Académique Documents

Professionnel Documents

Culture Documents

Traxxas Revo Slipper Rebuild

Transféré par

bernadysroseDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Traxxas Revo Slipper Rebuild

Transféré par

bernadysroseDroits d'auteur :

Formats disponibles

Slipper Clutch Rebuild Instructions

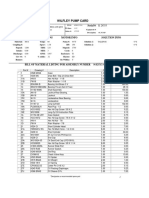

Remove Engine and Exhaust Loosen the set screw that secures the pipe hanger to the exhaust pipe. Remove the four cap head screws that secure the engine to the engine mount. Remove the air filter from the carburetor to aid in the removal of the engine. Push the engine slightly forward until the throttle arm on the carburetor slides out of the fork of the throttle bell crank. Carefully move the engine and exhaust system aside to access the spur gear. Install Rebuilt Kit Insert a 2.0mm hex wrench into the end of the slipper shaft to lock the shaft. Remove the slipper nut by turning the nut counterclockwise with the 8.0mm open-end wrench supplied inside the Revo instruction pack. Remove the slipper assembly from the slipper shaft. Note: The slipper hub (closest to the transmission) may be left on for this procedure. Remove the used pads from the pressure plate and replace them with the new pads from the rebuilt kit. The pads are placed onto the pressure plate by keying into the molded pins on the plate. Install the new steel slipper disc, clutch shoe assembly, and the rest of the slipper components onto the slipper shaft using the diagram below.

5352 (5.0 NL 4147)

Covers Part #5352

Reinstall Spur Gear and Engine Repeat the previous steps in reverse order to reinstall the spur gear and engine onto the Revo. Pay close attention to the orientation of the spur gear. The heads of the screws should fit snugly inside of the plastic fingers that are molded into the spur gear. The text located on the face of the spur gear should face away from the transmission. Remember to secure the yellow EZ-Start ground wire to the engine block with one of the inside engine mount screws. Adjusting the Slipper Clutch The slipper clutch can be adjusted to suit many different surface conditions and driving styles. Adjust slipper to Limit wheel spin for loose conditions. Keep the front wheels on the ground under heavy acceleration on high-bite surfaces. Protect the drivetrain from sudden impact or shock loads (such as landing from a jump with the engine under acceleration. Base slipper setting Use the 2.0mm hex wrench to hold the slipper shaft and the 8.0mm open end wrench to tighten the slipper nut. Tighten the slipper until you can just slowly turn the spur gear by hand while locking the slipper shaft. This a good starting point to protect the drivetrain from shock loads. Make further adjustments to suit your driving conditions. Do not make adjustments to the slipper clutch any larger than 1/8 turn at a time. Caution: Do not tighten the slipper to the point of eliminating slippage. This can permanently damage the slipper components.

5116 5x11 BB 5352 5352 2554 3x6 CS 5351 5352 5352 5351 3954 38-T 3953 opt. 36-T 3955 opt. 40-T 5367

Pay close attention to the orientation of the spring washers. Correct orientation of the spring washers is critical to proper performance of the slipper and to avoid damaged to the seal ball bearing inside the slipper system. Attach the threaded slipper nut until its slightly snug. Important: Do not over tighten the slipper nut. Refer to Adjusting the Slipper Clutch instructions above.

5352 (5.0 NL 4147)

If you have questions or need technical assistance, call Traxxas at

5116 5x11 BB 5352 Correct orientation on shaft

1- 8 8 8 - T R A X X A S

(1-888-872-9927) (U.S. residents only) Form 5352INST Rev 040723

www.TRAXXAS.com

Traxxas, 1100 Klein Road, Plano, TX 75074, Phone: 972-265-8000, Fax: 972-265-8011, e-mail: support@Traxxas.com

Vous aimerez peut-être aussi

- 2 Gear LinkageGolf Mk1Document46 pages2 Gear LinkageGolf Mk1SteggosPas encore d'évaluation

- Agri-Fab, Craftsman Front Mount DethatcherDocument12 pagesAgri-Fab, Craftsman Front Mount DethatcherKevins Small Engine and Tractor ServicePas encore d'évaluation

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellPas encore d'évaluation

- Installation Manual Reverse Gear 5 Speed Revision 7Document6 pagesInstallation Manual Reverse Gear 5 Speed Revision 7arieskittenPas encore d'évaluation

- Panthera Motorsports: List of Panthera Parts You NeedDocument10 pagesPanthera Motorsports: List of Panthera Parts You NeedJoe ScaliaPas encore d'évaluation

- rd-m592 2Document1 pagerd-m592 2faizgpPas encore d'évaluation

- SI 6PZRA 003 ENG - v1 - m56577569830677284Document1 pageSI 6PZRA 003 ENG - v1 - m56577569830677284lirch5Pas encore d'évaluation

- Instructions: 6 Speed Transmission Super KitDocument14 pagesInstructions: 6 Speed Transmission Super KitthailanPas encore d'évaluation

- Shimano Brake ManualDocument1 pageShimano Brake ManualscozansPas encore d'évaluation

- Alfa Alfasud 1.3 PDFDocument50 pagesAlfa Alfasud 1.3 PDFnubercard6111100% (1)

- Change Procedure of Hub BearingsDocument4 pagesChange Procedure of Hub BearingsRadu DumbravaPas encore d'évaluation

- GEARBOX MANUAL SF Revision DDocument37 pagesGEARBOX MANUAL SF Revision DaliPas encore d'évaluation

- BHW Balance Shaft Module ReplacementDocument32 pagesBHW Balance Shaft Module Replacementszasz100% (1)

- Manual de Instalacion Angelus 60LDocument15 pagesManual de Instalacion Angelus 60LAnonymous WaC9PaQmr100% (1)

- Steering Gear Manual Rack and PinionDocument4 pagesSteering Gear Manual Rack and PinionJeferson SilvaPas encore d'évaluation

- Jari Chief Manual 2015Document7 pagesJari Chief Manual 2015Dara Donelson100% (1)

- Clutch 95-96 GolfDocument9 pagesClutch 95-96 Golfpedro.tablet.velosoPas encore d'évaluation

- Cams Andrews 99 Gear-01Document4 pagesCams Andrews 99 Gear-01dsgoodrichPas encore d'évaluation

- Avid User Manual Bb7Document2 pagesAvid User Manual Bb7Elizabeth Soares BournePas encore d'évaluation

- Montagem Do Cilindro 422 - 522 enDocument38 pagesMontagem Do Cilindro 422 - 522 enSermenge SermengePas encore d'évaluation

- Clutch ManualDocument16 pagesClutch ManualCO BDPas encore d'évaluation

- Shimano Ultegra 6700 Shifters Double Owners ManualDocument2 pagesShimano Ultegra 6700 Shifters Double Owners ManualTimPas encore d'évaluation

- DL RD m760 2 PDFDocument1 pageDL RD m760 2 PDFtudor-72Pas encore d'évaluation

- Transfer Case Overhaul 1988 Jeep CherokeeDocument9 pagesTransfer Case Overhaul 1988 Jeep CherokeeAhmat Juhairi AriffinPas encore d'évaluation

- Diagnostics of Transmission and Drive Line Components.Document33 pagesDiagnostics of Transmission and Drive Line Components.ashifsha930Pas encore d'évaluation

- Owner'S Manual: Domestic Rotary LawnmowerDocument12 pagesOwner'S Manual: Domestic Rotary LawnmowerBobby ChippingPas encore d'évaluation

- ProLIGHT 2000 Maintenance ManualDocument19 pagesProLIGHT 2000 Maintenance ManualmegclayPas encore d'évaluation

- Steering Axle: Safety Precautions Maintenance and RepairDocument9 pagesSteering Axle: Safety Precautions Maintenance and RepairPhilip Peter HanssenPas encore d'évaluation

- SHEPPARD Kenworth Medium Duty HD94 ALTERNATE Steering-Gear Bleed Procedure 2Document3 pagesSHEPPARD Kenworth Medium Duty HD94 ALTERNATE Steering-Gear Bleed Procedure 2Mas Inyeccion ElectronicaPas encore d'évaluation

- Brake System: 1988 Jeep CherokeeDocument22 pagesBrake System: 1988 Jeep CherokeePreet_Raj_2303Pas encore d'évaluation

- Specifications 5.1: Starter Torque ValuesDocument14 pagesSpecifications 5.1: Starter Torque Valuesvette512Pas encore d'évaluation

- Shimano XTDocument1 pageShimano XTVennia PapadipoulouPas encore d'évaluation

- Shimano Tourney Rear and Knob AdjustmentDocument1 pageShimano Tourney Rear and Knob AdjustmentNiraj SuroopjeetPas encore d'évaluation

- General Clutch InstructionsDocument4 pagesGeneral Clutch InstructionstonythetigerPas encore d'évaluation

- CHEETAH E-SHIFT Pro Series Valve BodyDocument8 pagesCHEETAH E-SHIFT Pro Series Valve BodyhidraulicPas encore d'évaluation

- Www-Mywheelhorse-Com: Power Take-Off Pt-7Document2 pagesWww-Mywheelhorse-Com: Power Take-Off Pt-7theimproviserPas encore d'évaluation

- 1982 Xv750 Rear Wheel Swap Instruction ManualDocument13 pages1982 Xv750 Rear Wheel Swap Instruction ManualCorey St Pierre100% (1)

- MitzuDocument2 pagesMitzuLuis Fabio Aguilar MontoyaPas encore d'évaluation

- GasBike Bicycle Motor Engine Kit 80cc Installation ManualDocument15 pagesGasBike Bicycle Motor Engine Kit 80cc Installation ManualMichael James Webb100% (1)

- Spec Clutch InstallDocument11 pagesSpec Clutch InstallbmxnanithoPas encore d'évaluation

- Front Disk Brakes ConversionDocument4 pagesFront Disk Brakes Conversionzafar11Pas encore d'évaluation

- Install 2Document10 pagesInstall 2chimychanga33Pas encore d'évaluation

- FH FW Skhd3836g En-De Ower ManualDocument19 pagesFH FW Skhd3836g En-De Ower ManualEnrico TondiniPas encore d'évaluation

- Transmission Crankshaft Crank CaseDocument11 pagesTransmission Crankshaft Crank CaseJetion1Pas encore d'évaluation

- Atkinson Tractor Service Shop Manual Unit 2 - TransmissionDocument18 pagesAtkinson Tractor Service Shop Manual Unit 2 - TransmissionDavid Kelly100% (1)

- 80-96 F150 2 1/2" Lift Kit InstructionsDocument4 pages80-96 F150 2 1/2" Lift Kit Instructionsisaacllugo1Pas encore d'évaluation

- POWERBLOCDocument17 pagesPOWERBLOCcyril DESPRATPas encore d'évaluation

- Shimano Disk BrakeDocument1 pageShimano Disk Brakehayleymorris24Pas encore d'évaluation

- Jari Monarch Manual 2015Document7 pagesJari Monarch Manual 2015Dara Donelson100% (1)

- AssemblyDocument105 pagesAssemblyVinh TrinhvinhubPas encore d'évaluation

- WJ 3 Inch Lift InstallDocument3 pagesWJ 3 Inch Lift InstallGuillePas encore d'évaluation

- Drum Brake Installation: TIE DOWN ENGINEERING - 255 Villanova Drive SW - Atlanta, GA 30336Document4 pagesDrum Brake Installation: TIE DOWN ENGINEERING - 255 Villanova Drive SW - Atlanta, GA 30336asterdiscPas encore d'évaluation

- Install Instructions ExedyDocument2 pagesInstall Instructions Exedyrolo210100% (1)

- InstructionsDisc Brake InstallDocument2 pagesInstructionsDisc Brake InstallPeter JasonPas encore d'évaluation

- Front Crankshaft Seal Replacement Mk4 VW ALH and BEW TDI Engine - VW TDI Forum, Audi, Porsche, and Chevy Cruze Diesel ForumDocument10 pagesFront Crankshaft Seal Replacement Mk4 VW ALH and BEW TDI Engine - VW TDI Forum, Audi, Porsche, and Chevy Cruze Diesel ForumAladin MujakićPas encore d'évaluation

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementD'EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementPas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Essex Terraplane Six 1933 Owner's Manual of InformationD'EverandEssex Terraplane Six 1933 Owner's Manual of InformationPas encore d'évaluation

- Motorcycle, Solo (Harley-Davidson Model WLA)D'EverandMotorcycle, Solo (Harley-Davidson Model WLA)Pas encore d'évaluation

- Maintenance Manual Front AxleDocument65 pagesMaintenance Manual Front Axlehebert perezPas encore d'évaluation

- Illustrated Parts List: Spicer Tandem AxlesDocument16 pagesIllustrated Parts List: Spicer Tandem AxlesВалерий ГерасимовPas encore d'évaluation

- 6 - YX657 (Cummins) Second Edition Parts Catalog 2022-5-23Document375 pages6 - YX657 (Cummins) Second Edition Parts Catalog 2022-5-23GermanPas encore d'évaluation

- 4le1da07 DGK25B 01Document46 pages4le1da07 DGK25B 01Leo BurnsPas encore d'évaluation

- MD-II Question PapersDocument7 pagesMD-II Question PapersDinesh PatilPas encore d'évaluation

- Service Specifications Toyota ProboxDocument85 pagesService Specifications Toyota ProboxSimon Mwangi kabauPas encore d'évaluation

- Motoniveladora Champion Section - 2 - Circle - Drawbar - Moldboard PDFDocument182 pagesMotoniveladora Champion Section - 2 - Circle - Drawbar - Moldboard PDFedgaralbe88% (8)

- VW Polo 5 2010 Running Gear Axles Steering EngDocument223 pagesVW Polo 5 2010 Running Gear Axles Steering EngtestPas encore d'évaluation

- Ecomet Bs IIDocument359 pagesEcomet Bs IIvishal garadPas encore d'évaluation

- 660AC1A922 - PLUS 2508 (FINI) Catalogo Fini Plus 25Document12 pages660AC1A922 - PLUS 2508 (FINI) Catalogo Fini Plus 25tony GutierrezPas encore d'évaluation

- Fiat (SOFIM) Timing Belt ReplacementDocument5 pagesFiat (SOFIM) Timing Belt Replacementearl34100% (3)

- Pv6Uslp PV6UE-05 PV6U-O Compression of Series 6 ConnectorsDocument2 pagesPv6Uslp PV6UE-05 PV6U-O Compression of Series 6 ConnectorsDiego CapezioPas encore d'évaluation

- Agrokid 210 220 230 240 WSM PDFDocument488 pagesAgrokid 210 220 230 240 WSM PDFjwd80% (5)

- Breaker MX90 Parts ListDocument2 pagesBreaker MX90 Parts ListJhonathan Enrrique MazoPas encore d'évaluation

- Order Part Surabaya02Document97 pagesOrder Part Surabaya02AHASS SURYA BANGKIT MOTORPas encore d'évaluation

- How Automatic Transmissions Work ?Document17 pagesHow Automatic Transmissions Work ?bishal.sonar100% (2)

- Mercury Commander Side Mount ControlDocument18 pagesMercury Commander Side Mount ControlTab Sedgwick100% (1)

- Volvo V70 2001 FWD Transmission Aisin Warner AW55 50SN PartsDocument0 pageVolvo V70 2001 FWD Transmission Aisin Warner AW55 50SN Partsmtim360Pas encore d'évaluation

- Lista de Materiales 6KDocument3 pagesLista de Materiales 6KRoyer SanchezPas encore d'évaluation

- Peterbilt Essentials Module5 Axles SuspensionsDocument20 pagesPeterbilt Essentials Module5 Axles SuspensionsLuis Reinaldo Ramirez ContrerasPas encore d'évaluation

- Battery Electric: Master Cylinder Master Cylinder Master CylinderDocument5 pagesBattery Electric: Master Cylinder Master Cylinder Master CylinderВиктор МушкинPas encore d'évaluation

- T105se Jupiter Electrical 2Document1 pageT105se Jupiter Electrical 2Teguh MargiantoPas encore d'évaluation

- Mitsubishi FGC18 (AF81B-53446)Document935 pagesMitsubishi FGC18 (AF81B-53446)Vinicius NevesPas encore d'évaluation

- Engine Parts ManualDocument70 pagesEngine Parts ManualElvis Culma GallegoPas encore d'évaluation

- 3.0 GM TIER 2 Certified Engine Parts ManualDocument62 pages3.0 GM TIER 2 Certified Engine Parts ManualForktech100% (1)

- Atc TRT2221 (Ver 00)Document43 pagesAtc TRT2221 (Ver 00)sandyPas encore d'évaluation

- S10 Electric Power PackDocument16 pagesS10 Electric Power PackHENRY HUAMANPas encore d'évaluation

- Wheel Loader 937H: Technical SpecificationDocument3 pagesWheel Loader 937H: Technical SpecificationMuhamad AdamPas encore d'évaluation

- Bangkep Palu - StoreDocument1 pageBangkep Palu - StoreDaniel RashokyPas encore d'évaluation

- AUTOMOTIVE POWERTRAIN COURSE OutlineDocument2 pagesAUTOMOTIVE POWERTRAIN COURSE OutlineSelazinap LptPas encore d'évaluation