Académique Documents

Professionnel Documents

Culture Documents

2) BOQ - Nibu Khola IX MHS (12 KW) Nawmidanda VDC Panchthar - 20120928040957

Transféré par

barukomkssDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2) BOQ - Nibu Khola IX MHS (12 KW) Nawmidanda VDC Panchthar - 20120928040957

Transféré par

barukomkssDroits d'auteur :

Formats disponibles

ALTERNATIVE ENERGY PROMOTION CENTER RENEWABLE ENERGY FOR RURAL LIVLIHOOD PROGRAMME RURAL ENHANCED ENERGY SERVICES: KABELI

TRANSMISSION PROJECT Bill of Quantities and Specifications Subject: Site Verification, Electro Mechanical Equipment Supply, Delivery, Installation, Testing & Commissioning of Nibu Khola IX, (12 kW) Micro Hydropower System (MHS), Nawmidanda VDC, Panchthar.

ITB Reference: ITB/RERL/REES:KTP 2012/002

SN I

Particulars Mechanical Equipments

Specifications

Unit

Qty

Rate in Figure, Amount in Figure, Rs. Rs.

Rate in Word

Amount in Word

Remarks

1.1

The turbine runner should be of mild steel, rated to continuously deliver adequate shaft output at 504 rpm at the operating condition of site: 139 l/s Turbine:Cross Flow with 16 kW design flow and 15.13 m net head to generate 12 kW from generator. The shaft power with baseframe (12 casing should be of 10 mm thick MS. The set should be complete with any kW electrical output) inlet adapter pipe (to connect the main valve placed just ahead of the turbine),butterfly valve, base frame, foundation bolts and accessories, all complete. Power Transmission System: Drive System with necessary pulleys and Flat habasit belt, bearings and (Pully on turbine, pully on other necessary components required to change the necessary speed/ generator and habasit flat Belts ) orientation of the drive with safety guard etc. Penstock Pipes: Mild steel penstock pipes Mild steel penstock pipes 280 mm ID and 3 mm wall thickness, with the provision of flanged joints and with necessary accessories such as 'C' clamps, 'O' ring rubber gaskets, anchor, tarpaulin sheets, nuts and bolts all complete. The pipes should be pressure tested in the workshop to withstand the total head (including surge head). The bends should meets the quality of penstock pipe and should resist the pressure Mild Steel Bell Mouth with GI vent pipe 11/2'' ID, 1.35 m in length, with necessary accessories for fixing, all complete Mild Steel Gate of 1.2 m height & 0.5m X 0.5 m opening with necessary accessories for fixing, all complete A. Coarse trash-rack made of steel 0.6 m x 0.65 m having 40 x 40 x 5 mm angle iron and 30 x 5 mm flat iron strips @ 60 mm c/c all complete

Set

1.2

Set

43

1.3 Bends Bell Mouth with Air Vent pipe: GI vent pipe Sluice Gate ( For Intake & Gravel Trap ) Trash-racks: A. Steel coarse trash-rack (For Intake) B. Steel fine trash-rack 1.7 1.8

nos Set Set Set Set Set Set

2 1 2 1 1 2 1

1.4 1.5 1.6

B. Fine trash-rack made of steel 0.85 m x 1.5 m having 40 x 40 x 5 mm angle iron and 30 x 5 mm flat iron strips @ 15 mm c/c all complete Expansion joints 280 mm ID, made of MS, should be able to accommodate Expansion joints: (Sliding type) min of 30 mm length for expansion / contraction, with all necessary accessories, all complete Pressure Gauge Standard pressure gauge, fixing with all necessary accessories Sub Total (I)

140355064.xls.ms_office

Page 1

II

Electrical Equipment Synchronous generator 25 kVA, brushless, rated to continuously deliver 12 kW, 230/400 volts, 50 hertz, 1500 rpm, 3 phase 4 wire electrical outputs at Synchronous generator: 25 kVA, the generator terminal at 0.8 load power-factor at the operating condition of brushless , rated to continuously site. The generator should be self excited and self regulated type with AB deliver 12 kW series. The insulation class will be F with environmental protection IP 23.The set should be complete with base frames, foundation bolts, couplings and accessories all complete Three phase electronic load controller (ELC), thyrister type, 12 kW in vermin proof metal cubicle with resistive ballast loads 15 kW (water heaters) to continuously regulate and dump the load at the given site condition, all complete Ballast heater of 15 Kw with water tank to continuously regulate and dump Ballast Tank with Heater 15 kW the load at the given site condition, all complete Control, instrumentation, protection systems: As a minimum, the Control, instrumentation, protection and switchgear of main switch 40 A, 3 instrumentation should be for phase in a free standing steel cubicle for manual start, adequate monitoring generated voltage/ frequency, and protection of generator with necessary incoming / outgoing terminations load current, and ballast voltage, for inter-phasing to other components, all complete. kW and kWh. Three phase electronic load controller (ELC) with energy meter Control and power cable inside powerhouse: Power cable: Materials for power house wiring including necessary lighting and power fixtures Energy meter Sub- Total (II) 16 mm2 4 core cupper armored cable, for interconnecting generator, control panel, ELC, ballast, sensors etc, all complete 25 mm2 4 core aluminum armored cable for control panel feeder terminals (main switch) to the first pole, all complete Power house wiring with 5 light points and 2 power points, all complete. 4' * 40 watt tube lights - 2 nos, 75 watt bulbs with holders-3 nos, and single phase power socket- 2 nos with necessary number of switches and wires. As Per AEPC's CC unit Specification

2.1

Set

2.2

Set

2.3

Set

2.4

Set

2.5 2.6

m m

15 20

2.7

L.S.

2.8

No.

1 -

III

Transmission / Distribution Systems Conductors: ACSR conductors ACSR conductors, suspended overhead, with minimum of 4.5 ground clearance, having clearance of 300 mm between them. These should have approved current rating by NS. Resistance:>1.374 ohms/ km Resistance:>0.9116 ohms/km Resistance:>0.5449 ohms/ km Concentric cable Medium size Small size Large size Should include guy wire, turn buckle, rod, insulators and plates, all complete

3.1

3.2 3.3 3.4 3.5

a. Squirrel b. Weasel c. Rabbit d. Dog Service wire (4 mm2) Insulators (shackle) with 'D' Irons with necessary nuts, bolts, etc. all complete Stay sets

m m m m m Nos Nos Nos Sets Set

17780 1060 4600 4290 3510 114 473 155 68 43

Lightning arrestors: Lightning arrestors to be provided at every 500 m for current carrying 0.5 kV with necessary stand and conductors. All joints along the earth path should be able to carry a lightning accessories, all complete strike of 20 kA. Earthing arrangements: Sub Total (III) 8 SWG copper earth wire, 600 x 600 x 3 mm copper plate as earth electrode with necessary coke, lime, salt, nut, bolts, washer etc. all complete.

3.6

Sets

18

140355064.xls.ms_office

Page 2

IV

Miscellaneous Spare Parts : For turbine, generator, control panel and load controlling set etc. as deemed necessary. 10 % of bolts, one set gaskets and seals, HRC Fuse, Panel meter, one set of bearings of turbine and generators thyristers, Insulators, grease 1 kg Tools : Complete electromechanical tools set with tool box, which includes tester, digital clamp meter, hammer, slide wrench, grease gun, screw driver sets, flat and round file, hacksaw frame & 5 blades, chisel, wire steeper. HRC fuse 3 sets, 3 thyristers as spare, wire puller 2 ton, 2 safety belts, 2 safety helmets, alluminium ladder folding type (20 ft. long & 3.5 mm thick plate ISO standard).

L.S.

4.1

Spare Parts and Tools:

L.S.

Sub Total (IV) V Site verification, civil works supervision, installation, erection, testing & commissioning including a. Site Verification Site verification, civil works b. Civil Works Supervision supervision, Installation, c. Mechanical Equipment Installations erection, testing & commissioning including d. Electrical Equipment Installation maintenance for one year, all e. Erection / Fixation of Transmission / Distribution Lines complete f. Testing & Commissioning Sub Total (V)

5.1

L.S. L.S. L.S. L.S. L.S. L.S.

Cost Summary I. II. III. IV. Mechanical Equipments Electrical Equipments Transmission and Distribution Spare parts and tools Sub-Total (A) VAT (13%) Total (Sub-Total + VAT) Installation & Testing and others Grand Total Rs. Net total Rupees in word: -

V.

Note: 1. Original tender form should be submitted. 2. The rate and amount should be in figure and in word, double handwritten form will be rejected. 3. Form should be submitted with authorized person's signature and official seal in each page. 4. Photo copy of Pre- qualification certificate by AEPC should be submitted. 5. Pre- qualification validity renewal certificate by AEPC should be submitted.

Official Seal

Name and signature of authorized person: Name of manufacturer, Supplier & Installer: Contract address: Telephone No.: Date:

140355064.xls.ms_office

Page 3

Vous aimerez peut-être aussi

- Bhauta Khola HydrologyDocument30 pagesBhauta Khola HydrologyMilan ShresthaPas encore d'évaluation

- Energy Calc IRRPayback PeriodCost of ProjectDocument15 pagesEnergy Calc IRRPayback PeriodCost of ProjectArjun BaralPas encore d'évaluation

- Head Race CanalDocument12 pagesHead Race CanalKeshab BadalPas encore d'évaluation

- General Layout of Madhyamaheshwar SHP (3X5 MW)Document1 pageGeneral Layout of Madhyamaheshwar SHP (3X5 MW)krishbistPas encore d'évaluation

- Design of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Document20 pagesDesign of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Souvik DasPas encore d'évaluation

- Energy Calculation 4Document9 pagesEnergy Calculation 4Bidur GautamPas encore d'évaluation

- Gullu HEP (Hume Pipe)Document2 pagesGullu HEP (Hume Pipe)satyakam0601050Pas encore d'évaluation

- Report Rumrunga MHS 20120607113351Document36 pagesReport Rumrunga MHS 20120607113351Kroya HunPas encore d'évaluation

- Long Term Average Monthly Discharge: Middle Chameliya Hydropower ProjectDocument5 pagesLong Term Average Monthly Discharge: Middle Chameliya Hydropower ProjectPraveen ChaudharyPas encore d'évaluation

- 4MW Thak Chillas Hydropower ProjectDocument9 pages4MW Thak Chillas Hydropower Projectliu_jonesPas encore d'évaluation

- Feasibility Study Report Nar Khola HEP (Sept23 - 2022) (1) (1) - 1Document229 pagesFeasibility Study Report Nar Khola HEP (Sept23 - 2022) (1) (1) - 1Vswo DahalPas encore d'évaluation

- Bayakhola - Bangad Kupinde HydrologyDocument30 pagesBayakhola - Bangad Kupinde HydrologyMilan ShresthaPas encore d'évaluation

- Design Aspects and Sustainability of Mini/Micro Hydropower SchemesDocument78 pagesDesign Aspects and Sustainability of Mini/Micro Hydropower SchemesEriane GarciaPas encore d'évaluation

- Penstock Block 2Document28 pagesPenstock Block 2Mani ShresthaPas encore d'évaluation

- Feasibility Report Kathai-II Hydropower Project Project Civil DesignDocument48 pagesFeasibility Report Kathai-II Hydropower Project Project Civil DesignManzar MumtazPas encore d'évaluation

- Conical Tank Design For OSCARDocument2 pagesConical Tank Design For OSCARArie Emmanuel ListonPas encore d'évaluation

- Long Term Average Monthly Discharge: SUPER Inkhu Hydropwer Project-Option ADocument2 pagesLong Term Average Monthly Discharge: SUPER Inkhu Hydropwer Project-Option APraveen ChaudharyPas encore d'évaluation

- Saddle Support SpacingDocument1 pageSaddle Support SpacingdishkuPas encore d'évaluation

- KhoksarDocument212 pagesKhoksarMuhammed Raneef SPas encore d'évaluation

- Sickle PlateDocument8 pagesSickle PlatepitamberPas encore d'évaluation

- Babai Surge Analysis 2016june DraftDocument7 pagesBabai Surge Analysis 2016june DraftAyanilPas encore d'évaluation

- Pulichintala ProjectDocument5 pagesPulichintala Projectrn_nadhamPas encore d'évaluation

- FSR - UMI HEP 23 - Oct - 2016)Document208 pagesFSR - UMI HEP 23 - Oct - 2016)Manoj BaralPas encore d'évaluation

- ENCE 647 ENCE 647 Stability of Slopes Dr. Ahmet AydilekDocument23 pagesENCE 647 ENCE 647 Stability of Slopes Dr. Ahmet AydilekHoracioCruisePas encore d'évaluation

- LJKHP - FSR 03 Oct 2018Document133 pagesLJKHP - FSR 03 Oct 2018Manoj BaralPas encore d'évaluation

- Sickle PlateDocument24 pagesSickle PlateStalyn SimbañaPas encore d'évaluation

- Calculation of DischargeDocument2 pagesCalculation of DischargeCristina OrmenisanPas encore d'évaluation

- M S Pipe Weight CalculationDocument3 pagesM S Pipe Weight CalculationArun NandaPas encore d'évaluation

- Gate DetailsDocument149 pagesGate DetailsMadhav BaralPas encore d'évaluation

- Stability Analysis of Small DamsDocument6 pagesStability Analysis of Small DamsPrabhav Mishra100% (1)

- Final ModuleDocument90 pagesFinal ModuleSivaShankar100% (5)

- Salient FeaturesDocument3 pagesSalient FeaturesAnonymous ESZmDGPas encore d'évaluation

- Project Location: Diversion StructureDocument5 pagesProject Location: Diversion Structureelec310Pas encore d'évaluation

- Salient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Document3 pagesSalient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Bidur GautamPas encore d'évaluation

- Upper Sanjen HEP (78MW), Penstock Optimization: Base CaseDocument9 pagesUpper Sanjen HEP (78MW), Penstock Optimization: Base CaseJuben BhaukajeePas encore d'évaluation

- Susaune Khola Hydrology DesignDocument30 pagesSusaune Khola Hydrology DesignMilan ShresthaPas encore d'évaluation

- Calculation of The Net Head and Power GenerationDocument15 pagesCalculation of The Net Head and Power GenerationUdara PriyankaraPas encore d'évaluation

- Deu Mai Khola HEP Text - FeasibilityDocument73 pagesDeu Mai Khola HEP Text - Feasibility2003_335Pas encore d'évaluation

- Design & Finished Weight of Penstock With Joint Efficiency 0.85 MATERIAL ASTM 537 CL IASTM 517 GR F, No Rock ParticipationDocument4 pagesDesign & Finished Weight of Penstock With Joint Efficiency 0.85 MATERIAL ASTM 537 CL IASTM 517 GR F, No Rock ParticipationAshish SharmaPas encore d'évaluation

- BCC All SS CustomDocument48 pagesBCC All SS CustomNina Novita WulandariPas encore d'évaluation

- Hydraulic Design - ScanDocument36 pagesHydraulic Design - ScancjayamangalaPas encore d'évaluation

- Design of BandharaDocument21 pagesDesign of BandharaNeil Agshikar100% (1)

- Sub Head:LF Sluice at Ch:6.00: Formation of New Tank A/c Doripula Vagu Near Korlanka (V) Tiryani (M), Adilabad (District)Document4 pagesSub Head:LF Sluice at Ch:6.00: Formation of New Tank A/c Doripula Vagu Near Korlanka (V) Tiryani (M), Adilabad (District)rajuaeePas encore d'évaluation

- Istaru-Booni Hydropower Project (72 MW) : Calculation Sheet Rev:0 Contract:Feasibilty Study ofDocument3 pagesIstaru-Booni Hydropower Project (72 MW) : Calculation Sheet Rev:0 Contract:Feasibilty Study ofguildkeyPas encore d'évaluation

- Is Code Criteria For Design of Anchor Block For Penstock With Expansion JointDocument13 pagesIs Code Criteria For Design of Anchor Block For Penstock With Expansion Jointduldar docPas encore d'évaluation

- DPR Pahumara SHPDocument147 pagesDPR Pahumara SHPdzikriePas encore d'évaluation

- Design of Intake, Orifice&CanalDocument1 pageDesign of Intake, Orifice&CanalHutendra SilwalPas encore d'évaluation

- Expression of Interest (EOI) : Title of Consulting Service: BHP/CS/ICB-1/2077/78Document47 pagesExpression of Interest (EOI) : Title of Consulting Service: BHP/CS/ICB-1/2077/78Jyan DeuriPas encore d'évaluation

- Appendix ADocument14 pagesAppendix Ayam adhikariPas encore d'évaluation

- DCHP PDF Main Report Vol I719Document125 pagesDCHP PDF Main Report Vol I719Nabin AdhikariPas encore d'évaluation

- Brief Project ReportDocument38 pagesBrief Project ReportManoj BaralPas encore d'évaluation

- Salient Features CombinedDocument4 pagesSalient Features CombinedkrishbistPas encore d'évaluation

- KGHEP BoQDocument11 pagesKGHEP BoQMilan RautPas encore d'évaluation

- Forebay Tank - Design and Construction: Asanka Kumarasiri PG Diploma in Structural Engineering 2014Document17 pagesForebay Tank - Design and Construction: Asanka Kumarasiri PG Diploma in Structural Engineering 2014Anonymous pmwNrPum1CPas encore d'évaluation

- Outer Profile of Sickle Plate: Rad RadDocument3 pagesOuter Profile of Sickle Plate: Rad RadSambhav PoddarPas encore d'évaluation

- Analysis and Design of Intz Water Tank by Using Staad ProDocument8 pagesAnalysis and Design of Intz Water Tank by Using Staad ProEditor IJTSRDPas encore d'évaluation

- Design Sanjeev 1Document18 pagesDesign Sanjeev 1riteshreplyPas encore d'évaluation

- TrapezoidDocument11 pagesTrapezoidPrisoner SparrowPas encore d'évaluation

- XPDocument9 pagesXPsureshn829100% (1)

- Project Electrical Boq Feb 10-1Document40 pagesProject Electrical Boq Feb 10-1Vijaya Sarathi RaviPas encore d'évaluation

- V3i9 Ijertv3is090001 PDFDocument3 pagesV3i9 Ijertv3is090001 PDFbarukomkssPas encore d'évaluation

- NGR - Ohm Calc Trafo 5MVA-20kVDocument6 pagesNGR - Ohm Calc Trafo 5MVA-20kVbarukomkssPas encore d'évaluation

- AWSPipeWeld - American Welding SocietyDocument2 pagesAWSPipeWeld - American Welding Societybarukomkss100% (1)

- Kobelco - Kobe Steel PDFDocument6 pagesKobelco - Kobe Steel PDFbarukomkssPas encore d'évaluation

- Corrosion Rate Calculator: All CountriesDocument1 pageCorrosion Rate Calculator: All CountriesbarukomkssPas encore d'évaluation

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Document5 pagesPower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssPas encore d'évaluation

- Jembatan Bellie PDFDocument2 pagesJembatan Bellie PDFbarukomkssPas encore d'évaluation

- RTe BookGSDCalculatorDocument5 pagesRTe BookGSDCalculatorbarukomkssPas encore d'évaluation

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Document5 pagesPower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssPas encore d'évaluation

- Power Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275Document5 pagesPower Transmission: Schaberweg 30-34 61348 Bad Homburg Germany Telephone +49 6172 275-0 Telefax +49 6172 275-275barukomkssPas encore d'évaluation

- BSM Vol 1 Sec 15 Aug 2007 PDFDocument2 pagesBSM Vol 1 Sec 15 Aug 2007 PDFbarukomkssPas encore d'évaluation

- Pro & Contra Hydropower: AdvantagesDocument16 pagesPro & Contra Hydropower: AdvantagesbarukomkssPas encore d'évaluation

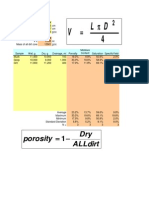

- Porosity by MassDocument1 pagePorosity by MassbarukomkssPas encore d'évaluation

- HourGlass ErrorDocument10 pagesHourGlass ErrorbarukomkssPas encore d'évaluation

- Neal Peres Da CostaDocument507 pagesNeal Peres Da CostaNoMoPoMo576100% (1)

- NAAC 10.12.1888888 NewDocument48 pagesNAAC 10.12.1888888 Newచిమ్ముల సందీప్ రెడ్డిPas encore d'évaluation

- Coding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringDocument14 pagesCoding Prony 'S Method in MATLAB and Applying It To Biomedical Signal FilteringBahar UğurdoğanPas encore d'évaluation

- MPDFDocument10 pagesMPDFshanmuganathan716Pas encore d'évaluation

- English Action Plan 2023-2024Document5 pagesEnglish Action Plan 2023-2024Gina DaligdigPas encore d'évaluation

- KarcherDocument21 pagesKarcherSIVARAMANJAGANATHANPas encore d'évaluation

- Nguyen Ngoc-Phu's ResumeDocument2 pagesNguyen Ngoc-Phu's ResumeNgoc Phu NguyenPas encore d'évaluation

- Mini Riset Bahasa Inggris BisnisDocument10 pagesMini Riset Bahasa Inggris BisnissyahsabilahPas encore d'évaluation

- Kelompok CKD - Tugas Terapi Modalitas KeperawatanDocument14 pagesKelompok CKD - Tugas Terapi Modalitas KeperawatanWinda WidyaPas encore d'évaluation

- Missing Person ProjectDocument9 pagesMissing Person ProjectLaiba WaheedPas encore d'évaluation

- Leap Motion PDFDocument18 pagesLeap Motion PDFAnkiTwilightedPas encore d'évaluation

- Vocabulary: Activity 1Document18 pagesVocabulary: Activity 1Aurora GonzalezPas encore d'évaluation

- Final ExaminationDocument15 pagesFinal ExaminationMAY ANN CATIPONPas encore d'évaluation

- Brochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Document2 pagesBrochure - Mounted Telescopic Crane (S) - NOVEMBER - 2018Fernanda RizaldoPas encore d'évaluation

- Integrated Curriculum For Secondary Schools: Mathematics Form 2Document139 pagesIntegrated Curriculum For Secondary Schools: Mathematics Form 2Izawaty IsmailPas encore d'évaluation

- Additional Material On CommunicationDocument15 pagesAdditional Material On CommunicationSasmita NayakPas encore d'évaluation

- DPL MDDocument3 pagesDPL MDCoy IngramPas encore d'évaluation

- Chemistry Project Paper ChromatographyDocument20 pagesChemistry Project Paper ChromatographyAmrita SPas encore d'évaluation

- Al Kindi AssingmentDocument9 pagesAl Kindi AssingmentMuhammad Sirajuddin MazlanPas encore d'évaluation

- DESBLOQUEADO Synesis Erik Hollnagel 2022Document81 pagesDESBLOQUEADO Synesis Erik Hollnagel 2022Tribu de SSOPas encore d'évaluation

- 688 (I) Hunter-Killer - User ManualDocument115 pages688 (I) Hunter-Killer - User ManualAndrea Rossi Patria100% (2)

- Chapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, ChemistryDocument9 pagesChapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, Chemistrypumeananda100% (3)

- Experiment #3 Venturi Meter: Home Unquantized ProjectsDocument7 pagesExperiment #3 Venturi Meter: Home Unquantized ProjectsEddy KimathiPas encore d'évaluation

- Class 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDocument12 pagesClass 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDiksha TPas encore d'évaluation

- Vernacular in Andhra PradeshDocument1 pageVernacular in Andhra PradeshNandyala Rajarajeswari DeviPas encore d'évaluation

- Universal Human Values NotesDocument13 pagesUniversal Human Values NotesS RamPas encore d'évaluation

- ECON 304 Course ContentDocument2 pagesECON 304 Course ContentAanand JhaPas encore d'évaluation

- Unit 8 - A Closer Look 2Document3 pagesUnit 8 - A Closer Look 2Trần Linh TâmPas encore d'évaluation

- Student Report: Social Studies Class TestDocument4 pagesStudent Report: Social Studies Class Testila thakurPas encore d'évaluation

- 2022 05 141RBSF351652506386Document6 pages2022 05 141RBSF351652506386tathagat jhaPas encore d'évaluation