Académique Documents

Professionnel Documents

Culture Documents

Grasim Industries Limited Material Enquiry Enquiry Number:1101300888/119 Enquiry Date: 05.04.2013 Bid Closing: 08.04.2013

Transféré par

Aparna SingotiaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Grasim Industries Limited Material Enquiry Enquiry Number:1101300888/119 Enquiry Date: 05.04.2013 Bid Closing: 08.04.2013

Transféré par

Aparna SingotiaDroits d'auteur :

Formats disponibles

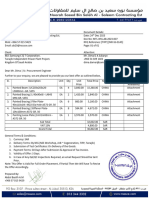

GRASIM INDUSTRIES LIMITED

STAPLE FIBRE DIVISION BIRLAGRAM, NAGDA Pin Code : 456331 Telephone No : 7366-246760-66 Fax No : 7366-247160/244114 http://www.birlavsf.com

Material Enquiry

FSTO-05

Enquiry Number :1101300888/119 Enquiry Date : 05.04.2013 Bid Closing : 08.04.2013

Vendor No.- 2500065 M. FABRICATION 26, SHIVPURARATLAM PHATAK, NAGDA - 456335 E-mail : m_fabricators@yahoo.co.in Phone No : 9425091263 Fax No:

Kind Attention : MR. M. SINGOTIA

Contact Person : NILESH JAIN Phone : 07366-255209(... Email : nilesh.j@adityabirla.com

Sub : Enquiry for submission of Offer Kindly Send your offer as per the terms and conditions specified below 1. Rates to be quoted only for the items mentioned in the enquiry, as per unit measure specified. However, if there is any deviation please mention the same in remarks column. 2. All cost elements like discount, P&F charges, Freight charges, Excise duty,Payment terms etc to be speficied clearly. 3. It is presumed that seller will furnish duplicate copy of excise invoice for availing CENVAT credit. Wherever applicable & please indicate the %, amount & unit (per unit). 4. The vendor should send regret intimation in case he is unable to quote against the enquiry clearly mentioning the reason in remark column. 5. The offer shall be valid for a minimum period of 90 days. 6. Make / Brand to be specifed where ever required. 7. The vendor should give the reference No. of our order in the remark column if he has supplied the item earlier. 8. The offer to be sent to us duly filled,signed & stamped by the vendor. 9. All Drawings / Samples / Catalogues wherever applicable sent with the enquiry to be returned to us along with the offer. 10. ONLY QUOTATIONS RECIEVED WITHIN ON OR BEFORE DUE DATE SHALL BE CONSIDERED. No. PR No. Item Code Item Description 1 50070046 1000005619 DISMENTALLNG & REPARING OF CATION EXCHAN ON SITE REPAIRING OF CATION EXCHANGER UNIT-1 AT DEMIN PLANT. SCOPE OF WORK INCLUDES1 DISMENTALLING OF MS CATION EXCHANGER MAN HOLES NIPPLES PIPINGS,PLATFORM AND DISH END. 2 CUTTING AND REMOVAL OF NOZZLE PLATE INSID TANK. 3 CUTTING OF NOZZLE PLATE SUPPORTS. 4 CUTTING OF SIDE SHELL PLATES AS PER REQUIREMENT. 5 REMOVAL OF OLD SCRAP MATERIAL FROM TANK AND SENT TO SCRAP YARD 6 FABRICATION OF NEW NOZZLE PLATES IN SEGMENTS AS PER DRAWING. 7 REPLACEMENT OF NOZZLE PLATE MS SUPPORTS <(>&<)> OTHER NIPPLES 8 INSTALLATION OF NEW NOZZLES PLATE ,IN SEGMENTS AS PER REQUIREMENTS 9 COMPLTE WELDING OF NOZZLE PLATE FROM BOTH ENDS. 10 INSTALLATION OF SIDE WALL PLATES , DISH END , PIPING AND NIPPLES BY WELDING . 11 GRINDING OF NOZZLE PLATE AND SHELL PLATE WELDING TO SUIT THE RUBBER LINING WORK. 12 HYDRO TESTING OF UNIT AFTER COMPLETION OF JOBS. 13 ALL TOOLS TACKELS <(>&<)> SAFETY EQUIPMENTS SHALL BE IN VENDOR SCOPE 14 ALL CONSUMABLES LIKE GAS, WELDING ELECTRODES IN VENDOR SCOPE 15 ALL STRUCTURAL STEEL MATERIAL SHALL BE SUPPLIED BY GRASIM. 16 ALL DRILLING JOBS OF NOZZLE PLATES DONE BY VENDOR . Quantity 1.000 UOM NO Rate

For STAPLE FIBRE DIVISION Authorised Signature

Vous aimerez peut-être aussi

- Schneider QuotationDocument12 pagesSchneider QuotationSumit Gadgilwar80% (10)

- InsulationDocument63 pagesInsulationSH1961Pas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- API 570 Piping InspectionDocument35 pagesAPI 570 Piping InspectionIrvansyah Razadin100% (9)

- GUS Trash Feasibility StudyDocument504 pagesGUS Trash Feasibility StudyDaily FreemanPas encore d'évaluation

- Quotation SS20220113 PCC PANEL PDFDocument2 pagesQuotation SS20220113 PCC PANEL PDFsunil halvadiyaPas encore d'évaluation

- 2013 Price ListsfDocument99 pages2013 Price Listsfrarunr1Pas encore d'évaluation

- SEC5 (1) WashpipeDocument22 pagesSEC5 (1) WashpipeCarlos Alberto PerdomoPas encore d'évaluation

- Panga SSB Camp QuotationDocument3 pagesPanga SSB Camp QuotationSaptarishi BhattacharjeePas encore d'évaluation

- Gillanders Arbuthnot & Co., LTD.: Micco DivisionDocument1 pageGillanders Arbuthnot & Co., LTD.: Micco DivisionSouvik DeyPas encore d'évaluation

- Request For Proposal in Two Bid System: Wncgoamo-Navy@nic - inDocument18 pagesRequest For Proposal in Two Bid System: Wncgoamo-Navy@nic - inmsadithianPas encore d'évaluation

- Left End View 1:1: 2637 - STP01 Strip Layout .. Summit Tool DesignDocument7 pagesLeft End View 1:1: 2637 - STP01 Strip Layout .. Summit Tool Designmanojsh8887Pas encore d'évaluation

- PO 20130916-01 For InvestaDocument10 pagesPO 20130916-01 For Investavinodkhare2007Pas encore d'évaluation

- Material Spec/ PriceDocument55 pagesMaterial Spec/ PriceSaravanan ManiPas encore d'évaluation

- SSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurDocument6 pagesSSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurMohit DagaPas encore d'évaluation

- Quotation Electrical ItemsDocument5 pagesQuotation Electrical ItemsSharafat Ali67% (3)

- C-s101 Dd3 Structural NotesDocument1 pageC-s101 Dd3 Structural Notesanthony christian yangPas encore d'évaluation

- DownloadDocument29 pagesDownloaddeepak.kumarPas encore d'évaluation

- Jarandeshewar Sugar Mills PVT LTD, Chimangaon: Item Name Unit Item Code SR No Req. NoDocument1 pageJarandeshewar Sugar Mills PVT LTD, Chimangaon: Item Name Unit Item Code SR No Req. NoKRISHNAPas encore d'évaluation

- PQ 0043760Document2 pagesPQ 0043760juandlc3368Pas encore d'évaluation

- Jegatheesh Rice Mill Srilanka 50 TPB QTN RmeshDocument5 pagesJegatheesh Rice Mill Srilanka 50 TPB QTN RmeshmayurupanPas encore d'évaluation

- Quotation CT PT Isolator VCB AB Switch Drop Out Fuse Set TPMO SMC LT Distribution BoxDocument3 pagesQuotation CT PT Isolator VCB AB Switch Drop Out Fuse Set TPMO SMC LT Distribution BoxSharafatPas encore d'évaluation

- Sample Tender DocumentDocument26 pagesSample Tender DocumentAnish BabuPas encore d'évaluation

- Petroleum Development Oman L.L.CDocument11 pagesPetroleum Development Oman L.L.Cvishnu RajPas encore d'évaluation

- Sub:Procurement Of11Kv, 3 Core, Pvcarmoured Power Cables. Ref.: (I) Adv. No. 03/2016-17, Tender Si No019Document22 pagesSub:Procurement Of11Kv, 3 Core, Pvcarmoured Power Cables. Ref.: (I) Adv. No. 03/2016-17, Tender Si No019okman17Pas encore d'évaluation

- LV Room PDFDocument1 pageLV Room PDFMuhammad Abubakar QureshiPas encore d'évaluation

- 43 National Aerospace LaboratoriesDocument3 pages43 National Aerospace LaboratoriesmanjunathaindustriesPas encore d'évaluation

- Commercial RFQ 6854Document2 pagesCommercial RFQ 6854Goody Freking FuttonPas encore d'évaluation

- ITP Structural SteelDocument14 pagesITP Structural SteelNavneet SinghPas encore d'évaluation

- Pump Data Sheet - 0410-PPC-0069 - 0070Document3 pagesPump Data Sheet - 0410-PPC-0069 - 0070Jorge Jesus Nayhua GamarraPas encore d'évaluation

- PR RbiaDocument25 pagesPR RbiaDexter G. BatalaoPas encore d'évaluation

- GMV 263Document2 pagesGMV 263bashok20Pas encore d'évaluation

- 2019 NTB Specificatons For The Supply of Schwing Pump PartsDocument23 pages2019 NTB Specificatons For The Supply of Schwing Pump PartsSamehPas encore d'évaluation

- Us FlyerDocument68 pagesUs FlyerMiltongrimi GrimilPas encore d'évaluation

- Gscontrol Offer of Fire Fighting PanelDocument5 pagesGscontrol Offer of Fire Fighting PanelGautam MishraPas encore d'évaluation

- 007.MTL-NSS-AB-2023-007 - Quotation For SS Fabrication & Coating - MR-SS-0145Document1 page007.MTL-NSS-AB-2023-007 - Quotation For SS Fabrication & Coating - MR-SS-0145abasithamPas encore d'évaluation

- 11-6233 Qt.Document4 pages11-6233 Qt.Avoor KhanPas encore d'évaluation

- RFQ 1101832113Document13 pagesRFQ 1101832113Soumyakanti S. Samanta (Pgdm 09-11, Batch II)Pas encore d'évaluation

- GRP TankDocument3 pagesGRP TankAdnan AkhtarPas encore d'évaluation

- Kiran Data-Quot 1Document1 pageKiran Data-Quot 1MangeshPas encore d'évaluation

- Gsecl Tenders 2ndDocument7 pagesGsecl Tenders 2ndSales JaincoRefPas encore d'évaluation

- Alberg Cutting Tool 2002 PDFDocument28 pagesAlberg Cutting Tool 2002 PDFApichat1967Pas encore d'évaluation

- Quotation-415 PCC Switchgear Panel & Other Items-BHELDocument4 pagesQuotation-415 PCC Switchgear Panel & Other Items-BHELSharafat AliPas encore d'évaluation

- Absolute Distillery 2020 - 030Document3 pagesAbsolute Distillery 2020 - 030Monkey GamerPas encore d'évaluation

- Jyoti Quote.Document2 pagesJyoti Quote.Mohit BansalPas encore d'évaluation

- PQ 0043361Document2 pagesPQ 0043361Divino Edgar LacambraPas encore d'évaluation

- 22-257 NotesDocument2 pages22-257 NotesSumit MishraPas encore d'évaluation

- Hacksaw BladeDocument12 pagesHacksaw BladeShankar GPas encore d'évaluation

- Little Green BookDocument73 pagesLittle Green BookghedjioskPas encore d'évaluation

- RFQ SmartformDocument1 pageRFQ SmartformAmey KadamPas encore d'évaluation

- Cable Tray & AccessoriesDocument11 pagesCable Tray & AccessoriesVikas TanejaPas encore d'évaluation

- Regal Roots - Grading and Sorting MachineryDocument14 pagesRegal Roots - Grading and Sorting MachineryAkshay JadhavPas encore d'évaluation

- MPLC Pro 786 1063Document2 pagesMPLC Pro 786 1063Muhammad Shoaib Aslam KhichiPas encore d'évaluation

- Purchase Order OriginalDocument3 pagesPurchase Order OriginalNayan VyasPas encore d'évaluation

- PQ 0044821Document2 pagesPQ 0044821Divino Edgar LacambraPas encore d'évaluation

- CS - FS - PSF - ACF QuotationDocument4 pagesCS - FS - PSF - ACF Quotationkiran raghukiranPas encore d'évaluation

- AV Steel Amended Po CGLDocument24 pagesAV Steel Amended Po CGLNirmit GandhiPas encore d'évaluation

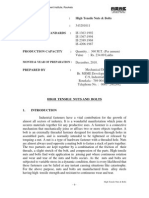

- High Tensile Nuts BoltsDocument10 pagesHigh Tensile Nuts BoltssagarhalappaPas encore d'évaluation

- GMV 324Document2 pagesGMV 324bashok20Pas encore d'évaluation

- PQ 0047043Document2 pagesPQ 0047043Divino Edgar LacambraPas encore d'évaluation

- Bhagwan Singh Patidar - Appointment LetterDocument3 pagesBhagwan Singh Patidar - Appointment LetterAparna SingotiaPas encore d'évaluation

- Amlawdabika Dam Labour Chart: Date Labour Time Dutey Hours O.T. Hours Total Hours Total MandaysDocument6 pagesAmlawdabika Dam Labour Chart: Date Labour Time Dutey Hours O.T. Hours Total Hours Total MandaysAparna SingotiaPas encore d'évaluation

- Adalat SystemDocument47 pagesAdalat SystemAparna Singotia0% (3)

- Adalat SystemDocument27 pagesAdalat SystemAparna SingotiaPas encore d'évaluation

- Final Vivek PDFDocument31 pagesFinal Vivek PDFAparna SingotiaPas encore d'évaluation

- Final Vivek PDFDocument31 pagesFinal Vivek PDFAparna SingotiaPas encore d'évaluation

- Final ThesisDocument394 pagesFinal ThesisAparna Singotia67% (3)

- AparnaDocument3 pagesAparnaAparna SingotiaPas encore d'évaluation

- Cognitive Dissonance and Affect An Initial Test of A Connectionist AccountDocument28 pagesCognitive Dissonance and Affect An Initial Test of A Connectionist AccountAparna SingotiaPas encore d'évaluation

- HR Acts 115Document17 pagesHR Acts 115Aparna SingotiaPas encore d'évaluation

- NEHADocument29 pagesNEHAAparna SingotiaPas encore d'évaluation

- Cognitive Dissonance and Affect An Initial Test of A Connectionist AccountDocument28 pagesCognitive Dissonance and Affect An Initial Test of A Connectionist AccountAparna SingotiaPas encore d'évaluation

- HR Acts 115Document17 pagesHR Acts 115Aparna SingotiaPas encore d'évaluation

- HR Acts 115Document17 pagesHR Acts 115Aparna SingotiaPas encore d'évaluation

- IntroductionDocument3 pagesIntroductionAparna SingotiaPas encore d'évaluation

- Fire Insurance: Presented By: Bal Krishna Dhakad Ashish Kaithwas Babita Malviya Devendra Singh ChouhanDocument13 pagesFire Insurance: Presented By: Bal Krishna Dhakad Ashish Kaithwas Babita Malviya Devendra Singh ChouhanAparna SingotiaPas encore d'évaluation

- Dove PresentationDocument16 pagesDove PresentationHira NasimPas encore d'évaluation

- FT 130405081496Document1 pageFT 130405081496Aparna SingotiaPas encore d'évaluation

- M.B.A. (Financial Services) : Course Curriculum Semesters I, II, III & IV 2010-12Document28 pagesM.B.A. (Financial Services) : Course Curriculum Semesters I, II, III & IV 2010-12Aparna SingotiaPas encore d'évaluation

- Marine Policies: - Harshit PatelDocument13 pagesMarine Policies: - Harshit PatelAparna SingotiaPas encore d'évaluation

- Hydro Test ProcedureDocument17 pagesHydro Test Procedureyaser elgoharyPas encore d'évaluation

- Sulphur and Its CompoundsDocument3 pagesSulphur and Its CompoundsvinayncskphbPas encore d'évaluation

- Dow Corning 111 Valve Lubricant and Sealant 10.15.10Document7 pagesDow Corning 111 Valve Lubricant and Sealant 10.15.10Syifa Alfi HabibiPas encore d'évaluation

- How To Stack Concrete Paving Moulds For The Best CuringDocument3 pagesHow To Stack Concrete Paving Moulds For The Best Curing7vortex9Pas encore d'évaluation

- Mitsubishi FV DrivelineDocument10 pagesMitsubishi FV Drivelinejs1290Pas encore d'évaluation

- Cromato AmarilloDocument3 pagesCromato Amarillohumbertotorresr100% (1)

- Full Download Automation Production Systems and Computer Integrated Manufacturing 4th Edition Groover Solutions ManualDocument36 pagesFull Download Automation Production Systems and Computer Integrated Manufacturing 4th Edition Groover Solutions Manualardellazusman100% (37)

- Separating Substances Virtual LabDocument4 pagesSeparating Substances Virtual LabColin ClarkPas encore d'évaluation

- Robotics SyllabusDocument1 pageRobotics SyllabusdsathiyaPas encore d'évaluation

- Pegler General Valves PDFDocument124 pagesPegler General Valves PDFtrija_mrPas encore d'évaluation

- 2701 MSDSDocument5 pages2701 MSDSAhmed Emad AhmedPas encore d'évaluation

- Shell Lubricants Tco Manufacturing PaperDocument13 pagesShell Lubricants Tco Manufacturing PaperNokiabhre WijayaPas encore d'évaluation

- Instruction: Check The Circle That Corresponds To Your AnswerDocument2 pagesInstruction: Check The Circle That Corresponds To Your AnswerXyrile InguilloPas encore d'évaluation

- Chapter 3 Maintenance PoliciesDocument50 pagesChapter 3 Maintenance Policiesrobel metikuPas encore d'évaluation

- Two Point CoilingDocument36 pagesTwo Point CoilingfarfromfreedPas encore d'évaluation

- Layout Room INDUSTRI FARMASIDocument1 pageLayout Room INDUSTRI FARMASIDwi MeliniaPas encore d'évaluation

- Trusses II Queenpost TrussesDocument11 pagesTrusses II Queenpost TrussesCristian Morar-BolbaPas encore d'évaluation

- 951-170-214 EN TCM 12-99714Document44 pages951-170-214 EN TCM 12-99714AlvaroPas encore d'évaluation

- Operation and Service Manual For Hermetic Utimeter Gtex ChemDocument78 pagesOperation and Service Manual For Hermetic Utimeter Gtex ChemMAXPas encore d'évaluation

- Catálogo Espesadores PDFDocument14 pagesCatálogo Espesadores PDFMax Gonzalez Cortes100% (1)

- Farrat Plate BrochureDocument12 pagesFarrat Plate BrochureShaneLinehanPas encore d'évaluation

- A Finite Difference Numerical Analysis of Galvanic Corrosion For Semi-InfiniteDocument7 pagesA Finite Difference Numerical Analysis of Galvanic Corrosion For Semi-InfiniteThiagoCarvalhoPas encore d'évaluation

- Oilgear Designers HandbookDocument250 pagesOilgear Designers HandbookMarco Hernandez100% (1)

- Study and Experimentation of Autoclaved Aerated Concrete by Using Fly AshDocument5 pagesStudy and Experimentation of Autoclaved Aerated Concrete by Using Fly AshInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Material Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Document3 pagesMaterial Safety Data Sheet (MSDS) : EMERGENCY: 800-424-9300Darius DsouzaPas encore d'évaluation

- HeaterDocument12 pagesHeaterErwin Paulian SihombingPas encore d'évaluation

- 10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsDocument3 pages10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsVignesh RajanPas encore d'évaluation

- MT6050i 8050i Installation 101102Document8 pagesMT6050i 8050i Installation 101102gabyPas encore d'évaluation