Académique Documents

Professionnel Documents

Culture Documents

Elvax Hose Tube

Transféré par

Asima AtharCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Elvax Hose Tube

Transféré par

Asima AtharDroits d'auteur :

Formats disponibles

DuPont Industrial Polymers: Elvax Resins for Hose and Tubing

Page 1 of 3

Site Elvax Home Home

Product Information

Elvax Resins for Hose and Tubing

z z z

Longer Flex Life Flexibility Below Zero Easy Thermoplastic Processing

Elvax resins offer a unique combination of processing and performance characteristics for use in flexible hose and tubing. These ethylene-vinyl acetate copolymers are inherently flexible, resilient and tough over a broad temperature range and have excellent resistance to flexural fatigue and environmental stress cracking. With no plasticizer to migrate and low odor, Elvax resins offer advantages in many applications traditionally served by plasticized vinyls and compounded rubbers. Subject to the extractional limits in F.D.A. regulation 177.1350, Elvax resins can be used as articles or components of articles intended for contact with food. Typical applications include tubing for beverage dispensers and hoses for swimming pools, heavy duty vacuum cleaners and ice rink cooling systems.

Grades of Elvax for Hose and Tubing

Commercial Elvax resins range in vinyl acetate content from 9% to 40% and in melt index from 0.3 to 500 dg/min. Flexibility, resilience, toughness and clarity are directly proportional to vinyl acetate content. Elvax resins containing from 9% to 25% vinyl acetate and having a melt index of 2.5 or below are generally preferred for hose and tubing applications. All of the resins in this range have a brittleness temperaturea below - 100C (148F). Table 1 shows other key properties of typical resin grades used for hose and tubing.

(aASTM D 746)

Processing Capabilities

Hose and tubing of Elvax resins can be produced using thermoplastic processing equipment or rubber processing equipment such as Banbury mixers, two-roll mills and cold feed extruders. Thermoplastic extrusions require temperatures of 120-200C (248-392F). The temperature profile will vary with machine type, size and screw design as well as die design.

Compounding

Elvax resins are compatible with a variety of other resins and elastomers including polyethylene, polypropylene, crepe rubber and styrene-butadiene rubber. Clays and other inorganic fillers may be added to modify physical properties and lower cost. Elvax resins readily accept colorants. Either transparent or opaque colors can be used. Pigments are generally preferred to dyes since they are, typically, more stable at extrusion temperatures and show better light-fastness. Because of their near transparency, Elvax resins provide an excellent base for developing strong colors at minimum pigment levels. Color concentrates based on Elvax are preferred for ease of blending.

Safety Precautions

http://www.dupont.com/industrial-polymers/elvax/E-45803-1.html 9/9/2005

DuPont Industrial Polymers: Elvax Resins for Hose and Tubing

Page 2 of 3

As with any hot material, care should be taken to protect the hands and other exposed parts of the body when handling molten polymer. At temperatures above 220C (428F), Elvax resins can evolve fumes. Proper ventilation should be provided to insure that people do not breathe the fumes. Spilled resin should be swept up promptly since pellets present a slipping hazard. More detailed information on safe handling and disposal of Elvax resins is provided in a Product Safety Bulletin and Material Safety Data Sheet available from your DuPont Ethylene Polymers representative or the nearest office.

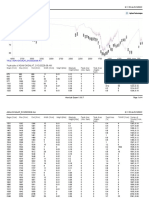

Table 1. Typical Properties of Elvax Resins Used in Hose and Tubinga

Melt Index, Density, Vinyl dg/min kg/m3 Acetate, ASTM (g/cm3) Resin w% ASTM Grade TGA D 1238 D 792 Elvax 770 9.5 .8 930 (0.930) Elvax 760Q 9.3 2.0 930 (0.930) Elvax 670 12.0 0.3 933 (0.933) Elvax 660 12.0 2.5 933 (0.933) Elvax 560 15.0 2.5 935 (0.935) Elvax 470 18.0 0.7 941 (0.941) Elvax 460 18.0 2.5 941 (0.941) Elvax 360 25.0 2.0 948 (0.948)

aTest

Flexural Tensile Vicat Modulus Strength Softening @23C @23C Elongation, Hardness, Temp., MPa (psi) MPa (psi) C (F) Shore D % ASTM ASTM ASTM ASTM ASTM b b D 1525 D 790 D 638 D 638 D 2240 98 21 700 82 46 (14 200) (3 000) (180) 93 18 700 79 46 (13 500) (2 600) (174) 83 25 700 79 44 (12 100) (3 600) (174) 77 18 700 74 44 (11 100) (2 600) (165) 61 18 750 69 41 (8 800) (2 600) (156) 49 23 750 66 41 (7 100) (3 400) (151) 48 19 750 64 39 (6 900) (2 700) (147) 22 20 750 53 37 (3 200) (2 900) (127)

specimens (except for melt index and % vinyl acetate) prepared by compression molding. D 638, Type IV test specimens; crosshead speed 5.1 cm (2 in)/min. Note: These data are represented to describe various grades of Elvax and are not intended as specifications.

bASTM

Site Home

Elvax Home

2005 DuPont Company.

All rights reserved.

We welcome and respond promptly to e-mail.

The technical data contained herein are guides to the use of DuPont resins. The advice contained herein is based upon tests and information believed to be reliable, but users should not rely upon it absolutely for specific applications because performance properties will vary with processing conditions. It is given and accepted at user's risk and confirmation of its validity and suitability in particular cases should be obtained independently. The DuPont Company makes no guarantees of results and assumes no obligations or liability in connection with its advice. This publication is not to be taken as a license to operate under, or recommendation to infringe, any patents. CAUTION: Do not use in medical applications involving permanent implantation in the human body. For other medical applications,

http://www.dupont.com/industrial-polymers/elvax/E-45803-1.html

9/9/2005

DuPont Industrial Polymers: Elvax Resins for Hose and Tubing

see "DuPont Medical Caution Statement", H-50102.

Page 3 of 3

http://www.dupont.com/industrial-polymers/elvax/E-45803-1.html

9/9/2005

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Data Cables With ChartDocument2 pagesData Cables With ChartAsima AtharPas encore d'évaluation

- Outer Facade SealingDocument5 pagesOuter Facade SealingAsima AtharPas encore d'évaluation

- Data Cables With Drawings and ChartsDocument16 pagesData Cables With Drawings and ChartsAsima AtharPas encore d'évaluation

- High Tech Industry's Use of Chemicals in ProductsDocument29 pagesHigh Tech Industry's Use of Chemicals in ProductsAsima AtharPas encore d'évaluation

- Arkema Functional Polyolefins CablesDocument1 pageArkema Functional Polyolefins CablesAsima AtharPas encore d'évaluation

- Eva TaneDocument1 pageEva TaneAsima AtharPas encore d'évaluation

- Elvax Molding GuideDocument11 pagesElvax Molding GuideAsima AtharPas encore d'évaluation

- DCP MSDSDocument4 pagesDCP MSDSAsima AtharPas encore d'évaluation

- 543Document27 pages543Asima AtharPas encore d'évaluation

- Fusabond mc190dDocument2 pagesFusabond mc190dAsima AtharPas encore d'évaluation

- Dicumyl Peroxide 1346: October 1999Document2 pagesDicumyl Peroxide 1346: October 1999Asima AtharPas encore d'évaluation

- DCPDocument3 pagesDCPAsima AtharPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Advent Technologies Presentation 6 August 2015Document15 pagesAdvent Technologies Presentation 6 August 2015Chatzianagnostou GeorgePas encore d'évaluation

- Pratical Physics by DR Giasuddin Ahmed and MD Shahabuddin WWW Euelibrary ComDocument74 pagesPratical Physics by DR Giasuddin Ahmed and MD Shahabuddin WWW Euelibrary ComAntony George80% (15)

- Particle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForDocument5 pagesParticle Size (Sieve Analysis) of Plastic Materials: Standard Test Methods ForMichele PreghenellaPas encore d'évaluation

- 2002 Atmospheric Residue As Feedstock To High-Severity Fluid Catalytic CrackingDocument11 pages2002 Atmospheric Residue As Feedstock To High-Severity Fluid Catalytic Crackingيا بقية الله ادركناPas encore d'évaluation

- Method Development & Optimization: Selection of The HPLC Method and SystemDocument16 pagesMethod Development & Optimization: Selection of The HPLC Method and SystemBruno IndústriaPas encore d'évaluation

- Ruthenium Detection by XRF in Metamorphic RocksDocument6 pagesRuthenium Detection by XRF in Metamorphic RocksTJPRC PublicationsPas encore d'évaluation

- Vessel Standard Operating ProceduresDocument23 pagesVessel Standard Operating ProceduresMaria OsawaPas encore d'évaluation

- Professional Application ManualDocument70 pagesProfessional Application ManualMuthuKumarPas encore d'évaluation

- Emr439r White Mica PDFDocument41 pagesEmr439r White Mica PDFGabriel Erazo FierroPas encore d'évaluation

- Hydraulic Power UnitDocument44 pagesHydraulic Power UnitDustin WhitePas encore d'évaluation

- Life Cycle of A StarDocument22 pagesLife Cycle of A Starေအာင္ ေက်ာ္ စြာPas encore d'évaluation

- Molecular Basis Off InheritanceDocument5 pagesMolecular Basis Off InheritanceShivam Kumar PathakPas encore d'évaluation

- York YLCA Series201 Catalogue Page Doc5063 v3 en-EUDocument4 pagesYork YLCA Series201 Catalogue Page Doc5063 v3 en-EUAndrew PeverillPas encore d'évaluation

- Quantum2 HandoutDocument188 pagesQuantum2 HandoutLizbethPas encore d'évaluation

- Accurate Rapid Analysis of Alkali Contents in Portland CementDocument4 pagesAccurate Rapid Analysis of Alkali Contents in Portland CementyinglvPas encore d'évaluation

- F-16a.1 Ginkgo GinkgolidesDocument3 pagesF-16a.1 Ginkgo GinkgolidesNarongchai PongpanPas encore d'évaluation

- Week 02Document10 pagesWeek 02Arfin FardiansyahPas encore d'évaluation

- Mysterious Mixtures ExperimentDocument13 pagesMysterious Mixtures ExperimentJerneth Nyka FloresPas encore d'évaluation

- Technical Literature of Geogrid TechGridDocument18 pagesTechnical Literature of Geogrid TechGridAshokan KPas encore d'évaluation

- Cleaning Validation For Biopharmaceutical Manufacturing at GenentechDocument4 pagesCleaning Validation For Biopharmaceutical Manufacturing at GenentechLisa Denysa SigarPas encore d'évaluation

- Isolation of Ecgonidine Methyl Ester From Coca SeedDocument3 pagesIsolation of Ecgonidine Methyl Ester From Coca SeedJames McNeePas encore d'évaluation

- Concrete Making MaterialsDocument55 pagesConcrete Making Materialsjaffna100% (1)

- Stability Testing-Basic Theory and Concept AplicationDocument16 pagesStability Testing-Basic Theory and Concept AplicationSham Saja100% (1)

- Off-Centre Anchoring of AZ Sheet Pile WallsDocument18 pagesOff-Centre Anchoring of AZ Sheet Pile WallsjmmPas encore d'évaluation

- Asam Oksalat PDFDocument4 pagesAsam Oksalat PDFfadhilPas encore d'évaluation

- Alpha-Lipoic Acid and Diabetic NeuropathyDocument7 pagesAlpha-Lipoic Acid and Diabetic NeuropathyPedro Rodriguez PicazoPas encore d'évaluation

- Basic Tools of Analytical Chemistry: Chapter OverviewDocument28 pagesBasic Tools of Analytical Chemistry: Chapter OverviewReza LaurinaPas encore d'évaluation

- Chapter 3 Alcohol & Ether1Document24 pagesChapter 3 Alcohol & Ether1Delicz TanPas encore d'évaluation

- NanobotsDocument28 pagesNanobotsMadhurima BhattacharyyaPas encore d'évaluation

- Discrimination Between Roasted Coffee, Roasted Corn and Coffee Husks by DiffuseDocument8 pagesDiscrimination Between Roasted Coffee, Roasted Corn and Coffee Husks by DiffuseJavier OrtizPas encore d'évaluation