Académique Documents

Professionnel Documents

Culture Documents

Lecture 17: Design and Static Strength of Welded Joints

Transféré par

sprashant5Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lecture 17: Design and Static Strength of Welded Joints

Transféré par

sprashant5Droits d'auteur :

Formats disponibles

Lecture 17

Design

Static Strength

of

Welded Joints

p1

(

'817

Lecture S;cope

Static strength of welded joints

- need for strength design

- types of loads carried by welds

- effective weld area

- stresses acti 19 on weld area

- allowable str'3sses on welds

- design of weld groups

p2

(

Lecture 17

Need 'for Strength Design

and rigidity are not critical in some

welded parts

- e.g. machine guards, furniture

-In such cases only casual attention is paid to weld

strength

Many other welded structures must meet

requimments for strength and/or rigidity

- ships, pressure vessels

- Metheds are required for ensuring that welded joints

between members possess adequate strength

p3

(

(

e17

Weld Joint Strength

Strength d3sign implies knowledge of -

-loads

- load carryin ~ area

- material properties

- failure criteria

p4

(

Types of Loads Carried by Welds

-

Lecture 17

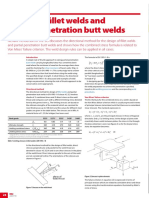

Full penetration groove

welds in tension

Compression nonnal

to axis of weld

Tension or

compression parallel

to weld axis

p ~

"e 17 p6

Lecture 17

Weld Design

Full PElnetration Groove Welds

- Usuall:( treated as a continuous part of the structureand

not analyzed

- Welds assumed to match parent strength

- Some codes reduce the allowable stress in welds not

subject to NDE by applying a "Joint Efficiency Factor"

Partial Penetration Groove, and Fillet Welds

- Since ':he effective area differs from the area of the base

metal, methods are needed to ensure the welds have

adequate strength to carry the imposed loads

p7

(

Effective Weld Area

Full Penetration Groove Welds .r:

- the effective area is the thickness of the thinner L

part joined

Partial PenetlCltion Groove Welds

- the effective area is nonnally the depth of the

chamfer multiplied by the weld length (may be

reduced for narrowweld preparations)

(

'817

Fillet Welds

- The effective area is nonnally taken as the

theoretical throat multiplied by the weld length

-for equal leg fillets T =O.707*fillet size

Actual ......

throat

a

'\} Theoretical

1-----_-1 Throat. T

p8

Lecture 17

Stresues on Weld Area

The force t"ansmitted by a unit area of weld may be

decomposnd into shear and normal stress components (fillet

weld shown)

P = Force vector

0.L = Stress normal to

weld throat

't' = shear stress acting

~ perpc:ndicular to

weld axis

'tI = shear stress

parallel to weld axis

weld throat area

p9

(

:e 17

Design Stresses on welds

IIW/ISO criterion for fillet weld stresses

- The IntemaHonallnstitute of Welding has published the

following cri':erion (see IIW doc XV-358-74 & Welding in

the World alticle Vol 2 No 21964.)

- adopted by ISO as recommendation R617

a :? R ro 2 3(" 2 ?l

a fJy-.1.+ .1.+,1

a

= allovrable stress in the base material

a

= 0.7 fJr structural steels up to 500 MPa UTS and 0.85 for

high-strength steels with UTS <= 600 MPa

p10

(

Lecture 17

Design Stresses on Welds

---;;.----------------

PrerE!quisites for IIWapproach:

- Stru<:tural steels UTS <= 600 MPa and minimum

elonnation 12%

- Proper design

- Adequate weld quality

P 11.

(

Design Stresses on Welds

AWS 01.1 standard approach for fillet/partial

penetration welds in steel structures

- Defines allowable values for each stress component

based (primarily) on weld metal tensile strength

- CSA W59 Ulies a similar approach but differs in detail

- Always consult the applicable standard

L- ----'

(

"e 17 p12

Design Stresses on Welds

AWS 01.1

Full Penetration Welds

Lecture 17

Te

no

ell

Te

pa

St

Stress in Weld Allowable Stress

nsion or compression Same as base metal

nnal and parallel to

ective area

nsion or compression Same as base metal

rallel to axis of weld

ear on the effective area 0.3 of nominal UTS of weld

metal, but not more than 0.4"

yield strength of base metal

p13

(,

Design Stresses on Welds

AWS 01.1

Partial Groove Welds

(

(

Stress

Compression nc

area Goints not d

Tension or comp

weld axis

Shear parallel to

Tension normal t<

in Weld Allowable Stress

rmal to effective 0.5 times nominal tensile strength

3signed to bear) of weld metal but not more than 0.6

times yield strength of base metal

"ession parallel to Same as base metal.

Need not be considered in design of

welds joining components of

built-up members

axis of weld 0.3 nominal tensile strength of

weld metal but not more than 0.4

yield strength of base metal

I effective area 0.3 nominal tensile strength of

weld metal but not more than 0.4

yield strength of base metal

P 14

Lecture 17

Desk:!'/1 Stresses on

....

AWS D1.1

Fillet \iVelds

-

Stress in Weld Allowable Stress

Comprf ssion normal to effective 0.5 limes nominal tensile strength

area (joints not designed to bear) of weld metal but not more than 0.6

times yield strength of base metal

Tensior or compression parallel to Same as base metal.

weld

Need not be considered in design of

welds joining components of

built-up members.

Shear parallel to axis of weld 0.3 nominal tensile strength of

weld metal but not more than 0.4

I yield strength of base metal

Tension normal to effective area 0.3 nominal tensile strength of

weld metal but not more than 0.4

i vield strenllth of base metal

p15

(,

e17

Example

,

Determine the required length Lof the fillet welds

L SMAW

~ P = 5 0 k N

Base meta ASTM A36 carbon steel

YS = 250 '1Pa (30 ksi) UTS = 410 MPa (60 ksi)

6018 SMA'I\! electrodes

-- -- ~ ~ - - - - - - ~

p16

(

Lecture 17

AWS Approach:

Weld effective area = 2*6*0.707*L = 8.5L

From statics, the applied stress = PIA = 50000/8.5L MPa

Stress is :;hear parallel to weld axis

AWS 01. 1allowable stress is minimum of:

0.3*",eld metal UTS = 0.3 * 410 = 123 MPa

0.4* base metal yield strength = 0.4* 250 = 100 MPa

Therefore PIA <= 100 MPa

i.e. 50000/8.5L <= 100 MPa

L >= 58.8 mm

Specify 60mm long fillets.

p17

(

Examp!le

____________ __ o., _

IIWApproach:

U

a

Weld effective ares = 2*6*0.707*L = 8.5L

Applied stress PIA = 50000/8.5L MPa = 't"1

Assume the allowa31e stress in the base material U is the

lesser of a

0.33 * ultimat'3 strength = 0.3*410 = 123 MPa

0.67* yield sllength = 0.67*250 = 167 MPa

Then,

123 >= o.7*V3*(50JOO/8.5L)A2

L >= 57.98 mm ( a with AWS)

p18

(

Lecture 17

In the previous example, the force carried by

the welds were determined by applying the

principles of static equilibrium

The forces carried by welds in more

compl icated connections cannot be so easily

determined

Various methods have been proposed to

determine the capacity of the weld group

- Mostl', empirical rules

- Either elastic or plastic analyses

----- ------- --------- ---

p1

{

(

:e 17

F"Uet W e ~ d Stress Distdbution

Design method8 usually assume uniform stress in welds and

ignore stress concentrations at ends and residual stress

OK if welds have sufficient deformation capacity

Stress in weld .....Stress concentrations

~ _ / at ends relieved by

Yield stress ~ - yielding

Distance along weld

::. p

p 20

(

Lecture 17

When welds W1 or W3 exist, the load carried

by each weld is not readily calculated _

- depends on loading and stiffness of parts joined

~ ~

12

S

~ ~

~ ~

~ .

t

':::;'

'::::::

~

I::::::

~

L1 W2 I ~ W 3

P

I

I ~

~

,::::::

- I ~

~

,

~

~ ~

p21

(

VVe'd

Qualitative behaviour

- L2 L1, W3 not present: the load is carried by W2

- L2<L1, W3 not present, the load is carried mostly by W1

- When W3 is present it takes most of the load

- The case of L2<1.5*L1 with W3 present is considered

useless

(

(

l _

e 17 p22

Lecture 17

A simple method for design of planar

connections subject to shear forces and

bending moments is to consider the welds as a

pattern of lines

Known as the "polar moment method"

- Welding in World artide, P 180, Welding Handbook

P 23

( I

(

e17

Weld Grouqos

Derivation

Assuming:

The welds are of equal size S

The force per unit length F at any point in the weld group is proportional to the

distance from the centroid C, i.e. F = kr.

F acts normal to the line joining the centroid

residual stresses are negligible

P 24

(

If dL is any elemental length of weld,

M= frdL

oJ

Since F = kr.

=kJ

w

Where Jw is the linear polar moment of inertia of the weld group about

the axis through C and normal to the plane.

Hence:

F

Mr

=

J

w

The weld throat T required to satisfy allowable stress limits can be found using:

Lecture 17

F

=

p25

(

e17

Weld Groups

Similar results apply for bending moments

parallel to the plane of the weld group. -

Shear forces are assumed uniformly distributed

P 26

(

Lecture 17

ProcHdure for polar moment method using

tabulated formulas

1. Fintl the position on the welded connection where the

combined forces are maximum

usuEllly the position furthest from the centroid of the connection

morE! than one load combination or position may need to be considered

sheElr forces are assumed uniformly distributed

2. Final the force per unit length resulting from each

loading at this position using the tabulated fonnulas

3. Add the forces vectorially

4. Determine the required throat size by dividing the total

unit force by the allowable weld stress

p27

(

ExarrtuJle 2

,

(

I p= 80 kN -

r - - - l " ~ ~ - - - - ' - i . +(18000Ib)

T

F 250

-. . -

(10")

!C

I

t

I

----+_250 __

(10")

,17 P 28

Lecture 17

Example 2

Step 1:. Identify the most highly stressed location

- The point of maximum combined unit force is at the top right

hand comer

Step 2: Determine unit forces at this point

- The distance from the centroid to the point of combined

stress, and the polar moment of inertia are given by the

table (handout) as:

c _ b (b +d) _ 95 mm

yr - 2b+d -

J = b_

3

+ (b +2d) + d

2

(6b+d) = 6.3x]06 mm 3

w 3 2b+d 12

p29

(

e17

Example .2

Step 2 (cont'd)

- The horizontal and vertical components of the twisting

moment are given by:

fh = Td/2 = 410 N/mm

J

w

Iv = TC

yr

= 306 N/mm

J

w

- The vertical shear force is

js = P/Lw = 158 N/mm

P 30

(

Lecture 17

Step 3: Determine the resultant force

r; :::: Vf/+(j:'+fsl :::: 620 N/m

Step 4: Determine the required weld size

Allowable weld stress for 6018 electrodes = 0.3*410 = 124 MPa

Required throat T = 620/124 mm= 5 mm

Assuming equal leg fillets, weld size =T/O.707 = 7mm

An 8 mm fillet weld should be specified on the weld symbol

p 31

(

ASME Boiler & Pressure Vessel

Code

Categories of weld joint in Class 3 nuclear vessels

(

f

e17

c

SEE NC-33!i12

P 32

Categories of Butt Joints

~ - ~ - ~ ~ ~

0rIIt-Y.... Jel...

Lecture 17

C.Wf<lo"I D BIIII J.. ilTt

P33

(

ASME.B&PV Code

Examples of permissible nozzle connections for

Class 3 nuclear vessels

(

e17

(a)

(e-I)

(e-1)

P 34

longltudln8l Box

Support Rods for

lower Skywalk

_ Support Rods to CeiUng

I Washer and Nut on Bottom

Upper Skywalk

f

~

f R o ~ Force Put Weld Root

In Tension

Lecture 17 p35

(

~ N e l d Structural Failures

Failures of w E ~ l d e d structures result in financial

loss, damage to the environment, and injury.or

loss of life

- Hyatt Regency hotel walkway collapse

- Ramsgate ferry ramp collapse

Codes and standards define rules for welded joint

design for various types of critical structure, e.g.

buildings, bridges, pressure vessels based on

tests, analysis and experience

Use of the applicable codes is advisable and may

be legally required.

P 36

(

Vous aimerez peut-être aussi

- Chapter 3B. Welded Connections: CE4: Design of Steel Structures - Prof. Dr. A. VarmaDocument14 pagesChapter 3B. Welded Connections: CE4: Design of Steel Structures - Prof. Dr. A. VarmaGPas encore d'évaluation

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceD'EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferencePas encore d'évaluation

- 2.1.6 NG1005 Welding and TestingDocument154 pages2.1.6 NG1005 Welding and TestingjovicatrpcevicPas encore d'évaluation

- ASME-Notch-Toughness & Supplementary Essential VariablesDocument16 pagesASME-Notch-Toughness & Supplementary Essential VariablesSuleyman Halicioglu100% (2)

- AWS Resources For Engineers: Monitoring and Control of Welding and JoiningDocument36 pagesAWS Resources For Engineers: Monitoring and Control of Welding and JoiningLázaro Magaña MartínezPas encore d'évaluation

- DNV OS-H102 Marine Operations Design and Fabrication 2012-01Document12 pagesDNV OS-H102 Marine Operations Design and Fabrication 2012-01Marios DiasPas encore d'évaluation

- Effect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Document10 pagesEffect of Heat Input On Microstructure and Mechanical Properties of The TIG Welded Joints of AISI 304Kaushik SenguptaPas encore d'évaluation

- Projection Welding Guide for Materials & DesignDocument20 pagesProjection Welding Guide for Materials & DesignCebrac ItatibaPas encore d'évaluation

- Tack WeldDocument1 pageTack Weldbhatti19Pas encore d'évaluation

- NozzlePRO 14.1NewFeatures-2019ReleaseDocument13 pagesNozzlePRO 14.1NewFeatures-2019ReleasedelitesoftPas encore d'évaluation

- AD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8Document1 pageAD 399 - Design of Partial Penetration Butt Welds in Accordance With BS EN 1993-1-8symon ellimacPas encore d'évaluation

- 5 - Section 14 - Arc Welding ConsumablesDocument11 pages5 - Section 14 - Arc Welding Consumablesrizkialia12Pas encore d'évaluation

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600Pas encore d'évaluation

- Weld Defects CswipDocument10 pagesWeld Defects CswipOLiver RobertPas encore d'évaluation

- Welded connection designDocument16 pagesWelded connection designAnkit SinghPas encore d'évaluation

- Welding Procedure Data Sheet for Steel Groups 1-3Document1 pageWelding Procedure Data Sheet for Steel Groups 1-3suronocaturatmojoPas encore d'évaluation

- Joining Processes: Permanent JointsDocument31 pagesJoining Processes: Permanent JointsgemnikkicPas encore d'évaluation

- Twi Hardness TestingDocument8 pagesTwi Hardness TestingchungndtPas encore d'évaluation

- Local Load Analysis - WRCB-107,297Document14 pagesLocal Load Analysis - WRCB-107,297Gaurav BedsePas encore d'évaluation

- Weld Imperfection Examination StandardDocument4 pagesWeld Imperfection Examination StandardMohd Akmal ShafiePas encore d'évaluation

- Mathcad - ASME I I VIII I Thickness Cylindrical ShellDocument3 pagesMathcad - ASME I I VIII I Thickness Cylindrical ShellkurcekPas encore d'évaluation

- Lunch & Learn: Structural Steel SelectionDocument17 pagesLunch & Learn: Structural Steel Selectionanuj SinghPas encore d'évaluation

- 6 - CE 511 - Base Plate Design PDFDocument33 pages6 - CE 511 - Base Plate Design PDFJayson RamosPas encore d'évaluation

- Welded Joint Design FundamentalsDocument16 pagesWelded Joint Design FundamentalsEngr Arfan Ali DhamrahoPas encore d'évaluation

- Forging Vs CastingDocument1 pageForging Vs CastingsdsadPas encore d'évaluation

- M. N. Dastur: 8S Company (P) LTD, KolkataDocument151 pagesM. N. Dastur: 8S Company (P) LTD, KolkataHari SankarPas encore d'évaluation

- The Use of Two Nuts To Prevent Self LooseningDocument4 pagesThe Use of Two Nuts To Prevent Self LooseningManojkumar ThilagamPas encore d'évaluation

- Residual Stresses in Weld JointsDocument8 pagesResidual Stresses in Weld Jointshayder1920Pas encore d'évaluation

- Chap8 RivetsDocument51 pagesChap8 RivetsManoj ManoharanPas encore d'évaluation

- Radiography TestDocument26 pagesRadiography TestHoangPas encore d'évaluation

- ASME B16.47 Series A FlangeDocument7 pagesASME B16.47 Series A FlangeManoah StephenPas encore d'évaluation

- Bolting and WeldingDocument73 pagesBolting and Weldinggerrydimayuga100% (2)

- Bolted Design Sandia ReducedDocument47 pagesBolted Design Sandia Reducedmiguelq_scribdPas encore d'évaluation

- Titanium FormingDocument5 pagesTitanium FormingSiavash IraniPas encore d'évaluation

- Torque Calculation For BoltDocument3 pagesTorque Calculation For BoltNaga Manikanta TatikondaPas encore d'évaluation

- Quality Level BDocument17 pagesQuality Level BUgonnaPas encore d'évaluation

- Demagnetization: BSS Non Destructive Testing PVT - LTDDocument18 pagesDemagnetization: BSS Non Destructive Testing PVT - LTDSANU100% (1)

- MDOT GussetPlate LFR Analysis 263315 7Document27 pagesMDOT GussetPlate LFR Analysis 263315 7ankitPas encore d'évaluation

- Vibration and Shock IsolationDocument3 pagesVibration and Shock IsolationSaravanan.KPas encore d'évaluation

- Introduction Fracture Mechanics 1Document15 pagesIntroduction Fracture Mechanics 1aap1Pas encore d'évaluation

- Failure Modes of Bolt and Nut Assemblies Under Tensile LoadingDocument11 pagesFailure Modes of Bolt and Nut Assemblies Under Tensile LoadingclevercogPas encore d'évaluation

- Steel WiseDocument1 pageSteel WisenvnagarajuPas encore d'évaluation

- Post Weld Toe Treatments Improve Fatigue Life FEA StudyDocument89 pagesPost Weld Toe Treatments Improve Fatigue Life FEA Studyvikrant GarudPas encore d'évaluation

- ASTM A262, CorrosietestenDocument2 pagesASTM A262, CorrosietestenSales HBS Solutions100% (1)

- Detecting and preventing lack of sidewall and inter-run fusion in weldsDocument4 pagesDetecting and preventing lack of sidewall and inter-run fusion in weldsguru_terexPas encore d'évaluation

- Oth 482Document145 pagesOth 482Hossein PapahnPas encore d'évaluation

- Measuring Fillet Weld Size It's Easy Right - Karsten Madsen - Pulse - LinkedInDocument5 pagesMeasuring Fillet Weld Size It's Easy Right - Karsten Madsen - Pulse - LinkedInnkvonPas encore d'évaluation

- High Cyclic Fatigue: A Review of Failure Analysis and Prediction MethodsDocument54 pagesHigh Cyclic Fatigue: A Review of Failure Analysis and Prediction Methodsmaurizio.desio4992Pas encore d'évaluation

- Introduction to Welding Processes and Their ApplicationsDocument4 pagesIntroduction to Welding Processes and Their ApplicationsSreejith MenonPas encore d'évaluation

- Fillet Weld and Partial Penetration Butt WeldDocument3 pagesFillet Weld and Partial Penetration Butt Weldsusan87Pas encore d'évaluation

- Fatigue Performance of Repair WeldsDocument197 pagesFatigue Performance of Repair WeldszhangjlPas encore d'évaluation

- Schaeffler Diagram PDFDocument16 pagesSchaeffler Diagram PDFrajesh_14Pas encore d'évaluation

- Hot Chamber Die Casting ProcessDocument1 pageHot Chamber Die Casting ProcessNordiana IdrisPas encore d'évaluation

- Cladding Using High Density Infrared Fusion Cladding Process PDFDocument5 pagesCladding Using High Density Infrared Fusion Cladding Process PDFangga fajarPas encore d'évaluation

- American Institute of Steel ConstructionDocument7 pagesAmerican Institute of Steel ConstructionsojeckPas encore d'évaluation

- MSN612215/MSN616218 Elemen Mesin I: Welding JointsDocument36 pagesMSN612215/MSN616218 Elemen Mesin I: Welding JointsDavid TaradePas encore d'évaluation

- Design of Structural MembersDocument153 pagesDesign of Structural Membersquiron20100% (1)

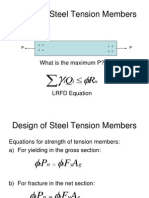

- 02 - Design of Steel Tension MembersDocument15 pages02 - Design of Steel Tension MembersMayur PatelPas encore d'évaluation

- Fatigue Failure of Welded JointsDocument40 pagesFatigue Failure of Welded JointsShahazad ShaikPas encore d'évaluation

- Flexibility Analysis of A Bare Pipe Line Used For Cryo ApplicationDocument12 pagesFlexibility Analysis of A Bare Pipe Line Used For Cryo ApplicationksvvijPas encore d'évaluation

- Air Cooled Heat ExchangerDocument2 pagesAir Cooled Heat Exchangersprashant5Pas encore d'évaluation

- Euro IV Tankages - CPCL Project Presentation: Kamal Nayak B Lakshman L R Shanmukha Sreenivas P Shiriram Prabhu SDocument29 pagesEuro IV Tankages - CPCL Project Presentation: Kamal Nayak B Lakshman L R Shanmukha Sreenivas P Shiriram Prabhu Ssprashant5Pas encore d'évaluation

- Thermal Stress Analysis of Process Piping System Installed On LNG Vessel Subject To Hull Design LoadsDocument16 pagesThermal Stress Analysis of Process Piping System Installed On LNG Vessel Subject To Hull Design LoadsprakashPas encore d'évaluation

- Seattle CNG Near MissDocument38 pagesSeattle CNG Near Misssprashant5Pas encore d'évaluation

- Earned Value Project ManagementDocument45 pagesEarned Value Project Managementsprashant5Pas encore d'évaluation

- Efficiency and Economy of Automating Displacements For FPSO Pipe Stress Analysis PDFDocument10 pagesEfficiency and Economy of Automating Displacements For FPSO Pipe Stress Analysis PDFjeganPas encore d'évaluation

- For Masela LNG PJ Piping Stress Analysis Review and SupportDocument23 pagesFor Masela LNG PJ Piping Stress Analysis Review and Supportsprashant5Pas encore d'évaluation

- Efficiency and Economy of Automating Displacements For FPSO Pipe Stress Analysis PDFDocument10 pagesEfficiency and Economy of Automating Displacements For FPSO Pipe Stress Analysis PDFjeganPas encore d'évaluation

- Earned Value Project ManagementDocument45 pagesEarned Value Project Managementsprashant5Pas encore d'évaluation

- Earned Value Project ManagementDocument45 pagesEarned Value Project Managementsprashant5Pas encore d'évaluation

- Natural Gas Storage TankDocument10 pagesNatural Gas Storage TankSurya Budi WidagdoPas encore d'évaluation

- Energies: Stress Analysis of LNG Storage Tank Outlet Pipes and FlangesDocument19 pagesEnergies: Stress Analysis of LNG Storage Tank Outlet Pipes and FlangesrodrigoperezsimonePas encore d'évaluation

- Efficiency and Economy of Automating Displacements For FPSO Pipe Stress Analysis PDFDocument10 pagesEfficiency and Economy of Automating Displacements For FPSO Pipe Stress Analysis PDFjeganPas encore d'évaluation

- Health Companion 12 - 2011an-02Document2 pagesHealth Companion 12 - 2011an-02sprashant5Pas encore d'évaluation

- Bentley AutoPIPE V8iDocument2 pagesBentley AutoPIPE V8iAleksandar Stefanovic100% (1)

- Methods For Design of Hoppers, Silo's, Bins & BunkersDocument10 pagesMethods For Design of Hoppers, Silo's, Bins & BunkersJaco KotzePas encore d'évaluation

- 919037Document64 pages919037imrock1234Pas encore d'évaluation

- Header Box Heat Exchanger ManufacturingDocument7 pagesHeader Box Heat Exchanger Manufacturingsprashant5Pas encore d'évaluation

- How Silos FailDocument14 pagesHow Silos FailMedhat Hasanain100% (2)

- Ped Guidelines enDocument250 pagesPed Guidelines enmithunjobsPas encore d'évaluation

- Heat Flow in Furnaces and Heat ExchangersDocument6 pagesHeat Flow in Furnaces and Heat Exchangerssprashant5Pas encore d'évaluation

- Methods For Design of Hoppers, Silo's, Bins & BunkersDocument10 pagesMethods For Design of Hoppers, Silo's, Bins & BunkersJaco KotzePas encore d'évaluation

- CNG Refueling Station Bid SpecificationsDocument12 pagesCNG Refueling Station Bid Specificationssprashant5Pas encore d'évaluation

- GALAMBOS Guide To Stability Design Criteria For Metal StructuresDocument468 pagesGALAMBOS Guide To Stability Design Criteria For Metal Structuressprashant578% (9)

- WRC 107Document2 pagesWRC 107sudhirm16Pas encore d'évaluation

- Pressure Vessel Design (CALD Series II Training Material)Document220 pagesPressure Vessel Design (CALD Series II Training Material)sprashant5Pas encore d'évaluation

- Stress Analysis Torispherical Shell With NozzleDocument6 pagesStress Analysis Torispherical Shell With NozzlepiolinwallsPas encore d'évaluation

- Pressure Vessel Design (CALD Series II Training Material)Document220 pagesPressure Vessel Design (CALD Series II Training Material)sprashant5Pas encore d'évaluation

- Mikavukasaragod Physics PDFDocument148 pagesMikavukasaragod Physics PDFRaj SinhaPas encore d'évaluation

- Statistical PhysicsDocument105 pagesStatistical PhysicsMahmuddin Nurul Fajri100% (2)

- The Physics of BilliardsDocument12 pagesThe Physics of Billiardssaeed sadeghi vahidPas encore d'évaluation

- Mechanics of Materials NotesDocument74 pagesMechanics of Materials Notesranjithkraj100% (2)

- CHE545 - Tutorial Gas AbsorptionDocument4 pagesCHE545 - Tutorial Gas AbsorptionZaiful AlifPas encore d'évaluation

- Seminar Report On: BeltsDocument14 pagesSeminar Report On: BeltsMayank RawatPas encore d'évaluation

- Heat Transfer Chapter One and TwoDocument74 pagesHeat Transfer Chapter One and TwoTariku Negash100% (2)

- Radius of CurvatureDocument15 pagesRadius of CurvatureLakshayPas encore d'évaluation

- Lesson 1 Big Bang TheoryDocument36 pagesLesson 1 Big Bang TheoryEthan LopezPas encore d'évaluation

- Calculate TDH and NPSH for pumpsDocument2 pagesCalculate TDH and NPSH for pumpsRajat MinochaPas encore d'évaluation

- HDI Direct Injection OperationDocument31 pagesHDI Direct Injection OperationdjautoPas encore d'évaluation

- Slab On GradeDocument56 pagesSlab On GradeTere Mota DondéPas encore d'évaluation

- Analize de Aciditate Si Isocianat La Fabricarea - The Plastics PDFDocument6 pagesAnalize de Aciditate Si Isocianat La Fabricarea - The Plastics PDFCorina StanculescuPas encore d'évaluation

- Electricity and Magnetism For Mathematicians GarrityDocument75 pagesElectricity and Magnetism For Mathematicians GarrityChristian Gonzalez43% (7)

- ChE 441 Problem Set 8Document5 pagesChE 441 Problem Set 8Ziyad Al Abasie50% (2)

- Real Gases Exercises Chapter 1 PropertiesDocument10 pagesReal Gases Exercises Chapter 1 PropertiesZakirPas encore d'évaluation

- SPE 63041 Design and Installation of Sand Separation and Handling SystemDocument10 pagesSPE 63041 Design and Installation of Sand Separation and Handling Systemalexalek2000Pas encore d'évaluation

- BS-200 Parameter Setting for UREA Test (40Document42 pagesBS-200 Parameter Setting for UREA Test (40Jose Rolando Orellana Rodriguez75% (4)

- Basic Electricity Final ExamDocument9 pagesBasic Electricity Final ExamrockerfxPas encore d'évaluation

- Rock Stress Measurement MethodsDocument50 pagesRock Stress Measurement MethodschouszeszePas encore d'évaluation

- NSO Class 11 Sample Paper 2019 20Document3 pagesNSO Class 11 Sample Paper 2019 20AYUSH ANANDPas encore d'évaluation

- EDC Formula Notes - PDF 65Document8 pagesEDC Formula Notes - PDF 65VenkatGollaPas encore d'évaluation

- PHY01Document66 pagesPHY01Jason DemdamPas encore d'évaluation

- PPTDocument12 pagesPPTChandan V ChanduPas encore d'évaluation

- Worksheet PhysicsDocument4 pagesWorksheet PhysicsKenneth BailadorPas encore d'évaluation

- Nuclear Physics: DAE SymposiumDocument579 pagesNuclear Physics: DAE SymposiumESPas encore d'évaluation

- CH 29Document13 pagesCH 29CristianPas encore d'évaluation

- Tutorial Sheet 1: Force Resolution, Resultant and EquilibriumDocument5 pagesTutorial Sheet 1: Force Resolution, Resultant and EquilibriumJahnavi JanuPas encore d'évaluation

- MORRIS JR., J. W. Overview of Dislocation Plasticity.Document36 pagesMORRIS JR., J. W. Overview of Dislocation Plasticity.Vitor Scarabeli BarbosaPas encore d'évaluation

- A Method To Model Wood by Using ABAQUS Finite Element SoftwareDocument58 pagesA Method To Model Wood by Using ABAQUS Finite Element SoftwareAnonymous 7MdZQn1Pas encore d'évaluation