Académique Documents

Professionnel Documents

Culture Documents

Dyes N Chemical of Bangladesh

Transféré par

Jayesh PatelTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Dyes N Chemical of Bangladesh

Transféré par

Jayesh PatelDroits d'auteur :

Formats disponibles

INTRODUCTION

Bangladesh's textile industry, which includes knitwear and ready-made garments along with specialized textile products, is the nation's number one export earner, accounting for 80% of Bangladesh's exports of $15.56 billion in 2009. Bangladesh is 2nd in world textile exports, and China which exported $120.1 billion worth of textiles in 2009. The industry employs nearly 3.5 million workers. Current exports have doubled since 2004. Wages in Bangladesh's textile industry were the lowest in the world as of 2010. The country was considered the most formidable rival to China where wages were rapidly rising and currency was appreciating. As of 2012 wages remained low for the 3 million people employed in the industry, but labor unrest was increasing despite vigorous government action to enforce labor peace. Owners of textile firms and their political allies were a powerful political influence in Bangladesh. The textile dyeing and washing industry plays an important role in the economical growth as well as the environmental sectors of Bangladesh. The textile dyeing industries has been condemned as being one of the worlds most offenders in terms of pollution. There are many dyeing industries in Bangladesh which are mainly located at Gazipur and Narayanganj industrial area. This study was aimed at the dyeing industries to assess the present situation of environmental impacts arising from the activities of dyeing industries in Bangladesh. This was done by analyzing numerous data obtained from different laboratory test concerning a range of water quality parameters of Bangladesh. Important water quality parameters like pH, turbidity, TSS, BOD, COD and presence of metals were measured by testing samples. The samples were collected from effluent water of a renowned and international buyer recognized industry named UNIQUE Washing and Dyeing industry Limited in Gazipur. The results show that all the water quality parameters are within the permissible limits. Though the water test report shows no vulnerable change in water quality for this particular industry, but the overall EIA report shows the highest negative impact on physico-ecological environment. The human interest related factors make the total EIV positive. Bangladesh has emerged, in just under decade, as the twelfth largest garment-manufacturing nation in the world, thanks largely to the Multi-Fiber Agreement (MFA), and the Generalized System of Preferences (GSP) of the European Union, that conferred significant quota benefits to

the country. The garment sector now accounts for about 77% of the countrys foreign exchange earnings, and 50% of its industrial work force . Textile is the most important sector of Bangladeshs economy. Textile industry uses large quantity of water in its production processes and highly polluted and toxic waste waters are discharged into sewers and drains without any kind of treatment. The textile dyeing industries of Gazipur and Narayanganj generate large amount of effluents, sewage sludge and solid waste materials everyday which are being directly discharged into the surrounding channel, agricultural fields, irrigation channels, surface water and these finally enter in to Turag and Shitalakkhya River.

Textile and dyeing industrial effluents may cause alteration of the physical, chemical, and biological properties of aquatic environment by continuous change in temperature, odor, noise, turbidity etc that is harmful to public health, livestock, wildlife, fish, and other biodiversity. The presence of dyes in surface and subsurface water is making them not only aesthetically objectionable but also causes many water borne diseases, viz. mucous membrane, dermatitis, perforation of nasal septum and severe irritation of respiratory tract. Contamination to this aquatic system brings serious threat to the overall epidemic and socio-economic pattern inside.

Industrial effluents impart a minor fraction of chemical load to the environment; its integrity renders the environmental quality fairly deplorable. For this, nearly 30 numbers of villages at Gazipur and a large number of people living near the D.N.D Embankment area are now being threatened due to the environmental degradation. People who live in these areas are utilizing surface water for their house hold washing, bathing, irrigation, fish culture and other necessary works. Furthermore no systemic data had been obtained on water quality of these areas. So, proper analysis is needed to assess the pollution level also for the protection of environment and natural resources. Such information is important for the authorities to take proper action in preventing pollution of the area for the good health of the population. Therefore in the present study we tried to determine the extent of pollution level of various physicochemical parameters and heavy metals in order to characterize the effluents of the textile dyeing industries

CHEMICAL COMPONENTS USED IN DYEING INDUSTRIES

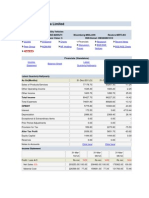

A dye can generally be described as a colored substance that has an affinity to the substrate to which it is being applied. The dye is usually used as an aqueous solution and may require a mordant to improve the fastness of the dye on the fiber. The dyes were obtained from animal, vegetable or mineral origin with no or very little processing. So dyes are mainly organic and inorganic chemical substances. And if these substances spread out in the environment, they may cause huge adverse impact on the environment [3]. Fig. 1 shows different types of dye used in unique washing and dyeing industry Ltd. in Bangladesh.

ENVIRONMENTAL SUSTAINABILITY OF TEXTILE DYEING INDUSTRIES

The textile industry is considered as the most ecologically harmful industry in the world. The eco-problems in textile industry occur during some production processes and are carried forward right to the finished product. In the production process like bleaching and then dyeing, the subsequent fabric makes a toxin that swells into our ecosystem. During the production process controlling pollution is as vital as making a product free from the toxic effect. Taking incremental steps in supply chain processes to make it happen that is need to believe in environmental sustainability; and need to be aware about the social, economical and ecological benefits of environmentally sustainable products and development processes. So the care for the Environment must influence the supply chain to use Sustainable Processes, run business operations in an environmentally friendly way, work to conserve energy and reduce

waste.Exploring and implementing sustainable textile materials and products through sustainable design approach.

A. Eco Friendly Textile Fibres

There are some Eco friendly Textile Fibres called green fibres which are described below: 1) Organic Cotton: Cotton is one of agriculture's most water-intensive and pest sensitive crops; it is estimated to consume 11% of the world's pesticides. A sustainable alternative is Organic cotton having social and environmental benefits includes: Organic cotton cultivation helps indecreasing pollution.Organic cotton cultivation helps in improving soil fertile. Organiccotton farming helps in preventing water, soil and air contamination. Equivalent/ better fiber properties help in diversified products development- suitable for all products. 2) Recycled Cotton: Recycled Cotton is also an ecofriendly choice in cotton clothing since recycled cotton is cotton fabric which is made from recovered cotton that would otherwise be cast off during the spinning, weaving or cutting process. The discarded cotton waste is collected, shredded into small fibers and processed again into yarns and fabrics. Truly ecofriendly because of waste recycling process, no chemicals used during processing, it helps in generating employment and good for the environment. 3) Recycled Polyester: Polyester fibre is one of the most non-biodegradable polymer which create environmental problems. The legislation opens the door towards working over recycling of PET. The Wellman Inc is the worlds largest Polyester recycler. A new generation of fiber that is most suitable for diversified products range such as backpacks and blankets, T-shirts, sportswear, soft luggage and socks. Whereas the certification obtained in licensed or patented yarns (eco spun) along with eco certification from Oekotex and SGS or any other environmental testing agency.

4) Sustainable Processing of Textiles: There is need for ecofriendly wet processing that is sustainable and beneficial methods. Number of sustainable practices has been implemented by various textile processing industries such as Eco friendly bleaching; Peroxide bleaching; Eco friendly dyeing and Printing; Low impact dyes; Natural dyes; Azo Free dyes; Phthalates Free Printing.

B. The Impact of Green Chemistry in Coloration

1) Dye Chemistry: If we look into the Dye chemistry, the appreciable work has been seen by alternative synthesis, sustainable source and natural platform chemicals. Dyes in effluent on other hand, is reduced due to efficiencies of dye sorption and cleaner treatment technologies. 2) Auxiliary Chemicals: Auxiliaries chemicals are those which are used other than colorants (dyes and pigments). Most of the harmful chemicals have been replaced with the sustainable ones or have less effect on theeffluent load and even reduction in use and emission of harmful auxiliaries (e.g.salt, reducing agents and carriers) Reduction in energy, water usage, time in the processes have also been in practice, some of the example such as use of automation in the form of controlled temperature and time of dyeing E-Control Dyeing and use of ultrasonic waves in dyeing that will gain commercially importance in nea

SOURCE :- http://www.ijesd.org/papers/164-D580.pdf

Reactive dye used in maximum textile of bangladesh

Bangladesh has textile based on cotton yarn. cotton fabric is processed in industries for dyeing and printing. Reactive dye is best for cotton goods. That s why about 70% industries use reactive dyes. Reactive dye react with the cellulosic fibers e.g. cotton,jute,viscose,flax,bast fibers. It can be applied to protein fibers e.g. wool & silk. Reactive dye contains reactive group and this reactive group forms convalent bonds with the fibers and becomes the part of the fiber.

Associated reasons are as follows: Reactive dyes are easily soluble in water The dyes have very stable electron arrangement and can protect the degrading of ultra violet ray Reactive dyes give brighter shades and have moderate rubbing fastness Dyeing method of reactive dyes is easy. It requires less time and low temperature for dyeing. Reactive dyes are comparatively cheap. Available in market Fixation occurs in alkaline condition Various shed formed. Fabric damage is less Stripping and topping is easy.

Source:- http://www.docstoc.com/docs/78810161

Role in Bangladeshs economy

The textile industry has played an important role in Bangladeshs economy for a long time. Currently, the textile industry in Bangladesh accounts for 45 percent of all industrial employment and contributes 5 percent to the total national income. The industry employs nearly 4 million people, mostly women. A huge 78 percent of the countrys export earnings come from textiles and apparel, according to the latest figures available. Bangladesh exports its apparel products worth nearly $5 billion per year to the United States, European Union (EU), Canada and other countries of the world. It is the sixth largest apparel supplier to the United States and EU countries.

Major products exported from Bangladesh include polyester filament fabrics, man-made filament mixed fabrics, PV fabrics, viscose filament fabrics and man-made spun yarns. Major garments exported include knitted and woven shirts and blouses, trousers, skirts, shorts, jackets, sweaters and sportswear, among other fashion apparel

A Picture Of Bangladesh's Textile Industry

Bangladeshs textile industry can be divided into three main categories: public sector; handloom sector; and the organized private sector. The private sector is the fastest growing sector in the country.

The handloom industry provides employment for a large segment of the population of Bangladesh and supplies a large portion of the fabric required by the local market. According to the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), the total fabric requirement in the captive market is about 3 billion yards, of which roughly 85 to 90 percent is imported from countries such as China, India, Hong Kong, Singapore, Thailand, Korea, Indonesia and Taiwan. Fabric demand is increasing at the rate of 20 percent per year.

Although the industry is one of the largest in Bangladesh and is still expanding, it faces serious

problems, principally because the country does not produce enough of the raw materials necessary for the industry to expand. The primary materials used in the spinning sector are raw cotton and man-made fibers such as viscose and polyester staple fibers. Unfortunately, none of these raw materials are produced in Bangladesh.

Most spinning mills in Bangladesh produce low-grade yarn. Available figures show that current yarn production satisfied only 22-percent of the total yarn demand. In spite of this drawback, as many as 116 new spinning mills, each having the capacity of 25,000 spindles, will be established in the near future.

The weaving sector also is plagued by a lack of organization and coordination. The existing weaving capacity in Bangladesh can meet only about 40 percent of fabric demand; the rest is imported. However, the increasing trend of expansion in the weaving sector is clear from the fact that 223 modern weaving plants, each with an annual capacity of 10 million meters, will be set up in the near future.

The knitting and hosiery sectors look brighter than weaving, and about 80 percent of garment accessories like cartons, threads, buttons, labels, poly bags, gum tapes, shirt boards and neck boards now are being produced within Bangladesh and contribute to the the national gross domestic product. However, the textile industry is just budding. Source: http://www.textileworldasia.com/Articles/2006/January/Features/Bangladesh_Country_Profile.ht ml

Vous aimerez peut-être aussi

- Example How To Write A ProposalDocument9 pagesExample How To Write A ProposalSpoorthi PoojariPas encore d'évaluation

- HGJHGJDocument2 pagesHGJHGJJayesh PatelPas encore d'évaluation

- 1 YtujuyikDocument1 page1 YtujuyikJayesh PatelPas encore d'évaluation

- HGJHGJDocument2 pagesHGJHGJJayesh PatelPas encore d'évaluation

- 1 YtujuyikDocument1 page1 YtujuyikJayesh PatelPas encore d'évaluation

- How To Write A Proposal TemplateDocument76 pagesHow To Write A Proposal TemplateJayesh PatelPas encore d'évaluation

- 1 YtujuyikDocument1 page1 YtujuyikJayesh PatelPas encore d'évaluation

- Student Exchange AgreementDocument9 pagesStudent Exchange AgreementJayesh PatelPas encore d'évaluation

- FedexDocument9 pagesFedexUbaid RaufPas encore d'évaluation

- 1 YtujuyikDocument1 page1 YtujuyikJayesh PatelPas encore d'évaluation

- MedicalTourismreport FinalDocument87 pagesMedicalTourismreport FinalJayesh PatelPas encore d'évaluation

- Format For Group Project of MDocument1 pageFormat For Group Project of MJayesh PatelPas encore d'évaluation

- Tata Global BeveragesDocument41 pagesTata Global Beveragesyeshadave18Pas encore d'évaluation

- Template - Black-Scholes Option Value: Input DataDocument2 pagesTemplate - Black-Scholes Option Value: Input Datamoneshivangi29Pas encore d'évaluation

- Human Resource Management With Small Firms Facts and ExplanationsDocument30 pagesHuman Resource Management With Small Firms Facts and ExplanationsAnggun MaharditaPas encore d'évaluation

- 1 YtujuyikDocument1 page1 YtujuyikJayesh PatelPas encore d'évaluation

- Black ScholesDocument1 pageBlack ScholesJayesh PatelPas encore d'évaluation

- 830203Document2 pages830203Jayesh PatelPas encore d'évaluation

- Maruti Suzuki India LimitedDocument4 pagesMaruti Suzuki India LimitedJayesh PatelPas encore d'évaluation

- Black ScholesDocument1 pageBlack ScholesJayesh PatelPas encore d'évaluation

- New MBA Detailed Syllabus Sem IIIDocument121 pagesNew MBA Detailed Syllabus Sem IIIsweetlionPas encore d'évaluation

- Call Center Metrics Paper Best PracticesDocument34 pagesCall Center Metrics Paper Best PracticesSharon FreemanPas encore d'évaluation

- FFFFFDocument1 pageFFFFFJayesh PatelPas encore d'évaluation

- Maruti Suzuki India LimitedDocument4 pagesMaruti Suzuki India LimitedJayesh PatelPas encore d'évaluation

- Maruti Suzuki India LimitedDocument4 pagesMaruti Suzuki India LimitedJayesh PatelPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Waste Generation and Characterization: Lesson 2 Week 2Document52 pagesWaste Generation and Characterization: Lesson 2 Week 2Jennyrose AmigoPas encore d'évaluation

- Business Plan of Green Wave Recycling Company LTDDocument11 pagesBusiness Plan of Green Wave Recycling Company LTDSADIA IBNATPas encore d'évaluation

- A Study of Scrap Rubber Devulcanization and PDFDocument216 pagesA Study of Scrap Rubber Devulcanization and PDFalfiharadisPas encore d'évaluation

- Identification of PolymersDocument11 pagesIdentification of PolymersßraiñlĕsšȜĭnšteĭñPas encore d'évaluation

- Sample Essay: © Macmillan Publishers 2004Document4 pagesSample Essay: © Macmillan Publishers 2004Leonardo MoraesPas encore d'évaluation

- MoneyMaking in Small-Scale ProductionNew111Document46 pagesMoneyMaking in Small-Scale ProductionNew111greatgenius100% (1)

- Annexure I Format of BRSR Core PDocument8 pagesAnnexure I Format of BRSR Core PMithilesh KumarPas encore d'évaluation

- Strategic Analysis and Recommendation For TATA SteelDocument17 pagesStrategic Analysis and Recommendation For TATA SteelmomPas encore d'évaluation

- Letters of ProcedureDocument30 pagesLetters of ProcedureVince Carlo ColladoPas encore d'évaluation

- Journal of Applied Corporate Finance 2019 PE 4.0Document10 pagesJournal of Applied Corporate Finance 2019 PE 4.0Herleif HaavikPas encore d'évaluation

- Effect of Human Activity On The EcosystemDocument65 pagesEffect of Human Activity On The EcosystemNabeel UddinPas encore d'évaluation

- Health, Safety, and Environmental (HSE)Document47 pagesHealth, Safety, and Environmental (HSE)Nizar Khalid100% (3)

- Polistiren ReciclareDocument18 pagesPolistiren ReciclareElena NanuPas encore d'évaluation

- Reading ComprehensionDocument3 pagesReading ComprehensionMiguel MartinezPas encore d'évaluation

- Fundamentals of Packaging TechnologyDocument731 pagesFundamentals of Packaging TechnologyRohit Chawla94% (17)

- Green Agenda For The Western Balkans enDocument22 pagesGreen Agenda For The Western Balkans enDragana DsPas encore d'évaluation

- EUBP PP Circular Economy PackageDocument4 pagesEUBP PP Circular Economy PackageDonato GalloPas encore d'évaluation

- IQOS 3 DUO Combined Users Guide ENGDocument13 pagesIQOS 3 DUO Combined Users Guide ENGbahaa mansourPas encore d'évaluation

- Samson's IT ReportDocument41 pagesSamson's IT ReportIjakeyi Samsoft100% (1)

- CW November 2019Document86 pagesCW November 2019maheshguptePas encore d'évaluation

- Composition of Plastic Waste Collected Via Kerbside v2Document36 pagesComposition of Plastic Waste Collected Via Kerbside v2ArunPas encore d'évaluation

- Business Sustainability, Governance and Ethics Cia 1: Sustainable Initiatives of HCLDocument11 pagesBusiness Sustainability, Governance and Ethics Cia 1: Sustainable Initiatives of HCLAnamika Lohani 2027340Pas encore d'évaluation

- TLE 6 INDUSTRIAL Arts Periodic Test Jose 2018 2019 2Document8 pagesTLE 6 INDUSTRIAL Arts Periodic Test Jose 2018 2019 2Flordeliza Manaois RamosPas encore d'évaluation

- No.2 ReportDocument75 pagesNo.2 ReportNawful MohammedPas encore d'évaluation

- REVISTA Europe11Document15 pagesREVISTA Europe11Pancho CorvalánPas encore d'évaluation

- About Britannia 2Document28 pagesAbout Britannia 2Buudha ChakrabortyPas encore d'évaluation

- ASP Catalogue 2018 WebDocument104 pagesASP Catalogue 2018 WebRenzo ArangoPas encore d'évaluation

- User'S Manual: Split Type Room Air ConditionerDocument24 pagesUser'S Manual: Split Type Room Air Conditionerkhr saabPas encore d'évaluation

- Presentation of DS For Stadium-BuildingDocument14 pagesPresentation of DS For Stadium-BuildingMike VPas encore d'évaluation

- 3RD QUARTER Examination in TLE 8Document3 pages3RD QUARTER Examination in TLE 8Gilda EstradaPas encore d'évaluation