Académique Documents

Professionnel Documents

Culture Documents

Thin-Cake Filtration Theory

Transféré par

MarcialDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thin-Cake Filtration Theory

Transféré par

MarcialDroits d'auteur :

Formats disponibles

THIN-CAKE FILTRATION THEORY By Martin Schaefer Project Manager of Filtration Technology BHS-Sonthofen GmbH

Barry A. Perlmutter President & Managing Director BHS-Filtration Inc.

9123-115 Monroe Road Charlotte, North Carolina 28270 Web site: www.bhs-filtration.com

Page 1 of 1

Tel: 704.845.1190 Fax: 704.845.1902 E-mail: info@bhs-filtration.com

A. Introduction In most industrial solid-liquid separation applications, the process steps of filtration, washing and dewatering (drying) are conducted on one filter. This paper describes the thin-cake filtration theory for these operations.

B. Filtration During the initial mechanism of cake forming in the filtration step, the filter cloth acts just to initiate filtration by capturing the first particles. These first particles form bridges over the pores of the cloth (bridging). During this initial phase, smaller particles may pass through the filter cloth leading to turbid liquid (filtrate). As soon as a first layer of particles has accumulated on the filter medium, this cake will then act as the actual filter medium. When plotting the amount of filtrate obtained at constant filtration pressure versus the filtration time, you get a filtration curve, which represents a root function, VF = Constant * tF 0.5, as shown in Figure 1. (Data, in Figure 1, is from an actual BHS test installation).

Filtrate versus filtration time on a BHS-AP300/1 (filter area 0.2 m)

30 25 20 15 10 5 0 0 10

Filtate VF [l]

VF = 4.2534tF0.4934

20 Filtration time tF [min]

30

40

Figure 1: Example of a Typical Filtration Curve The equation of the trend line for this specific chemical product was calculated by Excel. The exponent of 0.4934 almost exactly corresponds to the root function and the constant, in this case, equalled 4.2534. Accordingly, the filtrate flow rate is at its maximum in the beginning and then declines as a result of the constantly increasing filtration resistance (as the cake thickens).

9123-115 Monroe Road Charlotte, North Carolina 28270 Web site: www.bhs-filtration.com

Page 2 of 2

Tel: 704.845.1190 Fax: 704.845.1902 E-mail: info@bhs-filtration.com

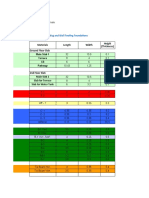

B. Filtration (continued) B.1. The important question that follows is what is the optimum filtration time, i.e. when is the most efficient filtration performance obtained? The filtration performance (P) is calculated using this formula: P = VF / (A * ttotal), where ttota l= tF + tside The side time (tside) includes the washing time, the drying time and the time for filter opening, cake discharge, closing, cleaning of the filter, if necessary, and other miscellaneous time. Every batch-operated filter has these side times, which are usually constant from process cycle to process cycle. When plotting the filtration performance (P, in liters/m2/hour), for example, and including a side time of 15 minutes (including washing and drying times), the result is as follows:

Filter performance versus filtration time

Filter performance P [l/mhr]

3 2,5 2 1,5 1 0,5 0 0 10 20 Filtration time tF [min] 30 40

From the curve, for this example, the maximum filter performance is obtained when the filtration time of 15 minutes equals the side time of 15 minutes. The mathematical formulas follow on page 4 of this article.

9123-115 Monroe Road Charlotte, North Carolina 28270 Web site: www.bhs-filtration.com

Page 3 of 3

Tel: 704.845.1190 Fax: 704.845.1902 E-mail: info@bhs-filtration.com

B. Filtration (continued) B.2. Mathematical Proofs for the Filter Performance (P) Equation (1): Equation (2): Equation (3): P = VF / A * ttotal ttotal = tF + tside tF / tF1 = V2 / V1

By solving equation (1) with equations (2) and (3), the result is P = (V1 tF / tF1)0. 5 / A (tF + tside) From Figure 1, (V1 / tF1)0.5 / A = Constant, and therefore, Filter Performance (P) is P = Constant * (tF0.5 / (tF + tside)) The condition for the maximum filter performance is based upon the first derivative (d), where the ratio of derivatives of the Filter Performance (dP) to Filtration Time (dtF) is equal to zero: Equation (4): and therefore Equation (5): (tF0.5 / (tF + tside))' = 0 (1st derivative = 0) dP / dtF = 0

By solving equation (5), the result is as follows: 0.5 tF-0.5 (tF + tside) - tF0.5 / (tF + tside) = 0 and therefore, the result is tside = tF The conclusion is that the side times and the filtration times must be as short as possible and as equal as possible which leads to thin cake filtration. Of course, one has to ensure that the filter cake can still be discharged, as a thin cake.

9123-115 Monroe Road Charlotte, North Carolina 28270 Web site: www.bhs-filtration.com

Page 4 of 4

Tel: 704.845.1190 Fax: 704.845.1902 E-mail: info@bhs-filtration.com

B.3. Parameters that Influence Filtration Performance: B.3.1. Filtration pressure The higher the filtration pressure, the higher the filtration performance for a non-compressible cake. In case of a compressible solid matter, an increase of pressure will often not result in an increased performance because the filter cake gets more impermeable due to the compression. Finally, the filtration pressure may also impact the cake-forming layer, which could lead to a turbid filtrate, if there is a fine particle tail in the particle size distribution. B.3.2. Temperature The higher the temperature of the slurry, the lower its viscosity. The lower the viscosity, the higher the filtration performance. As a general rule, therefore, increasing the filtration temperature will result in an increase in the filtration performance. B.3.3. Particle Size / Particle Size Distribution (PSD) The particle size and particle size distribution are important parameters, which can influence the filtration performance. As the filter cake begins to form, channels (capillaries) are formed between the particles. The smaller the capillaries, the higher the capillary pressure and thus the resistance of the filter cake. Small particles and a wide particle size distribution result in a densely packed filter cake and reduced filtration performance. In cases such as these, a thinner cake will mitigate this impact and allow for successful filtration. Another alternative would be to use filter aid, either as a precoat or body feed, to increase the filtration performance. B.3.4. Particle Shape The type and shape of the particles also impact the filtration performance. Hard, spherical particles will form a permeable cake with increased void volume leading to high rates. Irregularly shaped crystals, platelet-type or flat crystals as well as needles and amorphous crystals can pack together and result is a dense and low-permeable cake. In cases such as these, once again, thin-cake filtration, low filtration pressures or filter aid mitigate the impacts of the particle shape.

C. Washing of the Filter Cake When washing the filter cake, there are two mechanisms that occur: displacement washing and diffusional washing. With displacement washing, a large part of the void volume (which is still filled or saturated with mother liquor before washing starts) is replaced by the washing liquid. Diffusional washing is the more important mechanism to remove bound or inner liquid. These liquids are removed by the diffusion washing, i.e. the liquid to be washed out diffuses into the washing liquid. The driving force is the concentration difference.

9123-115 Monroe Road Charlotte, North Carolina 28270 Web site: www.bhs-filtration.com

Page 5 of 5

Tel: 704.845.1190 Fax: 704.845.1902 E-mail: info@bhs-filtration.com

C. Washing of the Filter Cake (continued) Depending upon the cake formation, there may be areas of the cake that have little or no permeability. These portions of the cake would not be efficiently washed by either mechanism. In cases such as these, there are generally two alternatives. The first would be a reslurry wash. The cake would be discharged to a reslurry vessel or reslurried in-situ. The second alternative, which would require less wash liquid and less handling of solids, would be a thinner cake to minimize the impermeable areas. This would allow for a more plug-flow effect for the displacement washing. For the bound liquids, there would be a lower concentration of bound liquids, which would require less diffusional liquids and less contact time. Finally, in terms of the parameters that impact washing, these would generally fall in the same category as the influences on filtration, as described in Section B.

D. Drying of the Filter Cake When dewatering the filter cake, the liquid remaining in the pores shall be replaced by gas (mechanical dewatering by blowing) with the objective of obtaining a residual moisture content as low as possible. During blow-out operation, the capillary pressure of the pores must be overcome. The smaller the capillaries, the higher the capillary pressure. As soon as the first capillaries are blown through, the gas consumption rises and reduction of the residual moisture becomes more ineffective. When this point occurs on the drying curve, there are two further approaches that are undertaken. First, the cake can be slowly compressed to allow for reduced gas consumption during this mechanical dewatering stage. Secondly, vacuum drying can be employed as well as thermal drying. During the blowing phase, one of the most important factors for a low residual moisture is a high blow out pressure rather than gas flow. Depending upon the product characteristics, time, temperature and cake thickness will also impact the drying curve.

Barry A. Perlmutter is currently President and Managing Director of BHS-Filtration Inc., a subsidiary of BHS-Sonthofen GmbH. BHS is a manufacturer of thin-cake filtration, washing and drying technologies. Barry has over 25 years of engineering and technical business marketing experience in the field of solid-liquid separation including filtration and centrifugation and process drying. He has published and lectured extensively worldwide on the theory and applications for the chemical, pharmaceutical and energy / environmental industries and has been responsible for introducing and creating growth for many European companies and technologies into the marketplace. He received a BS degree in Chemistry (Albany State, (NY) University), MS degree from the School of Engineering, Washington University, St. Louis and an MBA from the University of Illinois. Barry served on the Board of Directors of the American Filtration and Separations Society (AFS) and is a member of several internationally-recognized societies.

9123-115 Monroe Road Charlotte, North Carolina 28270 Web site: www.bhs-filtration.com Page 6 of 6 Tel: 704.845.1190 Fax: 704.845.1902 E-mail: info@bhs-filtration.com

BHS Thin-Cake Pressure and Vacuum Filtration Technologies For Batch/Continuous Operations From High Solids to Clarification Applications BHS-Sonthofen GmbH, founded in 1563, is a leader in technology and innovation. BHS specializes in thin-cake (3 mm up to 75 mm) filtration, cake washing and drying technologies. BHS serves three major market segments as follows: Chemical: Fine, Specialty, Agricultural, and Others Pharmaceutical: Bulk and Final Products Energy / Environmental: Refinery, Power Plants, Wastewater and Others Specialized Applications & Centres of Excellence: BHS is organized both locally and globally. BHS-Filtration Inc., a subsidiary of BHSSonthofen, is responsible for North and South America. For these markets, equipment and systems are manufactured with as much local content as possible. For specialized applications, BHS is organized globally with centres of excellence. For example, for terephthalic acid, power plant and the dewatering and drying of gypsum applications, this expertise resides at BHS-Sonthofen GmbH. For refinery and bio-energy applications, the expertise for process engineering, etc. resides at BHS-Filtration Inc. Product Technologies & Capabilities The BHS technologies and expertise are thin-cake (3 mm - 75 mm) filtration, cake washing and drying. The five patented BHS technologies are as follows: Rotary Pressure Filter Continuous-Indexing Vacuum Belt Filter Candle Filter Pressure Plate Filters Autopress, an Automated/Contained Specialized Filter Press These technologies are installed for pressure or vacuum filtration, for batch or continuous operations from high solids slurries (up to 60% solids) to clarification applications with solids to less than 1% and trace amounts. Process Lab Testing & On-Site Pilot Testing BHS conducts preliminary tests in our worldwide laboratories or at your facility. On-site tests with pilot rental units continue the process. Finally, BHS completes the project with a complete technical solution and performance guarantees. Contact us today. BHS Rotary Pressure Filter BHS Duplex Candle Filter BHS Vacuum Belt Filter

9123-115 Monroe Road Charlotte, North Carolina 28270 Web site: www.bhs-filtration.com

Page 7 of 7

Tel: 704.845.1190 Fax: 704.845.1902 E-mail: info@bhs-filtration.com

Vous aimerez peut-être aussi

- Excel Link For MatlabDocument6 pagesExcel Link For MatlabMarcialPas encore d'évaluation

- Tutorial ExcelDocument81 pagesTutorial ExcelMarcialPas encore d'évaluation

- PI-DataLink Avanzado PDFDocument166 pagesPI-DataLink Avanzado PDFMarcialPas encore d'évaluation

- Research Report of Mineral Processing 2Document17 pagesResearch Report of Mineral Processing 2MarcialPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Module 4 Active Faults and Other Earthquake Sources: Learning OutcomeDocument3 pagesModule 4 Active Faults and Other Earthquake Sources: Learning OutcomeFatima Ybanez Mahilum-LimbagaPas encore d'évaluation

- DR PDFDocument252 pagesDR PDFa_ouchar0% (1)

- Market AnalysisDocument4 pagesMarket AnalysisSaniya CharaniyaPas encore d'évaluation

- Assignment 1Document3 pagesAssignment 1farhang_tPas encore d'évaluation

- G.S 5Document2 pagesG.S 5Jamsher BalochPas encore d'évaluation

- Schneider Pressure Switch XMLDocument2 pagesSchneider Pressure Switch XMLhaoPas encore d'évaluation

- Digging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Document2 pagesDigging Deeper: Can Hot Air Provide Sustainable Source of Electricity?Рустам ХаджаевPas encore d'évaluation

- Assessment Questions: 1: Wash - Rinse and SanitizeDocument3 pagesAssessment Questions: 1: Wash - Rinse and SanitizeAna Margarita AycochoPas encore d'évaluation

- Learning Activity Sheets Introduction To World Religions and Belief SystemDocument56 pagesLearning Activity Sheets Introduction To World Religions and Belief SystemAngelica Caranzo LatosaPas encore d'évaluation

- Lecture 12Document8 pagesLecture 12Mechanical ZombiePas encore d'évaluation

- Prestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanDocument21 pagesPrestige Institute of Management & Research: Guided By:-Submitted By: - Prof. Arpit Loya Sumeet RattanSumeet700005Pas encore d'évaluation

- Course Registration SlipDocument2 pagesCourse Registration SlipMics EntertainmentPas encore d'évaluation

- Significance of GodboleDocument5 pagesSignificance of GodbolehickeyvPas encore d'évaluation

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocument47 pagesColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanPas encore d'évaluation

- Case Studies of Transportation Public-Private Partnerships Around The WorldDocument158 pagesCase Studies of Transportation Public-Private Partnerships Around The WorldzhenhuaruiPas encore d'évaluation

- Catalogo GatesDocument255 pagesCatalogo GatesBenjamin HedonewePas encore d'évaluation

- The FOA Reference For Fiber Optics - Fiber Optic TestingDocument19 pagesThe FOA Reference For Fiber Optics - Fiber Optic TestingvsalaiselvamPas encore d'évaluation

- Assignment Booklet July 2021Document22 pagesAssignment Booklet July 2021Saksham TiwariPas encore d'évaluation

- GP1 Q1 Week-1Document18 pagesGP1 Q1 Week-1kickyknacksPas encore d'évaluation

- CapstoneDocument23 pagesCapstoneA - CAYAGA, Kirby, C 12 - HermonPas encore d'évaluation

- CheckList For Checking of Drawings-R1Document4 pagesCheckList For Checking of Drawings-R1jatin kalraPas encore d'évaluation

- Industrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsDocument5 pagesIndustrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsMuhammad HaziqPas encore d'évaluation

- SSDsDocument3 pagesSSDsDiki Tri IndartaPas encore d'évaluation

- Implicit Explicit SignalsDocument8 pagesImplicit Explicit SignalsVersoza Nel100% (2)

- Drilling & GroutingDocument18 pagesDrilling & GroutingSantosh Laxman PatilPas encore d'évaluation

- G1CDocument12 pagesG1CKhriz Ann C ÜPas encore d'évaluation

- Nissan Copper LTDDocument11 pagesNissan Copper LTDankit_shahPas encore d'évaluation

- Kinematics in One DimensionDocument4 pagesKinematics in One DimensionAldrin VillanuevaPas encore d'évaluation

- JRC JFE-680 Instruct ManualDocument86 pagesJRC JFE-680 Instruct ManualMark Dominic FedericoPas encore d'évaluation

- Cisco 2500 Series RoutersDocument16 pagesCisco 2500 Series RoutersJull Quintero DazaPas encore d'évaluation