Académique Documents

Professionnel Documents

Culture Documents

APNEA-J-DSH-0002 Rev. 1

Transféré par

Michelle MartinezDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

APNEA-J-DSH-0002 Rev. 1

Transféré par

Michelle MartinezDroits d'auteur :

Formats disponibles

Project Title: FEED for APN E/F New Field Development STC - 0485 Authors Org.

Instrument

Document Number: APNEA-J-DSH-0002 Validation: Expired Date: -

TABLE OF CONTENTS

No.

1

Tag Number

APNEA-HCV-0158

Page

3

Rev. 0 1

Issue Date 19-Jan-2010 19-Feb-2010

Prep'd WID WID

Chk'd US US

App'd PW/JB PW/JB

Issue Purpose APPROVED FOR BID RE-APPROVED FOR BID

Owner Signature

Instrument - Data Sheet

DOCUMENT NO:

REV.

APNEA-J-DSH-0002

Actuated Choke Valve

APNE-A MONOPOD PLATFORM

PERTAMINA HULU ENERGI OFFSHORE NORTH WEST JAVA LTD.

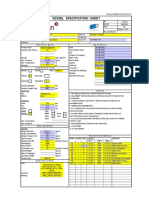

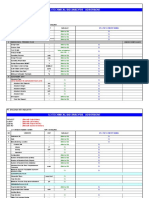

FEED for APN E/F New Field Development STC - 0485 Tag No. Service P&ID No. : : : APNEA-HCV-0158 APNE-A WELLHEAD 01 FLOWLINE MIKE-APNEA-P-PID-6001 GENERAL INFORMATION Line No. Hazardous Area Class. Electrical Certification

REV DESCRIPTION DATE PREP'D

REFERENCE DRAWING NO :

CHK'D

APP'D

COMP

0 1

APPROVED FOR BID RE-APPROVED FOR BID

19-Jan-2010 19-Feb-2010

WID WID

US US

PW/JB PW/JB

: PG-102-D-8" : Class I, Div.1, Group D, T3 : FM/UL/CSA

FLOW CONDITIONS : Case 1 (Early Production) 1 Fluid Type Hydrocarbon Gas 2 Phase 3 Flow Rate 8.8 MMSCFD 4 Molecular Weight 16.37 5 Viscosity cP 0.013 6 Upstream Density 1.849 lb/ft3 7 Specific Heat Ratio Cp/Cv 1.41 8 Gas Compressibility Factor, Z 0.93 9 Max Shutoff dP 725 10 Maximum 725 11 Inlet 633.4 Pressure, Psig 12 Outlet 132 13 Vapor Press. N/A 14 Critical Press. N/A Temperature, 15 Design 150 o 16 Operating 115.4 F Percent Travel 13 (Note 2) Note 3 17 Calculated Cv Note 3 18 Predictable SPL LINE 19 20 Pipeline Size & Inlet 8", Sch. 80 21 Schedule Outlet 8", Sch. 80 22 Pipeline Insulation N/A VALVE BODY / BONNET 23 24 Type Angle Body 6" 6" 25 Inlet/Outlet Size 26 Material Carbon Steel ASME 600# - Flanged 27 Pressure Class / End Connection 28 Number of Ports Note 3 29 Guiding Fully Balanced 30 Flow Direction Note 3 31 Type MFR. STD Bonnet 32 Material Carbon Steel 33 Lubricant & Isolation Valve N/A 34 Type MFR. STD Packing 35 Material Note 3 36 Shut-off Class ASME/ FCI 70.2 Class V 37 Manufacturer MASTER FLO or Equal 38 Model No. Note 3 TRIM 39 40 Type Cage with external sleeve 41 Selected Cv Note 3 42 Max. Flow for Trim Note 3 43 Characteristic Equal Percentage 44 Balanced or Unbalanced Note 3 45 Bean Carrier Material 316 SS 46 Seat Material Solid 5CB Tungsten Carbide 47 Cage / Guide Material Solid 5CB Tungsten Carbide 48 Stem Material UNS S17400 SS 49 Bolting Material 316 SS 50 Seal Material Teflon ACTUATOR 51 52 Actuator Type Pneumatic, Stepping Actuator 53 Manufacturer MASTER FLO or Equal 54 Model No. Note 3 55 Mounting Vertical 56 Fail Position Stay-put 57 Rated Output Torque Note 3 58 Stroking Time Note 3 59 Pneumatic Supply Pressure Min 80 psig/ Max 200 psig 60 Handwheel Type Declutchable, Top Mounted (Note 4) 61 Adjustable Mechanical Limit Stop Yes, required

Case 2 (Maximum) Case 3 (Minimum) Hydrocarbon Hydrocarbon Gas Liquid Gas Liquid 16.7 BPD 1.21 MMSCFD 0.57 BPD 15.97 MMSCFD 18 18 16.38 16.37 0.56 0.012 0.012 0.77 61.8 0.433 0.418 62.59 1.32 N/A 1.33 N/A 0.98 N/A 0.98 N/A 725 725 725 725 146.3 132.5 136.3 121 4.716 psia 2.719 psia 3193.5 psia 3193.5 psia 150 150 119 89 252 (Note 2) Note 3 17 (Note 2) Note 3 Note 3 Note 3 SOLENOID VALVES 62 63 Tag No. APNEA-SY-0158A APNEA-SY-0158B 2 EA 64 Valve Quantity 65 Manufacturer & Model No. BIFOLD FLUID POWER or Equal 66 Solenoid Type 3-way Universal, Pulse operated 67 Body Size No. of Ports 1/4" Three 68 Body / Trim Material 316 SS 69 Supply Voltage Power Consumption 24 VDC 3.5 W 70 Coil Housing Class H 71 Pneumatic Connection 1/4" NPTF 72 Electrical Connection 1/2" NPTF 73 Protection/Enclosure Class NEMA 4X & 7 74 Electrical Area Classification Class I, Div. 1, Gr. D & T3 75 Surge Suppression Diode Yes 76 Exhaust Bug Screen Yes, 316SS (Note 8) 77 Identification Plate Yes 78 I/P POSITIONER 79 80 Type N/A 81 Manufacturer & Model No. N/A 82 Signal Input N/A 83 Signal Output N/A 84 Gauges N/A 85 Elect. Area Classification N/A POSITION TRANSMITTER 86 87 Manufacturer & Model No. PROXIMITY or Equal 88 Tag No. APNEA-ZT-0158 89 Signal Output 4-20 mA, HART Protocol 90 Power Supply 24 V DC 91 Enclosure NEMA 4X & NEMA 7 92 Classification Area Class I, Div.1, Gr. D & T3 AIR SET 93 94 Manufacturer & Model No. FISHER or Equal 95 Body Material Set Pressure 316 SS Note 3 Yes 96 Gauge TEST 97 ASME B16.104-1976 (FCI 70.2-2006) 98 Seat Leakage Test API 6A 99 Body / Pressure Test 100 OTHERS 101 102 Tubing / Fittings 316 SS 103 Local Position Indicator Yes, Required 104

NOTES : 1. Valve and accessories shall be provided with 316 SS tag plate with tag number and service description engraved in 0.23 inch High x 0.01 inch Deep bold letters tied to it by a 316 SS wire. 2. Vendor to check and confirm. The sizing calculation shall be submitted for approval. 3. Vendor to furnish. 4. Handwheel diameter shall not exceed 2 ft (600 mm). 5. Two Solenoid valves are required, one for opening and another for remote closing using pulse signal. 6. Valves shall be supplied in accordance with General Instrumentation Specification (Doc. No. MIKE-J-SPE-0001). 7. Valve body and actuator shall be coated and painted in accordance with Painting Specification (Doc. No. MIKE-X-SPE-0004). 8. Bug screens shall be fitted to all exhausts.

APNEA-J-DSH-0002 Rev.1

Page 3 of 3

Vous aimerez peut-être aussi

- Volume3A MechDocument321 pagesVolume3A MechAdeel JamilPas encore d'évaluation

- BB.G VSP Pve Ed 20 Me Das 004 - 0Document9 pagesBB.G VSP Pve Ed 20 Me Das 004 - 0Luong AnhPas encore d'évaluation

- BFW Cooler Datasheet Rev-2Document3 pagesBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDPas encore d'évaluation

- SVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplaceDocument8 pagesSVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplacejfdlksaPas encore d'évaluation

- Line List: Bandar Abbas Gas Condensate Refinery ProjectDocument31 pagesLine List: Bandar Abbas Gas Condensate Refinery Projectmb_sirousPas encore d'évaluation

- Notes:: TAG# SV-01Document1 pageNotes:: TAG# SV-01omarPas encore d'évaluation

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajPas encore d'évaluation

- G I Drawing For Droplet SeperatorDocument4 pagesG I Drawing For Droplet SeperatorPerumal KumarPas encore d'évaluation

- 10083a 1X M6 Ab 00006 04Document1 page10083a 1X M6 Ab 00006 04wael zakariaPas encore d'évaluation

- IPA HeaterDocument14 pagesIPA HeaterNitin KurupPas encore d'évaluation

- 00000-JDS-014 (Pressure Safety Valve) Rev 0Document4 pages00000-JDS-014 (Pressure Safety Valve) Rev 0sithulibra100% (1)

- Hyd. Calc of 43p17 Ab - As Per P&idDocument7 pagesHyd. Calc of 43p17 Ab - As Per P&idAnindyaPas encore d'évaluation

- N2 Purging Demand Calculation Shutdown - Flare SystemDocument54 pagesN2 Purging Demand Calculation Shutdown - Flare SystemMoch FaridPas encore d'évaluation

- General Notes: FAC1-P-611003A /B FAC1-PM-611003A/BDocument1 pageGeneral Notes: FAC1-P-611003A /B FAC1-PM-611003A/Bsecret soldierPas encore d'évaluation

- Vessel Specification SheetDocument2 pagesVessel Specification Sheetangel gabriel perez valdezPas encore d'évaluation

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Document4 pagesENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronPas encore d'évaluation

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405Pas encore d'évaluation

- S.no Description Data For ApprovalDocument2 pagesS.no Description Data For ApprovalVenkatPas encore d'évaluation

- 1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วDocument18 pages1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วsarafan leewan0% (1)

- TBA - AdsorbentDocument4 pagesTBA - AdsorbentTifano KhristiyantoPas encore d'évaluation

- Lo21-21-P-Pi-16 - Rev.pDocument1 pageLo21-21-P-Pi-16 - Rev.psvnaik14Pas encore d'évaluation

- A2001-0003 - Rev.f - Condensate Filter GA DrawingDocument4 pagesA2001-0003 - Rev.f - Condensate Filter GA DrawingvamcodongPas encore d'évaluation

- r2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Document377 pagesr2b p3 206 02 P HD 00200 - Datasheets For Control Valve, Globe, U 21000 - Rev.1Diana Paula Echartea MolinaPas encore d'évaluation

- Pipi G Material Specificatio: Ref. Proce. O. Issue Umber Revision O. Revision Date ODS/SOP/008 To 015 2 1 1/8/2006Document78 pagesPipi G Material Specificatio: Ref. Proce. O. Issue Umber Revision O. Revision Date ODS/SOP/008 To 015 2 1 1/8/2006Aravind VickyPas encore d'évaluation

- TPL 1044 34570 VM DS 2817 R3Document29 pagesTPL 1044 34570 VM DS 2817 R3m 418Pas encore d'évaluation

- Stack Gas Specification: Project Name Client Location GeneralDocument6 pagesStack Gas Specification: Project Name Client Location Generalbudi utomoPas encore d'évaluation

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDocument6 pagesR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Sensors & Gauges Legend: C175-16 Genset Skid LimitDocument5 pagesSensors & Gauges Legend: C175-16 Genset Skid LimitTrungSon NguyenPas encore d'évaluation

- Jubail Export Refinery: Wash Water Break Tank 101-D-0004Document1 pageJubail Export Refinery: Wash Water Break Tank 101-D-0004ahm3d16nPas encore d'évaluation

- LPG Amine Cooler-SummaryDocument15 pagesLPG Amine Cooler-SummaryJEEVITHAPas encore d'évaluation

- Air Cooled COndenser PDFDocument7 pagesAir Cooled COndenser PDFRajAnandPas encore d'évaluation

- P&ID Cooling Water System PDFDocument2 pagesP&ID Cooling Water System PDFmuieed siddiquiPas encore d'évaluation

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomPas encore d'évaluation

- JO003-10-MAV-MDD-DSP-001 P&ID Lubrication OilDocument1 pageJO003-10-MAV-MDD-DSP-001 P&ID Lubrication OilHasan Mustafa0% (1)

- 1231 de 00 DC PCJ 001 01Document33 pages1231 de 00 DC PCJ 001 01Hamid MansouriPas encore d'évaluation

- Aux Steam Ee 00100 Axs 002Document15 pagesAux Steam Ee 00100 Axs 002anbarasusivaprakasam100% (1)

- Yazd-System Description For Start Up & Blow Down SystemDocument6 pagesYazd-System Description For Start Up & Blow Down Systemandri.motoGPas encore d'évaluation

- 15NO03 DS 60 001. Gas MeteringDocument42 pages15NO03 DS 60 001. Gas Meteringbagus handokoPas encore d'évaluation

- Cover Sheet: Signature Not VerifiedDocument14 pagesCover Sheet: Signature Not VerifiedvdrizzilsPas encore d'évaluation

- Revision Index Description and / or Revised Sheets: Technical Specification Un - Rio / Atp - Ro 1 of 73 75Document255 pagesRevision Index Description and / or Revised Sheets: Technical Specification Un - Rio / Atp - Ro 1 of 73 75neivaprojetosPas encore d'évaluation

- Mucog 1910502 Mec DS 055Document12 pagesMucog 1910502 Mec DS 055vinodPas encore d'évaluation

- WHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchDocument18 pagesWHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchYasin ElaswadPas encore d'évaluation

- Gresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectDocument56 pagesGresik Gas Cogeneration Plant PT Pembangunan Perumahan Gresik Gas Cogeneration Plant ProjectwahyuPas encore d'évaluation

- CompressorDocument33 pagesCompressorfvaefaPas encore d'évaluation

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01Pas encore d'évaluation

- IPS MBD21907 in 522 Datasheet of Emergency Relief Valve ADocument3 pagesIPS MBD21907 in 522 Datasheet of Emergency Relief Valve ANikhil KarkeraPas encore d'évaluation

- Surge Vessel Testing: (Update As of 30th April 2015)Document2 pagesSurge Vessel Testing: (Update As of 30th April 2015)Syed AliPas encore d'évaluation

- Engineering Units ConverterDocument19 pagesEngineering Units Convertertitou_d8638Pas encore d'évaluation

- For Information: GE OfficialDocument6 pagesFor Information: GE OfficialMaulik Dave50% (2)

- QIPP MPN018 J00 2304 (1) Instr ListDocument9 pagesQIPP MPN018 J00 2304 (1) Instr Listsivasri999Pas encore d'évaluation

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasPas encore d'évaluation

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatDocument3 pagesBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloPas encore d'évaluation

- Chiyoda Malaysia Sdn. BHD.: Anuj Maifeng Winms Anuj Maifeng WinmsDocument4 pagesChiyoda Malaysia Sdn. BHD.: Anuj Maifeng Winms Anuj Maifeng WinmsmeePas encore d'évaluation

- Sov - 1Document1 pageSov - 1biswasdipankar05Pas encore d'évaluation

- 0 WD990 EM440 00101 Equipment List RevFDocument20 pages0 WD990 EM440 00101 Equipment List RevFManuel Jesus Perez MelgarPas encore d'évaluation

- TK02 Rev01Document7 pagesTK02 Rev01mggz_15Pas encore d'évaluation

- Tds Tcs Tata Krishnapatnam Rev.r0Document46 pagesTds Tcs Tata Krishnapatnam Rev.r0SupriyaRongPas encore d'évaluation

- BKDD00-ME-4M-87-001 Data Sheet Control Valve (Rev 0)Document22 pagesBKDD00-ME-4M-87-001 Data Sheet Control Valve (Rev 0)nileshana100% (1)

- 008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BDocument17 pages008364-001-DS-I001 Dehydration Switching Valves Datasheet - Rev BNaveen KumarPas encore d'évaluation

- Design Economic Sewage Treatment PlantDocument17 pagesDesign Economic Sewage Treatment PlantDavid LambertPas encore d'évaluation

- Tomson 32LB220B4 2Document83 pagesTomson 32LB220B4 2lust1Pas encore d'évaluation

- F 2362 - 03 - RjiznjiDocument41 pagesF 2362 - 03 - RjiznjiHans AbantoPas encore d'évaluation

- Transformer Installation - Some Best PracticesDocument5 pagesTransformer Installation - Some Best PracticespctinformationPas encore d'évaluation

- DLTOVRDocument5 pagesDLTOVRMaran GanapathyPas encore d'évaluation

- Managing - Change & Transition - Harvard Business Review PressDocument113 pagesManaging - Change & Transition - Harvard Business Review PressTaz UddinPas encore d'évaluation

- SCCPCH Concept & ImplementationDocument11 pagesSCCPCH Concept & ImplementationSwandito HaryoyudantoPas encore d'évaluation

- HCM534DDocument8 pagesHCM534D3efooPas encore d'évaluation

- Operation Manual: XQ140/12Y Hydraulic Power TongDocument44 pagesOperation Manual: XQ140/12Y Hydraulic Power TongAgustin Roncallo100% (1)

- EN ISO 9606 1 2013 E Codified PDFDocument1 pageEN ISO 9606 1 2013 E Codified PDFPM LOgsPas encore d'évaluation

- Afni00 Unix PDFDocument19 pagesAfni00 Unix PDFMohammed Anas PMPas encore d'évaluation

- Voting Functionality of WorkflowDocument10 pagesVoting Functionality of WorkflowAmit Jain100% (2)

- HAV-EXT-QC-STA-0245: Method Statement of Hdpe PipingDocument19 pagesHAV-EXT-QC-STA-0245: Method Statement of Hdpe Pipingum erPas encore d'évaluation

- Safety and Control Devices PDFDocument20 pagesSafety and Control Devices PDFTarek ElMesalamyPas encore d'évaluation

- CAMBIUM ePMP 5.4.1 RC15 MIBDocument327 pagesCAMBIUM ePMP 5.4.1 RC15 MIBSeni SendirianPas encore d'évaluation

- Tushar Resume 2021,,FBDDocument2 pagesTushar Resume 2021,,FBDBaljeetPas encore d'évaluation

- Laborator 4 - Simple HTTP Client (Web Service Emulation)Document6 pagesLaborator 4 - Simple HTTP Client (Web Service Emulation)Marcel LefterPas encore d'évaluation

- Sizing Water Supply LinesDocument2 pagesSizing Water Supply LinesallovidPas encore d'évaluation

- EngineDocument79 pagesEngineEdi Ianto100% (2)

- APEGS Test: Competency Report: Name Discipline of Application JurisdictionDocument29 pagesAPEGS Test: Competency Report: Name Discipline of Application JurisdictionmycdrhelpPas encore d'évaluation

- The Unscrambler TutorialsDocument179 pagesThe Unscrambler TutorialsFahmi AckbarPas encore d'évaluation

- 2021.04.06-Riken - Design InformationDocument2 pages2021.04.06-Riken - Design InformationDo MinhPas encore d'évaluation

- Iso Fdis 16140-6 (E)Document34 pagesIso Fdis 16140-6 (E)Microbiologia GTA Alimentos100% (1)

- BT201 KT1025A B V2.3.zh-CN - enDocument45 pagesBT201 KT1025A B V2.3.zh-CN - enmothafaka75% (12)

- On Software Quality - Chapter 2.Document22 pagesOn Software Quality - Chapter 2.Manuel SosaetaPas encore d'évaluation

- 1.introduction and Overview of BNBCDocument47 pages1.introduction and Overview of BNBCShantonu DeyPas encore d'évaluation

- Rajdhan CatlogueDocument32 pagesRajdhan CatloguejatinPas encore d'évaluation

- 2.5.2. ELECTRICAL DBR (13th Dec.2019) PDFDocument28 pages2.5.2. ELECTRICAL DBR (13th Dec.2019) PDFCreative GroupPas encore d'évaluation

- Arduino Display Data Over Local NetworkDocument7 pagesArduino Display Data Over Local NetworkKarthikPas encore d'évaluation

- Phmetro Ec10 Hach PDFDocument40 pagesPhmetro Ec10 Hach PDFiptPas encore d'évaluation

- Data of Signal Source Band Tracking Source For LTDZ - 35-4400M - SpectrometerDocument2 pagesData of Signal Source Band Tracking Source For LTDZ - 35-4400M - SpectrometerDaniel PerezPas encore d'évaluation