Académique Documents

Professionnel Documents

Culture Documents

Flexure Design

Transféré par

Divyesh MistryCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Flexure Design

Transféré par

Divyesh MistryDroits d'auteur :

Formats disponibles

http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com ) 1-Nov 11.

1 INTRODUCTION Corbel or bracket is a reinforced concrete member is a short-haunched cantilever used to support the reinforced concrete beam element. Corbel is structural element to support the pre-cast structural system such as pre-cast beam and pre-stressed beam. The corbel is cast monolithic with the column element or wall element. This chapter is describes the design procedure of corbel or bracket structure. Since the load from precast structural element is large then it is very important to make a good detailing in corbel. 11.2 BEHAVIOR OF CORBEL The followings are the major items show the behavior of the reinforced concrete corbel, as follows : The shear span/depth ratio is less than 1.0, it makes the corbel behave in two-dimensional manner. Shear deformation is significant is the corbel. There is large horizontal force transmitted from the supported beam result from long-term shrinkage and creep deformation. Bearing failure due to large concentrated load. The cracks are usually vertical or inclined pure shear cracks. The mode of failure of corbel are : yielding of the tension tie, failure of the end anchorage of the tension tie, failure of concrete by compression or shearinga and bearing failure. The followings figure shows the mode of failure of corbel. CHAPTER 11 THE FLEXURE AND SHEAR DESIGN OF CORBEL (BRACKET) http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com 2-Nov Vu Vu Vu Vu Nu DIAGONAL SHEAR SHEAR FRICTION ANCHORAGE SPLITING VERTICAL SPLITING FIGURE 11.1 MODES OF FAILURE OF CORBEL 11.3 SHEAR DESIGN OF CORBEL 11.3.1 GENERAL Since the corbel is cast at different time with the column element then the cracks occurs in the interface of the corbel and the column. To avoid the cracks we must provide the shear friction reinforcement perpendicular with the cracks direction. ACI code uses the shear friction theory to design the interface area. 11.3.2 SHEAR FRICTION THEORY In shear friction theory we use coefficient of friction to transform the horizontal resisting force into vertical resisting force. The basic design equation for shear reinforcement design is : Vn Vu *11.1+ where : Vn = nominal shear strength of shear friction reinforcement

Vu = ultimate shear force = strength reduction factor ( = 0.85) http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com ) 3-Nov Vu Avf fy Avf fy SHEAR FRICTION REINFORCEMENT ASSUMED CRACK f FIGURE 11.1 SHEAR FRICTION THEORY The nominal shear strength of shear friction reinforcement is : TABLE 11.1 SHEAR FRICTION REINFORCEMENT STRENGTH VERTICAL SHEAR FRICTION REINFORCEMENT INCLINED SHEAR FRICTION REINFORCEMENT Vn Avf Vn Avf Vn = Avf fy = y n vf f AV #NAME? y u vf f V A ( ) Vn = Avf fy sinf + cosf ( )y f f n vf f sin cos AV + = ( )y f f u vf f sin cos V A

+ #NAME? where : Vn = nominal shear strength of shear friction reinforcement Avf = area of shear friction reinforcement Fy = yield strength of shear friction reinforcement = coefficient of friction TABLE 11.2 COEFFICIENT OF FRICTION METHOD COEFFICIENT OF FRICTION Concrete Cast Monolithic 1.4 Concrete Placed Against Roughened Hardened Concrete 1.0 Concrete Placed Against unroughened Hardened Concrete 0.6 Concrete Anchored to Structural Steel 0.7 The value of is : = 1.0 normal weight concrete = 0.85 sand light weight concrete = 0.75 all light weight concrete http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com 4-Nov The ultimate shear force must follows the following condiitons : Vu (0.2f'c)bwd Vu (5.50)bwd [11.1] where : Vu = ultimate shear force (N) fc = concrete cylinder strength (MPa) bw = width of corbel section (mm) d = effective depth of corbel (mm) 11.3.3 STEP BY STEP PROCEDURE The followings are the step by step procedure used in the shear design for corbel (bracket), as follows : Calculate the ultimate shear force Vu. Check the ultimate shear force for the following condition, if the following condition is not achieved then enlarge the section. Vu (0.2f'c )bwd Vu (5.50)bwd Calculate the area of shear friction reinforcement Avf. VERTICAL SHEAR FRICTION REINFORCEMENT INCLINED

SHEAR FRICTION REINFORCEMENT Vn Avf Vn Avf Vn = Avf fy = y n vf f AV #NAME? y u vf f V A ( ) Vn = Avf fy sinf + cosf ( )y f f n vf f sin cos AV + = ( )y f f u vf f sin cos V A + #NAME? The design must be follows the basic design equation as follows : Vn Vu 11.4 FLEXURAL DESIGN OF CORBEL 11.4.1 GENERAL The corbel is design due to ultimate flexure moment result from the supported beam reaction Vu and horizontal force from creep and shrinkage effect Nu. http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com ) 5-Nov h d min d/2 Nuc Vu a FIGURE 11.2 DESIGN FORCE OF CORBEL

11.4.2 TENSION REINFORCEMENT The ultimate horizontal force acts in the corbel Nuc is result from the creep and shrinkage effect of the pre-cast or pre-stressed beam supported by the corbel. This ultimate horizontal force must be resisted by the tension reinforcement as follows : y uc nf AN = [11.2] where : An = area of tension reinforcement Nuc = ultimate horizontal force at corbel fy = yield strength of the tension reinforcement = strength reduction factor ( = 0.85) Minimum value of Nuc is 0.2Vuc. The strength reduction factor is taken 0.85 because the major action in corbel is dominated by shear. 11.4.3 FLEXURAL REINFORCEMENT d h a Nuc Vu Ts Cc a jd FIGURE 11.3 ULTIMATE FLEXURE MOMENT AT CORBEL http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com 6-Nov The ultimate flexure moment Mu result from the support reactions is : Mu = Vu(a)+Nuc (h d) *11.3+ where : Mu = ultimate flexure moment Vu = ultimate shear force a = distance of Vu from face of column Nuc = ultimate horizontal force at corbel h = height of corbel d = effective depth of corbel The resultant of tensile force of tension reinforcement is : Tf = Af fy [11.4] where : Tf = tensile force resultant of flexure reinforcement Af = area of flexure reinforcement fy = yield strength of the flexure reinforcement The resultant of compressive force of the concrete is :

Cc = 0.85f'c ba(cos ) *11.5+ where : Cc = compressive force resultant of concrete fc = concrete cylinder strength b = width of corbel a = depth of concrete compression zone The horizontal equilibrium of corbel internal force is : H = 0 Cc =Ts ( ) 0.85f'c ba cos = Af fy ( ) = 0.85f' b cos Af a c fy [11.6] The flexure reinforcement area is : = 2 fda AM y u f [11.7] http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com ) 7-Nov ()

= 2 0.85f' b cos Af fd AM c fy y u f Cos value can be calculated based on the Tan value as follows : a Tan = jd [11.8] where : a = distance of Vu from face of column jd = lever arm Based on the equation above we must trial and error to find the reinforcement area Af. For practical reason the equation below can be used for preliminary : f (jd) AM y u f = f (0.85d) AM y u f = [11.9] where : Af = area of flexural reinforcement Mu = ultimate flexure moment at corbel fy = yield strength of the flexural reinforcement = strength reduction factor ( = 0.9) d = effective depth of corbel 11.4.4 DISTRIBUTION OF CORBEL REINFORCEMENTS a d h Vu Nuc

(2/3)d 23 As= Avf +An Ah= 13 Avf FRAMING REBAR d (2/3)d Ah= Af 2 1 REBAR FRAMING As= Af+An a Vu Nuc CASE 1 CASE 2 FIGURE 11.4 DISTRIBUTION OF CORBEL REINFORCEMENTS http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com 8-Nov From the last calculation we already find the shear friction reinforcement Avf, tension reinforcement An and flexural reinforcement Af. We must calculate the primary tension reinforcement As based on the above reinforcements. TABLE 11.3 DISTRIBUTION OF CORBEL REINFORCEMENTS CLOSED CASE As STIRRUP PRIMARY REINFORCEMENT Ah LOCATION 1 s Avf An 3 A 2 + s Avf An 3 A = 2 + h Avf 3 A=1d 3 2 2 As Af + An As = Af + An h Af 2 A=1d 3 2 where : As = area of primary tension reinforcement Avf = area of shear friction reinforcement An = area of tension reinforcement Af = area of flexure reinforcement

Ah = horizontal closed stirrup d = effective depth of corbel The reinforcements is taken which is larger, case 1 or case 2, the distribution of the reinforcements is shown in the figure above. 11.4.5 LIMITS OF REINFORCEMENTS The limits of primary steel reinforcement at corbel design is : y sc f 0.04 f' bd =A [11.10] where : As = area of primary tension reinforcement b = width of corbel d = effective depth of corbel The limits of horizontal closed stirrup reinforcement at corbel design is : ( ) Ah 0.5 As An *11.11+ where : As = area of primary tension reinforcement An = area of tension reinforcement 11.4.6 STEP BY STEP PROCEDURE The followings are the step by step procedure used in the flexural design for corbel (bracket), as follows : http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com ) 9-Nov Calculate ultimate flexure moment Mu. Mu = Vu(a)+Nuc (h d) Calculate the area of tension reinforcement An. y uc nf AN = Calculate the area of flexural reinforcement Af. f (0.85d) AM y u f = Calculate the area of primary tension reinforcement As. CLOSED CASE As STIRRUP

PRIMARY REINFORCEMENT Ah LOCATION 1 s Avf An 3 A 2 + s Avf An 3 A = 2 + h Avf 3 A=1d 3 2 2 As Af + An As = Af + An h Af 2 A=1d 3 2 Check the reinforcement for minimum reinforcement. y sc f 0.04 f' bd =A ( ) Ah 0.5 As An 11.5 APPLICATIONS 11.5.1 APPLICATION 01 DESIGN OF CORBEL Vu=150000 N 100 Nuc 400 200 http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com 11 - 1 0 PROBLEM Design the flexural and shear friction reinforcement of corbel structure above. MATERIAL Concrete strength = K 300 Steel grade = Grade 400 Concrete cylinder strength = f'c = 0.83 30 = 24.9 MPa 1 = 0.85 DIMENSION b = 200 mm h = 400 mm Concrete cover = 30 mm d = 370 mm DESIGN FORCE

Vu = 150000N Nuc = 0.2Vu = 0.2150000 = 30000 N Mu = Vu(a)+Nuc (h d) = 150000(100)+ 30000(400 370) = 15900000 Nmm LIMITATION CHECKING (0.2f'c)bwd = 0.85(0.2 24.9)200 370 = 313242 N (5.5)bwd = 0.85 5.5 200 370 = 345950 N Vu = 150000 < (0.2f'c)bwd = 313242 < (5.5)bwd = 345950 SHEAR FRICTION REINFORCEMENT = 1.4 = 1.41.0 = 1.4 315 400 1.4 0.85 150000 f V A y u vf = = #NAME? TENSION REINFORCEMENT 88 0.85 400 30000 f AN y uc n= = 0 FLEXURAL REINFORCEMENT ( ) ( ) 140 0.9 400 0.85 370 15900000 f 0.85d AM y u f= =

0 http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com ) 11-Nov PRIMARY TENSION REINFORCEMENT CLOSED STIRRUP CASE As (mm2) PRIMARY REINFORCEMENT (mm2) Ah (mm2) LOCATION (mm) 1 s Avf An 3 A2+ (315) 88 298 3 As 2 + As = 298 h Avf 3 A=1 (315) 105 3 Ah = 1 = d 3 2 247 2 As Af + An As 140 + 88 228 As = 228 The reinforcement of the corbel are : As = 298 mm2 Ah = 105 mm2 CHECK FOR AS MINIMUM AND AS MAXIMUM 0.00249 400 0.04 24.9

f 0.04 f' y c min = = = 0.00402 0.00249 200 370 298 bd A min s=>= = = OK Ahmin = 0.5(As An)= 0.5(298 88)= 210 mm2 Ah = 105 < Ahmin = 210 Ah = 210 mm2 The final reinforcement of the corbel are : As = 298 mm2 Ah = 210 mm2 CORBEL REINFORCEMENT As (mm2) Ah (mm2) As=3D16 16 603 4 D31 4 A3122 s = = = Ah=3(2 Legs D10) 10 471 4 D321 4 A32122 s =

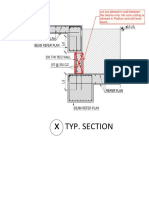

= = http://syaifulsipil96.blogspot.com/ syaiful_ashari@yahoo.com 11 - 1 2 SKETCH OF REINFORCEMENT 247 2 LEGS 10 3D16

from precast

the interface

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Slab-on-Ground DesignDocument28 pagesSlab-on-Ground DesignvPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Ste05121 Spreadsheet Anchor Bolt DesignDocument10 pagesSte05121 Spreadsheet Anchor Bolt Designsivaguruswamy thangarajPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- AS 404 – STEEL AND TIMBER DESIGN CODEDocument4 pagesAS 404 – STEEL AND TIMBER DESIGN CODEJoshua VicentePas encore d'évaluation

- Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 pagesCopper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsGreg YeePas encore d'évaluation

- Leanbody - Labrada - Calendar + ExeDocument10 pagesLeanbody - Labrada - Calendar + ExeDivyesh Mistry0% (1)

- Leanbody - Labrada - Calendar + ExeDocument10 pagesLeanbody - Labrada - Calendar + ExeDivyesh Mistry0% (1)

- Scaffolding Design CalculationDocument8 pagesScaffolding Design Calculationbenchinoun100% (2)

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesPas encore d'évaluation

- Calculation sheet for supporting beam designDocument24 pagesCalculation sheet for supporting beam designKhairul JaggerPas encore d'évaluation

- Example of BBSDocument42 pagesExample of BBSkevinPas encore d'évaluation

- Shear Wall 108Document8 pagesShear Wall 108Divyesh MistryPas encore d'évaluation

- Link Beam Calculations - DLFDocument1 pageLink Beam Calculations - DLFDivyesh MistryPas encore d'évaluation

- CYPEDocument2 pagesCYPEDivyesh MistryPas encore d'évaluation

- 312319Document6 pages312319Divyesh MistryPas encore d'évaluation

- How Are Column Moments Extracted at Diaphragm Locations?Document1 pageHow Are Column Moments Extracted at Diaphragm Locations?Divyesh MistryPas encore d'évaluation

- Annexure-A: Extent of WorkDocument1 pageAnnexure-A: Extent of WorkDivyesh MistryPas encore d'évaluation

- 3 Keys For Effective FatlossDocument18 pages3 Keys For Effective FatlossDivyesh MistryPas encore d'évaluation

- 005-Interlloy Grade 4340 Hardened and Tempered BarDocument3 pages005-Interlloy Grade 4340 Hardened and Tempered BarDhruv MehtaPas encore d'évaluation

- Topics For Tall Buildings ConferenceDocument3 pagesTopics For Tall Buildings ConferenceDivyesh MistryPas encore d'évaluation

- 11.tax Free Incomes FinalDocument35 pages11.tax Free Incomes Finalpraveenr5883Pas encore d'évaluation

- Typ. Stilt Loby SecctionDocument1 pageTyp. Stilt Loby SecctionDivyesh MistryPas encore d'évaluation

- List of Universities For ReDocument3 pagesList of Universities For ReDivyesh MistryPas encore d'évaluation

- Calculations Gravity Wind Point Loads With References DFGSDFGSDFGDSF SDFGDocument2 pagesCalculations Gravity Wind Point Loads With References DFGSDFGSDFGDSF SDFGDivyesh MistryPas encore d'évaluation

- Calculations Gravity Wind Point Loads With References DFGSDFGSDFGDSF SDFGDocument1 pageCalculations Gravity Wind Point Loads With References DFGSDFGSDFGDSF SDFGDivyesh MistryPas encore d'évaluation

- Leanbody Labrada CalendarDocument3 pagesLeanbody Labrada CalendarJaviDiazPas encore d'évaluation

- Calculations Gravity Wind Point Loads With References SDFGDocument1 pageCalculations Gravity Wind Point Loads With References SDFGDivyesh MistryPas encore d'évaluation

- Calculations Gravity Wind Point Loads With References SDFGDocument1 pageCalculations Gravity Wind Point Loads With References SDFGDivyesh MistryPas encore d'évaluation

- Engineering Is The Art of Modelling Materials We Do Not Wholly UnderstandDocument1 pageEngineering Is The Art of Modelling Materials We Do Not Wholly UnderstandDivyesh MistryPas encore d'évaluation

- Calculations Gravity Wind Point Loads With ReferencesDocument1 pageCalculations Gravity Wind Point Loads With ReferencesDivyesh MistryPas encore d'évaluation

- Trammo Inc Interview FormDocument1 pageTrammo Inc Interview FormDivyesh MistryPas encore d'évaluation

- Calculations Gravity Wind Point Loads With ReferencesDocument1 pageCalculations Gravity Wind Point Loads With ReferencesDivyesh MistryPas encore d'évaluation

- Nepal Hazard Risk Assessment: Progress Report July-August 2010Document5 pagesNepal Hazard Risk Assessment: Progress Report July-August 2010Divyesh MistryPas encore d'évaluation

- ToDocument1 pageToDivyesh MistryPas encore d'évaluation

- Methodology For The Design of Lightweight Concrete With Expanded Clay AggregatesDocument12 pagesMethodology For The Design of Lightweight Concrete With Expanded Clay AggregatesDivyesh MistryPas encore d'évaluation

- Wind Gust GraphDocument1 pageWind Gust GraphDivyesh MistryPas encore d'évaluation

- Pe FreshDocument8 pagesPe FreshJasminPamnaniPas encore d'évaluation

- Imm5604e PDFDocument1 pageImm5604e PDFEileen Perez SuarezPas encore d'évaluation

- 9 10 enDocument2 pages9 10 enparth kananiPas encore d'évaluation

- Ped PPT 31Document5 pagesPed PPT 31Axit PatelPas encore d'évaluation

- Modeling of Electrodynamic Bearings: Nicola Amati Xavier de Lépine Andrea TonoliDocument9 pagesModeling of Electrodynamic Bearings: Nicola Amati Xavier de Lépine Andrea TonoliDávid RúraPas encore d'évaluation

- 9003-01-4 Carbopol Thickener Carbomer in Cosmetics 980 White Powder EP980 INCI Name & CAS No. Carbomer 9003-01-4 DescriptionDocument2 pages9003-01-4 Carbopol Thickener Carbomer in Cosmetics 980 White Powder EP980 INCI Name & CAS No. Carbomer 9003-01-4 Descriptionshreeket3953Pas encore d'évaluation

- PPTCHAEN21 - Lecture Unit 2. Material Property ChartsDocument20 pagesPPTCHAEN21 - Lecture Unit 2. Material Property ChartsLady PenalozaPas encore d'évaluation

- AerosolsDocument4 pagesAerosolsUmesh KumarPas encore d'évaluation

- Electrical SafetyDocument12 pagesElectrical SafetyJasper CulipPas encore d'évaluation

- Comparison of Price For Water Treatment Chemicals by The Following 3 VendorDocument1 pageComparison of Price For Water Treatment Chemicals by The Following 3 VendorAK TRIPATHIPas encore d'évaluation

- Section Shape Types GuideDocument7 pagesSection Shape Types GuideFiona steelPas encore d'évaluation

- New Low-Temperature Performance-Grading Method: Using 4-mm Parallel Plates On A Dynamic Shear RheometerDocument6 pagesNew Low-Temperature Performance-Grading Method: Using 4-mm Parallel Plates On A Dynamic Shear RheometerLuis AlejandroPas encore d'évaluation

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakPas encore d'évaluation

- 10 1016@j Matchemphys 2019 05 033Document13 pages10 1016@j Matchemphys 2019 05 033Deghboudj SamirPas encore d'évaluation

- Luban HP2106N (Moplen HP500N) : Polypropylene HomopolymerDocument2 pagesLuban HP2106N (Moplen HP500N) : Polypropylene HomopolymerNazmul - Polymet SA100% (2)

- EN61326 - 1 - Zugehörige EMV NormenDocument30 pagesEN61326 - 1 - Zugehörige EMV NormenHans U. LerchPas encore d'évaluation

- Al Sand Casting ReportDocument5 pagesAl Sand Casting ReportRajib karmakarPas encore d'évaluation

- Miller Indices ClassDocument35 pagesMiller Indices ClassDhiyaAldeenAl-SerhanyPas encore d'évaluation

- Soil, Module 9, FinalDocument8 pagesSoil, Module 9, FinalJulia PomaresPas encore d'évaluation

- Iclp 2016LPofCFRPID256Document9 pagesIclp 2016LPofCFRPID256daniel govantesPas encore d'évaluation

- Chapter 2 Gear Drive-3Document41 pagesChapter 2 Gear Drive-3Abaziz Mousa OutlawZzPas encore d'évaluation

- 6 Exercises Solutions 2009 PDFDocument90 pages6 Exercises Solutions 2009 PDFsyafiq hashimPas encore d'évaluation

- Ultrasonic Wave Behavior at InterfacesDocument15 pagesUltrasonic Wave Behavior at InterfaceskingstonPas encore d'évaluation

- Foundation Example 9.7Document14 pagesFoundation Example 9.7Deana WhitePas encore d'évaluation

- EXP1 - Relative Density-MinDocument16 pagesEXP1 - Relative Density-MingoblinsbridePas encore d'évaluation