety, Remote Controlling and Auto Control of Water Tank MotorDocument3 pagesrt11 Elegant Home With Power Saving, Security, Safety, Remote Controlling and Auto Control of Water Tank MotorMechWindNaniPas encore d'évaluation

- Bridge Rectifier Testing PDFDocument1 pageBridge Rectifier Testing PDFScott MorrisonPas encore d'évaluation

- MCAGDocument5 pagesMCAGariptrPas encore d'évaluation

- Relee Modulare FINDERDocument76 pagesRelee Modulare FINDERionutPas encore d'évaluation

- Power Module, Half Bridge, 300V, 920ARMS.: 1. Electrical SpecificationDocument6 pagesPower Module, Half Bridge, 300V, 920ARMS.: 1. Electrical SpecificationCarlos Eloir Vidaña VazquezPas encore d'évaluation

- 00 Aeg Paleta Zaloznich ZdrojuDocument1 page00 Aeg Paleta Zaloznich ZdrojujawadazamPas encore d'évaluation

- Dynamic Modeling, Design, and Simulation of A Combined PEM Fuel Cell and Ultracapacitor System For Stand-Alone Residential ApplicationsDocument9 pagesDynamic Modeling, Design, and Simulation of A Combined PEM Fuel Cell and Ultracapacitor System For Stand-Alone Residential ApplicationsCh RajaPas encore d'évaluation

- Monitored Fire Alarm Device Control Unit Bn-307: FeaturesDocument4 pagesMonitored Fire Alarm Device Control Unit Bn-307: FeaturesUani MazlanPas encore d'évaluation

- Batt ChargerDocument2 pagesBatt Chargerdjoko witjaksonoPas encore d'évaluation

- Power Quality Improvement Using Facts Device (Statcom)Document6 pagesPower Quality Improvement Using Facts Device (Statcom)joPas encore d'évaluation

- BISS0001 (Sensor PIR) PDFDocument2 pagesBISS0001 (Sensor PIR) PDFMiguel SosaPas encore d'évaluation

- BJT BiasingDocument11 pagesBJT Biasingapi-3799467100% (4)

- CIGRE Bench Mark ModelDocument7 pagesCIGRE Bench Mark ModelCarlynMPas encore d'évaluation

- VT Guard RPO - ENDocument2 pagesVT Guard RPO - ENAlija KupusovićPas encore d'évaluation

- CEt 2019Document2 pagesCEt 2019Amit MishraPas encore d'évaluation

- M. MohanrajDocument5 pagesM. Mohanrajvaradha184Pas encore d'évaluation

- Excitation SystemsDocument17 pagesExcitation SystemsdceylPas encore d'évaluation

- D 612 Forward&ReverseModuleDocument1 pageD 612 Forward&ReverseModulenmanishnPas encore d'évaluation

- 8-Maintenance and InspectionDocument10 pages8-Maintenance and InspectionmominzadahPas encore d'évaluation

- Elmex LP April22.Document35 pagesElmex LP April22.Peter DavisPas encore d'évaluation

- Transformer Interview QuestionsDocument11 pagesTransformer Interview QuestionsAnonymous sAmJfcV33% (3)

- Electronics UploadDocument4 pagesElectronics UploadChetna SinghalPas encore d'évaluation

- InteliCharger 65 - 12 A DatasheetDocument3 pagesInteliCharger 65 - 12 A DatasheetAntonio Olivera ValenciaPas encore d'évaluation

- Auto Decel System Does Not WorkDocument2 pagesAuto Decel System Does Not Workabrham negashPas encore d'évaluation

- Installation Manual Series EW104: Power Amplifier For DC ValvesDocument6 pagesInstallation Manual Series EW104: Power Amplifier For DC Valvesmehdi810Pas encore d'évaluation

- G... B... 1 & GSF... 1 (Z4634en)Document34 pagesG... B... 1 & GSF... 1 (Z4634en)Serban LuminitaPas encore d'évaluation

- Electrical Interview QuestionDocument118 pagesElectrical Interview QuestionMumtaj Khan0% (1)

- Revised Fee-From 2019 AprilDocument13 pagesRevised Fee-From 2019 AprildeepusvvpPas encore d'évaluation

- Salient Features of The Rooftop Project 18 - 19Document3 pagesSalient Features of The Rooftop Project 18 - 19mehulpanchalPas encore d'évaluation