Académique Documents

Professionnel Documents

Culture Documents

Bochure Rendering and Biogas Euro Industries Bvba

Transféré par

Ali AkhterCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bochure Rendering and Biogas Euro Industries Bvba

Transféré par

Ali AkhterDroits d'auteur :

Formats disponibles

WASTE MANAGEMENT

DIGESTERS and SRS RENDERING

For the treatment of: Stable manure, Organic waste, Flotation sludges, Slaughterhouse waste, Intestines, Blood, Meat, Fat etc.

WASTE MANAGEMENT

Technic for quality and performance

Hof ten Bergestraat 7 2381 Weelde - Belgium

Tel. +32(0)14 65 66 67 E-mail: info@euroindustries.be

Euro Industries bvba in Belgium has extensive experience of treatment of a wide variety of organic wastes with a view to controlling and managing pollution, conforming to legislation regarding use, disposal and utilising by-products. For the treatment of organic wastes from slaughterhouses Euro Industries bvba offers two possible solutions, presented in this information brochure. The Basic Design Type and quantity of wastes and sludges coming from a slaughterhouse can be treated or by rendering or by anaerobe digestion (biogas). Both systems are in our delivery program, however the two systems are totally different from approach.

In a few words: A rendering system treats all the waste materials in order to be used as a fertilizer or for incineration (Category 2 and 1) or as an animal or for pet food (Category 3). The fat and oil coming from the rendering process can be used as a bio-fuel, so the complete process is a low energy cost process. A digester system treats all the waste materials in an air closed system with sufficient retention time in order to degree the organic materials and to produce interesting quantities of methane gas for heating system and steam boiler or also cogeneration and to produce electricity. The treated organic waste materials in the digester can be used after dewatering for composting and as a fertilizer.

ANAEROB DIGESTION (biogas) of slaughterhouse waste Our design utilises well-established mechanical principles proven in over a hundred digester systems, and has a number of advantages over other designs. The Euro Industries bvba digester system is suitable for treatment of a wide range of organic wastes including: Stable Manure All meat waste (intestines, red offals, white offals etc.) Stomach contents Blood Sludge from the waste water treatment

Bones and hairs are not treatable in a digester. In the Euro Industries anaerobe digester all materials can be treated up to an average dry substance of 15%. This is a special and unique advantage of our system. Due to the high possible dry substance, the system can be build as a compact equipment. Feeding the digester is never a problem. Holiday periods or periods in which it is not able to feed the digester do not disturb the process. In times of low feeding the digester, only the gas production is lower.

General description An anaerobic digester is a system which creates optimum conditions for the growth and action of anaerobic bacteria. These organisms occur naturally in habitats where air is absent such as the stomachs of animals, cesspits, swamps, and the muds of rivers, lakes and oceans, where they play a vital role in the decomposition of wastes and recycling of nutrients in the environment. By maintaining an optimum temperature and by regular feeding and mixing of wastes, a digester system speeds up the action of these bacteria enabling them to process wastes far more rapidly than would be possible in the often still and cold conditions where they are normally found. The digester tank comprises a sealed and insulated vessel which is sized to process as much waste as possible within the time required by the bacteria to decompose the wastes. The system contains a mechanical systems for heating, mixing, loading and unloading of wastes, together with an electrical system for operating, monitoring and controlling the process. The pasteurisation process for the total waste volume is included to be conform to the European legislation. The pasteurisation process is a closed system, working at a temperature of minimum 75 C

Digester mixing The digester is mixed by gas re-circulation. Gas produced by the digesting wastes is routed from the gas outlet to a condensation trap which collects moisture from the cooling moist gas, and to a gas holder. The mixing system is the most important mechanical system in the short term. Digester system The digesting wastes are maintained at an operating temperature of 36-38 C by the combustion of some of the biogas produced by the digesting wastes. At this temperature a Mesophilic process takes place inside the digester. An alternative digesting process is the Thermophilic process which takes place at 55C. The disadvantage of the Thermophilic process is the instability and high maintenance and operation cost.

Gas pressure sensing system A gas pressure manometer responds to variation in gas pressure in the gas system. This signal is used to control gas use and heating systems.

Digester heating A gas boiler heats water which is circulated to heat exchangers suspended from the roof of the digester. This design allows the heat exchangers to be removed in the unlikely event they should require repair or maintenance, and allows total access to all parts of the heating circuit. The Heating system contains a thermostat which controls the maximum temperature of the hot water circuit. The temperature of the heating circuit water should not exceed 60 C due to the high probability of caking of the heat exchangers above this temperature. The temperature of the digesting wastes is measured by a probe mounted in flanges on the digester roof, and is indicated by the digital temperature gauge on the control panel.

Features of the Euro Industries bvba Digester System Low profile rectangular tank which may be partially or fully buried and is sympathetic to planning requirements. Durable well-proven materials for digester construction. Effective low-power gas mixing system proven on high solids wastes. Removable inox heat-exchangers without process decommissioning. Reduced pumping duty. Modular design. Low cost multi-stage option for process flexibility. The Euro Industries digesters are made with isolated polyester roof elements for easy access, mounting of all equipment and complete gas closed for a pressure of 20 mbar.

The Euro Industries Digester System is a cost effective method of waste treatment that can produce valuable by-products Recycling of organic wastes reduces depend on artificial fertilisers and reduces the consumption of non renewable resources. Production and sale of by-products from digested waste can make a significant contribution to the economic viability of a waste treatment system. Co-generation of electricity and hot water.

SRS CONTINUOUS RENDERING SYSTEM

The Euro Industries Continuous Rendering System is designed for processing organic waste from slaughterhouses. The SRS Rendering System is a key component and build as a compact unit. It is manufactured in three sizes with capacities of 500, 1.000 and 2.000 kilograms per hours. The organic wastes are fed continuously to shredders, sterilisation and Pentra Dryer where they are reduced in particle size, heated and transported to the sterilisation and Pentra Dryer in order to ensure the highest possible product quality conform to the legislation concerning sterilisation time, pressure and temperature. The problem In most cases, at this moment the blood, flotation sludges soft offals, hairs and other waste material from a slaughterhouse are collected for central treatment or rendering at high cost. The circumstances to treat the waste materials at site are changed. We offer the possibility to treat the waste at site at low cost, no smell and no noise. The result is to obtain a serious volume reduction and valuable material that can

be used as pet food or as fertilizer direct after the treatment in the SRS unit.

How does the SRS unit work ? The equipment for the treatment of blood, single or together with other organic waste is based on the idea that a complete closed system can not produce any smell during the treatment. An industrial process that recovers a product within the new legislation of the EU for pet food or fertilizer. The idea of our engineers was to develop an equipment that could treat the waste materials at an acceptable price in a continuous process and at a very low level of cost for maintenance and operation. The SRS unit can work in a continuously automatic operation, during 24 hours per day. For the complete equipment a minimum of space is required. The complete equipment does fit in two 40 feet containers.

Comparison of different rendering processes The conditions of each different rendering system have a considerable effect on the materials and energy requirements and also on the properties of the final product.

Batch versus continuous systems Batch and continuous rendering systems each have advantages and disadvantages. A batch rendering system cooks, pressurizes, and sterilizes in the same vessel. The following major disadvantages of batch systems are:

PENTA DRYER

The organic waste, coagulated and pre-dewatered, blood, offals, sludge, hairs, feathers and other solids are pressed into the step of sterilisation. The sterilisation is a continuous sterilisation type, with a guaranteed sufficient retention time of minimum 20 minutes, at a minimum pressure of 3 bar and a minimum temperature of 133,3 C. This means that the system is completely conform to the minimum levels of the new EC legislation. After the coagulation and sterilisation the product will be treated in the next step by a centrifuge, this means that the materials are almost dry when they come out of the centrifuge. The dry substance after the centrifuge is around 40 %. The warm liquids coming from the centrifuge are collected in the waste warm liquids tank and are used for pre-warming the incoming organic waste. All energy is almost completely re-used. After the continues treatment in the centrifuge the materials are collected in a closed hopper before the final drying steps. The condensates returning of the Penta Dryer system is approx. 90 C. and returned to the steam boiler. The last part of the installation is the cooling screw conveyor, to cool down the meal coming from the Penta Dryer. The vapours from the Penta Dryer are send to an air condensers. This condenser collects all the vapours and after cooling the condensate the water is returned to the waste water treatment system.

Fat is darker. The high cooking and pressing temperature produces fines which pass into fat. Carcass materials must be cut and washed otherwise it generates a loss of fat and protein and adds water to the raw material. Since batch rendering processes are not contained in enclosed vessels, there is increased potential for re-contaminated of cooked products, and plant sanitation is more difficult. It is difficult to control the end point of the cooking process. There is a high consumption of steam if vent steam is not recovered as hot water. Finally it is a labor-intensive process.

Continuous system advantages Continuous systems consist of a single cooker. Continuous systems usually have a higher capacity than batch systems. Continuous systems occupy considerably less space than batch cooker systems of equivalent capacity, thus saving construction costs. Single-cooker units are inherently more efficient than multiple-cooker units in terms of steam consumption. Thus, continuous systems achieve a significant savings in fuel usage by the boilers. Likewise, less electric power is consumed for agitation in the single continuous cooker units. They are labor-efficient Continuous systems are more conductive to computerized control through centers located inside environmentally controlled rooms. Such control centers feature process control panels, which provide a schematic flow diagram of the entire process; indicator lights show. Whether individual equipment components are on or off. Process microcomputers control all start/stop operations in an interlocking sequence, adjust the speeds of computerized control through centers located inside environmentally controlled rooms. Such the key equipment parts, and control various process elements to optimize plant operation.

Features of the Euro Industries SRS Rendering System Less space required. Durable well-proven materials for SRS construction. Effective low-power and energy consumption. Fully automatic operation, saving on maintenance and operation cost. Containerised Modular design. Production of tallow and meal of high quality The meal fat is about 5 - 8% Approximately 40% less steam is used compared with batch rendering The SRS unit answers completely to the recent developments and legislation in the field of treatment of organic waste, more specific the new classification and the hygienic demands versus the destination of the product.

General Compared a conventional batch dry rendering method using screw press defatting to a continuous wet rendering method using centrifugal defatting for processing inedible raw material (76,5% soft offal, 15 % industrial bones, and 8.5% swine cadavers) there are several features.

Te

ch

n ic

fo r

qu

al i

ty

an

dp

WASTE MANAGEMENT

Hof ten Bergestraat 7 2381 Weelde - Belgium Tel . +32(0)14 65 66 67 E-mail: info@euroindustries.be

er

f or

ma

nc

8

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- NJ Mpje PDFDocument168 pagesNJ Mpje PDFPatrick Mata100% (3)

- Build Your Own Garden Pond PDFDocument10 pagesBuild Your Own Garden Pond PDFMwagaVumbiPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Recrystallization NotesDocument9 pagesRecrystallization NotesanrychoPas encore d'évaluation

- 101 Madani PearlsDocument42 pages101 Madani PearlsMuhammad WajeehPas encore d'évaluation

- Predicting Production Performance of A Field With Complex Reservoir Heterogeneities Undergoing Water Injection - A Case Study of A Niger-Delta FieldDocument14 pagesPredicting Production Performance of A Field With Complex Reservoir Heterogeneities Undergoing Water Injection - A Case Study of A Niger-Delta FieldnoorPas encore d'évaluation

- Sistema de Lubricacion Emd 645Document21 pagesSistema de Lubricacion Emd 645Adriana Rojas VerasteguiPas encore d'évaluation

- Chapter 5 FiltrationDocument26 pagesChapter 5 FiltrationRalph Evidente100% (1)

- 8 Grade Chemistry Unit Review: Name: Teacher: Date: Laylee Taghizadeh Stegemann April 19, 2021Document4 pages8 Grade Chemistry Unit Review: Name: Teacher: Date: Laylee Taghizadeh Stegemann April 19, 2021Laylee TaghizadehPas encore d'évaluation

- Sewing ThreadsDocument27 pagesSewing ThreadsRikhil NagpalPas encore d'évaluation

- Questionnaire Hip ImplantDocument3 pagesQuestionnaire Hip ImplantAli AkhterPas encore d'évaluation

- Questionnaire FlangeJjointsDocument7 pagesQuestionnaire FlangeJjointsAli AkhterPas encore d'évaluation

- Employment BenefitsDocument44 pagesEmployment BenefitsSharmila BalasubramaniPas encore d'évaluation

- CH 2Document14 pagesCH 2Ali AkhterPas encore d'évaluation

- Product Design ProcessDocument1 pageProduct Design ProcessAli AkhterPas encore d'évaluation

- Need Identification and Problem DefinitionDocument17 pagesNeed Identification and Problem DefinitionAli AkhterPas encore d'évaluation

- Presentation 1Document3 pagesPresentation 1Ali AkhterPas encore d'évaluation

- Mos Projects: DeadlinesDocument1 pageMos Projects: DeadlinesAli AkhterPas encore d'évaluation

- Timetable Spring 2013Document3 pagesTimetable Spring 2013Ali AkhterPas encore d'évaluation

- LECT-Ch 2-Design and Concurrent EnggDocument20 pagesLECT-Ch 2-Design and Concurrent EnggAli AkhterPas encore d'évaluation

- Ch-1 Engineering DesignDocument18 pagesCh-1 Engineering DesignAli AkhterPas encore d'évaluation

- Proposal For HRM PresentationDocument1 pageProposal For HRM PresentationAli AkhterPas encore d'évaluation

- Design in EngineeringDocument17 pagesDesign in EngineeringAli AkhterPas encore d'évaluation

- Product Design and Design ProcessDocument61 pagesProduct Design and Design ProcessAli AkhterPas encore d'évaluation

- Waste 2 Water Food Waste Digester BrochureDocument4 pagesWaste 2 Water Food Waste Digester BrochureAli AkhterPas encore d'évaluation

- Blessings of SalahDocument58 pagesBlessings of SalahAli Asghar AhmadPas encore d'évaluation

- MOS Projects OldDocument13 pagesMOS Projects OldAli AkhterPas encore d'évaluation

- ReadmeDocument1 pageReadmeAli AkhterPas encore d'évaluation

- 19 Darood-O-SalamDocument12 pages19 Darood-O-SalamNazeerPas encore d'évaluation

- Current Students Allotment ListDocument17 pagesCurrent Students Allotment ListAli AkhterPas encore d'évaluation

- 1 2 3 4 5 6 7 8 Total 0 0: Semester Sgpa Credit HoursDocument1 page1 2 3 4 5 6 7 8 Total 0 0: Semester Sgpa Credit HoursAli AkhterPas encore d'évaluation

- List of Countries Included in The Quota SchemeDocument2 pagesList of Countries Included in The Quota SchemeAlex TefovPas encore d'évaluation

- Five Year Academic CalenderDocument5 pagesFive Year Academic CalenderAli AkhterPas encore d'évaluation

- Letter of ReferenceDocument1 pageLetter of ReferenceAli AkhterPas encore d'évaluation

- Dawat-E-Islami: Namaz Timings: Topi, PakistanDocument12 pagesDawat-E-Islami: Namaz Timings: Topi, PakistanAli AkhterPas encore d'évaluation

- Project CharterDocument3 pagesProject CharterAli AkhterPas encore d'évaluation

- Ahle Sunnah Tauheed and ShirkDocument18 pagesAhle Sunnah Tauheed and ShirkTariq Mehmood TariqPas encore d'évaluation

- Time TableDocument1 pageTime TableAli AkhterPas encore d'évaluation

- Solution Chemistry OPTandonDocument24 pagesSolution Chemistry OPTandonCaleb AsharleyPas encore d'évaluation

- TSADocument44 pagesTSAdraj1875977Pas encore d'évaluation

- MSDS - Prominent-GlycineDocument6 pagesMSDS - Prominent-GlycineTanawat ChinchaivanichkitPas encore d'évaluation

- Automated Sorting of Polymer Flakes Fluorescence Labeling and Development of A Measurement System PrototypeDocument12 pagesAutomated Sorting of Polymer Flakes Fluorescence Labeling and Development of A Measurement System PrototypeSəkinə ƏliyevaPas encore d'évaluation

- Appendix C - ART Windcube Lidar v2.1 Maintenance - v02Document2 pagesAppendix C - ART Windcube Lidar v2.1 Maintenance - v02Vo Quang Kiet (ヴォー クァン キエット)Pas encore d'évaluation

- Copper Sulphate Penta HydrateDocument2 pagesCopper Sulphate Penta HydrateBLi'H'Abiee100% (1)

- The Soil. Physical, Chemical and Biological Properties: Cations/soils-GlossaryDocument13 pagesThe Soil. Physical, Chemical and Biological Properties: Cations/soils-GlossaryAr Chandra MauliPas encore d'évaluation

- Bacterial ConjugationDocument5 pagesBacterial ConjugationPrasenjit VighnePas encore d'évaluation

- WWW - Studyguide.pk: AS Physics - Revision Notes Unit 2 - Electricity and Thermal PhysicsDocument3 pagesWWW - Studyguide.pk: AS Physics - Revision Notes Unit 2 - Electricity and Thermal PhysicsHany ElGezawyPas encore d'évaluation

- 316 On 6mo - White PaperDocument13 pages316 On 6mo - White Papermarvin_slPas encore d'évaluation

- Govpub C13Document12 pagesGovpub C13Manush SekaranPas encore d'évaluation

- 0620 m23 QP 22-MinDocument14 pages0620 m23 QP 22-Minjelani17fPas encore d'évaluation

- Äèàìåòð Ñòàëè Ïðåä. Îòêë. ÏÎ Äèàìåòðó Ñòàëè Êâàëèòåòîâ h5 h11 h10 h9 h8 h7 h6 h12Document7 pagesÄèàìåòð Ñòàëè Ïðåä. Îòêë. ÏÎ Äèàìåòðó Ñòàëè Êâàëèòåòîâ h5 h11 h10 h9 h8 h7 h6 h12TetianaPas encore d'évaluation

- Fruits150058 PDFDocument21 pagesFruits150058 PDFJimantolo AjiPas encore d'évaluation

- Manufacture of Soap From Fatty AcidsDocument4 pagesManufacture of Soap From Fatty Acidsראול אפונטהPas encore d'évaluation

- Hepatoprotective Activity of Aqueous Extract of Channa Striatus (Haruan) On Co-Amoxiclav-Induced Liver Damage in Adult Male Sprague-Dawley RatsDocument21 pagesHepatoprotective Activity of Aqueous Extract of Channa Striatus (Haruan) On Co-Amoxiclav-Induced Liver Damage in Adult Male Sprague-Dawley RatsLet BorlagdanPas encore d'évaluation

- Efinal Format AppendicesDocument13 pagesEfinal Format AppendicesRRPas encore d'évaluation

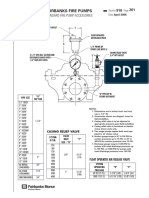

- Fire Pump AccessoriesDocument23 pagesFire Pump AccessoriesMuhammad ArslanPas encore d'évaluation

- Modal FibreDocument10 pagesModal Fibresaran7ran100% (5)

- Smaw 12 Module 1Document7 pagesSmaw 12 Module 1Francis Rico Mutia RufonPas encore d'évaluation

- Safety CatalogDocument107 pagesSafety CatalogMiguel G V PPas encore d'évaluation

- L. Saavedra, E. M. Hebert, C. Minahk, P FerrantiDocument49 pagesL. Saavedra, E. M. Hebert, C. Minahk, P FerrantiLeidy UribePas encore d'évaluation