Académique Documents

Professionnel Documents

Culture Documents

414

Transféré par

rojasbelloDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

414

Transféré par

rojasbelloDroits d'auteur :

Formats disponibles

D I E S E L G E N E R A T O R

S E T

STANDBY 800 ekW PRIME 725 ekW

60 Hz

Caterpillar is leading the power generation marketplace with Power Solutions engineered to deliver unmatched flexibility, expandability, reliability, and cost-effectiveness.

Shown with Optional Equipment

FEATURES

FULL RANGE OF ATTACHMENTS Wide range of bolt-on system expansion attachments, factory designed and tested UL 2200 UL 2200 Listed configuration available ENCLOSURES (Optional) Weather protective and sound attenuated SINGLE-SOURCE SUPPLIER Complete systems designed at Caterpillar ISO9001 certified facilities Certified Prototype Tested with torsional analysis WORLDWIDE PRODUCT SUPPORT Worldwide parts availability through the Caterpillar dealer network With over 1,200 dealer outlets operating in 166 countries, youre never far from the Caterpillar part you need. 99.5% of parts orders filled within 48 hours. The best product support record in the industry. Caterpillar dealer service technicians are trained to service every aspect of your electric power generation system. Preventive maintenance agreements The Cat Scheduled Oil Sampling (SOSSM) program cost effectively detects internal engine component condition, even the presence of unwanted fluids and combustion by-products

CAT 3412 STA DIESEL ENGINE Reliable, rugged, durable design Field-proven in thousands of applications worldwide Four-stroke-cycle diesel engine combines consistent performance and excellent fuel economy with minimum weight CAT SR4B GENERATOR Designed to match performance and output characteristics of Caterpillar diesel engines Optimum winding pitch for minimum total harmonic distortion and maximum efficiency Segregated AC/DC, low voltage accessory box provides single point access to accessory connections UL 1446 Recognized Class F available for UL 2200 packaged generator set CAT CONTROL PANELS Three levels of controls, designed to meet individual customer needs: EMCP II provides digital monitoring, metering, and protection EMCP II provides EMCP II features along with full-featured power metering and protective relaying Switchgear conversion provides easy interface for remote switchgear

W H E R E

T H E

W O R L D

T U R N S

F O R

P O W E R

S T A N D B Y P R I M E 6 0 H z

8 0 0 7 2 5

e k W e k W

FACTORY INSTALLED STANDARD & OPTIONAL EQUIPMENT

System Air Inlet Cooling Standard Modular air cleaner, single element with dust evacuator Service indicator Radiator with guard (duct flange included) Coolant drain line with valve Fan and belt guards Caterpillar Extended Life Coolant Low coolant level alarm and shutdown Stainless steel exhaust flex and ANSI weld flange Optional Dual element air cleaner Heavy-duty air cleaner Jacket water heater with shutoff valves Heat exchanger and expansion tank

Exhaust

Fuel

Generator

Governor Control Panels Lube Mounting

Primary fuel filter/water separator Secondary fuel filter Fuel priming pump Flexible fuel lines Permanent magnet class H insulation class F temperature rise [130 C standby/105 C prime] Reactive droop kit 2:1 Volts/Hz AVR Extension box Electronic EMCP II Lubricating oil and filter Oil drain line with valves Fumes disposal Formed steel base Linear vibration isolators between base and engine-generator 45 amp charging alternator Energized To Run (ETR) fuel shutoff solenoid 24 volt starting motor Batteries with rack and cables Battery disconnect switch

20 dBA muffler and ANSI weld flanges 25 dBA muffler and ANSI weld flanges 30 dBA muffler and ANSI weld flanges Elbow kit, through-wall installation kit Manifold and turbocharger guards All mufflers have side/end inlet options Manual transfer pump (3) Automatic transfer systems to choose from Low fuel level alarm and shutdown Self excited Digital Voltage Regulator Digital Voltage Regulator with KVAR/PF control Anti-condensation space heater Oversize and premium generators Circuit breaker, UL listed, 3-pole with shunt trip Multiple breaker capability Electronic load sharing Switchgear conversion EMCP II Local alarm and remote annunciator modules Manual sump pump Integral fuel tank base Sub base fuel tank Wide base Skid base Heavy-duty starting system Integral 5 and 10 amp battery chargers Oversize batteries Ether starting aid Enclosures sound attenuated, weather protective Automatic transfer switches Floor standing circuit breakers

Starting/ Charging

Other

SPECIFICATIONS

CAT SR4B GENERATOR

Frame size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 597 Type . . . . . . . . . Permanent magnet, static regulated, brushless Construction . . . . . . . . . . . . . . . . . . Single bearing, close coupled Three phase . . . . . . . . . . . . . . . . . . . . . . . . . 12 lead reconnectable Insulation . . . . . . Class H with tropicalization and antiabrasion IP rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drip proof IP22 Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pilot shaft Overspeed capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150% Wave form. . . . . . . . . . . . . . . . . . . . . . . . . . Less than 5% deviation Paralleling capability . . . . . . . . . . . . . . . . With droop transformer Voltage regulator . . . . . 3-phase sensing with 2 Volts-per-Hertz Voltage regulation . . . . . . . . . . . . . . Less than 1/2% (steady state) Less than 1% (no load to full load) TIF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 50 THD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 5%

CAT ENGINE

3412 STA, V-12, 4-stroke-cycle watercooled diesel Bore mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137 (5.4) Stroke mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152 (6.0) Displacement L (cu in) . . . . . . . . . . . . . . . . . . . . . . . . 27.0 (1649) Compression ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.0:1 Aspiration . . . . . . . . . . . . . . . . . . . . . . . Turbocharged, Aftercooled Fuel system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical pump Governor type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronic

CAT CONTROL PANEL

24 Volt DC Control NEMA 1, IP22 enclosure Electrically dead front Lockable hinged door Generator instruments meet ANSI C-39-1 Terminal box mounted Single location customer connector point UL 508A Listed Consult your Caterpillar dealer for available voltages.

S T A N D B Y P R I M E 6 0 H z

8 0 0 7 2 5

e k W e k W

TECHNICAL DATA

Generator Set 1800 rpm/60 Hz Package Performance Power rating Power rating @ 0.8 PF Fuel Consumption 100% load with fan 75% load with fan 50% load with fan Cooling System Ambient air temperature Air flow restriction (system) Air flow (maximum @ rated speed for standard radiator arrangement) Engine coolant capacity with radiator Engine coolant capacity without radiator Exhaust System Combustion air inlet flow rate Exhaust stack gas temperature Exhaust gas flow rate Exhaust flange size (internal diameter) Exhaust system backpressure (maximum allowable) Heat Rejection Heat rejection to coolant (total) Heat rejection to exhaust (total) Heat rejection to atmosphere from engine Heat rejection to atmosphere from generator Alternator* Motor starting capability @ 30% voltage dip Frame Temperature rise Lube System Refill volume with filter change for standard sump ekW kVA L/hr L/hr L/hr Deg C kPa m3/min L L m3/min Deg C m3/min mm kPa kW kW kW kW kVA Deg C L Qts 139 Gal/hr Gal/hr Gal/hr Deg F in water cfm Gal Gal cfm Deg F cfm in in water Btu/min Btu/min Btu/min Btu/min 221.8 165.7 115.7 52 0.12 1695 133 58.6 69.6 518 195.1 203 6.7 508 855 131 40.15 2407 597 130 147 139 Standby DM0636-02 800 1000 58.6 43.8 30.6 126 0.48 59,894 35.1 15.5 2458 964 6889 8 26.9 28,890 48,624 7450 2283 198.8 150.6 106.5 50 0.12 1695 133 58.6 63.0 512 175.2 203 6.7 457 764 108 35.84 2407 597 105 147 Prime DM0633-02 725 906 52.5 39.8 28.1 122 0.48 59,894 35.1 15.5 2225 953 6186 8 26.9 25,990 43,449 6142 2038

*UL 2200 Listed packages may have oversized generators with a different temperature rise and motor starting characteristics.

RATING DEFINITIONS AND CONDITIONS

Meets or Exceeds International Specifications: ABGSM TM3, AS1359, AS2789, BS4999, BS5000, BS5514, DIN6271, DIN6280, EGSA101P, IEC34/1, ISO3046/1, ISO8528, JEM1359, NEMA MG1-22, VDE0530, 89/392/EEC, 89/336/EEC Standby Output available with varying load for the duration of the interruption of the normal source power. Standby power in accordance with ISO8528. Fuel stop power in accordance with ISO3046/1, AS2789, DIN6271, and BS5514. Prime Output available with varying load for an unlimited time. Prime power in accordance with ISO8528. 10% overload power in accordance with ISO3046/1, AS2789, DIN6271, and BS5514 available on request. Ratings are based on SAE J1349 standard conditions. These ratings also apply at ISO3046/1, DIN6271, and BS5514 standard conditions. Fuel rates are based on fuel oil of 35 API [@ 16 C (60 F)] gravity having an LHV of 42 780 kJ/kg (18,390 Btu/lb) when used at 29 C (85 F) and weighing 838.9 g/liter (7.001 lbs/U.S. gal.). Additional ratings may be available for specific customer requirements. Consult your Caterpillar representative for details.

S T A N D B Y P R I M E 6 0 H z

8 0 0 7 2 5

e k W e k W

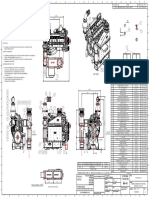

STANDBY/PRIME POWER GENERATOR SET PACKAGE TOP VIEW

4485.0 [176.57] Air Inlet Air Cleaner Exhaust Fumes Disposal Tube Radiator Cap

1812.4 [71.35]

Fumes Disposal Tube Oil Level Gauge Oil Filler Fuel Priming Pump

Air Cleaner Air Inlet

STANDBY/PRIME POWER GENERATOR SET PACKAGE SIDE VIEW

Oil Filler PEEC Electronic Governor Control Box 4485.0 [176.57] Exhaust (See Detail Sheet 8) Fuel Priming Pump 35.1 [1.38] = Maximum Stroke Air Filter Fuel Pressure Gauge Shunt Line Connection 3/4 Std Pipe Tap Oil Level Gauge Lifting Eye

1938.0 [76.30]

1939.6 [76.36]

Fumes Disposal Tube 31.75 [1.25] ID 2 Places

Customer Mounting Holes Primary Fuel Filter 32.0 [1.26] Removal Distance Fuel Supply 1/2-14 NPTF Fuel Return 1/2-14 NPTF Fuel Filter 27.9 [1.10] Removal Distance

Customer Mounting Holes Oil Filter 27.9 [1.10] Removal Distance Oil Drain Customer Mounting Holes

Package Dimensions Length Width Radiator Height Control Panel Height Shipping Weight 4485.0 mm 1812.4 mm 1939.6 mm 1938.0 mm 6762 kg 176.57 in 71.35 in 76.36 in 76.30 in 14,910 lb Note: General configuration not to be used for installation. See general dimension drawings for detail (Drawing #186-3619).

www.CAT-ElectricPower.com TMI Reference No.: DM0636-02, DM0633-02 U.S. sourced LEHX9481-03 (11-00) 2000 Caterpillar All rights reserved. Printed in U.S.A. Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- AwardDocument3 pagesAwardrojasbelloPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- UnabomberDocument1 pageUnabomberrojasbelloPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- LEKQ7518 G3500 Engine BasicsDocument50 pagesLEKQ7518 G3500 Engine BasicsJaime Calmet100% (8)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- PDFSig QFormal RepDocument1 pagePDFSig QFormal RepcarloschmPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Avance de ObrasDocument1 pageAvance de ObrasrojasbelloPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Caso de Estudio ManufactureraDocument2 pagesCaso de Estudio ManufacturerarojasbelloPas encore d'évaluation

- Caso de Estudio EDUCACIÓNDocument3 pagesCaso de Estudio EDUCACIÓNrojasbelloPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- GEP33-1 (3-Phase) : Diesel Generating SetDocument6 pagesGEP33-1 (3-Phase) : Diesel Generating SetAndres AlegriaPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Caso de Estudio TelecomunicacionesDocument2 pagesCaso de Estudio TelecomunicacionesrojasbelloPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Wheel - Dozers - WD600-3 PDFDocument8 pagesWheel - Dozers - WD600-3 PDFJohn AndersonPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Eq Generacion Electrica Iluminacion Olympian GEP135-2Document6 pagesEq Generacion Electrica Iluminacion Olympian GEP135-2Luis Antonio Salleres CasalPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- GEH275Document6 pagesGEH275fmpinho100% (1)

- SerialDocument1 pageSerialJuan Pablo AnselmoPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- SerialDocument1 pageSerialJuan Pablo AnselmoPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Change LogDocument7 pagesChange LogrojasbelloPas encore d'évaluation

- EulaDocument8 pagesEularojasbelloPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Read MeDocument1 pageRead MerojasbelloPas encore d'évaluation

- Read MeDocument1 pageRead MerojasbelloPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Read MeDocument1 pageRead MerojasbelloPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Read MeDocument1 pageRead MerojasbelloPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Steam Install AgreementDocument2 pagesSteam Install Agreementkoi9Pas encore d'évaluation

- Installation TroubleshootDocument1 pageInstallation TroubleshootJayesh KatariaPas encore d'évaluation

- HHC (S) 775 60Document4 pagesHHC (S) 775 60rojasbelloPas encore d'évaluation

- Ip 40 ElecDocument1 pageIp 40 ElecrojasbelloPas encore d'évaluation

- Problem A Stem A 3Document9 pagesProblem A Stem A 3rojasbelloPas encore d'évaluation

- Nissan Skyline r33 GTST Cam Belt ChangeDocument9 pagesNissan Skyline r33 GTST Cam Belt Changestoopid_isPas encore d'évaluation

- 1000kva Cat GeneratorDocument6 pages1000kva Cat GeneratorAdnan80Pas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- CF250T-5 (V5) Maintenance ManualDocument236 pagesCF250T-5 (V5) Maintenance ManualmoorerhousePas encore d'évaluation

- General Characteristics: DescriptiveDocument5 pagesGeneral Characteristics: DescriptiveJovan KosticPas encore d'évaluation

- How The Efficiency of Radiator For Transformer Cooling Is MeasuredDocument4 pagesHow The Efficiency of Radiator For Transformer Cooling Is MeasuredAbdulyunus AmirPas encore d'évaluation

- How Cooling System WorksDocument32 pagesHow Cooling System WorksAiman NasirPas encore d'évaluation

- Illustrated Parts Catalog: Stemme S10Document82 pagesIllustrated Parts Catalog: Stemme S10AndresLopezMllanPas encore d'évaluation

- Parts Manual: CMP20-30L FX20-30L SF20-30LDocument117 pagesParts Manual: CMP20-30L FX20-30L SF20-30LLuiz SchwindenPas encore d'évaluation

- Unit Description SpecificationDocument7 pagesUnit Description SpecificationSoporte Tecnico AutoMotrixPas encore d'évaluation

- F 008am - Plta Pscs Pc1250 8Document6 pagesF 008am - Plta Pscs Pc1250 8TaufikPas encore d'évaluation

- Gas Turbine Start SystemDocument108 pagesGas Turbine Start Systemhumane2896% (28)

- GEP150 (3-Phase) : Diesel Generating SetDocument6 pagesGEP150 (3-Phase) : Diesel Generating Setluis100% (1)

- A Case Study On Power Train in Supra 2011 and 2012Document11 pagesA Case Study On Power Train in Supra 2011 and 2012Murali S Krishnan100% (1)

- Maintenance Intervals - Operation and Maintenance Manual Expert (432d)Document47 pagesMaintenance Intervals - Operation and Maintenance Manual Expert (432d)Luis Carlos Gutierrez ArapaPas encore d'évaluation

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocument50 pagesMaintenance Intervals: Operation and Maintenance Manual ExcerptVidi Efendi50% (2)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Engine Cooling SystemDocument28 pagesEngine Cooling SystemSagar Dadhich100% (1)

- TF April 2014 WebDocument20 pagesTF April 2014 Webjaskaran singhPas encore d'évaluation

- 16 - Cooling PDFDocument13 pages16 - Cooling PDFMichael SakellaridisPas encore d'évaluation

- Vios (Mar 2023)Document8 pagesVios (Mar 2023)Vasanthan PadbanadhanPas encore d'évaluation

- IGNIS Uputstvo ENGDocument13 pagesIGNIS Uputstvo ENGVeronica WaltersPas encore d'évaluation

- P825031 PyrobanDocument4 pagesP825031 PyrobanLAryo YogisworoPas encore d'évaluation

- GETrans - GEVO Tier 4 Locomotive Support SystemsDocument142 pagesGETrans - GEVO Tier 4 Locomotive Support SystemsTim MarvinPas encore d'évaluation

- Authority: London Borough of Hackney Property Condition Survey UPRN: 100023020750 Wally Foster Community CentreDocument42 pagesAuthority: London Borough of Hackney Property Condition Survey UPRN: 100023020750 Wally Foster Community CentreFederico OrtizPas encore d'évaluation

- Sharan No. 802 / 1: RelaysDocument10 pagesSharan No. 802 / 1: RelaysYaryna LiubuskaPas encore d'évaluation

- Cooling Fan RecallDocument10 pagesCooling Fan RecalljamesPas encore d'évaluation

- Lebh0023 01Document64 pagesLebh0023 01Sergio Ramos Rivera100% (1)

- Systems Operation Testing and Adjusting: 400C Industrial EngineDocument68 pagesSystems Operation Testing and Adjusting: 400C Industrial EnginejwdPas encore d'évaluation

- Nad 5986 DC enDocument3 pagesNad 5986 DC enmnezamiPas encore d'évaluation

- Lamborghini Diablo Engine Parts ManualDocument40 pagesLamborghini Diablo Engine Parts ManualAndrei Huţanu100% (1)

- SD310Document2 pagesSD310Alberto Jamaica DelgadoPas encore d'évaluation