Académique Documents

Professionnel Documents

Culture Documents

10-Operation of Framo Cargo Pumps

Transféré par

Florin KaraDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10-Operation of Framo Cargo Pumps

Transféré par

Florin KaraDroits d'auteur :

Formats disponibles

Operation of FRAMO Cargo Pumping System

Contents: 1.0 2.0 3.0 4.0 5.0 6.0 1.0 Loading the cargo tanks Discharging of parcel cargoes Discharging of homogeneous cargoes (parallel pumping) Cargo heating by deck mounted heaters Stripping Tank cleaning LOADING THE CARGO TANKS

Date: 02Nov93 Rev.B 20Sep99 Page 3 of 8

Correct operation of pumps and valves is essential to avoid pressure surges in a cargo pipeline system during loading. Pressure surges may cause severe damage to the pipeline, hoses, metal arms and cargo pumps. Pressure surges will be excessive if a valve is closed too quickly and especially where long pipelines and high ow rates are involved. Note: If a seperate drop line is installed, we recommend to load through the drop line only. lf this is not possible due to valve arrangement, use following procedures to avoid pressure peaks in the cargo piping during loading. 1.1 Procedure for loading through the drop line and cargo pump

1. 1.2 Keep manifold valve closed until the cargo reach the manifold. 1. 1.3 Open the manifold valve partly to ll cargo line on deck. 1.1.4 ** Open the cargo pump discharge valve and drop line valve slowly, until you reach maximum capacity, or maximum 8 bar cargo pressure, measured at the top of the pump. For minimum opening time, see table on page 4. 1.1.5 Continue to load through the drop line and the cargo pump. 1.2 Procedure for loading through the cargo pump without drop line

1.2.1 Keep manifold valve partly closed until the cargo reach the manifold. 1.2.2 Open manifold valve partly, to ll cargo line on deck. 1.2.3 ** Open cargo pump discharge valve slowly. For minimum opening time, see table on page 4. 1.2.4 ** Open the manifold valve slowly until you reach maximum capacity, or maximum 8 bar cargo pressure, measured at the top of the pump. For minimum opening time, see table on page 4. 1.2.5 Continue to load through the cargo pump.

Operation of FRAMO Cargo Pumping System

Date: 02Nov93 Rev.B 20Sep99 Page 4 of 8

Note 1: Maximum acceptable loading pressure is 8 bar at the pumps top cover plate. During the initial stages of loading into each individual tank the ow rate in its branch line should not exceed a linear velocity of 1 metre/ second. Note 2: For sampling procedures, ref. charterers requirements. Note 3: If the loading has been stopped and the cargo valves closed, it is important to restart the loading by following the same procedure as described above! Note 4: For some ships like OBOs, it might be necessary to load through the pump only, until the cargo is above the drop line outlet. This because the drop line outlet is high above the tank top. **) Valves which control liquid ow should be opened slowly. The time taken for power operated valves to move from open to shut and from shut to open should be checked regularly at their normal operating temperatures. Minimum opening time for cargo valves:

Cargo pump type SD50 SD100 SD100 SD125 SD150 SD150 SD200 SD200 SD 250 SD300 SD350 SD350 Cargo pipe diameter (mm) < 100 100 150 151 200 201 250 251 400 > 400 Minimum opening time (seconds) 10 15 20 25 30 45

2.0 2.1

DISCHARGING OF PARCEL CARGOES Start the hydraulic power plant and increase the hydraulic system pressure to approximately 150 bar. If the hydraulic oil temperature is below 20 C, circulate the oil for heating at maximum 100 bar prior to raising the hydraulic system pressure to 150 bar. Start the cargo pump slowly and let it run with hydraulic pressure 40-50 bar for approximately 1-2 minutes with closed cargo pump valve. Raise the pumps discharge pressure above manifold pressure to avoid back ow (overpumping). Then open the cargo pump discharge valve. Increase the hydraulic motor pressure until required discharge pressure or capacity is achieved. lf required, increase the hydraulic system pressure. Follow the same procedure for the next parcel. Ensure that enough hydraulic power is available. lf not, the hydraulic pressure will drop, and the capacity/ head will be reduced. The hydraulic system pressure should be maximum 15 bar above the highest consumer pressure in order to minimize energy consumption, noise level and wear and tear.

2.2

2.3

2.4

2.5

2.6

Note: Remember to purge the cofferdam before and after using the cargo pump!

Vous aimerez peut-être aussi

- 10-Operation of Framo Cargo PumpsDocument8 pages10-Operation of Framo Cargo PumpswojciechkoziolPas encore d'évaluation

- 12 - Operation & Maintenance of Framo PumpDocument20 pages12 - Operation & Maintenance of Framo PumpPrabhakar SubramanyaPas encore d'évaluation

- Operation Manual for Framo Cargo Pumps SD ModelsDocument16 pagesOperation Manual for Framo Cargo Pumps SD Modelscaptulcc100% (2)

- Framo Cargo Pumps As.cDocument9 pagesFramo Cargo Pumps As.cPawan KumarPas encore d'évaluation

- Discharging Operation in Oil TankersDocument6 pagesDischarging Operation in Oil TankersSatyabrat Gaan100% (1)

- Framo Cargo Pumps MaintenanceDocument6 pagesFramo Cargo Pumps MaintenanceOsman ŞenerPas encore d'évaluation

- O-53b Cargo Pumping SystemDocument453 pagesO-53b Cargo Pumping SystemTimmyJuri100% (1)

- ENSCO 8501: General InformationDocument1 pageENSCO 8501: General InformationtphsbPas encore d'évaluation

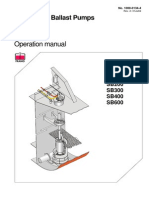

- Operation Manual for Framo Submerged Ballast PumpsDocument13 pagesOperation Manual for Framo Submerged Ballast PumpskokiPas encore d'évaluation

- 26-Replacement of FCV To STC ValvesDocument4 pages26-Replacement of FCV To STC Valvespapaki2100% (2)

- SC 15TW-Stainless Steel 13Document44 pagesSC 15TW-Stainless Steel 13roherneville100% (1)

- New Manual For U-Type Oil Heater (FINAL REV)Document14 pagesNew Manual For U-Type Oil Heater (FINAL REV)Cristian Ramiro CZ100% (1)

- Scanjet Service KitsDocument2 pagesScanjet Service KitsAlberto LunardiniPas encore d'évaluation

- Disc Separator SpecificationDocument4 pagesDisc Separator SpecificationyovanPas encore d'évaluation

- Procedure For LSMGO & ULSFO Change-OverDocument7 pagesProcedure For LSMGO & ULSFO Change-OverGauravPas encore d'évaluation

- FRAMO SYSTEM Drain and VentDocument3 pagesFRAMO SYSTEM Drain and VentjoelandrewpintoPas encore d'évaluation

- Cargo Oil Pump Turbine Operating Instructions: StartingDocument4 pagesCargo Oil Pump Turbine Operating Instructions: StartingSaratkumar RatnalaPas encore d'évaluation

- Framo Service ManualDocument210 pagesFramo Service ManualGonçalo CruzeiroPas encore d'évaluation

- Flyer TL-FADocument20 pagesFlyer TL-FAmingo622Pas encore d'évaluation

- Chintana Naree BriefDocument11 pagesChintana Naree BriefWinston Rodrigues100% (1)

- SC 30Tl: Instruction ManualDocument52 pagesSC 30Tl: Instruction Manualgeorgios giatroudakisPas encore d'évaluation

- Wartsila O Pumps Svanehoj BallastDocument4 pagesWartsila O Pumps Svanehoj BallastBoris SitorusPas encore d'évaluation

- Framo Pressure System Adjustment GuideDocument8 pagesFramo Pressure System Adjustment GuideGonçalo Cruzeiro100% (2)

- HPCE Dynamis 500+ Operations ManualDocument24 pagesHPCE Dynamis 500+ Operations Manualods13 FilPas encore d'évaluation

- Mitsubishi Hiden SystemsDocument3 pagesMitsubishi Hiden SystemsMedha Jog KatdarePas encore d'évaluation

- Marichem Marigases CatalogueDocument325 pagesMarichem Marigases CatalogueRifat Azad0% (2)

- Cargo Ballast Pumps - HTMLDocument5 pagesCargo Ballast Pumps - HTMLstamatisPas encore d'évaluation

- ODMEDocument5 pagesODMEAkhil MathewPas encore d'évaluation

- Chapter 6ADocument22 pagesChapter 6Amaninder_khasria100% (3)

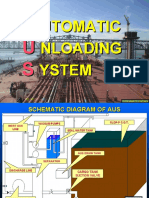

- Automatic Unloading SystemDocument12 pagesAutomatic Unloading SystemDimitrios Nikolaidis100% (1)

- Jowa Backflush ProcedureDocument2 pagesJowa Backflush ProcedureMYO WINPas encore d'évaluation

- Operation Manual for Framo Submerged Ballast PumpsDocument13 pagesOperation Manual for Framo Submerged Ballast PumpsKamal වන්නි ஆரச்சி100% (1)

- Final Stage Discharging ProcedureDocument36 pagesFinal Stage Discharging ProcedureSandro AraújoPas encore d'évaluation

- 382.002 Tank Cleaning Equipment (Instructions & Spare Parts)Document72 pages382.002 Tank Cleaning Equipment (Instructions & Spare Parts)Andrew100% (1)

- GrabDocument15 pagesGrabvihaanPas encore d'évaluation

- Equivalent List Vecom Marine PDFDocument1 pageEquivalent List Vecom Marine PDFEurotech Tra TranPas encore d'évaluation

- Erma First Ballast Water Treatment SystemDocument5 pagesErma First Ballast Water Treatment Systemvangeliskyriakos8998Pas encore d'évaluation

- Accommodation Ladder NewDocument9 pagesAccommodation Ladder NewBrian Voyd RebitoPas encore d'évaluation

- Pa ManuelDocument82 pagesPa ManuelThanh Nghị BùiPas encore d'évaluation

- Alfa Laval PureBallast 3Document45 pagesAlfa Laval PureBallast 3pimentel.octavio2678100% (1)

- Inert Gas System ComponentsDocument28 pagesInert Gas System ComponentsAjit R ChavanPas encore d'évaluation

- SC 360apr-Th-M 04 28-40Document13 pagesSC 360apr-Th-M 04 28-40Ivaylo IvanovPas encore d'évaluation

- Hsfo Lsmgo PDFDocument2 pagesHsfo Lsmgo PDFRajTiwariPas encore d'évaluation

- Automatic Unloading SystemDocument3 pagesAutomatic Unloading Systemnirmalgupte22Pas encore d'évaluation

- FRAMO Subm Cargo PumpDocument5 pagesFRAMO Subm Cargo PumpCvita CvitićPas encore d'évaluation

- SB300 T 1000-0163-4 PDFDocument19 pagesSB300 T 1000-0163-4 PDFJagmohan SinghPas encore d'évaluation

- 13-Framo Submerged Cargo Pump-Purging RoutineDocument12 pages13-Framo Submerged Cargo Pump-Purging Routinepillainaveen100% (1)

- Technische Dokumentation Technical Documentation: Fallreepanlage Accommodation Ladder SystemDocument23 pagesTechnische Dokumentation Technical Documentation: Fallreepanlage Accommodation Ladder SystemGogaPas encore d'évaluation

- Marichem-Marigases CatalogueDocument324 pagesMarichem-Marigases CatalogueDmitriy BelskyyPas encore d'évaluation

- Sili Pump: Marine Pump Specialist in ChinaDocument0 pageSili Pump: Marine Pump Specialist in ChinaRizky Aprianto SetiawanPas encore d'évaluation

- Collision ValveDocument7 pagesCollision ValveInan AkdoganPas encore d'évaluation

- Raising steam from cold condition safelyDocument3 pagesRaising steam from cold condition safelybadpplPas encore d'évaluation

- Principle of OperationDocument5 pagesPrinciple of OperationAnonymous b68EQRPas encore d'évaluation

- Mm-10 Tank Cleaning MachineDocument149 pagesMm-10 Tank Cleaning MachineStasio80Pas encore d'évaluation

- Components of FRAMO SystemDocument26 pagesComponents of FRAMO SystemtomryanPas encore d'évaluation

- Alatas inspection report details maintenance needs for 3 shipboard cranesDocument15 pagesAlatas inspection report details maintenance needs for 3 shipboard cranesFaraz AhmedPas encore d'évaluation

- FRAMO - Oil Analysis LimitsDocument8 pagesFRAMO - Oil Analysis LimitsFelipePas encore d'évaluation

- Operation Manual for Framo Cargo PumpsDocument16 pagesOperation Manual for Framo Cargo PumpsOana Pavel91% (11)

- GRACE DAHLIA Report Cargo 2Document41 pagesGRACE DAHLIA Report Cargo 2Badrul 'boxer' HishamPas encore d'évaluation

- Offshore VessellDocument50 pagesOffshore VessellFlorin KaraPas encore d'évaluation

- Ship Modeling From Stem To SternDocument294 pagesShip Modeling From Stem To SternFlorin Kara100% (2)

- Internal Combustion Engine CoolingDocument6 pagesInternal Combustion Engine CoolingFlorin KaraPas encore d'évaluation

- Dokmar Ship Knowledge A Modern Encyclopedia by K. Van DokkumDocument340 pagesDokmar Ship Knowledge A Modern Encyclopedia by K. Van Dokkumamin_corporation50% (4)

- MSCS) (V4.12.10) MSC Server Hardware DescriptionDocument148 pagesMSCS) (V4.12.10) MSC Server Hardware DescriptionDeepak JoshiPas encore d'évaluation

- Dynamic Programming Algorithm Explained in ECE 551 LectureDocument11 pagesDynamic Programming Algorithm Explained in ECE 551 Lectureadambose1990Pas encore d'évaluation

- Fire ZoneDocument8 pagesFire ZoneKannan NPas encore d'évaluation

- Doubble EncriptionDocument60 pagesDoubble Encriptiondeepak kumarPas encore d'évaluation

- Operating Instruction Precision Balance: Kern EwDocument15 pagesOperating Instruction Precision Balance: Kern EwjohnPas encore d'évaluation

- Diebold ManualDocument2 pagesDiebold Manualjoseperezlopes069Pas encore d'évaluation

- Discussion QuestionsDocument45 pagesDiscussion QuestionsSriRahayuPas encore d'évaluation

- Lsi/Csi: 24-Bit Dual-Axis Quadrature CounterDocument12 pagesLsi/Csi: 24-Bit Dual-Axis Quadrature CounterWilliam Méndez PérezPas encore d'évaluation

- Service Manual Trucks: Fault Codes Tachograph Tac-Dig, Tac-Dig2Document70 pagesService Manual Trucks: Fault Codes Tachograph Tac-Dig, Tac-Dig2Deny Adi IrawanPas encore d'évaluation

- Chm580 Experiment 3Document9 pagesChm580 Experiment 3ohhiPas encore d'évaluation

- Lecture 5 (River As A Geological Agent)Document20 pagesLecture 5 (River As A Geological Agent)Boos yousufPas encore d'évaluation

- Vikramraju Updated Excel (EXCEL GOODIES)Document40 pagesVikramraju Updated Excel (EXCEL GOODIES)vikramrajuu0% (1)

- Chapter 7 MCDADocument26 pagesChapter 7 MCDARosmira Natasha Binti RosleePas encore d'évaluation

- P&ID ManualDocument35 pagesP&ID Manualdharan kumarPas encore d'évaluation

- 3dsmax2013 PU06 Readme0Document6 pages3dsmax2013 PU06 Readme0Divad Zoñum CostaPas encore d'évaluation

- TVS Apache RTR 180 Service ManualDocument25 pagesTVS Apache RTR 180 Service ManualSandino JosePas encore d'évaluation

- Filter 7Document480 pagesFilter 7Pranjal TripathiPas encore d'évaluation

- Raman BandsDocument2 pagesRaman Bandspreyas1Pas encore d'évaluation

- Class XII Computer Project - Hotel ManagementDocument29 pagesClass XII Computer Project - Hotel ManagementLakshmi Puthiyedath71% (7)

- Roll Handling Data Form: Company DetailsDocument1 pageRoll Handling Data Form: Company DetailsAlfredo MinchezPas encore d'évaluation

- LEMBARAN KERJA BI TAHUN 4 (m7-10) PDPRDocument9 pagesLEMBARAN KERJA BI TAHUN 4 (m7-10) PDPRnurulwaznahPas encore d'évaluation

- VT2009B Eng 02 953680Document2 pagesVT2009B Eng 02 953680gabrieltracto100% (1)

- CH3 SolutionsDocument40 pagesCH3 SolutionsRonelPas encore d'évaluation

- Chieftain 2100X (2-Deck) Data SheetDocument1 pageChieftain 2100X (2-Deck) Data SheetbrianPas encore d'évaluation

- PAPER I MATHEMATICS PRACTICE SETDocument6 pagesPAPER I MATHEMATICS PRACTICE SETRitesh Raj PandeyPas encore d'évaluation

- T00051 Thrust PositionDocument17 pagesT00051 Thrust PositionmahdilabedPas encore d'évaluation

- Physico-Chemical Properties of DrugsDocument64 pagesPhysico-Chemical Properties of DrugsYap Jacky33% (6)

- A510m 06Document7 pagesA510m 06psewag100% (1)

- Navisworks BasicTrainingDocument54 pagesNavisworks BasicTrainingMadhankumarPas encore d'évaluation