Académique Documents

Professionnel Documents

Culture Documents

Methods For The Characterization of Jet Propellent-8: Vapor and Aerosol

Transféré par

kmeriemDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Methods For The Characterization of Jet Propellent-8: Vapor and Aerosol

Transféré par

kmeriemDroits d'auteur :

Formats disponibles

BIOMEDICAL CHROMATOGRAPHY Biomed. Chromatogr.

21: 463472 (2007) Published online 7 March 2007 in of Wiley InterScience Methods for the characterization Jet Propellent-8 (www.interscience.wiley.com) DOI: 10.1002/bmc.776

ORIGINAL RESEARCH 463 ORIGINAL RESEARCH

Methods for the characterization of Jet Propellent-8: vapor and aerosol

S. D. Gregg,1 J. L. Campbell,2 J. W. Fisher 2 and M. G. Bartlett1*

1 2

Department of Pharmaceutical and Biomedical Sciences, College of Pharmacy, The University of Georgia, Athens, GA 30602-2352, USA Department of Environmental Health Sciences, College of Public Health, The University of Georgia, Athens, GA 30602-2102, USA

Received 6 November 2006; revised 7 November 2006; accepted 8 November 2006

ABSTRACT: Jet Propellant-8 (JP-8) has been responsible for the majority of reported chemical exposures by the US Department of Defense. Concerns related to human exposure to JP-8 are relatively new; therefore, there is a lack of literature data. Additionally, health effects related to the composition of the exposure have only recently been considered. Two major questions exist: (1) what is the compositional difference between the aerosol and vapor portions of JP-8 under controlled conditions and (2) what is the most representative method to sample JP-8 aerosol and vapor? Thirty-seven standards, representing more than 40% of the mass of JP-8, were used for characterization of the neat fuel, vapor and aerosol portions. JP-8 vapor samples at a concentration of 1600 mg/m3 were prepared in Tedlar bags. A portion of the vapor samples was adsorbed on charcoal, Tenax and custom mixed phase sorbents. These samples were then extracted using organic solvent and analyzed using gas chromatography/mass spectrometry. The vapor samples extracted from the sorbent tubes were directly compared with a vapor bag. The samples collected using Tenax sorbent tubes were found to be most representative of the composition of the vapor bags. In another set of experiments, aerosolized JP-8 was generated using a collision nebulizer. Aerosol samples were collected and the chemical composition was characterized. The entire aerosol distribution was collected on a glass lter, extracted into solvent, and analyzed by GC-MS. Finally, the composition of the vapor and aerosol was compared. The vapor was found to represent the lower molecular weight components of JP-8, while the aerosol was composed of higher molecular weight components. Therefore, the vapor and aerosol should be treated as two discrete forms of exposure to JP-8. Copyright 2007 John Wiley & Sons, Ltd. KEYWORDS: gas chromatographymass spectrometry; JP-8 hydrocarbon fuel; aerosol composition; vapor composition

INTRODUCTION

Jet Propellant-8 (JP-8) is a kerosene-based fuel used universally by North Atlantic Treaty Organization (NATO) countries. Over 20 years it has replaced JP-4 as the main fuel of the military, because it is less volatile and has a higher ash point (Bogdan et al., 2001). These characteristics make this fuel less likely to produce catastrophic events in crashes or during warfare. JP-8 is colorless and contains additives specic to its military use. JP-8 is formulated based on performance and therefore its composition varies from batch to batch. In general, the composition of JP-8 is 3361% hydrocarbons, 1222% aromatics (benzene, substituted

*Correspondence to: M. G. Bartlett, Department of Pharmaceutical and Biomedical Sciences, College of Pharmacy, The University of Georgia, Athens, GA 30602-2352, USA. E-mail: bartlett@rx.uga.edu Abbreviations used: JP-8, Jet Propellant-8. Contract/grant sponsor: Air Force Ofce for Scientic Research; Contract/grant number: F49620-03-1-0157. Copyright 2007 John Wiley & Sons, Ltd.

benzenes, naphthalene and substituted naphthalene), 1045% alicyclic hydrocarbons (cycloalkanes), 0.55% olens and 00.3% sulfur-containing heterocyclics (National Academy of Sciences, 2003). JP-8 is responsible for the majority of all chemical exposures reported for the US Department of Defense Personnel (Agency for Toxic Substances and Disease Registry, 1998). As a result, exposure to JP-8 has been studied, with a wide variety of health effects having been noted. However, the composition and subsequent effects of the vapor and aerosol portions of JP-8 have not been considered in any of these studies. The United States alone uses 609,550 barrels of jet fuel per year (without wartime use being taken into consideration; Maurice et al., 2001). Exposure to JP-8 is very common among military personnel, but uncommon in those not directly associated with military activity. Tu et al. (2004) conducted a study observing human exposure to JP-8. They examined breath, blood and urine samples from military workers in six areas, including fuel cell workers, crew chiefs, mechanics, fuel specialists and incidental workers. Eighteen students from Johns Hopkins were also examined for this study

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

464

ORIGINAL RESEARCH

S. D. Gregg et al.

in the same manner. These subjects came into contact with the vapor and aerosol portion of this fuel. Breath samples were taken before and after work; blood and urine samples were taken after work only. A neurocognitive test was given along with a questionnaire. In this study, they observed that the Johns Hopkins group showed signicantly lower concentrations of aliphatic and aromatic hydrocarbons vs the military group. Little difference was seen pre- and postwork. This nding was expected because there was no direct contact with the aerosolized fuel. In the military group, fuel specialists showed the greatest exposure to JP-8. This study also found that smokers showed a signicantly greater exposure to JP-8. In another study, Scandinavian fuel workers exposed to the aviation fuel Jet-A, which is similar to JP-8 but lacks the performance enhancing additives, reported fatigue, headache, dizziness, nausea, anxiety, vegetative hyperactivity and attention span deciency (Knave et al., 1976, 1978; Struwe et al., 1983). In another study, JP-8 exposed workers were shown to display subtle decits in their ability to maintain balance (Smith et al., 1997). In addition to the human studies mentioned above, there are many animal studies that have looked at the effect of exposure to vapor (Mattie et al., 1991; Ritchie et al., 2001; Rossi et al., 2001) and aerosolized JP-8 (Hays et al., 1995; Pfaff et al., 1995, 1996; Harris et al., 1997ac, 2000). These studies nd few if any effects from exposure to the vapor but note adverse effects from exposure to the aerosolized fuel at occupational levels. The ndings of both the human and animal studies suggest that there is signicantly greater risk from exposure to the aerosolized fuel than simply to the vapor. In collaboration with the Air Force Ofce for Scientic Research, our laboratory is involved in the development of a physiologically based pharmacokinetic model (PB/PK) for JP-8 that will be effective in describing and predicting plasma and tissue concentrations of JP-8 and many of its components in rodents and humans. A PB/PK model has been developed for decane (a component present in JP-8; Perleberg et al., 2004). The next and most important step in further model development is to characterize the vapor and aerosolized fuel, the two major forms of exposure. JP-8 samples can be divided into three classications. Neat JP-8 is the liquid fuel containing all of the components of kerosene and additional performance additives. The vapor represents the volatile fraction of JP-8. The aerosol is composed of small droplets and is believed to represent the higher molecular weight fraction of JP-8. Several methods have been developed to measure components of JP-8 from these types of samples (Gregg et al., 2006). Occupational exposure to JP-8 occurs through a number of routes including inhalation of the vapor and/or aerosol and dermal absorption

Copyright 2007 John Wiley & Sons, Ltd.

of the aerosol and/or neat JP-8 (Pleil et al., 2000; Muhammad et al., 2004). It is important to understand the difference between the aerosol and the vapor portions of JP-8 in order to know how to accurately incorporate these two routes of exposure into physiological models of human internal dosimetry. A major issue in this type of analysis is the collection of vapor samples. The National Institute for Occupational Safety and Health (NIOSH) approves monitoring of vapor samples by their collection on an adsorbent, such as activated charcoal or Tenax (Cohen and Hering 1995). These collected samples are then analyzed by thermal desorption or direct injection following liquid extraction. There are many types of adsorbents that can be used for complex samples such as JP-8, but it is important to compare these extracted samples with unabsorbed vapor samples because part of the sample distribution may be lost during the collection and extraction process. Therefore, it is important to understand the sample collection process and its potential inuence on the sample composition. Neat JP-8, vapor and aerosol samples were analyzed to determine the differences in their composition. The samples were characterized with respect to 37 standards that represent >40% of the weight of the fuel (Ritchie et al., 2003). Several different adsorbents are used to trap the vapor samples. Statistical comparisons were made between the different adsorbents to nd the one that had the least difference from unabsorbed vapor samples. This information can be used to aid in the construction of a more realistic physiologically based pharmacokinetic model to predict occupational and environmental exposure to JP-8.

EXPERIMENTAL SECTION

Experiments were carried out using an Agilent Technologies 6890N gas chromatograph directly connected to a model 5973 mass selective detector. This system was controlled using Chemstation version G1701DAD.01.00 software. A Petrocol DH 150 column with dimensions 150 m 0.25 mm i.d. 1.0 m lm was used for this separation. The initial oven temperature program was as follows: hold at 90C for 30 min followed by a ramp to 210C over 303 min. For liquid samples, 3 L were introduced into the GC for analysis. Helium (National Specialty Gas, Durham, NC, USA, ultra carrier grade) was used as the carrier gas. The instrument was run in split mode with a ratio of 3:1. The total ow of gas was 6.7 mL/min. All analysis was done using electron ionization (EI) in the positive ion mode with a lament voltage of 70 eV. Mass spectrometric conditions were as follows: the source temperature was set to 230C, and the instrument was operated in full-scan mode low mass 35.0 to high mass 400.0 at a scan rate of 5.87 scans/s (Dietzel et al., 2005). All chemicals used were analytical grade. Five samples of neat JP-8 (Wright-Patterson Air Force Base, Dayton, OH, USA) were run for characterization. A

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

Methods for the characterization of Jet Propellent-8

ORIGINAL RESEARCH

465

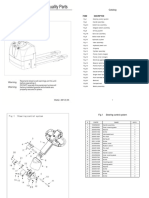

concentration of 2 L/mL (1.6 mg/mL) of JP-8 in chloroform (EMD Chemicals, Gibbstown, NJ, USA) was placed into a vial for analysis by the GC-MS system. Analysis of the neat fuel was needed to compare all subsequent analysis done with the vapor and aerosol portions. After the completion of the GC-MS sequence, samples were characterized using retention time matches with 37 authentic standards and comparison to the Wiley EI library (version G1035). A generated vapor bag, charcoal tubes (SKC Inc., Eighty Four, PA, USA), Tenax tubes (SKC Inc., Eighty Four, PA, USA) and custom tubes (Supelco, Bellefonte, PA, USA) were used to analyze the vapor phase of JP-8. To make the vapor bags, 4 L of air were pumped into a 5 L Tedlar bag (SKC Inc., Eighty Four, PA, USA). After the bag was completely lled with air, 8 L of neat JP-8 were injected into a septum located on the bag. The bag was then heated for 5 min using a heat gun at 197C, allowed to cool and then reheated. The nal concentration of the bag was approximately 1600 mg/m3. After the bag returned to ambient temperature, 1 mL of vapor was extracted from the bag using a gas tight syringe and directly injected into the GC-MS system for analysis. This process was repeated using ve different bags to allow for statistical comparisons. Experiments were also conducted to look at the effects of heating the bag vs allowing the vapor phase to arrive at equilibrium without any heating. Using the above procedure, vapor bags were made to examine components adsorbed to Tenax, charcoal, and custom made mixed phase charcoal sorbent tubes. Each collection tube was attached to the vapor bag. A low ow rate vacuum pump (SKC Inc., Eighty Four, PA, USA, model 210-2002) attached with Tygon tubing was used to pull approximately 500 mL of vapor from the tedlar bag through each sorbent tube at a ow rate of 100 cm3/min for 5 min. The main chamber of each sorbent tube was removed and extracted for 1 h using 1 mL chloroform for charcoal adsorbents or methyl tertiary butyl ether- MTBE (Aldrich, Milwaukee, WI, USA) for Tenax adsorbents. No mechanical agitation or heating was used to assist the extraction process. Two milliliters of chloroform were used to extract the vapor from the custom-made tubes because the packing for the tube was twice the mass of the other tubes, and 1 mL was therefore not sufcient for extraction. When adjusted for dilution, the custom-made sorbent tubes did not show a reduction in concentration when compared with the other sorbent tubes. After desorption, 100 L of the extracting solvent were placed into sample vials containing an insert for small sample volumes and 3 L were injected into the GCMS system. This entire process was repeated 5 times for each type of sorbent tube (n = 5). Schematics of the various sorbent tubes used for the sample collections are shown in Fig. 1. The sorbent tubes contained additional chamber(s) to determine sample breakthrough. No breakthrough from the rst sorbent chamber was noted for any of the tubes in this study. The aerosolized fuel was generated using a collision nebulizer (BGI Inc., Waltham, MA, USA; shown in Fig. 2; Gussman 1984; Smith et al., 2005). A 50 mL aliquot of JP-8 was placed into the nebulizer jar. Compressed air was used at a ow rate of 12 L/min to generate an aerosol. The aerosolized fuel was pulled through a glass ber lter followed in series by a sorbent tube using the low ow rate

Copyright 2007 John Wiley & Sons, Ltd.

Figure 1. Depiction of the vapor traps used to characterize the vapor phase of JP-8. Traps A and C have two distinctive chambers. Chamber 1 is the sorbent layer; this is the chamber analyzed in this study. Chamber 2 is the backup sorbent layer. This chamber served to detect any breakthrough that may occur during sample collection. Little breakthrough occurred using our sampling method because of the low concentration and small sampling window. Tube B was a custom-made tube. This tube consists of two sorbent layers and two backup sorbent layers. vacuum pump set to 200 mL/min. The sampling time was 15 min. The JP-8 was extracted by placing the glass ber lter in 5 mL of chloroform for 1 h. The sorbent tubes were extracted as described above. A 100 L aliquot of the solvent was transferred into vial inserts and analyzed using the GCMS system. The process was repeated ve times (n = 5). Recovery studies were performed for all of the sorbent tubes being used. Concentrations of 2, 25 and 100 g/mL of JP-8 in chloroform were examined. The main chamber of each tube was removed and spiked with 10 L of the working standard and desorbed in 1 mL chloroform (charcoal tube), 2 mL chloroform (custom charcoal tube), and 1 mL MTBE (Tenax tube) for 1 h. A 10 L aliquot of the working standard were also spiked into blank solvent for comparison. Chloroform and MTBE were used as stated above. A 3 L aliquot of each sample was injected into the GC-MS system for analysis. The recoveries were run in replicates of ve (n = 5) for each sorbent tube and blank. To determine the recovery, the area of each compound identied was compared to the area of the spiked solvent blank. The results of the recovery study were used to determine the tube that provided the highest recovery and that best represented the vapor composition of JP-8. Statistical comparisons were made using one-way analysis of variance (ANOVA) on the peak area ratios between two sets of data to determine if differences observed between the groups could be explained by the variance in the data. If the

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

466

ORIGINAL RESEARCH

S. D. Gregg et al.

Figure 2. Schematic showing the apparatus used to generate aerosamples. Using compressed air at a ow of 30 psig, JP-8 was nebulized and traveled through a stainless steel tube. JP-8 was then pulled through the glass ber lter and through the absorbent tube for analysis. This gure is available in colour online at www.interscience.wiley.com/ journal/bmc F score showed that the differences between the two groups was not explained by the variance in the data, a Tukeys pairwise comparison was conducted to determine which component(s) contributed to the observed differences. All of the statistical tests were performed at the 99% level of condence using SAS/STAT (SAS Institute Inc., Cary, NC, USA).

RESULTS AND DISCUSSION

Upon analysis of a solution of 1.6 mg/mL of neat JP-8 in chloroform, 34 of the 37 standards were identied above the limit of detection (S/N of 3/1) of 1 g/mL for the individual components. The three compounds that were below this threshold were octadecane, 3,4,5trimethylheptane, and indene. The compounds 3,4,5trimethylheptane and indene were not observed in any experiments involving the diluted fuel, vapor or aerosolized JP-8. The other 35 components were identied in the vapor, the aerosol or both. Table 1 lists the 37 standard compounds as well as their respective retention times, molecular weights and vapor pressures. The vapor and aerosolized JP-8 concentrations selected for these studies were 1600 mg/m3. Acute neurological effects have been observed in humans exposed to as little as 250 mg/m3 of aircraft fuel (not necessarily JP-8; Knave et al., 1976, 1978; Struwe et al., 1983). Dopamine levels have been shown to decrease, leading to behavior modication in rats when exposed to JP-8 vapor at 1000 mg/m3 (Ritchie et al., 2001; Rossi et al., 2001). Lung toxicity has been observed in rats exposed to aerosolized JP-8 above 520 mg/m3 and in mice to exposures above 2800 mg/m3 (Pfaff et al., 1995; Whitman and Hinz, 2001). Therefore, the concentration chosen for these studies was comparable to those used in

Copyright 2007 John Wiley & Sons, Ltd.

many animal studies and was at a level that would be expected to cause acute toxicity in humans. One of the main goals for this part of the study was to identify the compositional differences between the aerosol and vapor portions of JP-8. In the aerosol generation system that was used in the study only 510% of the fuel was present as aerosol droplets. Therefore, it was difcult to directly compare the vapor and aerosol samples because of differences in their concentrations. Therefore, all of the peak area data was normalized to undecane. Undecane provided the largest peak area for almost all of the JP-8 samples (vapor, aerosol, neat fuel). In studies involving aerosol and vapor sampling it is important to insure that the vapor samples are not signicantly impacted by the presence of aerosol an vice versa. We rst studied the adsorption of JP-8 vapor on the glass ber lter. Using a vapor bag, we pulled 500 mL of 1600 mg/m3 JP-8 vapor sample through the glass ber lter (n = 3). After solvent extraction, we did not observe any JP-8 components on the glass ber lter. We were also concerned about the aerosol samples contributing to the signals obtained from the vapor traps. We therefore compared the results of the vapor samples generated from the vapor bags with those generated from the aerosolized fuel and found no statistical difference in the samples. Therefore, over the 15 min that we collected samples we did not observe any evidence that the aerosol particle samples were impacting the vapor samples. Aerosol Twenty-nine of the 37 standard compounds were identied in this portion of JP-8. It was hypothesized that the aerosol samples would not contain some of

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

Methods for the characterization of Jet Propellent-8

ORIGINAL RESEARCH

467

Table 1. Identity of components and gas chromatographic retention times from JP-8. The components shown with * were not identied in any form of the fuel. Compounds Heptane Octane Nonane Decane Undecane Dodecane Tridecane Tetradecane Pentadecane Hexadecane Heptadecane Octadecane Xylene 2-Ethyltoluene Mesitylene Pseudocumene 1,2,3-Trimethylbenzene Naphthalene 1-Methylnaphthalene 2-Methylnaphthalene 1,2-Dimethylnaphthalene Ethylbenzene Propylbenzene Methylcyclohexane 1,3-Dimethylcyclohexane Propylcyclohexane 1,4-Diethylbenzene 2-Methylnonane 2-Methyldecane 3-Methyldecane 4-Methyldecane 3,4,5-Trimethylheptane* 2,3,5-Trimethylnapthalene 1,2,3,4-Tetrahydronaphthalene Indene* Phenylcyclohexane Cumene Retention time (min) 35.44 46.50 62.39 84.00 107.70 134.64 163.61 189.31 216.91 241.90 268.81 299.44 60.84 79.56 76.97 82.41 88.51 130.22 166.47 161.32 204.94 55.21 73.54 38.95 44.95 70.63 95.47 76.95 98.57 100.32 97.73 74.44 232.81 125.20 93.06 169.56 66.90 Molecular weight (g) 100.20 114.23 128.26 142.28 156.31 170.34 184.36 198.39 212.42 226.44 240.47 254.50 106.17 120.19 120.19 120.19 120.19 128.17 142.2 142.2 156.23 106.17 120.19 98.19 112.21 126.24 134.22 142.28 156.31 156.31 156.31 142.28 170.25 132.20 116.16 160.26 120.19 Vapor pressure (mmHg) 40 @ 20C 11 @ 20C 10 @ 20C 1 @ 16.5C 1 @ 33C 1 @ 47.8C 1 @ 59.4C 1 @ 76.4C 1 @ 92C 1 @ 105.3C 1 @ 115C 1 @ 119C 8.6 @ 25C 8 @ 20C 2.49 @ 25C 7 @ 44.4C N/A 0.05 @ 20C N/A 1 @ 61C N/A 10 @ 20C 2.5 @ 20C 37 @ 20C N/A 8.7 @ 37.7C N/A N/A N/A N/A N/A N/A N/A 0.18 @ 20C N/A N/A 8 @ 20C

the lower molecular weight components (i.e. heptane, methylcyclohexane), but would contain most of the heavier compounds (i.e. octadecane). This expectation was conrmed. The aerosol was missing the following lower molecular weight components seen in the vapor as well as the neat fuel: mesitylene, methylcyclohexane and 1,3-dimethylcyclohexane. The aerosol also contained a detectable amount of the high molecular weight component octadecane. The aerosol also contained 2methylnonane, another higher molecular weight component not observed in the vapor. The aerosol was rst compared to the neat fuel. It was unclear whether there would be much difference between the aerosol and the neat fuel. However, it was hypothesized that these small droplets with high surface area would preferentially evaporate the more volatile components of JP-8, causing differences in composition. When compared using the statistical approach described above, several components present in both samples showed a signicant difference in their

Copyright 2007 John Wiley & Sons, Ltd.

means. The components octane (21%), nonane (55%), phenylcyclohexane (84%) and ethylbenzene (25%) were all signicantly lower in the aerosol sample relative to the neat fuel. It was also noted that heptane was absent from the aerosol sample but was observed in the neat fuel. All other components that were present in both the neat fuel and aerosol were statistically indistinguishable when compared. In general, the components that were reduced have higher vapor pressures and lower molecular weights relative to other components of JP-8. However, there was a notable exception. Phenylcyclohexane was much higher in molecular weight and, while it does not have a reported vapor pressure, the fact that it elutes 70 min after the other compounds that were reduced in concentration demonstrated that its vapor pressure was likely to be much lower. It was unclear why this particular compound was so different. The following compounds showed enrichment in the aerosol relative to the neat fuel: 1,4 diethylbenzene (463%), 1-methylnaphthalene

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

468

ORIGINAL RESEARCH

S. D. Gregg et al.

(164%), 2-methylnaphthalene (194%), naphthalene (183%), 1,2,3,4 tetrahydronaphthalene (156%), dodecane (113%), tridecane (124%), tetradecane (140%), pentadecane (141%), hexadecane (181%) and heptadecane (177%). The higher levels of the above compounds in the aerosol suggest that these compounds may be involved in the greater toxicity noted from exposure to the aerosolized fuel relative to the vapor. Vapor Studies of the vapor involved two basic questions. First what, if any, were the compositional differences between the neat fuel and the vapor? Second, what is the most appropriate method to collect a vapor sample of JP-8? To address this rst question we prepared a vapor bag as described previously. Of the 37 standards, 28 were identied in the vapor bag sample (see Table 2). The vapor bag did not contain a detectable amount of octadecane. In addition, six components that were

observed in neat JP-8 were not identied in the vapor bag; these included heptane, 1,2-dimethylnaphthalene, 2-methylnonane, 2,3,5-trimethylnaphthalene, heptadecane and cumene. From the statistical comparison of the neat fuel to the vapor bag it was determined that phenylcyclohexane (70%), 1,4 diethylbenzene (411%), 2-methyldecane (350%), propylbenzene (355%), pseudocumene (151%), 1,2,3,4 tetrahydronaphthalene (124%), naphthalene (190%), propylcyclohexane (144%), octane (135%), nonane (121%), decane (121%), dodecane (89%), tridecane (80%), tetradecane (74%), pentadecane (83%) and hexadecane (13%) were the components present in both samples that showed signicant difference when comparing the normalized peak areas. These compounds represent a wide range of molecular weights and volatility. Heptane and cumene had low abundance in the neat fuel and their absence was probably a reection of the lower overall concentration of the vapor sample relative to the neat fuel. However, the higher molecular weight compounds were believed

Table 2. Comparison of components observed and absent from the various vapor traps used to characterize the vapor phase of JP-8. Components in bold were not seen in the analysis Tenax Heptane Octane Decane Undecane Dodecane Tridecane Tetradecane Pentadecane Hexadecane Heptadecane Octadecane Xylene 2-Ethyltoluene Mesitylene Pseudocumene 1,2,3 TMB Naphthalene 1-Methylnaphthalene 2-Methylnaphthalene 1,2-DMN Ethylbenzene Propylbenzene Methylcyclohexane 1,3-Dimethylcyclohex Propylcyclohexane 1,4-Diethylbenzene 2-Methylnonane 2-Methyldecane 3-Methyldecane 4-Methyldecane 2,3,5-Trimethylnap 1,2,3,4-Tetrahydron Phenylcyclohexane Cumene Nonane Charcoal Heptane Octane Decane Undecane Dodecane Tridecane Tetradecane Pentadecane Hexadecane Heptadecane Octadecane Xylene 2-Ethyltoluene Mesitylene Pseudocumene 1,2,3 TMB Naphthalene 1-Methylnaphthalene 2-Methylnaphthalene 1,2-DMN Ethylbenzene Propylbenzene Methylcyclohexane 1,3-Dimethylcyclohex Propylcyclohexane 1,4-Diethylbenzene 2-Methylnonane 2-Methyldecane 3-Methyldecane 4-Methyldecane 2,3,5-Trimethylnap 1,2,3,4-Tetrahydron Phenylcyclohexane Cumene Nonane Custom Heptane Octane Decane Undecane Dodecane Tridecane Tetradecane Pentadecane Hexadecane Heptadecane Octadecane Xylene 2-Ethyltoluene Mesitylene Pseudocumene 1,2,3 TMB Naphthalene 1-Methylnaphthalene 2-Methylnaphthalene 1,2-DMN Ethylbenzene Propylbenzene Methylcyclohexane 1,3-Dimethylcyclohex Propylcyclohexane 1,4-Diethylbenzene 2-Methylnonane 2-Methyldecane 3-Methyldecane 4-Methyldecane 2,3,5-Trimethylnap 1,2,3,4-Tetrahydron Phenylcyclohexane Cumene Nonane Vapor bag Heptane Octane Decane Undecane Dodecane Tridecane Tetradecane Pentadecane Hexadecane Heptadecane Octadecane Xylene 2-Ethyltoluene Mesitylene Pseudocumene 1,2,3 TMB Naphthalene 1-Methylnaphthalene 2-Methylnaphthalene 1,2-DMN Ethylbenzene Propylbenzene Methylcyclohexane 1,3-Dimethylcyclohex Propylcyclohexane 1,4-Diethylbenzene 2-Methylnonane 2-Methyldecane 3-Methyldecane 4-Methyldecane 2,3,5-Trimethylnap 1,2,3,4-Tetrahydron Phenylcyclohexane Cumene Nonane

Copyright 2007 John Wiley & Sons, Ltd.

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

Methods for the characterization of Jet Propellent-8

ORIGINAL RESEARCH

469

to demonstrate discrimination against these species from the evaporation process. These ndings were consistent with the earlier ndings from ExxonMobile that several higher molecular weight components of JP-8 were decreased in vapor samples (Whitman and Hinz, 2001). We also investigated two different methods to generate JP-8 vapor bags. In one method the vapor bags were allowed to reach equilibrium by heating followed by allowing the vapor bag to return to room temperature. This bag was then sampled using a gas-tight syringe. Secondly, to insure that we were not forcing less volatile compounds into the vapor by heating the vapor bag, we allowed another set of vapor bags to arrive at equilibrium at ambient temperature for 24 h. Using the statistical approach described above, the two methods for creating vapor bags were found to be equivalent. Therefore, we used the heated vapor bags for all experiments because these could be prepared in approximately 1 h. A nal set of experiments were done to determine the most representative method to sample JP-8 vapor. Three different sorbent tubes were evaluated for their ability to retain and then allow the components to be extracted using solvents. The three types of sorbent materials were charcoal, Tenax and a customized mixed phase. Each of the sorbents was compared to determine which of the tubes most resembled samples taken directly from the vapor bag. The rst sorbent tube characterized was the charcoal tube. Of the 28 components present in the vapor bag, the charcoal tube contained 21. The charcoal tube was missing several of the higher end components including: pentadecane, hexadecane, heptadecane, octadecane, 1methylnonane, 2-methylnonane, 1,2-dimethylnaphthalene and 2,3,5-trimethylnaphthalene. The charcoal tube was also missing the following lower molecular weight components: heptane, xylene, mesitylene and 1,2,3trimethylbenzene. Of these only heptane was not found in the vapor bag. When the 21 detected compounds were compared statistically with the vapor bag, tridecane (31%), naphthalene (19%), ethylbenzene (85%), 1,4 diethylbenzene (58%), phenylcyclohexane (980%) and nonane (31%) were different. The charcoal tube had signicant differences when compared with the vapor bag. Higher molecular weight compounds were lower in abundance or were missing, indicating that these compounds may not be efciently desorbed from the charcoal tubes. The second vapor trap to be analyzed was the custom sorbent tube. Of the 28 components present in the vapor bag, the custom tube contained 24, about 85.7% of the components. Like the charcoal tube, several of the higher molecular weight components were absent. These included: pentadecane, hexadecane, heptadecane, octadecane, 1-methylnonane, 2-methylnonane, 1,2Copyright 2007 John Wiley & Sons, Ltd.

dimethylnaphthalene and 2,3,5-trimethylnaphthalene. These components were also not identied in the charcoal tube. Heptane, xylene and mesitylene were observed in the custom tube, but not in the charcoal tube. Therefore, the custom tube appears to provide better representation of the vapor samples for the lower molecular weight components versus the charcoal sorbent tubes. Next the custom tube was statistically compared to the vapor bag. When compared with the vapor bag, octane (213%) and methylcyclohexane (309%) showed a signicant difference in their mean areas. These two components were 23 times higher in concentration in vapor samples collected on the custom sorbent tubes relative to the vapor bag. These are two of the most volatile components in JP-8. These ndings, along with the generally higher relative levels of the lower molecular weight compounds, indicate that the custom sorbent tubes may actually be over-representing these components. The last sorbent tube to be analyzed was the Tenax tube. Of the 28 components present in the vapor bag, 26 were identied in the Tenax tube. Like the previous tubes, several higher end components were absent during analysis: hexadecane, heptadecane, octadecane, 1,2dimethylnaphthalene and 2,3,5-trimethylnaphthalene. Lower end components absent included heptane and 1,3-dimethylcyclohexane. Three components present in the Tenax tube were not seen in the vapor bag. When compared with the vapor bag, only phenylcyclohexane (38%) was found to show a statistically signicant difference in mean area. A side-by-side view of the sorbent tubes and the vapor bag can be seen in Table 2. To determine which sorbent tube most accurately represented the vapor bag standard, we used two factors: (1) the intensities of components that were observed and (2) the number of identied components present in the vapor bag vs the various sorbent tubes. Using these criteria we concluded that the Tenax tube provided the best representation of the vapor bag compared to the carbon based sorbent tubes. Figure 3 shows the superimposed gas chromatograms showing vapor, aerosol, neat fuel and a comparison of the Tenax sorbent tube versus the vapor bag used for collection. Figure 3B shows the amount of each compound present in JP-8. Aerosol vs vapor Since exposure to aerosolized JP-8 appears to cause greater health effects in human, we felt that it was important to compare the vapor and the aerosol portions of JP-8. There were four compounds that were observed in the aerosol that were not observed in the vapor samples. These were cumene, 2-methylnonane,

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

470

ORIGINAL RESEARCH

S. D. Gregg et al.

Figure 3. (A) Total ion chromatogram demonstrating that the Tenax tube is lacking the higher end components. After about 225 min no additional peaks were observed. In the Tenax tube extraneous peaks (*) are seen due to impurities in the extracting solvent used (MTBE). These were acetic acid and 2-pentanone. The Tenax tube was determined to be most like the vapor standard. This gure is available in colour online at www.interscience.wiley.com/journal/bmc

heptadecane and octadecane. In addition seven compounds were found to be statistically lower in the vapor bag relative to the aerosol, 1-methylnaphthalene (42%), 2-methylnaphthalene (53%), dodecane (79%), tridecane (64%), tetradecane (53%), pentadecane (59%) and hexadecane (7%). Overall the compounds that are lowered or missing were higher molecular weight components with the exception of cumene. Cumene was a low abundance component of JP-8 and was probably observed in the aerosol because of higher overall concentrations for these samples. The aerosol samples were missing three compounds relative to the vapor samples. These were mesitylene, methylcyclohexane and 1,3-dimethylcyclohexane. In addition, octane (16%), nonane (45%), pseudocumene (68%), propylbenzene (27%), propylcyclohexane (53%), and 2-methyldecane (36%) were observed in statistically lower abundances in aerosol samples. In this case all of the compounds that were missing or decreased in abundance were the lower molecular weight compounds. The aerosol should be viewed as a liquid suspension. This reasoning may explain why some compounds were

Copyright 2007 John Wiley & Sons, Ltd.

observed in the aerosol portion and not the vapor portion of JP-8. As a result of being a suspension, heavier compounds tended to be present in higher concentrations for longer periods of time. In the vapor portion, these heavier components were present for shorter periods of time, making the relative abundance of lighter weight compounds more pronounced. Recovery Recovery studies were performed for each of the sorbent tubes used to analyze JP-8 vapor. Data obtained from the charcoal tube revealed that recovery ranged from 19 to 118% with 2-ethyltoluene, pseudocumene, naphthalene, ethylbenzene and propylbenzene yielding recovery percentages of <60%. The Tenax tube recovery ranged from 72 to 112%. All components had recovery percentages of >90% with the exception of naphthalene and 1-methylnaphthalene (seen in the lowest concentration). The custom tube recovery ranged from 40 to 107%. This tube also showed slightly lower recovery percentages for the aromatic

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

Methods for the characterization of Jet Propellent-8

ORIGINAL RESEARCH

471

compounds <72%. The Tenax tubes showed the greatest recovery for all compounds. Results can be seen in Table 3.

CONCLUSIONS

Both JP-8 vapor and aerosol samples were analyzed and compared with neat fuel to determine if these sample types were unique. GC-MS analysis followed by statistical analysis of the data showed that these two types of samples were unique. The aerosol contained a greater abundance of higher molecular weight compounds, while the vapor was found to contain a greater abundance of lower molecular weight compounds. Comparison of three different types of sorbent tubes revealed that vapor samples trapped and extracted from Tenax were most representative of the vapor and therefore, this sorbent is recommended for sampling

JP-8 atmospheres. The glass ber lters were sufcient in the collection of the aerosol samples. The knowledge of the composition of JP-8s three major forms will aid in the design of more realistic exposure models for this fuel. Owing to these differences, the vapor and the aerosol should be treated as discrete exposure routes in future models of toxicity. Finally, the increased abundances of several higher molecular weight components in the aerosol samples present a possible explanation for increased health effects noted for exposure to aerosolized JP-8 when compared with vapor exposures. Acknowledgements This work was funded by the Air Force Ofce for Scientic Research (grant number F49620-03-1-0157). We also thank Katherine Dietzel for her input on these studies.

Table 3. Recovery results shown for charcoal, custom and Tenax sorbent tubes Charocoal tube Compound Heptane Octane Nonane Decane Undecane Dodecane Tridecane Tetradecane Pentadecane Hexadecane Heptadecane Octadecane Xylene 2-Ethyltoluene Mesitylene Pseudocumene 1,2,3 Trimethylbenzene Naphthalene 1-Methylnaphthalene 2-Methylnaphthalene 1,2-Dimethylnaphthalene Ethylbenzene Propylbenzene Methylcyclohexane 1,3 Dimethylcyclohexane Propylcyclohexane 1,4-Diethylbenzene 2-Methylnonane 2-Methyldecane 3-Methyldecane 4-Methyldecane 1,2,3,4 Tetrahydronaphthalene Phenylcyclohexane Cumene

ND = not detected. Copyright 2007 John Wiley & Sons, Ltd. Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

Custom tube ND 105% 100% 97% 95% 92% 87% 80% ND ND ND ND 32% 44% ND 49% ND 66% ND ND ND 32% 66% 108% 108% 103% 84% 85% 79% 103% 102% 61% ND ND ND 80% 82% 84% 84% 86% 85% 85% ND ND ND ND 40% 66% ND 72% 77% ND ND ND ND ND ND 67% ND 99% 78% 85% 91% 95% 107% ND ND ND ND 87% 91% 92% 93% 94% 93% 93% ND ND ND ND 45% 81% ND 71% 86% 71% ND ND ND ND 68% 100% ND 104% 96% 95% 93% 104% 105% 84% ND ND ND 87% 89% 89% 91% 91% 90% 89% ND ND ND ND 48% 74% ND 58% 86% 71% ND ND ND ND 71% 94% ND 98% 92% 92% 91% 98% 98% 85% ND ND ND 105% 104% 101% 96% 96% 99% 99% 94% ND ND ND 107% 100% ND 95% 91% 85% 72% 97% ND ND 95% 91% ND 101% 90% 101% 112% 103% 99% 92% ND ND

Tenax tube ND 95% 101% 99% 100% 100% 101% 101% 101% ND ND ND 97% 100% ND 97% 98% 100% 98% 97% ND ND 97% 98% ND 99% 99% 98% 100% 102% 101% 94% ND ND ND 102% 102% 102% 103% 102% 102% 102% 102% ND ND ND 100% 105% ND 100% 101% 100% 98% 100% ND ND 102% 109% ND 101% 100% 101% 102% 103% 101% 98% ND ND

2 g/mL 25 g/mL 100 g/mL 2 g/mL 25 g/mL 100 g/mL 2 g/mL 25 g/mL 100 g/mL ND 86% 107% 110% 111% 110% 107% 106% ND ND ND ND ND 79% ND 81% ND 98% ND ND ND 103% ND ND ND 110% ND 118% 107% 105% 116% 116% ND ND ND 94% 96% 92% 90% 85% 79% 71% ND ND ND ND 39% 34% ND 43% ND 57% ND ND ND 19% 55% 103% 98% 101% 74% 85% 74% 99% 101% 52% ND ND

472

ORIGINAL RESEARCH

S. D. Gregg et al. Maurice LQ, Lander H, Edwards T and Harrison III WE. Advanced aviation fuels: a look ahead via a historical prospective. Fuel 2001; 80(5): 747756. Muhammad F, Brooks JD and Riviere JE. Comparative mixture effects of JP-8(100) additives on the dermal absorption and disposition of jet fuel hydrocarbons in different membrane model systems. Toxicology Letters 2004; 150(3): 351365. The National Academy of Sciences. Toxicologic Assessment of Jet-Propulsion 8. The National Academies Press: Washington, DC, 2003. Perleberg UR, Keys DA and Fisher JW. Development of a physiologically based pharmacokinetic model for decane, a constituent of jet propellent-8. Inhalation Toxicology 2004; 16(1112): 771783. Pfaff J, Parton K, Lantz RC, Chen H, Hays AM and Witten ML. Inhalation exposure to JP-8 jet fuel alters pulmonary function and substance P levels in Fischer 344 rats. Journal of Applied Toxicology 1995; 15(4): 249256. Pfaff JK, Tollinger BJ, Lantz RC, Chen H, Hays AM and Witten ML. Neutral endopeptidase (NEP) and its role in pathological pulmonary change with inhalation exposure to JP-8 jet fuel. Toxicology and Industrial Health 1996; 12(1): 93103. Pleil JD, Smith LB and Zelnick SD. Personal exposure to JP-8 jet fuel vapors and exhaust at air force bases. Environmental Health Perspectives 2000; 108(3): 183192. Ritchie GD, Rossi J 3rd, Nordholm AF, Still KR, Carpenter RL, Wenger GR and Wright DW. Effects of repeated exposure to JP-8 jet fuel vapor on learning of simple and difcult operant tasks by rats. Journal of Toxicology and Environmental Health A 2001 64(5): 385415. Ritchie G, Still K, Rossi J 3rd, Bekkedal M, Bobb A and Arfsten D. Biological and health effects of exposure to kerosene-based jet fuels and performance additives. Journal of Toxicology and Environmental Health B Critical Review 2003; 6(4): 357451. Rossi J 3rd, Nordholm AF, Carpenter RL, Ritchie GD and Malcomb W. Effects of repeated exposure of rats to JP-5 or JP-8 jet fuel vapor on neurobehavioral capacity and neurotransmitter levels. Journal of Toxicology and Environmental Health A 2001; 63(6): 397428. Smith AQ, Campbell JL, Keys DA and Fisher JW. Rat tissue blood partition coefcients for n-alkanes (C8 to C12). International Journal of Toxicology 2005; 24(1): 3541. Smith LB, Bhattacharya A, Lemasters G, Succop P, Puhala E 2nd, Medvedovic M and Joyce J. Effect of chronic low-level exposure to jet fuel on postural balance of US Air Force personnel. Journal of Occupational and Environmental Medicine 1997; 39(7): 623632. Struwe G, Knave B and Mindus P. Neuropsychiatric symptoms in workers occupationally exposed to jet fuela combined epidemiological and casuistic study. Acta Psychiatrica Scandinavica. Supplementum 1983; 303(67): 5567. Tu RH, Mitchell CS, Kay GG and Risby TH. Human exposure to the jet fuel, JP-8. Aviation, Space, and Environmental Medicine 2004; 75(1): 4959. Whitman FT and Hinz JP. Sensory Irritation Study in Mice JP-4, JP8, JP-8+100. USA Force and Exxon Mobil Biomedical Sciences Inc., 2001.

REFERENCES

Agency for Toxic Substances and Disease Registry (ATSDR). Toxicological Prole for JP-5 and JP-8. Atlanta, Ga. US Department of Health and Human Services, Public Health Service, Agency for Toxic Substances and Disease Registry, 1998. Bogdan S, Boulares H, Rosenthal S, Iyer S, Hamilton I and Smulson M. Mechanisms of JP-8 Jet fuel toxicity. I. Induction of apoptosis in rat lung epithelial cells. Toxicology and Industrial Health 2001; 171(2): 94106. Cohen I and Hering SV. Air Sampling and Analysis of Air Contaminants: An Overview. ACGIH: Cincinnati, OH, 1995. Dietzel KD, Campbell JC, Bartlett MG, Witten ML and Fisher JW. Validation of a gas chromatography/mass spectrometry method for the quantication of aerosolized Jet Propellant 8. Journal of Chromatography A 2005; 1093(12): 1120. Gregg SD, Campbell JC, Dietzel KD, Fisher JW and Bartlett MG. A review of analytical methods for the identication and quantication of hydrocarbons found in jet propellant 8 and related petroleum based fuels. Biomedical Chromatography 2006; 20(67): 492507. Gussman RA. Note on the particle size output of collision nebulizers. American Industrial Hygiene Association Journal 1984; 45: 812. Harris DT, Sakiestewa D, Robledo R and Witten M. Immunotoxicological effects of JP-8 jet fuel exposure. Toxicology and Industrial Health 1997a; 13(1): 4355. Harris DT, Sakiestewa D, Robledo R and Witten M. Protection from JP-8 jet fuel induced immunotoxicity by administration of aerosolized substance P. Toxicology and Industrial Health 1997b; 13(5): 571588. Harris DT, Sakiestewa D, Robledo R and Witten M. Short-term exposure to JP-8 jet fuel results in long-term immunotoxicity. Toxicology and Industrial Health 1997c; 13(5): 559570. Harris DT, Sakiestewa D, Robledo R and Witten M. Effects of shortterm JP-8 jet fuel exposure on cell-mediated immunity. Toxicology and Industrial Health 2000; 16(2): 7884. Hays AM, Parliman G, Pfaff JK, Lantz RC, Tinajero J, Tollinger B, Hall JN and Witten ML. Changes in lung permeability correlate with lung histology in a chronic exposure model. Toxicology and Industrial Health 1995; 11(3): 325336. Knave B, Persson HE, Goldberg JM and Westerholm P. Longterm exposure to jet fuel: an investigation on occupationally exposed workers with special reference to the nervous system. Scandinavian Journal of Work, Environment and Health 1976; 2(3): 152164. Knave B, Olson BA, Elofsson S, Gamberale F, Isaksson A, Mindus P, Persson HE, Struwe G, Wennberg A and Westerholm P. Long-term exposure to jet fuel. II. A cross-sectional epidemiologic investigation on occupationally exposed industrial workers with special reference to the nervous system. Scandinavian Journal of Work, Environment and Health 1978; 4(1): 1945. Mattie DR, Alden CL, Newell TK, Gaworski CL and Flemming CD. A 90-day continuous vapor inhalation toxicity study of JP-8 jet fuel followed by 20 or 21 months of recovery in Fischer 344 rats and C57BL/6 mice. Toxicologic Pathology 1991; 19(2): 7787.

Copyright 2007 John Wiley & Sons, Ltd.

Biomed. Chromatogr. 21: 463472 (2007) DOI: 10.1002/bmc

Vous aimerez peut-être aussi

- Guide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsDocument12 pagesGuide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsMauricio Javier León TejadaPas encore d'évaluation

- Separation ChemistryDocument435 pagesSeparation ChemistryVladyi92% (12)

- Centrifugal PumpDocument56 pagesCentrifugal Pumpchandraa2208Pas encore d'évaluation

- Check ListDocument6 pagesCheck ListosersPas encore d'évaluation

- Cramkshaft Main Bearimg InstallDocument5 pagesCramkshaft Main Bearimg InstallNimPas encore d'évaluation

- Pso MPPTDocument10 pagesPso MPPTDileep GPas encore d'évaluation

- BS en 50483 6 2009Document27 pagesBS en 50483 6 2009Shara LogisticPas encore d'évaluation

- Welding Procedure Specification: Material / Joints QualifiedDocument2 pagesWelding Procedure Specification: Material / Joints QualifiedFernando LlontopPas encore d'évaluation

- Handbook of Instrumental Techniques For Analytical CHemistry - Fran A.Settle PDFDocument728 pagesHandbook of Instrumental Techniques For Analytical CHemistry - Fran A.Settle PDFGuto Steinhorst100% (5)

- Training CoursesDocument16 pagesTraining CoursesFeroz KhanPas encore d'évaluation

- Indhealth 56 346Document10 pagesIndhealth 56 346zamPas encore d'évaluation

- Baldwin Figueredo Wright Wong Witten 2007Document11 pagesBaldwin Figueredo Wright Wong Witten 2007api-244286238Pas encore d'évaluation

- Environmental Forensics for Persistent Organic PollutantsD'EverandEnvironmental Forensics for Persistent Organic PollutantsGwen O'SullivanPas encore d'évaluation

- Toxic Effects of Various Modifications of A NP Following InhalationDocument405 pagesToxic Effects of Various Modifications of A NP Following Inhalationfelipe de jesus juarez torresPas encore d'évaluation

- Chlorodifluoromethane CASRN 75-45-6: IRIS Assessment Development ProcessDocument12 pagesChlorodifluoromethane CASRN 75-45-6: IRIS Assessment Development ProcessridwanPas encore d'évaluation

- A Systematic Review of The Effects of E-Cigarette Use On Lung FunctionDocument7 pagesA Systematic Review of The Effects of E-Cigarette Use On Lung FunctionEva Paula Badillo SantosPas encore d'évaluation

- Food and Chemical Toxicology: SciencedirectDocument10 pagesFood and Chemical Toxicology: SciencedirectgustavoPas encore d'évaluation

- RPT 08 05Document11 pagesRPT 08 05CHRISTOS KALOUDISPas encore d'évaluation

- Mercury, Elemental CASRN 7439-97-6: IRIS Assessment Development ProcessDocument28 pagesMercury, Elemental CASRN 7439-97-6: IRIS Assessment Development ProcessYogi AndriantPas encore d'évaluation

- Evaluating The Toxicity of Airborne Particulate Matter and Nanoparticles by Measuring Oxidative Stress Potential A Workshop Report and ConsensusDocument26 pagesEvaluating The Toxicity of Airborne Particulate Matter and Nanoparticles by Measuring Oxidative Stress Potential A Workshop Report and ConsensusJota Gomez CdlmPas encore d'évaluation

- Caldwell Etal 2014 Chemo SphereDocument9 pagesCaldwell Etal 2014 Chemo SphereAiniiSumichelzPas encore d'évaluation

- AerotoxicSynd Anewoccupdisease Michaelisetal2017Document15 pagesAerotoxicSynd Anewoccupdisease Michaelisetal2017Andres SanchezPas encore d'évaluation

- Endotoxinas 1Document9 pagesEndotoxinas 1Carlos Israel Esparza AndradePas encore d'évaluation

- 5 OriginalResearch AerotoxicSyndrom ENGDocument14 pages5 OriginalResearch AerotoxicSyndrom ENGvonmanoPas encore d'évaluation

- Ing The Quality Objectivity Tility and Integrity of Information Di Seminated by The Environmental Protection Agency (EPA IQG) - Your RFRDocument7 pagesIng The Quality Objectivity Tility and Integrity of Information Di Seminated by The Environmental Protection Agency (EPA IQG) - Your RFRapi-312036241Pas encore d'évaluation

- Markers of Pulmonary Oxygen Toxicity in Hyperbaric Oxygen Therapy Using Exhaled Breath AnalysisDocument9 pagesMarkers of Pulmonary Oxygen Toxicity in Hyperbaric Oxygen Therapy Using Exhaled Breath AnalysisThijs WingelaarPas encore d'évaluation

- Fla Van OneDocument474 pagesFla Van OneMadhu SudhanPas encore d'évaluation

- CREDO Project NewsletterDocument20 pagesCREDO Project NewsletterKarolina PendovskaPas encore d'évaluation

- Artigo Alterações - 060123Document20 pagesArtigo Alterações - 060123Tatiane Soares CondePas encore d'évaluation

- Afroz Et AlDocument5 pagesAfroz Et AleditorijmrhsPas encore d'évaluation

- Is The Fish Embryo Toxicity Test FET Wit PDFDocument14 pagesIs The Fish Embryo Toxicity Test FET Wit PDFErfinaPas encore d'évaluation

- Annual Drug Data Report Vol-1 1971Document228 pagesAnnual Drug Data Report Vol-1 1971lasicablava50% (2)

- Patrick F. Dunn, Flint O. Thomas, James B. Leighton, Dayu LVDocument7 pagesPatrick F. Dunn, Flint O. Thomas, James B. Leighton, Dayu LVMichael AlexanderPas encore d'évaluation

- Food Chemistry: Joash Ban Lee Tan, Yau Yan LimDocument9 pagesFood Chemistry: Joash Ban Lee Tan, Yau Yan Limgigel_negoescuPas encore d'évaluation

- Invited ReviewDocument24 pagesInvited ReviewMadhav 360Pas encore d'évaluation

- Separations 08 00035 v2Document17 pagesSeparations 08 00035 v2Khánh Linh LêPas encore d'évaluation

- Hong Kong College of Anaesthesiologists Intermediate Fellowship Examination June / August 2007 Examiners' Report GeneralDocument6 pagesHong Kong College of Anaesthesiologists Intermediate Fellowship Examination June / August 2007 Examiners' Report GeneralJane KoPas encore d'évaluation

- Oecd/Ocde 413: Oecd Guidelines For The Testing of ChemicalsDocument23 pagesOecd/Ocde 413: Oecd Guidelines For The Testing of ChemicalsAngelPas encore d'évaluation

- Ehp 7059Document6 pagesEhp 7059Amirullah AbdiPas encore d'évaluation

- Ethylene Glycol: Hazard SummaryDocument4 pagesEthylene Glycol: Hazard SummaryAdityas Kinanti Putri MawarniPas encore d'évaluation

- 2004 Clinica Chimica ActaDocument15 pages2004 Clinica Chimica ActaDina MansourPas encore d'évaluation

- StrobeDocument6 pagesStrobeAanh EduardoPas encore d'évaluation

- Dose-Controlled Exposure of A549 Epithelial Cells at The Air-Liquid Interface To Airborne Ultrafine Carbonaceous ParticlesDocument7 pagesDose-Controlled Exposure of A549 Epithelial Cells at The Air-Liquid Interface To Airborne Ultrafine Carbonaceous Particlesdorelia_simonaPas encore d'évaluation

- Exposure To Ambient Fine Particles Causes Abnormal Energy Metabolism and ATP Decrease in Lung TissuesDocument10 pagesExposure To Ambient Fine Particles Causes Abnormal Energy Metabolism and ATP Decrease in Lung TissuesMaria Elena Gonzalez DiazPas encore d'évaluation

- Heath2016 Article FateAndEffectsOfTheResiduesOfADocument5 pagesHeath2016 Article FateAndEffectsOfTheResiduesOfARICARDO GRANDASPas encore d'évaluation

- 10 1 1 232 716 PDFDocument17 pages10 1 1 232 716 PDFSounak BosePas encore d'évaluation

- 1437 FTP PDFDocument11 pages1437 FTP PDFDébora Costa ReisPas encore d'évaluation

- Allergens Causing Occupational Asthma: An Evidence-Based Evaluation of The LiteratureDocument25 pagesAllergens Causing Occupational Asthma: An Evidence-Based Evaluation of The Literaturedaniel salinasPas encore d'évaluation

- Peel (VOCs Asthma SR) 2020Document18 pagesPeel (VOCs Asthma SR) 2020Luis Taborda BarataPas encore d'évaluation

- 10.1007@s00204 019 02490 XDocument10 pages10.1007@s00204 019 02490 Xtypp3t5r3gzPas encore d'évaluation

- Fotheringham. Walking Test Comparisons.Document19 pagesFotheringham. Walking Test Comparisons.Stijn van den BerkmortelPas encore d'évaluation

- Isopropanol: Monographs Supplement 7 (1987)Document10 pagesIsopropanol: Monographs Supplement 7 (1987)mangala jesudossPas encore d'évaluation

- Koenig Et Al. (2004) - Pulmonary Effects of Indoor - and Outdoor-Generated Particles in Children With AsthmaDocument5 pagesKoenig Et Al. (2004) - Pulmonary Effects of Indoor - and Outdoor-Generated Particles in Children With AsthmanimaaandmPas encore d'évaluation

- Mutlu 2013Document18 pagesMutlu 2013paulsteaua4968Pas encore d'évaluation

- Mutagenic IndexDocument9 pagesMutagenic IndexfaisalnadeemPas encore d'évaluation

- Acetophenone: Hazard SummaryDocument4 pagesAcetophenone: Hazard Summaryalejandra rojasPas encore d'évaluation

- Funari 2015Document22 pagesFunari 2015ShahinuzzamanAdaPas encore d'évaluation

- Gauderman - Association Between Air Pollution A Lung Function Growth in Southern California Children - Results A Second Cohort - 2002Document9 pagesGauderman - Association Between Air Pollution A Lung Function Growth in Southern California Children - Results A Second Cohort - 2002Beatriz OliveiraPas encore d'évaluation

- Role of Pharmacokinetics Inestablishing Bioequivalence For Orally Inhaled Drug Products - Workshop Summary ReportDocument18 pagesRole of Pharmacokinetics Inestablishing Bioequivalence For Orally Inhaled Drug Products - Workshop Summary Reportvg_vvgPas encore d'évaluation

- Comparative Responses of Rats and Mice Exposed To Linear/branched, Linear, or Branched Ammonium Perfluorooctanoate (APFO)Document15 pagesComparative Responses of Rats and Mice Exposed To Linear/branched, Linear, or Branched Ammonium Perfluorooctanoate (APFO)Tainara VitórioPas encore d'évaluation

- 2008 Anabolic Steroid UseDocument22 pages2008 Anabolic Steroid UseAlbert JacksonPas encore d'évaluation

- Turinabol Metabolites New WADA MethodDocument15 pagesTurinabol Metabolites New WADA MethodRebeca JolónPas encore d'évaluation

- Environmental Effects of Dredging: Technical NotesDocument13 pagesEnvironmental Effects of Dredging: Technical NotesSalvatore ChiavariniPas encore d'évaluation

- A Comprehensive Study On The Performance of Different RetentionDocument12 pagesA Comprehensive Study On The Performance of Different Retentionkassim AliPas encore d'évaluation

- WRC ReportDocument613 pagesWRC ReportAnup SharmaPas encore d'évaluation

- Review Epidemiological Basis For Particulate Air Pollution Health StandardsDocument12 pagesReview Epidemiological Basis For Particulate Air Pollution Health StandardslbarretoPas encore d'évaluation

- ICRP 53 - Radiation Dose To Patients From RadiopharmaceuticalsDocument340 pagesICRP 53 - Radiation Dose To Patients From Radiopharmaceuticalsraymond_lane_7Pas encore d'évaluation

- Amphetamines in Nasal InhalersDocument3 pagesAmphetamines in Nasal InhalersdelhostPas encore d'évaluation

- Science of The Total Environment: Contents Lists Available atDocument10 pagesScience of The Total Environment: Contents Lists Available atJam OdonelPas encore d'évaluation

- Oecd Guideline For The Testing of ChemicalsDocument14 pagesOecd Guideline For The Testing of ChemicalsUpendra ShrimaliPas encore d'évaluation

- JM 300181 JDocument14 pagesJM 300181 JkmeriemPas encore d'évaluation

- Aptamer-Based Inhibition Assay For The Electrochemical Detection of Tobramycin Using Magnetic MicroparticlesDocument7 pagesAptamer-Based Inhibition Assay For The Electrochemical Detection of Tobramycin Using Magnetic MicroparticleskmeriemPas encore d'évaluation

- 004aa PDFDocument16 pages004aa PDFkmeriemPas encore d'évaluation

- Acid-Base Titrimetric Assay of Hydroxyzine Dihydrochloride in Pharmaceutical SamplesDocument6 pagesAcid-Base Titrimetric Assay of Hydroxyzine Dihydrochloride in Pharmaceutical SampleskmeriemPas encore d'évaluation

- 177 FTPDocument11 pages177 FTPkmeriemPas encore d'évaluation

- v31 207 214Document8 pagesv31 207 214kmeriemPas encore d'évaluation

- JICS 1 2 Article 1Document9 pagesJICS 1 2 Article 1kmeriemPas encore d'évaluation

- 9Document5 pages9kmeriemPas encore d'évaluation

- 177 FTPDocument11 pages177 FTPkmeriemPas encore d'évaluation

- 129 FTPDocument11 pages129 FTPkmeriemPas encore d'évaluation

- WaleedDocument7 pagesWaleedkmeriemPas encore d'évaluation

- IssaY ConductometricAndPotentiometric 2010Document8 pagesIssaY ConductometricAndPotentiometric 2010kmeriemPas encore d'évaluation

- 36Document7 pages36kmeriemPas encore d'évaluation

- 6 Kalyanaramu Et AlDocument8 pages6 Kalyanaramu Et AlkmeriemPas encore d'évaluation

- 9 Nuclear Magnetic Resonance Spectroscopy: 1573 - C09.fm Page 407 Tuesday, November 25, 2003 11:37 AMDocument44 pages9 Nuclear Magnetic Resonance Spectroscopy: 1573 - C09.fm Page 407 Tuesday, November 25, 2003 11:37 AMkmeriem100% (1)

- 9 Nuclear Magnetic Resonance Spectroscopy: 1573 - C09.fm Page 407 Tuesday, November 25, 2003 11:37 AMDocument44 pages9 Nuclear Magnetic Resonance Spectroscopy: 1573 - C09.fm Page 407 Tuesday, November 25, 2003 11:37 AMkmeriem100% (1)

- 2006 Drug Trend ReportDocument49 pages2006 Drug Trend ReportkmeriemPas encore d'évaluation

- 50 3 395Document13 pages50 3 395kmeriemPas encore d'évaluation

- Spectrophotometric Assay of Phenylephrine Hydrochloride Using 4-Aminoantipyrine and Copper (II)Document7 pagesSpectrophotometric Assay of Phenylephrine Hydrochloride Using 4-Aminoantipyrine and Copper (II)kmeriemPas encore d'évaluation

- 6 Electroanalytical Methods: 1573 - C06.fm Page 273 Friday, November 14, 2003 5:11 PMDocument27 pages6 Electroanalytical Methods: 1573 - C06.fm Page 273 Friday, November 14, 2003 5:11 PMkmeriemPas encore d'évaluation

- 1573 Ch07Document16 pages1573 Ch07kmeriem100% (1)

- 1573 Ch05Document7 pages1573 Ch05kmeriemPas encore d'évaluation

- 1573 Ch05Document7 pages1573 Ch05kmeriemPas encore d'évaluation

- Issaq - A Century of Separation ScienceDocument769 pagesIssaq - A Century of Separation ScienceAlexander VelascoPas encore d'évaluation

- 6 Electroanalytical Methods: 1573 - C06.fm Page 273 Friday, November 14, 2003 5:11 PMDocument27 pages6 Electroanalytical Methods: 1573 - C06.fm Page 273 Friday, November 14, 2003 5:11 PMkmeriemPas encore d'évaluation

- 1 s2.0 0021967394800235 MainDocument27 pages1 s2.0 0021967394800235 MainkmeriemPas encore d'évaluation

- 5989 6639enDocument85 pages5989 6639enSoma GhoshPas encore d'évaluation

- 10.1385 - 0 89603 315 5@99Document5 pages10.1385 - 0 89603 315 5@99kmeriemPas encore d'évaluation

- Activity Sheets SMAW 7.23Document5 pagesActivity Sheets SMAW 7.23Jerome Cailo DiazPas encore d'évaluation

- Chemistry, Intermediate II Year Model Question PapersDocument3 pagesChemistry, Intermediate II Year Model Question PapersAkshay PandeyPas encore d'évaluation

- EEC 319 Engineer in The Society DocumentDocument3 pagesEEC 319 Engineer in The Society Documentgodspower odior100% (1)

- Potsdam Village Police Dept. Blotter April 12, 2018Document2 pagesPotsdam Village Police Dept. Blotter April 12, 2018NewzjunkyPas encore d'évaluation

- 507 39 Solutions-Instructor-manual Ch7 DRCSDocument13 pages507 39 Solutions-Instructor-manual Ch7 DRCSArun GoyalPas encore d'évaluation

- SG-05 Safety Guideline For Illumination at WorkplaceDocument5 pagesSG-05 Safety Guideline For Illumination at WorkplacebsrchandruPas encore d'évaluation

- Hepworth Clay DoPs - Full SetDocument54 pagesHepworth Clay DoPs - Full SetAnonymous XYAPaxjbYPas encore d'évaluation

- PCMX Data Eng 01Document13 pagesPCMX Data Eng 01spamPas encore d'évaluation

- Elmer TutorialsDocument65 pagesElmer TutorialsmariomatoPas encore d'évaluation

- NC100HDocument2 pagesNC100HDouglas GilbPas encore d'évaluation

- 3000w Inverter Parts ListDocument6 pages3000w Inverter Parts ListayoowuyePas encore d'évaluation

- MSM Carbon FibreDocument35 pagesMSM Carbon FibrelokeshkrkushwahaPas encore d'évaluation

- Plastic Coatings: Advanced Polymer Technologies ForDocument13 pagesPlastic Coatings: Advanced Polymer Technologies ForFazlul HoquePas encore d'évaluation

- Roland Sands Design US CatalogDocument56 pagesRoland Sands Design US Catalogsema2210Pas encore d'évaluation

- Catalog: Ningbo Liftstar Material Handling Equipment Co., LTDDocument27 pagesCatalog: Ningbo Liftstar Material Handling Equipment Co., LTDKiều Văn TrungPas encore d'évaluation

- FMS 2009 Question Paper and Answer KeyDocument6 pagesFMS 2009 Question Paper and Answer KeyHarish PotterPas encore d'évaluation

- Mitsubishi Electric Industrial Robots: Communication Middleware (Melfarxm - Ocx) Instruction ManualDocument152 pagesMitsubishi Electric Industrial Robots: Communication Middleware (Melfarxm - Ocx) Instruction ManualRafael GagoPas encore d'évaluation

- Datasheet 783Document2 pagesDatasheet 783veertulPas encore d'évaluation

- (INGCO) 06 November 2023 Stock ReportDocument23 pages(INGCO) 06 November 2023 Stock ReportMandiri JayaPas encore d'évaluation

- Technical Brochure Metal Ceilings V100-V200-en EUDocument12 pagesTechnical Brochure Metal Ceilings V100-V200-en EUNicu PotîngPas encore d'évaluation

- SikaRapid-2 2011-10 - 1 PDFDocument2 pagesSikaRapid-2 2011-10 - 1 PDFmehrdad_so1981Pas encore d'évaluation

- Maxstar140str (KK013519)Document52 pagesMaxstar140str (KK013519)mrtans0% (1)