Académique Documents

Professionnel Documents

Culture Documents

Maillard Reaction in Molasses Storage Tank PDF

Transféré par

Arthur Yanez100%(2)100% ont trouvé ce document utile (2 votes)

493 vues4 pagesThe Maillard reaction was observed in a molasses storage tank in a Mauritian sugar factory near the end of the 1994 crushing season. The remedial action taken is detailed and the economic loss due to the incident is assessed. The mechanisms of the reaction and measures for its prevention are reviewed.

Description originale:

Titre original

Maillard Reaction In Molasses Storage Tank.pdf

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentThe Maillard reaction was observed in a molasses storage tank in a Mauritian sugar factory near the end of the 1994 crushing season. The remedial action taken is detailed and the economic loss due to the incident is assessed. The mechanisms of the reaction and measures for its prevention are reviewed.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

100%(2)100% ont trouvé ce document utile (2 votes)

493 vues4 pagesMaillard Reaction in Molasses Storage Tank PDF

Transféré par

Arthur YanezThe Maillard reaction was observed in a molasses storage tank in a Mauritian sugar factory near the end of the 1994 crushing season. The remedial action taken is detailed and the economic loss due to the incident is assessed. The mechanisms of the reaction and measures for its prevention are reviewed.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

MAILLARD REACTION IN MOLASSES STORAGE TANK

ILWONG SAK HOI AND 2JCCHASTEAU DE BALYON

'Mauritius Sugar IndustryResearchInstitute, Reduit, Mauritius

2Flacq UnitedEstates Ltd, Union Flacq, Mauritius

Abstract

The Maillard reaction was observed in a molasses storage

tank in a Mauritian sugar factory near the end of the 1994

crushing season. The remedial action taken is detailed and the

economic loss due to the incident is assessed. The mecha-

nisms of the Maillard reaction and measures for its prevention

are reviewed.

Keywords: Froth fermentation, foaming, Maillard reaction,

molasses cooling.

Introduction

With the ad.vent of the continuous C-centrifugal, which

enables the cunng of more viscous massecuites than had hith-

erto been possible by the batch machines either the

massecuites are re-heated to a high or steam is

used generously to lower the massecuite viscosity, with the

result that the temperature of the final molasses is above

40C, and may reach 55-60C. If the hot molasses is not

cooled before being pumped to the storage tank, a Maillard

type reaction may occur in the tank, with catastrophic conse-

quences.

Occurrence of the incident

Near the end of the 1994 crushing season, it was noticed on

28 November at Flacq United Estates Ltd (FUEL) sugar fac-

tory that it took longer than usual to fill a 24 ton molasses

tanker. The molasses was darker in colour than normal, it was

'froth fermenting' with evolution of carbon dioxide and its

temperature was 63C. The 7 000 ton capacity mild steel

tank, 12 m high and 23 m diameter, was hot and vapour was

coming out of the air vent. The tank was about half full at the

time the incident was reported. A sample of the molasses was

analysed and it was found that the sucrose content was al-

ready down from 37,8% to 12,7%, and the reducing sugars up

from 12,93% to 17,3% (Table 1). Neither re-circulation of the

Table 1

Comparison of deteriorated with undeteriorated molasses

molasses to a second tank, nor the addition of ice or water

through the air vent, were possible at the time. Nothing much

could be done to save the molasses. Trends in brix, sucrose

and reducing sugar contents are shown in Table 2.

Table 2

Trends in brix, sucrose and reducing sugar contents in the

deteriorated molasses

Day Date Brix % Sucrose %

Reducing Temperature

sugars % C

1 28.11.94 86,4 12,7 17,3 63

2 29.11.94 86,2 13,3 17,1 63

3 30.11.94 84,7 13,5 20,8 64

12 09.12.94 84,2 10,2 21,1 69

When evolution of the carbon dioxide had subsided, most

of the molasses had turned into a dark brown carbonaceous

mass, .only a sIJ.1all proportion remaining in the liquid

state. ThISliquid portion was analysed and the analytical data

are compared in Table 2 with those of the undeteriorated mo-

lasses obtained just before the occurrence of the incident.

It can be seen that there is a marked decrease in brix, pol,

sucrose and total sugars, and a gain in reducing sugars. This is

consistent with the findings of earlier workers (Fromen and

Bowland, 1961; Tseng, 1965). As the potassium present in

the deteriorated molasses was not negligible and had certain

fertiliser value, the molasses was therefore discharged into a

canal, pH adjusted to 6,8 with milk of lime, and mixed with

river for surface irrigation of cane. This was a very slow

operation as the manhole of the molasses tank was partially

blocked by solid carbonaceous mass and it took a fortnight to

dispose of all the fluid contents of the storage tank.

The brown solid was found to contain 30,9% moisture and

the analytical data on the dried solid (Table 3) show that it

consists mainly of organic material and can be easily burnt

away. Anon (1953) reported that the porous material left after

a similar incident in Egypt has a thermal value of 5 336 calo-

ries (1 270 J).

Table 3

Composition of brown carbonaceous mass from deteriorated molasses

When the reaction in the tank had subsided and the tempera-

ture had dropped, large sections of the molasses tank wall were

Component

Brix %

Pol %

Reducing sugars %

Sucrose %

Total sugars %

Carbonated ash %

Calcium %

Magnesium %

Nitrogen %

Phosphorus %

Potassium %

Sodium %

Deteriorated

51,72

1,85

15,95

2,17

18,12

8,19

0,50

0,41

0,34

0,08

3,38

1,18

Molasses

Undeteriorated

83,46

30,40

12,93

37,80

50,73

10,27

1,02

0,43

0,64

0,10

1,27

1,18

Loss of ignition %

Solids insoluble in HCI %

Silica %

Mixed oxides %

Sodium %

Calcium %

Magnesium %

82,8

0,57

0,38

0,94

2,00

1,82

0,81

ProcS Afr Sug Technol Ass (1996) 70 251

Maillard Reaction in Molasses Storage Tank

cut off to enable a rock breaker to move into the tank to break

the solid mass into small pieces for transportation to the ba-

gasse storage area, where spontaneous combustion took place

before the solid pieces could be used as fuel in the boilers.

The loss of the molasses was estimated at 2,0 M roupies

and the cost of the clean-up operation and repairs to the stor-

age tank amounted to 1,2 M roupies.

Discussion

Molasses storage tank

The molasses tank storage conditions at the factory are

summarised in Table 4.

Air inletpipe

(6,3emdiameter)

L Wong Sak Hoi and JC Chasteau de Balyon

//" - - - - - 1 ; - Open-ended

branch pipe

(3,8 emdiam)

1 m from

periphery

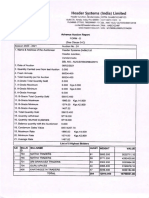

Table 4

Molasses storage conditions at FUEL sugar factory

before modification

FIGURE 1: Topviewof the air injection system 20 cmabovethebase

of a molasses storage tank

A well-designed molasses tank should be equipped with

the facilities of re-circulation, for pumping the molasses from

one storage tank to another. It should have an air injection

system and, most important of all, adequate ventilation on the

roof top. After the incident, the two air vents have been en-

larged from 15 to 75 cm diameter at FUEL sugar factory.

The retrieval of molasses from the tank should be on a first-

in, first-out basis so that its storage period would not be un-

duly long.

The design of one of the storage tanks at the molasses ter-

minal is described below. It is 25 m in diameter, 12 m high,

and has a cone roof with four air vents of 40 em diameter each

and two manholes of 60 em diameter each. At about 20 em

above the base of the tank there is an air injection system

whereby air from a compressor unit is led by a 6,3 ern diam-

eter pipe to the centre of the tank, where the air is distributed

into six 3,8 em diameter branch pipes equidistant from each

other. The pipes are open-ended and are situated 1 m from the

periphery of the tank wall, as illustrated in Figure 1. The air

compressor is electrically driven, water-cooled and operating

at 600 rpm and 100 psi. The temperature of the exit air is

about 30C. Compressed air is introduced into each tank for

two hours a day with the objective of breaking through the

upper surface of the molasses to enable the hot gases, if any,

to be carried away into the atmosphere.

Trivett (1953) first claimed that foaming can be controlled

to a certain extent by introduction of compressed air into the

mass of the molasses and Parsons (1958) described an air in-

jection and a calcium hypochlorite dosing system in a tank at

the molasses terminal in the Philippines to control molasses

foaming.

Tank no

Height of tank

Diameter of tank

Type of tank

Capacity of tank

Methodof filling

Method of emptying

Temperaturecontrol

Facilities for re-circulation

Facilities for ventilation

Facilities for air injection

Facilities for inhibitor dosing

Averagelength of storage period

Temperature of molasses entering

storage

1

12 m

23 m

mild steel

7000 tons

from above

from below

nil

nil

two air vents of 15 cm 6 each

not operational

nil

4 weeks maximum

60C

Mechanism of Maillard reaction

Back in the 1950s, when incidents of froth fermentation

were reported, it was recognised that the change was chemi-

cal and not biological as there was an absence of yeast,

mould, bacteria or other micro-organisms. It was a spontane-

ous exothermic chemical change with evolution of carbon di-

oxide and the formation of volatile acids, mainly acetic. The

decomposition is essentially a reaction between amino acids

and reducing sugars (Maillard, 1912a, 1912b).

Honig (1965) summarised the mechanism of the Maillard

reaction as follows:

1. Amino acid + hexose amino acid-hexose compound (col-

ourless)

2. Amino acid +amino acid - hexose compound polymerised

product (I) with dehydration (yellow)

3. Polymerised product (I) undergoes decarboxylation and

internal combustion

C02 + dehydration product (II) (brown melanoidin)

4. Polymerisation product (II) humic acid + insoluble non-

sugars (dark reddish- brown).

Ducatillon et al. (1985) reported that, during the froth fer-

mentation, the pH drop provokes sucrose hydrolysis to reduc-

ing sugars, which in turn react with amino acids to produce

more brown melanoidin and eventually humic acid.

Hucker and Brooks (1942) found that molasses instability

depends on morphological history. Molasses that had been

heated produced more gas than that which had not, and in-

ferred that the higher the temperature the molasses had been

subjected to in the factory process, the lower the critical

foaming temperature and the greater the foaming on subse-

quent storage.

Newell (1979) studied the factors affecting Maillard reac-

tion occurring in massecuites and molasses, and found effects

of high temperature, high brix and low purity to be signifi-

cant.

Preventive measures

After the incident at FUEL sugar factory, molasses after

curing is cooled in an air cooling tower followed by further

cooling in a crystalliser (Figure 2). Molasses at 60C is

pumped to the distributing compartment of the cooling tower

at the rate of 6-7 t/h. It overflows under gravity from one in-

clined plate to another, and is cooled by air to about 55C. It

252 Proc S Afr Sug Technol Ass (1996) 70

L Wong Sak Hoi and JC Chasteau de Balyon Maillard Reaction in Molasses Storage Tank

o 0 0 0 0 a 0 0 0 0 Molasses distributing

o a a 0 0 0 0 0 0 0 compartment

Inlet molasses (60C)

-

Cooling tower

I

r--'

- .

--1

r

-

Water cooled crystalliser

FIGURE 2: Molasses coolingsystemat FUELfactoryafter modification

EXit molasses (45C)

then falls into the water-cooled crystalliser, where a further

temperature drop to 45C is achieved.

Tubular and plate heat exchangers had been used by Julli-

enne and Munsamy (1981) for molasses cooling. Broadfoot et

al. (1990) converted a discarded rotary mud filter to a full

scale scraped rotary drum molasses cooler. The temperature

of the molasses dropped from 60 to 38C when the cooler

operated at a speed of 2,6 rpm, processing 10 t/h molasses

with a molasses film thickness of 1,1 mm on the drum.

Quinan and de Viana (1991) used a plate heat exchanger to

cool molasses from 57 to 37C with water at 30C.

Antifoam chemicals such as sulphur dioxide, sodium sul-

phite and related compounds have been used in the sugar in-

dustry, and their inhibitive action on the Maillard reaction

was reported by Trivett (1953). Anet and Igles (1964) showed

that bisulphite addition compounds are relevant in the inhibi-

tion of browning by sulphur dioxide.

At MTMD, molasses is now diluted to 83 brix, and cooled

before being sent to the storage tank, which is now equipped

with systems of molasses re-circulation, level control and

temperature control. When the molasses temperature exceeds

55C an alarm is triggered off. A molasses first-in, first-out

system is adopted and a close watch is maintained on the

amount of steam injected in the centrifugals.

Proc S Afr Sug Technol Ass (1996) 70

Conclusions

To avoid the Maillard reaction occurring in the storage

tank, the molasses must be cooled to below 40C. It is there-

fore essential that after the centrifugal station molasses

should not be heated to lower its viscosity to facilitate pump-

ing. The molasses storage tank should be well equipped with

facilities for ventilation and re-circulation with an air injec-

tion, and preferably an inhibitor dosing system.

Acknowledgements

The authors wish to thank the Director of the MSIRI and

the Manager of FUEL sugar factories for permission to pub-

lish the paper, Mr J Deville, Senior Assistant Director at the

MSIRI for review of the paper, Mr JC Ng of the Mauritius

Molasses Co Ltd for information on molasses storage tank

design, and the staff in the Sugar Technology Division of the

MSIRI for their valued assistance in carrying out the sample

analysis.

REFERENCES

Anet, EFU andIngles,DL(1964). Mechanism of inhibitionof non-enzymic brown-

ing by sulphite. Chemistry and Industry: 1319.

253

Maillard Reaction in Molasses Storage Tank

Anon (1953). Spontaneouscombustionin storedmolasses.SAfr SugJ 37(11): 741-

743.

Broadfoot, R, White, ET, Fitzmaurice,AL andStendl, RJ(1990). Coolingof molas-

ses with a scraped rotary drum. ProcAust SocSug CaneTechnol12: 245-255.

Ducatillon,JP, Deruy, G and Lescure, JP (1985). Utilisationdu dosage des carbon-

ates pour la detectionde la reactionde Maillard. Sucrerie Francoise: 133-136.

Fromen, G and Bowland, E (1961). What causes rapid deterioration and destruction

of blackstrapmolasses. Louisiana SugarJournal 23(10): 28-32.

Honig, P (1965). Quantitative aspects of gas formation in final molasses (during

boilingof C-strikesand duringstorage, effect of compositionandage of molasses

and temperature). Proc int SocSug CaneTechnol XII: 1741-1749.

Hucker, GJ and Brooks, RF(1942). Food Research7. P 481.

Jullienne, LMSA and Munsamy, S (1981). Assessment of final molasses coolers.

ProcSAfr Sug Technol Ass 55: 83-84.

254

L Wong Sak Hoi andIC Chasteau de Balyon

Maillard, LC (1912a). Action des acides aminos sur les sucres; formation des

melanoidines par role metheique. Compt rend 154: 66.

Maillard, LC(1912b). Formationd'humus et de combustiblesmineraux sans inter-

ventions de I'oxygene atrnospherique des micro-organismes des hautes

temperatures ou des fortes pressions. Compt rend 155: 1554.

Newell,OM(1979). A preliminary investigation intofactors affectinggas formation

in massecuiteand molasses. ProcSAfr Sug Tee/mol Ass 53: 62-65.

Parsons, MJ (1958). Control of foaming in molassestank. SugarNews 34: 21-23.

Quinan, PB and de Viana, M (1991). Cooling final molasses through a plate heat

exchanger. ProcAust Soc Sug CaneTechnol13: 195-203.

Trivett, JC (1953). Defrothingof final molasses. Proc int Soc Sug Cane Tee/mol

VIII: 801-807.

Tseng, RH (1965). Rapid deterioration of molasses in storage. Taiwan Sugar XII:

1320.

ProcS Afr Sug Technol Ass (1996) 70

Vous aimerez peut-être aussi

- Chlorine: International Thermodynamic Tables of the Fluid StateD'EverandChlorine: International Thermodynamic Tables of the Fluid StatePas encore d'évaluation

- Electrochemical Processes in Biological SystemsD'EverandElectrochemical Processes in Biological SystemsAndrzej LewenstamPas encore d'évaluation

- Oxidation of Organic Compounds: Medium Effects in Radical ReactionsD'EverandOxidation of Organic Compounds: Medium Effects in Radical ReactionsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Activated Carbon For Purification of AlcoholDocument28 pagesActivated Carbon For Purification of AlcoholcmdcscribdPas encore d'évaluation

- Applied Energy: Shuvashish Behera, Rama Chandra Mohanty, Ramesh Chandra RayDocument4 pagesApplied Energy: Shuvashish Behera, Rama Chandra Mohanty, Ramesh Chandra RaygeoPas encore d'évaluation

- Nickel and Ruthenium CatalystsDocument11 pagesNickel and Ruthenium CatalystsOscarOchoaPas encore d'évaluation

- Method of Preparing S Nitrofurfural DiacetateDocument8 pagesMethod of Preparing S Nitrofurfural DiacetateKarla VTPas encore d'évaluation

- Proceedings. American Society of Sugar Cane Technologists. Vol. 1 - Papers For December, 1971Document21 pagesProceedings. American Society of Sugar Cane Technologists. Vol. 1 - Papers For December, 1971Josue QuirozPas encore d'évaluation

- ChemicaDocument47 pagesChemicaleeba simonPas encore d'évaluation

- Optimization of Sugar Cane Bagasse Pretreatment Process Using RSMDocument10 pagesOptimization of Sugar Cane Bagasse Pretreatment Process Using RSMInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- An Overview of Organic Liquid Phase Hydrogen Carriers: SciencedirectDocument17 pagesAn Overview of Organic Liquid Phase Hydrogen Carriers: Sciencedirectsj singhPas encore d'évaluation

- Synthesis of Furfural From Bagasse: Submitted To UIT-RGPVDocument14 pagesSynthesis of Furfural From Bagasse: Submitted To UIT-RGPVvivekPas encore d'évaluation

- ErythromycinDocument2 pagesErythromycinAHMAD SYAUQI AIMAN BIN ABU BAKARPas encore d'évaluation

- Research ProjectDocument30 pagesResearch ProjectYasser AshourPas encore d'évaluation

- 1 finalreportGALALshared PDFDocument231 pages1 finalreportGALALshared PDFTram LaiPas encore d'évaluation

- Separations and Reactors Design Project Production of Allyl ChlorideDocument8 pagesSeparations and Reactors Design Project Production of Allyl ChlorideAdelina SimionPas encore d'évaluation

- Beet SugarDocument14 pagesBeet SugarMinjdeDiosPas encore d'évaluation

- 7acids and Other Products of Oxidation of SugarsDocument108 pages7acids and Other Products of Oxidation of SugarsHung le Van100% (1)

- Xanthan Gum ProductionDocument7 pagesXanthan Gum ProductionAreen Emilia Faizlukman JerryPas encore d'évaluation

- 3.natural Coagulant Review PaperDocument19 pages3.natural Coagulant Review PaperMagesh kumarPas encore d'évaluation

- Edible TallowDocument3 pagesEdible TallowteddydePas encore d'évaluation

- Maza Gomez ThesisDocument154 pagesMaza Gomez ThesisSulaiman Salihu100% (1)

- Yeast ProductionDocument7 pagesYeast Productionboonsom100% (1)

- Essential Rendering OperationsDocument21 pagesEssential Rendering OperationsMauricio GuanellaPas encore d'évaluation

- Sugar Cane Juice Clarification Process - Google PatentsDocument6 pagesSugar Cane Juice Clarification Process - Google Patentskaushikei22Pas encore d'évaluation

- Hydrogenation of Fatty Acid Methyl Esters To FattyDocument9 pagesHydrogenation of Fatty Acid Methyl Esters To FattyYulius Harmawan Setya PratamaPas encore d'évaluation

- Chapter 2 Material and Energy BalancesDocument15 pagesChapter 2 Material and Energy Balancesaa0809Pas encore d'évaluation

- MTO-II Manual PDFDocument24 pagesMTO-II Manual PDFDhande SanketPas encore d'évaluation

- Details of Manufacturing Butter PDFDocument7 pagesDetails of Manufacturing Butter PDFgutierrez_rgcPas encore d'évaluation

- Reactor Design 1Document8 pagesReactor Design 1Daneyal BabarPas encore d'évaluation

- Synthesis of 2-Ethylhydroanthraquinone For The Production of Hydrogen Peroxide in A Catalytic Slurry Reactor: Design CaseDocument6 pagesSynthesis of 2-Ethylhydroanthraquinone For The Production of Hydrogen Peroxide in A Catalytic Slurry Reactor: Design CasezibaPas encore d'évaluation

- Sucralose: Omar A.A. Aldeeb, Hoda Mahgoub, Nagwa H. FodaDocument40 pagesSucralose: Omar A.A. Aldeeb, Hoda Mahgoub, Nagwa H. FodaDanaePas encore d'évaluation

- Lecture 20 Sodium Thiosulfate PDFDocument5 pagesLecture 20 Sodium Thiosulfate PDFPutri AzzahraPas encore d'évaluation

- US Patent Manufacturing of Propylene GlycolDocument5 pagesUS Patent Manufacturing of Propylene GlycolRegiyanti RPas encore d'évaluation

- Alternative Process of Glucose To Be SorbitolDocument3 pagesAlternative Process of Glucose To Be SorbitolNabilatun SholikhaPas encore d'évaluation

- 1 - Presentation Genencor 2011 05 25Document120 pages1 - Presentation Genencor 2011 05 25Kannan RanganathanPas encore d'évaluation

- Dimethyl Ether SDS E4589Document7 pagesDimethyl Ether SDS E4589Daniil GhilescuPas encore d'évaluation

- Msds Hydroxypropyl Starch Ether HpsDocument8 pagesMsds Hydroxypropyl Starch Ether HpsWANGYUSHENG Kima Chemical Co LtdPas encore d'évaluation

- The Chemistry of EthanolDocument21 pagesThe Chemistry of EthanolHarvey Obispo AceritPas encore d'évaluation

- 1bottles Group Production of Bisphenol-ADocument112 pages1bottles Group Production of Bisphenol-AJames BelciñaPas encore d'évaluation

- 7 Nicotinate Articlerod PDFDocument8 pages7 Nicotinate Articlerod PDFheriPas encore d'évaluation

- HP Pavilion 15-AB Series Quanta X1BD DAX1BDMB6F0 Rev F SchematicsDocument49 pagesHP Pavilion 15-AB Series Quanta X1BD DAX1BDMB6F0 Rev F Schematicsvi aPas encore d'évaluation

- Optimization of Baker's Yeast Drying in Industrial Continuous Fluidized Bed DryerDocument6 pagesOptimization of Baker's Yeast Drying in Industrial Continuous Fluidized Bed DryerMohamadMostafaviPas encore d'évaluation

- Process Flow Diagram For Vco DrawDocument1 pageProcess Flow Diagram For Vco DrawRembert BlanquezaPas encore d'évaluation

- MSDS Gengard GN8168Document11 pagesMSDS Gengard GN8168carrspaintsPas encore d'évaluation

- Frontiers of CO Capture and Utilization (CCU) Towards Carbon NeutralityDocument19 pagesFrontiers of CO Capture and Utilization (CCU) Towards Carbon Neutrality¡SrDanecMxPas encore d'évaluation

- 113.ammonium ChlorideDocument19 pages113.ammonium ChloridetadiyosPas encore d'évaluation

- Chapter 2 - History of Dimensional AnalysisDocument7 pagesChapter 2 - History of Dimensional AnalysisShaikh Abdur RazzakPas encore d'évaluation

- IEA - IEA Oil Information 2018-IEA (2018) PDFDocument758 pagesIEA - IEA Oil Information 2018-IEA (2018) PDFivanushk417Pas encore d'évaluation

- Soluble SilicatesDocument311 pagesSoluble SilicatesRicardo Castillo RamirezPas encore d'évaluation

- Ferrous Glycinate (Processed With Citric Acid) : SynonymsDocument3 pagesFerrous Glycinate (Processed With Citric Acid) : SynonymsIfra AkhlaqPas encore d'évaluation

- Biological Management of Solar SaltworksDocument4 pagesBiological Management of Solar SaltworksmarcusdelbelPas encore d'évaluation

- Advantages of Non-Perforated Coating PansDocument3 pagesAdvantages of Non-Perforated Coating PanschevypickupPas encore d'évaluation

- Chapter 9.6 QuizDocument2 pagesChapter 9.6 QuizspeedkillzPas encore d'évaluation

- Continuous Fat Splitting Plants Using The Colgate-Emery ProcessDocument5 pagesContinuous Fat Splitting Plants Using The Colgate-Emery ProcessAri nahirPas encore d'évaluation

- Efectos de Las Concentraciones de Oxígeno Disuelto y Ácido Acético en La Producción de Ácido Acético en El Cultivo Continuo de Acetobacter AcetiDocument6 pagesEfectos de Las Concentraciones de Oxígeno Disuelto y Ácido Acético en La Producción de Ácido Acético en El Cultivo Continuo de Acetobacter AcetiWendy Rivera100% (1)

- Msds Stearic AcidDocument6 pagesMsds Stearic AcidSanggari MogarajaPas encore d'évaluation

- Material Safety Data Sheet: Oxbow Calcining LLCDocument4 pagesMaterial Safety Data Sheet: Oxbow Calcining LLCFinka Pertama PutriPas encore d'évaluation

- 2zno 3b2o3 3h2o, Reological ModelDocument4 pages2zno 3b2o3 3h2o, Reological ModelKary ShitoPas encore d'évaluation

- Infectious Diseases - 02Document21 pagesInfectious Diseases - 02Arthur YanezPas encore d'évaluation

- Infectious Diseases - 05Document27 pagesInfectious Diseases - 05Arthur YanezPas encore d'évaluation

- Infectious Diseases - 03Document23 pagesInfectious Diseases - 03Arthur YanezPas encore d'évaluation

- Infectious Diseases - 04Document21 pagesInfectious Diseases - 04Arthur YanezPas encore d'évaluation

- Clinical Microbiology - Documenti GoogleDocument10 pagesClinical Microbiology - Documenti GoogleArthur YanezPas encore d'évaluation

- Clinical MicrobiologyDocument16 pagesClinical MicrobiologyArthur YanezPas encore d'évaluation

- Clinical Microbiology (24 - 11 - 21)Document19 pagesClinical Microbiology (24 - 11 - 21)Arthur YanezPas encore d'évaluation

- Antimicrobial Pharmacology (19.10.2021)Document24 pagesAntimicrobial Pharmacology (19.10.2021)Arthur YanezPas encore d'évaluation

- Centenarians As A Model of LongevityDocument28 pagesCentenarians As A Model of LongevityArthur YanezPas encore d'évaluation

- Clinical Microbiology - (10.11)Document11 pagesClinical Microbiology - (10.11)Arthur YanezPas encore d'évaluation

- 1-Clinical Microbiology (27.10)Document11 pages1-Clinical Microbiology (27.10)Arthur YanezPas encore d'évaluation

- 02-Clinical Microbiolgy ReviewDocument23 pages02-Clinical Microbiolgy ReviewArthur YanezPas encore d'évaluation

- Clinical Microbiology (17 - 11)Document8 pagesClinical Microbiology (17 - 11)Arthur YanezPas encore d'évaluation

- Antimicrobial Pharmacology-03Document21 pagesAntimicrobial Pharmacology-03Arthur YanezPas encore d'évaluation

- Infectious Disease Pharmacology 04Document29 pagesInfectious Disease Pharmacology 04Arthur YanezPas encore d'évaluation

- 5-Medical Gases Systems. The Fifth Lecture.Document17 pages5-Medical Gases Systems. The Fifth Lecture.Fireproof Sistemas Electromecánicos100% (1)

- Infectious Pharmacology 01Document19 pagesInfectious Pharmacology 01Arthur YanezPas encore d'évaluation

- 2-Medical Gases Systems. The Second Lecture.Document12 pages2-Medical Gases Systems. The Second Lecture.Fireproof Sistemas ElectromecánicosPas encore d'évaluation

- 1-Medical Gases Systems. The First Lecture.Document18 pages1-Medical Gases Systems. The First Lecture.Fireproof Sistemas Electromecánicos100% (1)

- Immunosenescence, Inflammaging and Cell SenescenceDocument63 pagesImmunosenescence, Inflammaging and Cell SenescenceArthur YanezPas encore d'évaluation

- 4-Medical Gases Systems. The Fourth Lecture.Document23 pages4-Medical Gases Systems. The Fourth Lecture.Fireproof Sistemas ElectromecánicosPas encore d'évaluation

- 3-Medical Gases Systems. The Third Lecture.Document17 pages3-Medical Gases Systems. The Third Lecture.Fireproof Sistemas ElectromecánicosPas encore d'évaluation

- Biomarkers of AgeDocument36 pagesBiomarkers of AgeArthur YanezPas encore d'évaluation

- Mahase - BMJ - Covid-19 Universities Roll Out Pooled Testing of Students in Bid To Keep Campus OpenDocument2 pagesMahase - BMJ - Covid-19 Universities Roll Out Pooled Testing of Students in Bid To Keep Campus OpenArthur YanezPas encore d'évaluation

- Lavezzo - Suppression of A SARS-CoV-2 Outbreak in The Italian Municipality of Vo'Document19 pagesLavezzo - Suppression of A SARS-CoV-2 Outbreak in The Italian Municipality of Vo'Arthur YanezPas encore d'évaluation

- Nelson 20th MCQDocument593 pagesNelson 20th MCQcharlesy T89% (19)

- Biology of AgingDocument37 pagesBiology of AgingArthur YanezPas encore d'évaluation

- Medical Education - 2009 - Bordage - Conceptual Frameworks To Illuminate and MagnifyDocument8 pagesMedical Education - 2009 - Bordage - Conceptual Frameworks To Illuminate and MagnifyArthur YanezPas encore d'évaluation

- Research in Medical Education - A Primer For Medical StudentsDocument16 pagesResearch in Medical Education - A Primer For Medical StudentsArthur YanezPas encore d'évaluation

- How To Build A Shipping Container HouseDocument37 pagesHow To Build A Shipping Container Housegschiro93% (14)

- ITC Schemes Debit Working - RelianceDocument462 pagesITC Schemes Debit Working - ReliancehwagdarePas encore d'évaluation

- Recipe Mushroom QuicheDocument3 pagesRecipe Mushroom QuicheGMHeathcliffPas encore d'évaluation

- Applying For A Job: Eats RestaurantDocument3 pagesApplying For A Job: Eats RestaurantJuniorChancoPas encore d'évaluation

- Role of Packaging On Consumer Buying BehaviorDocument93 pagesRole of Packaging On Consumer Buying BehaviorAqeelaBabar67% (3)

- 06 Raise Organic Small RuminantsDocument44 pages06 Raise Organic Small RuminantsAlma Chavez Cubilla88% (8)

- Prevalence and Awareness of Obesity and Its Risk Factors Among Adolescents in Two Schools in A Northeast Indian CityDocument12 pagesPrevalence and Awareness of Obesity and Its Risk Factors Among Adolescents in Two Schools in A Northeast Indian CityShamerra SabtuPas encore d'évaluation

- The Csec HelperDocument71 pagesThe Csec Helperapi-291242485100% (1)

- Bianchi's Pizzeria MenuDocument3 pagesBianchi's Pizzeria MenuHattiesburgooPas encore d'évaluation

- NFDN 2004 Prenatal Teaching Plan Case 4Document7 pagesNFDN 2004 Prenatal Teaching Plan Case 4api-328324207100% (2)

- Artisan Pizza and Flatbread in Five Minutes A DayDocument13 pagesArtisan Pizza and Flatbread in Five Minutes A DayMacmillan Publishers60% (5)

- Indian Agrochemicals Industry: Insights and Outlook: February, 2019 I Industry ResearchDocument17 pagesIndian Agrochemicals Industry: Insights and Outlook: February, 2019 I Industry ResearchVenkatram PailaPas encore d'évaluation

- (Averrhoa Bilimbi Linn) Dan Lama Penyimpanan Terhadap KarakteristikDocument10 pages(Averrhoa Bilimbi Linn) Dan Lama Penyimpanan Terhadap KarakteristikAnisandrianiPas encore d'évaluation

- Wildlife Id GuideDocument23 pagesWildlife Id GuideJoPas encore d'évaluation

- 17 Mejores Recetas de Batidos VerdesDocument38 pages17 Mejores Recetas de Batidos VerdesSimónHernandezcCastañedaPas encore d'évaluation

- Got LunchDocument7 pagesGot LunchROSA MARIA EL CAJUTAYPas encore d'évaluation

- Diaspora OromiaDocument10 pagesDiaspora OromiaKhadar WarsamePas encore d'évaluation

- Volume 94, Issue 18Document28 pagesVolume 94, Issue 18The TechniquePas encore d'évaluation

- Lava Latte MenuDocument2 pagesLava Latte MenuIan ArungaPas encore d'évaluation

- Laboy Tiller RTB PDFDocument16 pagesLaboy Tiller RTB PDFMaria RicPas encore d'évaluation

- IMC BaskinRobbinsDocument19 pagesIMC BaskinRobbinsmanju09dreams100% (1)

- fm3 Chapter08Document19 pagesfm3 Chapter08catherinephilippouPas encore d'évaluation

- Pharmaceutical Dosage FormsDocument14 pagesPharmaceutical Dosage FormsMustafa Hamido0% (1)

- Chicken Meat Vs Duck MeatDocument67 pagesChicken Meat Vs Duck Meatsantaanaalfie137Pas encore d'évaluation

- Winners and Losers in Forest Product CommercialisDocument58 pagesWinners and Losers in Forest Product CommercialisJob MateusPas encore d'évaluation

- 08.02.2021 HeaderDocument17 pages08.02.2021 HeaderRoshniPas encore d'évaluation

- Healthy Camping RecipesDocument34 pagesHealthy Camping RecipesRecipeRain100% (1)

- Synopsis: For The Proposed Assignment of Consumer BehaviourDocument4 pagesSynopsis: For The Proposed Assignment of Consumer BehaviourAmitesh PuriPas encore d'évaluation

- Use of English: Such: +a/an (Singular) o Nada (En Plural)Document9 pagesUse of English: Such: +a/an (Singular) o Nada (En Plural)Sara Fernandez BuendiaPas encore d'évaluation

- Gardosol: Description: GARDOSOL Has Been Registered Under The NSF International Registration Guidelines ForDocument2 pagesGardosol: Description: GARDOSOL Has Been Registered Under The NSF International Registration Guidelines ForAardwolf PestkarePas encore d'évaluation

- Recipes From The Lee Bros. Charleston KitchenDocument13 pagesRecipes From The Lee Bros. Charleston KitchenThe Recipe Club100% (5)