Académique Documents

Professionnel Documents

Culture Documents

University of Malaya Mechanical Engineering Department Strength of Materials Lab Title: Torsion Objective

Transféré par

Muhammad Firdaus ZarmaniTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

University of Malaya Mechanical Engineering Department Strength of Materials Lab Title: Torsion Objective

Transféré par

Muhammad Firdaus ZarmaniDroits d'auteur :

Formats disponibles

Torsion

UNIVERSITY OF MALAYA MECHANICAL ENGINEERING DEPARTMENT STRENGTH OF MATERIALS LAB Title: Objective To conduct a torsion test for a specified specimen to determine: a. Modulus of Rigidity b. Shear stress at the limit of proportionality c. General characteristics of the torque, angle of twist relationship Equipment TecQuipment Torsion Testing Machine and Torsiometer, steel ruler and micrometer. Procedure 1. Measure the overall length and diameter of the test section of the specimen. 2. Draw a line down the length of the test section of the specimen with a pencil; this serves as a visual aid to the degree of twist being put on the specimen during load. 3. Mount the specimen firmly in the Torsion Testing Machine. For each increment of strain, record the following:a) Angle of twist of the specimen in degrees. b) Applied torque. c) Angle of twist over the 50 mm gauge length in radians, as recorded by the dial gauge indicator. d) When the elastic limit has been passed continue to test to destruction with ever increasing increments of strain, recording for each strain increment:i. Angle of twist in degrees. ii. Applied torque. NOTE: In some tests it may be found unnecessary to use the Torsiometer after the elastic limit has been reached. If this is the case, the torsiometer can be removed from the specimen and readings of twist can be taken directly from the machine scales. To remove the Torsiometer, unclamp the two caps screws securing it to the specimen and slip each end clamp off the specimen. The end clamps has been slotted for this purpose. It is not possible to remove the centre cylindrical spacer of the Torsiometer as this would involve disturbing the end fixing of the specimen, i.e. releasing it from the chunk. THIS SHOULD NOT BE DONE UNDER ANY CIRCUMSTANCES DURING TEST. Torsion

Torsion

Results Initial diameter of specimen .. Final diameter of specimen Gauge length of specimen .. Final gauge length of specimen .. Initial overall length of specimen ... Final overall length of specimen . Dimensional drawing for specimen should be included in the report. Plot graph for applied torque versus twist angle. Use gradient of graph to determine the modulus of rigidity. Also, determine torque from graph and calculate shear stress at the limit of proportionality. Plot graph for applied torque versus twist angle of specimen (twist angle specimen as the basis) for full experiment. Experiment should be done until failure occur. Discussion 1. 2. 3. 4. Comments on the data obtain from experiment. Comments on the results obtain from experiment. Comments on the equipment and experiment procedures. Discuss on the error occur in determining modulus of rigidity by using twist angle from dial machine and compares the results with the results from Torsiometer.

Vous aimerez peut-être aussi

- Prompting Science and Engineering Students in Practical TrigonometryD'EverandPrompting Science and Engineering Students in Practical TrigonometryPas encore d'évaluation

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryD'EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryPas encore d'évaluation

- Lab Report 2Document6 pagesLab Report 2sachin succaramPas encore d'évaluation

- 1 Torsion TestDocument4 pages1 Torsion TestArda ÇolakPas encore d'évaluation

- Laboratory Manual: MEC259 Unified Mechanical Engineering IIDocument35 pagesLaboratory Manual: MEC259 Unified Mechanical Engineering IIHimanshu Kumar Raut100% (2)

- MENG222 Lab 1 by 19700203Document11 pagesMENG222 Lab 1 by 19700203Rewaa AlashquarPas encore d'évaluation

- Som Manual-2013 RegDocument26 pagesSom Manual-2013 RegsugunavidiyadarPas encore d'évaluation

- Unified Mechanical Engineering Lab-2Document38 pagesUnified Mechanical Engineering Lab-2sharmashnPas encore d'évaluation

- Twist Test-ManualDocument4 pagesTwist Test-ManualMahdi GharibPas encore d'évaluation

- MOS PracticalDocument36 pagesMOS PracticalEternalPas encore d'évaluation

- Laboratory Manual: Strength of Material and Measurement LaboratoryDocument17 pagesLaboratory Manual: Strength of Material and Measurement LaboratoryPiyuesh GoyalPas encore d'évaluation

- Department of Mechanical Engineering Lab Manual: Course Title Course Code: Course Structure Course Co-OrdinatorDocument50 pagesDepartment of Mechanical Engineering Lab Manual: Course Title Course Code: Course Structure Course Co-OrdinatorVikrant ThakurPas encore d'évaluation

- CEN206Document10 pagesCEN206shiaondo543Pas encore d'évaluation

- Standard Operating Procedure: Tools RequiredDocument3 pagesStandard Operating Procedure: Tools RequiredNirmal WiresPas encore d'évaluation

- Strength of MaterialDocument18 pagesStrength of MaterialMamta SinghPas encore d'évaluation

- Determination of Strain in A Steel Bar PDFDocument8 pagesDetermination of Strain in A Steel Bar PDFEarl AradoPas encore d'évaluation

- Sokoine University of Agriculture: Department of Engineering Sciences and TechnologyDocument16 pagesSokoine University of Agriculture: Department of Engineering Sciences and TechnologyEngr.Hamid Ismail CheemaPas encore d'évaluation

- Lab Manual: International Islamic University Malaysia Department of Mechanical EngineeringDocument36 pagesLab Manual: International Islamic University Malaysia Department of Mechanical EngineeringMuhamad HilmiPas encore d'évaluation

- UitmDocument19 pagesUitmHaziq PazliPas encore d'évaluation

- Mechanics of Solids Laboratory Manual: Tensile TestDocument8 pagesMechanics of Solids Laboratory Manual: Tensile TestVIPAN KUMARPas encore d'évaluation

- Lab C - Torsion - Mech - MRPDocument5 pagesLab C - Torsion - Mech - MRPIdaam Abdulla SaaidPas encore d'évaluation

- Torsion Test Lab Report PDFDocument40 pagesTorsion Test Lab Report PDFengkuPas encore d'évaluation

- Torsion Test: Mechanics of Materials LaboratoryDocument4 pagesTorsion Test: Mechanics of Materials LaboratoryMohanad HazemPas encore d'évaluation

- TEST NoDocument9 pagesTEST NoPattarawat NakkumPas encore d'évaluation

- Torsion Test1Document6 pagesTorsion Test1musher95100% (1)

- Torsion Lab Report Mechanical EngineeringDocument13 pagesTorsion Lab Report Mechanical EngineeringOmar A-gPas encore d'évaluation

- CE6411 Strength of MaterialsDocument38 pagesCE6411 Strength of Materialsamns99Pas encore d'évaluation

- Laboratory Manual of Tensile TestDocument11 pagesLaboratory Manual of Tensile TestVIPAN KUMARPas encore d'évaluation

- Strength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD BarsDocument61 pagesStrength of Materials Lab Manual: 1. Tension Test On MS Bar and HYSD Barsswe_maniPas encore d'évaluation

- Experiment 1Document7 pagesExperiment 1waseemjuttPas encore d'évaluation

- Strength of Materia Lab Manual UET, LahoreDocument14 pagesStrength of Materia Lab Manual UET, LahoreRizwan Khurram100% (3)

- Report TorsionDocument17 pagesReport TorsionAhmad Haziq DanialPas encore d'évaluation

- Ramkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryDocument34 pagesRamkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryMaynak DeyPas encore d'évaluation

- Som ExperimentsDocument17 pagesSom ExperimentsAnudeex ShettyPas encore d'évaluation

- Bending Test: Final RecommendationDocument4 pagesBending Test: Final RecommendationfarhanfiksiPas encore d'évaluation

- Strength of Material Experiment 3 (Torsion Test)Document20 pagesStrength of Material Experiment 3 (Torsion Test)Atikah Mohd57% (7)

- MEC424 Content TorsionDocument12 pagesMEC424 Content TorsionHaFiy HaZimPas encore d'évaluation

- BME Mannual BT 203-1Document41 pagesBME Mannual BT 203-1shivanshu tiwariPas encore d'évaluation

- Engineering Council Certificate Level Engineering Materials C102 Tutorial 6 - Materials TestingDocument11 pagesEngineering Council Certificate Level Engineering Materials C102 Tutorial 6 - Materials TestingcataicePas encore d'évaluation

- 85-218-Lab 2-ManualDocument5 pages85-218-Lab 2-Manualjoseph0% (1)

- MOS Lab Manual - NewDocument41 pagesMOS Lab Manual - NewPavan Kalyan SuryavamshiPas encore d'évaluation

- Tensile Testing of Mild Steel Circular Bar: Marisha Bhatti 19AE30010Document11 pagesTensile Testing of Mild Steel Circular Bar: Marisha Bhatti 19AE30010Marisha BhattiPas encore d'évaluation

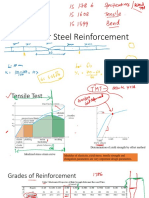

- CVP243 Steel ReinforcementDocument9 pagesCVP243 Steel ReinforcementManikyaMayankPas encore d'évaluation

- Mos Lab Manual PDFDocument34 pagesMos Lab Manual PDFs.rihanaPas encore d'évaluation

- 5.tension Test FinalDocument7 pages5.tension Test FinalFausto Da GamaPas encore d'évaluation

- Ansys Full ReportDocument12 pagesAnsys Full ReportikhwanmazliPas encore d'évaluation

- AMT 2 Dipak PhokeDocument20 pagesAMT 2 Dipak PhokeAVINASH BHUSAREPas encore d'évaluation

- Torsion of ShaftDocument8 pagesTorsion of ShaftHan Keong ChiewPas encore d'évaluation

- FM and SM Lab ManualDocument87 pagesFM and SM Lab ManualGeorge OliverPas encore d'évaluation

- 4.som Lab Torsion TestDocument5 pages4.som Lab Torsion Testmailsfree13Pas encore d'évaluation

- Steel TestsDocument4 pagesSteel TestsSaradhiJannPas encore d'évaluation

- Strength of Materials Laboratory ExperimentsDocument20 pagesStrength of Materials Laboratory Experimentskenneth iyahenPas encore d'évaluation

- Strength of Materials Lab-Ahmed AlsharaDocument24 pagesStrength of Materials Lab-Ahmed AlsharaMṜ ΛßßΛSPas encore d'évaluation

- Lab 4-TORSION TEST PDFDocument6 pagesLab 4-TORSION TEST PDFJesse Lee0% (3)

- BMT LAB NEW Final111111 PDFDocument85 pagesBMT LAB NEW Final111111 PDFmohanPas encore d'évaluation

- The Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionD'EverandThe Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionPas encore d'évaluation

- Mechanical Characterization of Materials and Wave Dispersion: Instrumentation and Experiment InterpretationD'EverandMechanical Characterization of Materials and Wave Dispersion: Instrumentation and Experiment InterpretationYvon ChevalierPas encore d'évaluation

- MFAP Battery CalculationDocument4 pagesMFAP Battery CalculationMuhammad Firdaus ZarmaniPas encore d'évaluation

- October 4, 2012 Via E-Mail Mr. Scott Goldenberg Chief Financial Officer The TJX Companies, Inc. 770 Cochituate Road Framingham, MA 01701Document2 pagesOctober 4, 2012 Via E-Mail Mr. Scott Goldenberg Chief Financial Officer The TJX Companies, Inc. 770 Cochituate Road Framingham, MA 01701Muhammad Firdaus ZarmaniPas encore d'évaluation

- Leaking From Upstairs Neighbor - Who's ResponsibleDocument7 pagesLeaking From Upstairs Neighbor - Who's ResponsibleMuhammad Firdaus ZarmaniPas encore d'évaluation

- Schedule of Technical DataDocument12 pagesSchedule of Technical DataMuhammad Firdaus ZarmaniPas encore d'évaluation

- Engine Test CellDocument1 pageEngine Test CellMuhammad Firdaus ZarmaniPas encore d'évaluation

- CFD - AbDocument1 pageCFD - AbMuhammad Firdaus ZarmaniPas encore d'évaluation

- Senarai Buku - Budaya Dan Seni RusiaDocument1 pageSenarai Buku - Budaya Dan Seni RusiaMuhammad Firdaus ZarmaniPas encore d'évaluation

- Books in The BoxesDocument1 pageBooks in The BoxesMuhammad Firdaus ZarmaniPas encore d'évaluation

- Student Confirmation StatusDocument1 pageStudent Confirmation StatusMuhammad Firdaus ZarmaniPas encore d'évaluation

- Integrated Design Project TopicsDocument1 pageIntegrated Design Project TopicsMuhammad Firdaus ZarmaniPas encore d'évaluation

- Hardness TestsDocument13 pagesHardness TestsMuhammad Firdaus ZarmaniPas encore d'évaluation

- Perform Components and ElementsDocument270 pagesPerform Components and ElementstgsergiuPas encore d'évaluation

- Astm F1717-21Document11 pagesAstm F1717-21wenhsiaochuanPas encore d'évaluation

- Simplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E SchwerDocument14 pagesSimplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E Schwersvk_ntPas encore d'évaluation

- HSS Article LimitState Plastification 0718 060120Document3 pagesHSS Article LimitState Plastification 0718 060120clam2014Pas encore d'évaluation

- Answer KeyDocument13 pagesAnswer KeyLəonardo SasingPas encore d'évaluation

- Tensile Strength and Elongation at Yield - ASTM D638Document7 pagesTensile Strength and Elongation at Yield - ASTM D638Silverio AcuñaPas encore d'évaluation

- Composite BeamsDocument21 pagesComposite BeamshaysamPas encore d'évaluation

- Alloy 800 Data SheetDocument2 pagesAlloy 800 Data SheetETSPas encore d'évaluation

- Experimentos Johnson Cook PDFDocument125 pagesExperimentos Johnson Cook PDFwircexdjPas encore d'évaluation

- Som VivaDocument13 pagesSom VivaDoddaBasappaKPas encore d'évaluation

- UntitledDocument187 pagesUntitledudomPas encore d'évaluation

- Study of Tensile Strength and Hardness Property For EpoxyDocument10 pagesStudy of Tensile Strength and Hardness Property For EpoxychethanapraoPas encore d'évaluation

- Astm D707Document5 pagesAstm D707LIN SONGPas encore d'évaluation

- Design of Steel and Timber Structures Examples PDFDocument78 pagesDesign of Steel and Timber Structures Examples PDFsamson100% (3)

- Stability of Tapered and Stepped Steel Columns With Initial ImperfectionsDocument10 pagesStability of Tapered and Stepped Steel Columns With Initial ImperfectionskarpagajothimuruganPas encore d'évaluation

- ACI - Sezen - Setzler - 2008-Reinforcement Slip in Reinforced Concrete ColumnsDocument10 pagesACI - Sezen - Setzler - 2008-Reinforcement Slip in Reinforced Concrete ColumnsTeddy SusantoPas encore d'évaluation

- Pressuremeter Tests in Municipal Solid Waste Measurement of Shear Stiffness - DixonDocument14 pagesPressuremeter Tests in Municipal Solid Waste Measurement of Shear Stiffness - DixonSen HuPas encore d'évaluation

- CSiXRevit 2018 Manual PDFDocument102 pagesCSiXRevit 2018 Manual PDFRubén Cuán RPas encore d'évaluation

- Residual Stress 2Document10 pagesResidual Stress 2suganthi1711Pas encore d'évaluation

- Data Sheet S690QL1Document2 pagesData Sheet S690QL1wajdiPas encore d'évaluation

- Reinforced Concrete I PalestineDocument188 pagesReinforced Concrete I PalestineVeymar Gilbert Tórrez Macías100% (1)

- Specialty ConnectorsDocument62 pagesSpecialty ConnectorsLuis David Concha CastilloPas encore d'évaluation

- Solid Mechanics Chapter-2Document18 pagesSolid Mechanics Chapter-2Md. Azmain AdilPas encore d'évaluation

- Chapter-3 Design For Compression Member - StrutDocument16 pagesChapter-3 Design For Compression Member - Strutzakai zakiPas encore d'évaluation

- HS 800 SpecsDocument8 pagesHS 800 Specspradeep yadavPas encore d'évaluation

- Storage of Bulk Solids - 3Document31 pagesStorage of Bulk Solids - 3Naman GoelPas encore d'évaluation

- Introduction and API Standards of CasingsDocument57 pagesIntroduction and API Standards of CasingsSeyid khaledPas encore d'évaluation

- Steel Connections Theory EnuDocument138 pagesSteel Connections Theory EnuDon Adrián OnigaPas encore d'évaluation

- Stiffner Design For Beam Column ConnectionsDocument84 pagesStiffner Design For Beam Column ConnectionsfabnamePas encore d'évaluation