Académique Documents

Professionnel Documents

Culture Documents

09 Gasic PDF

Transféré par

ramadan1978Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

09 Gasic PDF

Transféré par

ramadan1978Droits d'auteur :

Formats disponibles

The International Journal of TRANSPORT & LOGISTICS Meunarodni asopis TRANSPORT I LOGISTIKA UDC: 663.931:621.

867

CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION OF RAW MATERIAL IN A COFFEE PROCESSING PLANT IZBOR OPTIMALNOG SISTEMA TRANSPORTA SIROVINE U FABRICI ZA PRERADU KAFE

Milomir GAI, Mile SAVKOVI University of Kragujevac, Faculty of Mechanical Engineering, Kraljevo, Serbia

Abstract: This paper gives the comparative analysis of various solutions to the raw material transportation from the receiving silo to the system for ground coffee packing. On a real example of coffee processing plant it is obtained optimal case for raw material transportation. This paper also the analysis of efficiency of optional solutions to the raw material transportation. Key words: transportation, logistics, optimization, layout Apstrakt: U radu je izvrena uporedna analiza varijantnih reenja transporta sirovine od prijemnog silosa do sistema za pakovanje mlevene kafe. Na konkretnom primeru postrojenja za preradu kafe u jednoj fabrici izvren je izbor optimalne varijante za transport sirovine. Takoe, izvrena je i analiza efikasnosti varijantnih reenja transporta sirovine. Kljune rei: transport, logistika, optimizacija, layout

1 INTRODUCTION It is obvious that in many factories transportation is considered to be marginal work which is done by improvisation or in few cases as an isolated problem succeeding the choice of equipment and its assembling. Transportation system is an essential part of production and therefore it can save both time and expenses, from coming the raw material into production process to the finished products. Constant development of transportation means has made production planning easier and has decreased total costs per product unit. Development of transportation means has also influenced its variety regarding the type, capacity, energy expenditure, space necessary for installment, size of transportation paths. The project of transportation system should include the whole system of material flow, which involves not only solving

1 UVOD Evidentno je da se u mnogim preduzeima zahtevi transporta posmatraju kao sporedni poslovi koji se reavaju improvizacijom ili u manjem broju sluajeva kao izolovani problem nakon izbora opreme i njene montae. Transportni sistem je integralni deo proizvodnje i znatno utie na utedu u trokovima u vremenu i radu, od ulaska sirovine u proces proizvodnje do izlaska gotovog proizvoda. Stalni razvoj transportnih sredstava poslednjih godina doprinosi lakem planiranju proizvodnje i smanjenju ukupnih trokova po jedinici proizvoda. Razvoj transportnih sredstava uticao je i na pojavu njihove raznovrsne lepeze po tipu, uinku, potronji energije, potrebnom prostoru za ugradnju, veliini transportnih puteva. Projektovanje sistema transporta traba da obuhvati ceo sistem kretanja materijala, to znai

85

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

the isolated transportation systems but planning many mutually dependant transportation requirements. 2 ANALYSIS OF TRANSPORTATION SYSTEM The analysis of transportation system of a coffee processing plant within the factory relates to the choice of optimal variant of transportation. Since complete equipment for coffee processing has been previously chosen, the choice of transportation means is limited a lot. Transportation from receiving ramp to the warehouse is done by means of pallet truck (Q1=2500 kg). From the warehouse or interwarehouse the coffee is transported to the receiving container of the silo for green coffee, and then to the roasting plant (Q2=550 kg). Roasted coffee is then transported to the mixer and after that to the grinder. After grinding the coffee is transported to the packing machines. Maximal quantity of coffee in the receiving container of packing machine is Qp=600 kg. Diagram of transportation process is shown in figure 1. Interwarehouse

i planiranje niza meusobno zavisnih transportnih zahteva, a ne samo reavanje izolovanih transportnih sistema. 2 ANALIZA SISTEMA TRANSPORTA Analiza sistema transporta postrojenja u jednoj fabrici za preradu kafe odnosi se na izbor optimalne varijante transporta. Poto je prethodno usvojena kompletna oprema postrojenja za preradu kafe izbor transportnih sredstava je u mnogome ogranien. Transport od prijemne rampe do skladita sirovine vri se pomou viljukara (Q1=2500 kg). Iz skladita sirovine ili meuskladita kafa se transportuje do prijemnog bunkera sirove kafe, a odatle do postrojenja za prenje (Q2=550 kg). Prena kafa se dalje transportuje do miksera a zatim do mlina za mlevenje. Nakon mlevenja kafa se transportuje do maina za pakovanje. Maksimalna koliina kafe u prijemniku maine za pakovanje iznosi Qp=600 kg. Blok dijagram transportnih procesa prikazan je na slici 1. Roasting plant Grinder

External transportation

Material warehouse

Mixer

container for green coffee

Packing machines

Figure 1 Diagram of transportation process slika 1 Blok dijagram transportnih procesa 2.1 Pallet trucks transportation According to defined parameters of transportation units (Q1=2500 kg and Q2=550 kg) and according to the fact that work is done in covered space the analysis has been done for electric pallet truck E12 and E30 made by ''Linde''. Basic technical parameters are given in table 1. Figure 2 shows transportation paths in the production plant: L1-warehouse-receiving container for greencoffee L1-interwarehouse-receiving container for green coffee L2- receiving silo - roasting machine L3- roasting machine- mixer L4- mixer - grinder L5- grinder - packing machine 86 2.1. Transport viljukarom Saglasno definisanoj veliini transportnih jedinica (Q1 =2500 kg i Q2 =550 kg) i injenici da se rad odvija u zatvorenom prostoru sprovedena je analiza za elektro viljukare E12 i E30 proizvo aa Linde. Osnovni tehniki parametri dati su u tabeli 1. Na slici 2 prikazani su transportni putevi u proizvodnom pogonu: L1 - skladite-prijemnik sirove kafe L1 - me uskladite-prijemnika sirove kafe L2 - prijemni bunker-maina za prenje L3 - maina za prenje-mikser L4 - mikser-mlin L5 - mlin- maina za pakovanje kafe

Stock

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

For defined average lengths of transportation paths: L1=24 m; L1=9 m; L2=15 m; L3=11 m; L4=9 m; L5=4.5 m; H=2.5 m; Hi=1.5 m; we get the average values of duration of pallet truck cycle: TC,E12 =92 s; TC,E12 =87 s; Transportation system, shown in figure 2, is a closed system, where the number of units in the system is r=6. The average number of cycles in zah . this system is: = 38

h

Za utvrene prosene vrednosti duina transportnih puteva: L1=24 m; L1=9 m; L2=15 m; L3=11 m; L4=9 m; L5=4.5 m; H=2.5 m; Hi=1.5 m; dobijaju se prosene vrednosti trajanja ciklusa viljukara: TC ,E12 = 92s; TC ,E 30 = 87s; Transportni sistem prikazan na slici 2 predstavlja zatvoreni sistem opsluivanja gde je broj jedinica u sistemu r=6. Utvreni prosean broj zahteva u ovom sistemu iznosi: = 38 zah .

h

Table 1 Basic technical parameters of the pallet truck Tabela 1 Osnovni tehniki parametri viljukara Technical parameters Carrying capacity (kg) Lifting speed with/without load (m/s) Lowering speed with/without load (m/s) Driving speed with/without load (m/s) Power for driving/lifting (kW) Width of transportation path (mm)

Type of pallet truck E12 E30 1200 3000 0.37/0.55 0.27/0.48 0.36/0.47 0.5 3.1/3.5 4.2/4.4 6/5 12.8/13.5 1600 1800

Figure 2 Transportation paths in the production plant slika 2 Prikaz transportnih puteva u proizvodnom pogonu Average number of units which can be supplied by pallet trucks in time unit is:

E12 =

1 1 3600 = 39.1 E 30 = 3600 = 41.4 87 92

Prosean broj jedinica koje viljukari mogu opsluiti u jedinici vremena iznosi:

E12 =

1 1 3600 = 39.1 E 30 = 3600 = 41.4 87 92

Coefficient of system loading, i.e. flow intensity is:

E12 = 38 38 = = 0.972 E 30 = = = 0.918 E12 39.1 E 30 41.4

Koeficijent optereenja intenzitet protoka iznosi:

E12 =

sistema,

odnosno

38 38 = = 0.972 E 30 = = = 0.918 E12 39.1 E 30 41.4

State probability of the system is [2]:

Verovatnoe stanja sistema su [2]:

87

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

Pr = r ! P0

r

T&L - 11/06

(1)

P0 = 1 1 + r + r ( r 1) + ... + r !

2 r

P0 =

1 1 + r + r ( r 1) + ... + r !

2 r

Pr = r ! P0 (1)

Average number of units to be supplied is:

N zw = ( n 1) Pn

n =1 r

Prosean broj zahteva koji eka opsluivanje je:

N zw = ( n 1) Pn

n =1 r

(2)

(2)

that is: N zw,E12 = 3.97; N zw,E 30 = 3.91; . Average break-downs of units to be supplied and time needed for supply are:

odnosno: N zw,E12 = 3.97; N zw,E 30 = 3.91; . Prosean zastoj jedinica za opsluivanje i vreme ekanja jedinice na opsluivanje iznosi:

N wE12 =

( n 1) P

n =1

r

r

; = 0.66 N

wE 30

( n 1) P

n =1

r

r

= 0.65

(3)

N wE12 =

( n 1) P

n =1

r

r

= 0.66 N wE 30 =

( n 1) P

n =1

r

r

= 0.65

(3)

twE12 =

( n 1) P

n =1

= 1.04 min twE 30 =

( n 1) P

n =1

= 1.03 min

twE12 =

( n 1) P

n =1

; = 1.04 min twE 30 =

( n 1) P

n =1

= 1.03 min

By analysis of results obtained we can conclude that a pallet truck is very busy and it cannot be used for other transportation activities so it is better to use two pallet trucks type E30. State probabilities of the system are:

P0 = 1 r ( r 1) r! + ... + P0 1+ r + 2 c!

2 2

Analizom dobijenih rezultata moe se zakljuiti da je visoka zauzetost jednog viljukara i ne moe se koristiti za dopunske aktivnosti transporta pa je bolje reenje usvojiti dva viljukara E30. Verovatnoe stanja sistema su:

P0 = 1 r ( r 1) r! + ... + P0 1+ r + 2 c!

2 2

= 0.00854

= 0.00854

P6 =

r! P0 = 0.345 c! c

P6 =

r! P0 c!

= 0.345 c

Average number of units to be supplied and time needed for supply are:

N zw = ( n c ) Pn = 2.88

n=c r

Prosean broj zahteva koji eka na opsluivanje i vreme ekanja na opsluivanje iznose:

N zw = ( n c ) Pn = 2.88

n=c r

(4)

(4)

Nw =

(n c) P

n =c

= 0.48

tw =

(n c) P

n =c

(5) = 0.76 min

Nw =

(n c) P

n =c

= 0.48

tw =

(n c) P

n =c

= 0.76 min

(5)

2.2. Pneumatic transportation The force to be realized in pneumatic line is:

T=

2.2. Pneumatski transport Sila koju treba ostvariti u pneumatskom vodu je:

T=

v Amax

g

( vv vM ) = 0.03 daN

2

(6)

v Amax

g

( vv vM ) = 0.03 daN

2

(6)

where: = 0.23 - coefficient of material properties,

gde je: = 0.23 - koeficijent svojstva materijala,

88

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

projection of the area of the biggest section perpendicular to flow speed, 3 - density of coffee beam, M = 440 kg / m v = 1.2 kg / m3 - air density, vv = 15 m / s - chosen air speed, vm - speed of mixture flow. For pressure fall in the air line pv = 0.025MPa ,the value of pressure in delivery line is p p = 0.36 MPa , where:

Lr =31 m

Amax = 0.011 m2 -

projekcija povrine najveeg preseka upravno na brzinu strujanja, 3 - gustina kafe u zrnu, M = 440 kg / m v = 1.2 kg / m3 - gustina vazduha, vv = 15 m / s - usvojena brzina vazduha, vm - brzina strujanja meavine Za pad pritiska u vazdunom vodu

pv = 0.025MPa ,vrednosti pritiska potisnog ureaja

Amax = 0.011 m2 -

iznosi p p = 0.36 MPa , pri emu je poznato:

Lr =31 m

- reduced pipeline length - reduced vertical pipeline length

- redukovana duina cevovoda

Lv =8 m

Lv =8 m

-redukovana vertikalna duina cevovoda

Air quantity needed for transportation of coffee beam is:

Vk = 0.785 dc2 vv = 0.17 m3 / s

Potrebna koliina vazduha za transport kafe u zrnu iznosi:

Vk = 0.785 dc2 vv = 0.17 m3 / s

(7)

(7)

where: dc =0.13 m - pipeline diameter. Based on theoretical operation of air machine: p we obtain the A = 230300 p log M = 12811.6 Nm / m3

M b

gde je: dc =0.13 m - prenik cevovoda. Na osnovu teorijskog rada maine za vazduh: p dobija se A = 230300 p log M = 12811.6 Nm / m3

M b

pb

pb

power of driving electromotor needed to realize the operation of machine of air transportation:

PM = AM Vk

potrebna snaga pogonskog elektromotora za rad maine za vazduni transport:

PM = AM Vk

= 3.6 kW

- adopted PM = 4 kW .

= 3.6 kW

- usvojeno PM = 4 kW .

Capacity of realized transportation is:

Qm = D 2 vM c c = 1.5 kg / s = 90 kg / min 4

Kapacitet ostvarenog transporta iznosi:

Qm = D 2 vM c c = 1.5 kg / s = 90 kg / min 4

Capacity to be realized is: Q p = 60 kg / min . The receiving silo is unloaded for 10 minutes at least. For other transportation cycles (L1, L2, L3, L4 and L5) and for the same capacity the necessary power of driving aggregates is: PM = 3 kW . Average quantity of material leaving the receiving silo in one cycle is: Q1 = 550 kg . Average number of cycles during one working hour is 4.

Potreban kapacitet koji treba ostvariti iznosi: Q p = 60 kg / min . Najmanje vreme pranjenja prijemnog bunkera iznosi 10 minuta. Za ostale transportne cikluse (L1, L2, L3, L4 L5) i isti kapacitet potrebna snaga pogonskih agregata isnosi: PM = 3 kW . Prosena vrednost koliine materijala koja izlazi z prijemnog bunkera, u jednom ciklusu, iznosi Q1 = 550 kg . Prosean broj ciklusa u jednom satu rada postrojenja je 4.

89

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

If arriving flow acts according to Poisson distribution, the flow intensity and average material quantity to be supplied is:

=

Q n 550 4 = 36.7 kg / min <1; = 1 c = 60 60

Ukoliko se dolazni tok ponaa po Poason-ovoj raspodeli intenzitet protoka i prosena koliina materijala koju treba opsluiti iznose:

= ; <1

Q1 nc 550 4 = = 36.7 kg / min 60 60

For average system efficiency of 70% the value of material flow is:

=

36.7 = 52.4 kg / min 0.7

Za usvojeno proseno iskorienje sistema od 70% potrebna vrednost protoka materijala je:

=

36.7 = 52.4 kg / min 0.7

Real flow intensity is: st = 0.41 . Average number of units to be supplied in onechannel system (1 kg is 1 unit) is:

Nw = 2 (1 )

Stvarni intenzitet protoka iznosi: st = 0.41 . Prosean broj jedinica u redu ekanja jednokanalnog sistema opsluivanja (1 kg je jedna jedinica) isnosi:

Nw = 2 (1 )

= 0.14 kg

= 0.14 kg

2.3 Belt conveyer and bucket elevator transportation Required capacity can be acquired by coupled system: bucket elevator and belt conveyer. Adopted technical parameters of the elevator are: Q=4.4t/h transportation capacity, io=0.4 dm bucket volume, nk=260 - number of buckets, tk=007m - bucket pitch, nc=120c/h - number of unloading. Driving volume of buckets and driving weight of load are:

ip = m3 ; q = i = 1.9 i0 G p p = 0.005 tk m

3

2.3 Transport trakastim transporterom i elevatorom sa koficama Zahtevani kapacitet moe se ostvariti korienjem spregnutog sistema elevatora sa koficama i trakastog transportera. Usvojeni tehniki parametri elevatora su: Q=4.4t/h kapacitet transporta, io=0.4 dm3 zapremina kofice, nk=260 - broj kofica, tk=007m korak kofice, nc=120c/h - broj pranjenja kofica. Pogonska zapremina kofica i pogonska masa tereta iznose:

ip = m 3 ; q = i = 1.9 i0 = 0.005 G p p tk m

( kg/m ) ;

( kg/m ) ;

where: p = 0.85 - coefficient of bucket loading. Approximate value of driving weight of moving parts is:

qE = k E Q = 2.64 ( kg / m )

gde je: p = 0.85 - koeficijent punjenja kofica Priblina vrednost pogonske mase pokretnih delova elevatora iznosi:

qE = k E Q = 2.64 ( kg / m )

where k E = 0.6 - coefficient of driving mass. Needed power of elevator driving engine is:

pri emu je k E = 0.6 - koeficijent pogonske mase Potrebna snaga pogonskog motora elevatora iznosi:

90

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

P= kp 1 1 2 Q g H 1 + = 4.4 g 4.5 1 + =0.1 3600 H 3600 4.5

T&L - 11/06

( kW )

P=

kp 1 1 2 Q g H 1 + = 4.4 g 4.5 1 + =0.1 3600 H 3600 4.5

PM = 0.75 kW

( kW )

so adopted power is: PM = 0.75 kW . By unloading the elevator, the material is put to the straight belt conveyer (figure 3). The resistance in return run is:

W1 2 = g ( qr + qT ) L = 41 N

pa je usvojena snaga:

Pranjenjem elevatora materijal se nasipa na pravolinijski trakasti transporter (slika 3). Otpor u povratnoj grani iznosi:

W1 2 = g ( qr + qT ) L = 41 N

where:

qr = ( 10 B + K ) / l = 10 kg / m

gde je:

qr = ( 10 B + K ) / l = 10 kg / m

qT = 0.44 kg / m - driving mass of the belt

qT = 0.44 kg / m - pogonske mase trake

= 0.02 - coefficient of friction between belt

= 0.02 -koeficijent trenja trake

and pulley The resistance over the tension drum is:

W2 3 = (k p 1) S 2

i doboa Otpor preko zateznog doboa iznosi:

W2 3 = (k p 1) S 2

where: kp = 1.07 - coefficient of resistance. W2-3 = 2.87 + 0.07 S1 Resistance in straight loaded part is:

W34 = g ( qG + qT + qg ) L = 45.8 N

gde je: kp = 1.07 - koeficijent otpora. W2-3 = 2.87 + 0.07 S1 O tpor u pravolinijskom optereenom delu iznosi:

W34 = g ( qG + qT + qg ) L = 45.8 N

Maximal value of the force is:

S max = k p S 4 = 1.15 S1 + 96

Maksimalna vrednost sile iznosi:

S max = k p S4 = 1.15 S1 + 96

so:

Smax 1.15 S1 + 96 S max = = = 2.56 S1 S1 S1

tako da je odnos:

S max 1.15 S1 + 96 S max = = = 2.56 S1 S1 S1

Values of forces in the points 1, 2, 3, 4 are:

S1 = 68 N ; S 2 = 109 N ; S3 = 116.6 N ; S4 = 162.5 N ; S max = 174 N ; F0 = 106 N

Vrednosti sila u odgovarajuim takama iznose:

S1 = 68 N ; S 2 = 109 N ; S3 = 116.6 N ; S4 = 162.5 N ; S max = 174 N ; F0 = 106 N

Belt speed necessary to realized the required capacity is v = 0.8 m / s; so the power of driving aggregate is:

P= F0 v

Potrebna brzina kretanja trake za projektovani kapacitet iznosi v = 0.8 m / s; ; tako da je snaga pogonskog agregata:

P= F0 v

106 0.8 = 154 W 0.55

-adopted:- PM = 0.75 kW

106 0.8 = 154 W 0.55

- usvojeno:-

PM = 0.75 kW

91

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

Carrying run 3 v 2 Return run Tension pulley

Load 4

1 Driving pulley

Figure 3 Diagram for calculation of conveyer slika 3 Karakteristine take za proraun transportera For other transportation cycles (L 1, L2 , L3, L4 L5 ) and same capacity, the power of driving aggregates required is: PM = 0.55 kW . Average material quantity to be supplied is:

t =

Q1 nc 550 4 = = 36.7 kg / min 60 60

Za ostale transportne cikluse (L1, L2, L3, L4 L5) i isti kapacitet potrebna snaga pogonskih agregata iznosi: PM = 0.55 kW . Prosena koliina materijala koju je neophodno opsluiti (ide dalje u proces) iznosi:

t =

Q1 nc 550 4 = = 36.7 kg / min 60 60

If average system efficiency is 70%, the average value of material flow to be provided is:

=

36.7 = 52.4 kg / min 0.7

Ako je proseno iskorienje sistema 70%, potrebna prosena vrednost protoka materijala koju treba obezbediti iznosi:

=

36.7 = 52.4 kg / min 0.7

so real flow intensity is: pa je stvarni intenzitet protoka:

st = 0.51 .

st = 0.51 .

Average number of units to be supplied in one-channel system is (if 1kg is 1 unit):

Nw = 2 (1 )

= 0.27 kg

Prosean broj jedinica u redu ekanja (ukoliko se usvoji da je 1 kg jedna jedinica) za jednokanalni sistem opsluivanja iznosi:

Nw = 2 (1 )

Chances for overloading during operation is:

P( n > N ) = n ( 1 ) = N +1=0.5237 =3 10 -11

n= N

= 0.27 kg

Verovatnoa da e doi do prepunjavanja u radu je:

P( n > N ) = n ( 1 ) = N +1=0.5237 =3 10 -11

n= N

3. COMPARATIVE ANALYSIS AND CHOISE OF TRANSPORTATION SYSTEM Comparative analysis should provide the choice of optimal variant based on a number of required criteria. In terms of mathematics, the optimization is based on search for extreme values of criterion function s [7]:

Max { f1 ( x ) , f 2 ( x ) ,..., f n ( x ) n 2}

3. UPOREDNA ANALIZA I IZBOR TRANSPORTNOG SISTEMA Zadatak uporedne analize jeste da se omogui izbor optimalne varijante na osnovu veeg broja zadatih kriterijuma. U matematikom obliku optimizacija se svodi na traenje ekstrema kriterijumskih funkcija [7]:

Max { f1 ( x ) , f 2 ( x ) ,..., f n ( x ) n 2}

(12)

(12)

with defined limitations: 92

pri zadatim ogranienjima:

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

x A [ A1, A2,..., Am ]

(13)

x A [ A1, A2,..., Am ]

(13)

where: n criterion number, m alternative number, f j criteria,

Ai alternatives for consideration.

gde su: n broj kriterijuma, m broj alternativa, f j kriterijumi,

Ai alternative za razmatranje.

During consideration, values fij are known for each criterion fj for each possible alternative Ai:

f ij = f j ( Ai ) ; ( i, j ) ; i = 1,2,...,m ; j = 1,2,...,n ;

(14)

U razmatranju su poznate vrednosti fij svakog razmatranog kriterijuma fj za svaku od moguih alternativa Ai:

f ij = f j ( Ai ) ; ( i, j ) ; i = 1,2,...,m ; j = 1,2,...,n ;

(14)

The problem is solved by MODIPROM method [6] which is based on improving the group of methods for multicriteria ranging named PROMETHEE. The values of criterion functions and alternatives of transportation are shown in table2. Table 2. Values of criterion functions Tebela 2. Vrednosti kriterijumskih funkcija

Criterion type K1 K2 K3 K4 K5 Discontinuous transportation A1 264 0.8 26.3 41400 0.46

Reavanje razmatranog problema izvedeno je metodom MODIPROM [6] koja je zasnovana na poboljanju grupe metoda za viekriterijumsko rangiranje poznatih pod nazivom PROMETHEE. Vrednosti kriterijumskih funkcija i alternative transporta prikazane su u tabeli 2.

Continuous transportation A2 A3 0.14 0.27 0.14 0.31 16 15.5 27000 21600 0.41 0.51

Optimization criterion min min min max min

Priority level 1.3 1.2 1 1 1

Criteria for analysis are: K1 Average number of units to be supplied K2 Level of free areas being busy K3 Energy expenditure K4 Realized capacity of transportation K5 Flow intensity Alternatives are: A1 Transportation by pallet trucks type E30 A2 Pneumatic transportation A3 Transportation by elevator and conveyer The results of analysis done by the program package MODIPROM are shown in figure 4. Based on the analysis carried out, it is chosen the pneumatic transportation between the machines except for the transportation from the grinder to the packing machines where we chose the third alternative. Diagram of regulating the transportation process is shown in figure 5.

Kriterijumi za analizu su: K1 Prosean broj jedinica u redu ekanja K2 Stepen zauzetosti slobodnih povrina K3 potronja energije K4 Ostvareni kapacitet transporta K5 Intenzitetprotoka Alternative su: A1 transport viljukarima E30 A2 Pneumatski transport A3 transport elevatorom i transporterom Rezultati analize programskim MODIPROM prikazani su na slici 4. paketom

Na osnovu izvrene analize izabran je pneumatski transport izmeu maina izuzev transporta od mlina do maina za pakovanje gde je izabrana trea alternativa. Blok dijagram upravljanja procesom transporta prikazan je na slici 5.

93

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

0.350 0.300 A2 A2 A2

0.200

1 2 3

Podaci za analysis analizu Values for Ai Aim Cilj A1 0.00000 A2 1.00000 A3 0.38889

0.100

0.000

A3 A3 A3

-0.100

-0.200 A1 A1 -0.300 -0.350 A1

Figure 4 Values of criterion functions for defined alternatives slika 4 Vrednosti kriterijumskih funkcija za zadate alternative

Up PT-Pneumatic transportation turned on Ip PT- Pneumatic transportation turned off Up T-Conveyer turned on Ip T-Conveyer turned off PPK-Receiving container of roasting plant PSK- Receiving container for green coffee Packing

Up PT Up PT PSK ........ ........ Ip PT

Warehouse

Interwarehouse

Choice of warehouse

Roasted coffee stock

Up PT

Adequate type

? Yes Ip T ........ No Yes Up T

Blendin

PPK Yes Up PT Yes Ip PT Up PT Ip PT

Blending done

No Mixer

Grinde r Blending done

Up PT Yes Ip PT No Yes No

.....

There is stock

Roasting done

No

Adequate type

Figure 5 Diagram of regulating the transportation process slika 5 Blok dijagram upravljanja procesom transporta 4 CONCLUSION The given analysis provides optimal solution for internal transportation based on a number of criteria. Presented method does not depend on the number of analysis criteria nor on the number of alternatives. The optimal solution reached in this paper has many advantages over other solutions so it is necessary to do the analysis before final layout of equipment and installations. 4 ZAKLJUAK

Temporary warehouse for d ff

Sprovedenom analizom dolazi sei do optimalnog reenja procesa unutranjeg transporta prema veem broju kriterijuma. Izloeni postupak ne zavisi od broja kriterijuma za analizu kao ni od broja alternativa. Dobijeno optimalno reenje ima niz prednosti u odnosu na druga reenja pa je neophodno analizu sprovesti pre konanog rasporeda opreme i instalacija.

94

M. Gai, M. Savkovi, CHOICE OF OPTIMAL SYSTEM FOR TRANSPORTATION

T&L - 11/06

REFERENCES / LITERATURA [1] Zrni, .: Projektovanje fabrika. Mainski fakultet Beograd, Beograd, 1993. [2] Zrni, ., Savi, D: Simulacija procesa unutranjeg transporta. Mainski fakultet Beograd, Beograd, 1987. [3] Gai, M.: Transportni ureaji-neprekidni transport. Mainski fakultet Kraljevo, Kraljevo, 1997. [4] Jefti, V. :Transportne maine za nasipne i komadne terete sa neprekidnim nainom rada. Mainski fakultet Ni, Ni, 2001. [5] Gai, M., Savkovi, M.: Mainsko-tehnoloki projekat postrojenja za preradu kafe. Mainski fakultet Kraljevo, Kraljevo, 2005. [6] Kolarevi, M.: Brzi razvoj proizvoda. Zadubina Andrejevi, Beograd, 2004.

Reviewal/Recenzija: prof. dr Dragoslav Kuzmanovi

95

Vous aimerez peut-être aussi

- Event Management (MAX FIT)Document12 pagesEvent Management (MAX FIT)vkrish6Pas encore d'évaluation

- Oupa Nhambe - Control Project Part 2Document19 pagesOupa Nhambe - Control Project Part 2Oupa100% (4)

- Chap5 Open SystemDocument19 pagesChap5 Open SystemRoberto Pu100% (4)

- Facility Management SystemDocument6 pagesFacility Management Systemshah007zaad100% (1)

- An Adaptive Fuzzy Pid Control of Hydro-Turbine Governor: Xiao-Ying Zhang, Ming-Guang ZhangDocument5 pagesAn Adaptive Fuzzy Pid Control of Hydro-Turbine Governor: Xiao-Ying Zhang, Ming-Guang ZhangPadmo PadmundonoPas encore d'évaluation

- Politehnički Fakultet U Zenici Katedra Za Industrijski Inženjering I CIM Tehnologije Predmet: Upravljanje ProizvodnjomDocument5 pagesPolitehnički Fakultet U Zenici Katedra Za Industrijski Inženjering I CIM Tehnologije Predmet: Upravljanje ProizvodnjomLori BradyPas encore d'évaluation

- A Comparison Between MPC and Pi Controllers Acting On A Refrigerated Gas PlantDocument7 pagesA Comparison Between MPC and Pi Controllers Acting On A Refrigerated Gas PlantAlberto Fonseca UribePas encore d'évaluation

- PDC Lab 8Document9 pagesPDC Lab 8Mustafa BarwaniwalaPas encore d'évaluation

- A PID Automatic Tuning Method For Distributed-Lag Processes (2009)Document7 pagesA PID Automatic Tuning Method For Distributed-Lag Processes (2009)René PereiraPas encore d'évaluation

- An Efficient Adaptive Fir Filter Based On Distributed ArithmeticDocument6 pagesAn Efficient Adaptive Fir Filter Based On Distributed ArithmeticinventionjournalsPas encore d'évaluation

- Reviews 1 - AnswerDocument13 pagesReviews 1 - AnswerQuỳnh NguyễnPas encore d'évaluation

- Modeling, Simulation and Control of High Speed Nonlinear Hydraulic ServoDocument13 pagesModeling, Simulation and Control of High Speed Nonlinear Hydraulic ServoJoseph JosePas encore d'évaluation

- MPC of Four Tank SystemDocument7 pagesMPC of Four Tank Systemmail2saravanancPas encore d'évaluation

- Homework #2: Universidad Popular Del CesarDocument3 pagesHomework #2: Universidad Popular Del Cesarstalin roblesPas encore d'évaluation

- Lec12 MM1k Queueing System2Document24 pagesLec12 MM1k Queueing System2Rashi SinhaPas encore d'évaluation

- Laboratory Experimental Testing of InertersDocument6 pagesLaboratory Experimental Testing of Inertersนิติพล ไชยวงศ์Pas encore d'évaluation

- (Ebook) Multivariable Control, An Introduction PDFDocument14 pages(Ebook) Multivariable Control, An Introduction PDFCaterine Feria RamirezPas encore d'évaluation

- PCT 301T ModelingDocument21 pagesPCT 301T ModelingPortia ShilengePas encore d'évaluation

- Algorithms For Energy Efficient Reconstruction of A Process With A Multihop Wireless Sensor NetworkDocument4 pagesAlgorithms For Energy Efficient Reconstruction of A Process With A Multihop Wireless Sensor NetworkCecilia Camarena QuispePas encore d'évaluation

- Robust Linear ParameterDocument6 pagesRobust Linear ParametervinaycltPas encore d'évaluation

- Systems Methodology and Design IIDocument22 pagesSystems Methodology and Design IIYorghos MenikidisPas encore d'évaluation

- Models - Mph.pid ControlDocument14 pagesModels - Mph.pid ControlArunkumar SeshadriPas encore d'évaluation

- Tdoa Based Ugv Localization Using Adaptive Kalman Filter AlgorithmDocument10 pagesTdoa Based Ugv Localization Using Adaptive Kalman Filter AlgorithmAndra HuangPas encore d'évaluation

- QueueingDocument50 pagesQueueingJagan RajendiranPas encore d'évaluation

- Reviews 1: International UniversityDocument11 pagesReviews 1: International UniversityQuỳnh NguyễnPas encore d'évaluation

- Journal Pre-Proofs: International Journal of Electronics and Commu-NicationsDocument27 pagesJournal Pre-Proofs: International Journal of Electronics and Commu-NicationspetruskaraPas encore d'évaluation

- Modeling of The Modified Quadruple-Tank Process: A. Numsomran, V. Tipsuwanporn, K. TirasesthDocument6 pagesModeling of The Modified Quadruple-Tank Process: A. Numsomran, V. Tipsuwanporn, K. Tirasesthanon_369320474Pas encore d'évaluation

- Distillation ColumnDocument4 pagesDistillation ColumnjanurangPas encore d'évaluation

- Speed Control of A DC Motor Using BP Neural Networks: Zilong Liu Xianyi Zhuang Shuyi WangDocument4 pagesSpeed Control of A DC Motor Using BP Neural Networks: Zilong Liu Xianyi Zhuang Shuyi WangAnonymous hJbJ6TGGLPas encore d'évaluation

- Basic Integrated Modelling: A Case Study: Mario E. Salgado and Diego R. OyarzúnDocument15 pagesBasic Integrated Modelling: A Case Study: Mario E. Salgado and Diego R. Oyarzúnñ=?!2Pas encore d'évaluation

- International Journal o F Mineral Processing,: NodesDocument18 pagesInternational Journal o F Mineral Processing,: Nodessebas panezPas encore d'évaluation

- Circulating Load Calculation in Grinding Circuits PDFDocument6 pagesCirculating Load Calculation in Grinding Circuits PDFMickShazanPas encore d'évaluation

- Stochastic Processes: Andrei SleptchenkoDocument27 pagesStochastic Processes: Andrei SleptchenkoSyeda Ushna RahimPas encore d'évaluation

- DP 8955Document97 pagesDP 8955Krishna KishorePas encore d'évaluation

- 2.004 Dynamics and Control Ii: Mit OpencoursewareDocument7 pages2.004 Dynamics and Control Ii: Mit OpencoursewareVishay RainaPas encore d'évaluation

- DC Motor Speed Control For Electric Locomotive Equipped by Multi-Level DC-DC ConverterDocument7 pagesDC Motor Speed Control For Electric Locomotive Equipped by Multi-Level DC-DC Convertervinay kumarPas encore d'évaluation

- Performance of Multi-Step-Ahead-Prediction ARX For Steam Temperature in A Self-Refilling Distillation Essential Oil Extraction SystemDocument4 pagesPerformance of Multi-Step-Ahead-Prediction ARX For Steam Temperature in A Self-Refilling Distillation Essential Oil Extraction SystemHicham FouraijiPas encore d'évaluation

- XX Paper 24Document9 pagesXX Paper 24VindhyaPas encore d'évaluation

- Experiment - 4: Level Control in A Cylindrical Tank ProcessDocument2 pagesExperiment - 4: Level Control in A Cylindrical Tank ProcessanirudhPas encore d'évaluation

- Journal of Computer Engineering & Technology (JCET) : ©iaemeDocument10 pagesJournal of Computer Engineering & Technology (JCET) : ©iaemeIAEME PublicationPas encore d'évaluation

- Teoria Controlador PIDDocument5 pagesTeoria Controlador PIDEmanuel MorochoPas encore d'évaluation

- Real-Time Model Predictive Control of A Laboratory Liquid Tanks SystemDocument7 pagesReal-Time Model Predictive Control of A Laboratory Liquid Tanks SystemVaghela ChintanPas encore d'évaluation

- Auto-Tuning of Pid Controllers For Mimo Processes by Relay FeedbackDocument6 pagesAuto-Tuning of Pid Controllers For Mimo Processes by Relay FeedbackGabriela PaesPas encore d'évaluation

- Study of The Economic Dispatch Problem On IEEE 30-Bus System Using Whale Optimization AlgorithmDocument8 pagesStudy of The Economic Dispatch Problem On IEEE 30-Bus System Using Whale Optimization Algorithmbalasim HusseinPas encore d'évaluation

- Experiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETDocument18 pagesExperiment 06: Study of Process Control-I: Mesbah Ahmad Lecturer Department of Chemical Engineering, BUETMd Abid AfridiPas encore d'évaluation

- Fujimoto - 2007Document6 pagesFujimoto - 2007Ariana Ribeiro LameirinhasPas encore d'évaluation

- Littles LawDocument22 pagesLittles LawupamaharikrishnanPas encore d'évaluation

- Coupled TankDocument5 pagesCoupled TankDevraj MandalPas encore d'évaluation

- Channel Equal Is at IonDocument18 pagesChannel Equal Is at Ionritu_ranjan15Pas encore d'évaluation

- Citation Linear Parameter-Varying System Identification of An Industrial Ball Screw SetupDocument7 pagesCitation Linear Parameter-Varying System Identification of An Industrial Ball Screw SetupJessica JaraPas encore d'évaluation

- Stochastic State Estimation of A Multivariable Process Using Unscented Kalman FiltersDocument10 pagesStochastic State Estimation of A Multivariable Process Using Unscented Kalman FiltersAraouf GaaloulPas encore d'évaluation

- Lab Manual - TheoryDocument49 pagesLab Manual - TheoryLovely VinayPas encore d'évaluation

- TPE-Lec # 6Document34 pagesTPE-Lec # 6mamoona aliPas encore d'évaluation

- 656 OrtegaDocument6 pages656 OrtegaAnonymous WkbmWCa8MPas encore d'évaluation

- Learning Control and Neuro - Fuzzy Learning Control To Increase The Frequency of Fatigue TestsDocument16 pagesLearning Control and Neuro - Fuzzy Learning Control To Increase The Frequency of Fatigue TestsGerardo Castillo AlvaPas encore d'évaluation

- 2nd SessionalDocument6 pages2nd SessionalPraveen JangidPas encore d'évaluation

- Poles Selection TheoryDocument6 pagesPoles Selection TheoryRao ZubairPas encore d'évaluation

- Coupled Tank (Task)Document17 pagesCoupled Tank (Task)Anaya KhanPas encore d'évaluation

- A Unified Approach For Generalized Minimum Variance Controller For Linear Time-Varying SystemsDocument10 pagesA Unified Approach For Generalized Minimum Variance Controller For Linear Time-Varying SystemsTJPRC PublicationsPas encore d'évaluation

- Chapter 5 - Energy Analysis For Open Systems Compatibility ModeDocument35 pagesChapter 5 - Energy Analysis For Open Systems Compatibility ModekhameesmarwanPas encore d'évaluation

- Lab Sheet2Document3 pagesLab Sheet2Amrit SapkotaPas encore d'évaluation

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlD'EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlÉvaluation : 5 sur 5 étoiles5/5 (1)

- Motor-Vehicle Performance On Ascending GradesDocument9 pagesMotor-Vehicle Performance On Ascending Gradesramadan1978Pas encore d'évaluation

- TRB The Climbing Lane Design 104-001Document11 pagesTRB The Climbing Lane Design 104-001ramadan1978Pas encore d'évaluation

- Theory and Practice of Ecolocilac in Transport Sector PDFDocument18 pagesTheory and Practice of Ecolocilac in Transport Sector PDFramadan1978Pas encore d'évaluation

- MNUl For Diverge Traffic According by HBS ISEHP - 2016 - Submission - 49Document13 pagesMNUl For Diverge Traffic According by HBS ISEHP - 2016 - Submission - 49ramadan1978Pas encore d'évaluation

- The Use of Energy Methods at The Calculation of Vehicle Impact Velocity 27 PagesDocument27 pagesThe Use of Energy Methods at The Calculation of Vehicle Impact Velocity 27 Pagesramadan1978Pas encore d'évaluation

- The Usage of A Laser Height Sensors For Estimating Road Unevenness Profile PDFDocument12 pagesThe Usage of A Laser Height Sensors For Estimating Road Unevenness Profile PDFramadan1978Pas encore d'évaluation

- Driver's Reaction Time in A Complex Road Situation (Braking With Driving Around An Obstacle)Document14 pagesDriver's Reaction Time in A Complex Road Situation (Braking With Driving Around An Obstacle)ramadan1978Pas encore d'évaluation

- Draft of Freight Transport Car Park FacilityDocument7 pagesDraft of Freight Transport Car Park Facilityramadan1978Pas encore d'évaluation

- Countdown Timers at Intersections With Traffic Lights - Evaluation of The Regulation Journal of Laws of 31.5.2017 Item 1062Document12 pagesCountdown Timers at Intersections With Traffic Lights - Evaluation of The Regulation Journal of Laws of 31.5.2017 Item 1062ramadan1978Pas encore d'évaluation

- Introduction and Application of Tire Pressure Monitoring System 025-O14-038 PDFDocument8 pagesIntroduction and Application of Tire Pressure Monitoring System 025-O14-038 PDFramadan1978Pas encore d'évaluation

- Bank Soal LettersDocument17 pagesBank Soal Lettersderoo_wahidahPas encore d'évaluation

- BSBMGT516 Facilitate Continuous Improvement: Summative Assessment 1Document4 pagesBSBMGT516 Facilitate Continuous Improvement: Summative Assessment 1Mmc MixPas encore d'évaluation

- A Study On Mental Health and Quality of Work Life Among Teachers Working in Corporate SchoolsDocument6 pagesA Study On Mental Health and Quality of Work Life Among Teachers Working in Corporate SchoolsKannamma ValliPas encore d'évaluation

- Plasticizers For CPE ElastomersDocument8 pagesPlasticizers For CPE Elastomersbatur42Pas encore d'évaluation

- Application For MigrationDocument8 pagesApplication For Migrationmoments444Pas encore d'évaluation

- Sworn Statement of Assets, Liabilities and Net WorthDocument2 pagesSworn Statement of Assets, Liabilities and Net WorthFaidah Palawan AlawiPas encore d'évaluation

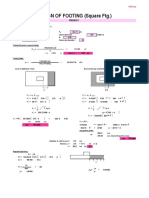

- Design of Footing (Square FTG.) : M Say, L 3.75Document2 pagesDesign of Footing (Square FTG.) : M Say, L 3.75victoriaPas encore d'évaluation

- 09 20 17Document26 pages09 20 17WoodsPas encore d'évaluation

- Business en Pre Above S+T ReadingDocument3 pagesBusiness en Pre Above S+T Readingsvetlana939Pas encore d'évaluation

- 20779A ENU CompanionDocument86 pages20779A ENU Companionmiamikk204Pas encore d'évaluation

- Affidavit To Use The Surname of The FatherDocument2 pagesAffidavit To Use The Surname of The FatherGlenn Lapitan Carpena100% (1)

- High-Rise Climb V0.6a Smokeydots PDFDocument10 pagesHigh-Rise Climb V0.6a Smokeydots PDFHer Lan OPas encore d'évaluation

- Bit2203 Advanced Object-Oriented Programming Lectures Sep 2021Document250 pagesBit2203 Advanced Object-Oriented Programming Lectures Sep 2021Agnes MathekaPas encore d'évaluation

- Types of Foundation and Their Uses in Building ConstructionDocument4 pagesTypes of Foundation and Their Uses in Building ConstructionCraig MPas encore d'évaluation

- Assignment Mid Nescafe 111173001Document5 pagesAssignment Mid Nescafe 111173001afnan huqPas encore d'évaluation

- Framework For Durable ConcreteDocument8 pagesFramework For Durable ConcreteDai ThanhPas encore d'évaluation

- Lab - Report: Experiment NoDocument6 pagesLab - Report: Experiment NoRedwan AhmedPas encore d'évaluation

- Diagrama Electronico EGED 285Document2 pagesDiagrama Electronico EGED 285Carlos Juarez Chunga100% (1)

- ISA 265 Standalone 2009 HandbookDocument16 pagesISA 265 Standalone 2009 HandbookAbraham ChinPas encore d'évaluation

- ADocument2 pagesAẄâQâŗÂlïPas encore d'évaluation

- Method Statement Footing - PDF - Concrete - Deep FoundationDocument12 pagesMethod Statement Footing - PDF - Concrete - Deep FoundationJYDP RPas encore d'évaluation

- Taiwan Petroleum Facilities (1945)Document85 pagesTaiwan Petroleum Facilities (1945)CAP History LibraryPas encore d'évaluation

- Material Safety Data Sheet: Pilot IIDocument7 pagesMaterial Safety Data Sheet: Pilot IIBeyar. ShPas encore d'évaluation

- Ex-Capt. Harish Uppal Vs Union of India & Anr On 17 December, 2002Document20 pagesEx-Capt. Harish Uppal Vs Union of India & Anr On 17 December, 2002vivek6593Pas encore d'évaluation

- MEC 400 CHAPTER 4 (Engineering Solution)Document21 pagesMEC 400 CHAPTER 4 (Engineering Solution)hidayatullahPas encore d'évaluation

- BS351: Financial Reporting: Learning ObjectivesDocument3 pagesBS351: Financial Reporting: Learning ObjectivesMajeed Ullah KhanPas encore d'évaluation

- Marc-André Ter Stegen PES 2021 StatsDocument1 pageMarc-André Ter Stegen PES 2021 StatsSom VasnaPas encore d'évaluation

- Summer Training Report On: Prepared and Presented ToDocument95 pagesSummer Training Report On: Prepared and Presented ToShubh SinghalPas encore d'évaluation