Académique Documents

Professionnel Documents

Culture Documents

Lca PDF

Transféré par

ayaskantkTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Lca PDF

Transféré par

ayaskantkDroits d'auteur :

Formats disponibles

Toward a Sustainable Cement Industry

Substudy 6:What LCA Can Tell Us about the Cement Industry March 2002

by Steven B. Young, Shannon Turnbull, Andrea Russell Five Winds International

with contributions from Konrad Saur, Five Winds International, Germany Kun Mo Lee, Anjou University, Korea Jose Antonio Costa Perez, Brazil

An Independent Study Commissioned by:

World Business Council for Sustainable Development This substudy is one of 13 research investigations conducted as part of a larger project entitled, "Toward a Sustainable Cement Industry". The project was commissioned by the World Business Council for Sustainable Development as one of a series of member-sponsored projects aimed at converting sustainable development concepts into action. The report represents the independent research efforts of Battelle Memorial Institute and their subcontractors to identify critical issues for the cement industry today, and pathways forward toward a more sustainable future. While there has been considerable interactive effort and exchange of ideas with many organizations within and outside the cement industry during this project, the opinions and views expressed here are those of Battelle and its subcontractors. Battelle Battelle endeavors to produce work of the highest quality, consistent with our contract commitments. However, because of the research nature of this work, the recipients of this report shall undertake the sole responsibility for the consequence of their use or misuse of, or inability to use, any information, data or recommendation contained in this report and understand that Battelle makes no warranty or guarantee, express or implied, including without limitation warranties of fitness for a particular purpose or merchantability, for the contents of this report. Battelle does not engage in research for advertising, sales promotion, or endorsement of our clients' interests including raising investment capital or recommending investments decisions, or other publicity purposes, or for any use in litigation. The recommendations and actions toward sustainable development contained herein are based on the results of research regarding the status and future opportunities for the cement industry as a whole. Battelle has consulted with a number of organizations and individuals within the cement industry to enhance the applicability of the results. Nothing in the recommendations or their potential supportive actions is intended to promote or lead to reduced competition within the industry.

(W H A T L C A C A N T E L L U S A B O U T T H E C E M E N T I N D U S T R Y )

Foreword

Many companies around the globe are re-examining their business operations and relationships in a fundamental way. They are exploring the concept of Sustainable Development, seeking to integrate their pursuit of profitable growth with the assurance of environmental protection and quality of life for present and future generations. Based on this new perspective, some companies are beginning to make significant changes in their policies, commitments and business strategies. The study, of which this substudy is a part, represents an effort by ten major cement companies to explore how the cement industry as a whole can evolve over time to better meet the need for global sustainable development while enhancing shareholder value. The study findings include a variety of recommendations for the industry and its stakeholders to improve the sustainability of cement production. Undertaking this type of open, self-critical effort carries risks. The participating companies believe that an independent assessment of the cement industrys current status and future opportunities will yield long-term benefits that justify the risks. The intent of the study is to share information that will help any cement company regardless of its size, location, or current state of progress to work constructively toward a sustainable future. The pursuit of a more sustainable cement industry requires that a number of technical, managerial, and operational issues be examined in depth. This substudy, one of 13 conducted as a part of the project, provides the basis for assessing the current status or performance and identifies areas for progress toward sustainability on a specific topic. The project report entitled Toward a Sustainable Cement Industry may be found on the project website: http://www.wbcsdcement.org.

Study Groundrules This report was developed as part of a study managed by Battelle, and funded primarily by a group of ten cement companies designated for this collaboration as the Working Group Cement (WGC). By choice, the study boundaries were limited to activities primarily associated with cement production. Downstream activities, such as cement distribution, concrete production, and concrete products, were addressed only in a limited way. Battelle conducted this study as an independent research effort, drawing upon the knowledge and expertise of a large number of organizations and individuals both inside and outside the cement industry. The cement industry provided a large number of case studies to share practical experience. Battelle accepted the information in these case studies and in public information sources used. The WGC companies provided supporting information and advice to assure that the report would be credible with industry audiences. To assure objectivity, a number of additional steps were taken to obtain external input and feedback. A series of six dialogues was held with stakeholder groups around the world (see Section 1.5). The World Business Council for Sustainable Development participated in all meetings and monitored all communications between Battelle and the WGC. An Assurance Group, consisting of distinguished independent experts, reviewed both the quality and objectivity of the study findings. External experts reviewed advanced drafts of technical substudy reports. The geographic scope of the study was global, and the future time horizon considered was 20 years. Regional and local implementation of the study recommendations will need to be tailored to the differing states of socioeconomic and technological development.

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

List of Acronyms

AFR BRE ECCO EPP ESSAM GHG LCA LCCA LCI NIST NSW PCA SETAC WBCSD Alternative Fuels and Raw Materials Building Research Establishment Environmental Council of Concrete Organizations Environmentally preferable purchasing Ecologically Sustainable Strategic Asset Management Greenhouse gas Life Cycle Assessment Life Cycle Costing Analysis Life Cycle Inventory National Institute for Standards and Testing New South Wales Portland Cement Association Society of Environmental Toxicology and Chemistry World Business Council for Sustainable Development

ii

(W H A T L C A C A N T E L L U S A B O U T T H E C E M E N T I N D U S T R Y )

Glossary

Allocation Partitioning the input and output flows of a unit process to the product system under study.1 Cement Within the cement industry, and especially the technical domain, this term is often understood as Ordinary Portland Cement. Comparative assertion Environmental claim regarding the superiority or equivalence of one product versus a competing product that performs the same function.1 Co-product Any of two or more products from the same unit process.1 Eco-efficiency Reduction in the resource intensity of production; i.e., the input of materials, natural resources and energy compared with the output; essentially, doing more with less. Extended Producer Responsibility An strategy to reduce the impact from a product by making the manufacturer of the product responsible for the entire life cycle of the product and especially for the take-back, recycling and final disposal of the product.45 Flow Input to or output from a process or system.1 Functional unit Quantified performance of a product system for use as a reference unit in a life cycle assessment study.1

Greenhouse gases Gases in the earths lower atmosphere that may contribute to global warming, including the major component CO2.

Life cycle Consecutive and interlinked stages of a product system, from raw material acquisition or generation of natural resources to the final disposal.1 Life cycle approach Using a systems perspective (cradle-to-grave) to evaluate the full life cycletypically from raw materials through production to application and ultimate end-of-life. The approach also often involves consideration of multiple environmental issues (resources, air, water, land, etc.) and provides evaluations of impacts and their importance, for purposes of decision-making or management. Life Cycle Assessment (LCA) The LCA acronym is usually reserved for Life Cycle Assessment. This is a technical analytical procedure or method that includes the compilation and evaluation of the inputs and outputs and the potential impacts of a product system throughout its life cycle. Basic guidance and rules for LCA are defined in the ISO 14040 series of standards; however, key methodological requirements are not prescribed in the standard (boundary setting, cut-offs, allocations, determination and inclusion of significant inputs and outputs, etc.); rather these details are left to specific methods to determine. Life cycle data Life cycle data on resource inputs and environmental outputs of activities, products and systems have been compiled over the last few decades. Other categories of data are environmental effect information; weighting schemes; and life cycle costs. Life Cycle Inventory (LCI) analysis In LCA, the step of collection of the data necessary to meet the goals of the defined study, essentially an inventory of input/output data with respect to the system being studied.

iii

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

Life cycle management An approach to various management functions that takes into account the whole life cycle of the product or service. Life cycle methods Based on a life cycle approach, specific analysis methods have been developed to serve specific decision-making or management purposes (costing, design, marketing, strategy, etc.), and emphasis specific elements of analysis (graphical flowcharting, data inventory, impact assessment, interpretation). Life cycle study Life cycle studies are outcomes of analyses that use a life cycle approach, and may include results from LCA, qualitative life cycle reviews, life cycle costing, life cycle design, etc. In undertaking a study, the analyst needs to consider appropriate methods, tools and datadepending on the specific decision-making or management needs. Life cycle tools Numerous tools are available for users to apply life cycle methods and undertake life cycle studies. These include decision support tools such as software, matrices and checklists. Both quantitative and qualitative life cycle tools are used. Moreover, one or more methods (e.g., environmental indicators) might be available within a single tool. Integrated Product Policy An approach that considers how the environmental performance of products can be improved most cost-effectively. It is founded on the consideration of the impacts of products throughout their life-cycle, from the natural resources from which they come, through their use and marketing to their eventual disposal as waste (European Commission). Product stewardship All parties - designers, suppliers, manufacturers, distributors, retailers, consumers, recyclers, and disposers - involved in producing, selling, or using a product take responsibility for the full environmental and economic impacts of that product.45 Product system Collection of materially and energetically connected unit processes that perform one or more defined functions; can also include service systems.1 Stakeholder A person or group that has an investment, share, or interest in something, as a business or industry. Sustainable development Ability to continually meet the needs of the present without compromising the ability of future generations to meet their own needs. System boundary Interface between a product system and the environment or other product systems.1 Unit process Smallest portion of a product system for which data are collected when performing a life cycle assessment.1

iv

(W H A T L C A C A N T E L L U S A B O U T T H E C E M E N T I N D U S T R Y )

Executive Summary

Life Cycle Assessment (LCA) is a systems analysis tool to inform environmental decisionmaking for Sustainable Development. The goal of this substudy was to provide guidance to the cement industry regarding their use of LCA as part of their efforts to contribute to sustainable development. This substudy had two main objectives: 1. 2. To document the status of LCA and the cement industrys experience with LCA. To identify the potential relevance and value of LCA to designing a sustainable future for the cement industry.

The systems analysis that LCA provides is rigorous, science-based and whole-systems focused and is now standardized under the ISO 14040 international standards. From cradle-to-grave, the life cycle includes processes beginning at resource extraction from the earth and continues through cement production, to cement applications like concrete structures, their use, and product end-of-life. LCA results provide information that assists in defining key environmental issues, identifying important processes or activities across the system, and help provide structure in determining best options from an eco-efficiency perspective. Given the whole life-cycle concept of LCA, there is clear utility for LCA in the context of cement applications like concrete products and building structures. However, experience and practice show a broader relevance of LCA to the industry. Research unearthed about 80 publications related to LCA of cement. Some of these addressed cement directly; others applied the method for different purposes related to cement. Examples of LCA application to cement and downstream products are provided for Europe, Australia, Japan, Canada, Brazil and the U.S. The following ten uses of LCA for the cement industry were identified, including existing and potential applications. They are rated according to their value to the cement industry. Use of LCA

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Generic data sets Performance Improvement Industry Benchmarking Technology Assessment Industrial Ecology Assessment Greenhouse Gas Measurement Environmental Reporting Labeling Marketing Sales Support

Value to the cement industry

High Mid Mid Mid-High Low Mid Low-Mid Mid Mid-High Mid

There are more than 30 LCA software tools presently available. It was judged that the most useful tools to the cement industry are those with high quality databases, that comply with the ISO 14040 series of LCA standards, and that can be used to fulfill the full LCA methodology (from goals and scope definition, to inventory, to Life Cycle Impact Assessment and final Interpretation). LCA tools and data are primarily used to evaluate cement applications or endproducts, the results of which impact the use and selection of cement in the marketplace.

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

Recommendations

The industry should compile LCA data on cement and provide this information to support customers and other stakeholders. This effort, already well underway in some regions, meets basic requirements but is nonetheless challenging in the effort required. Internal use of LCA by the sector should continue, as this has already demonstrated value on a case-by-case basis in areas such as AFR evaluations. Cement customers and users should be informed on LCA by the cement industry. Professionals like architects and engineers need to be aware of the environmental advantages and disadvantages of cement and cement applications throughout the whole life cycle, not just during production. Coordination of LCA efforts is recommended. A mechanism is necessary to ensure consistency and accountability of methodologies and databases across the industry and internationally. Regional assistance will be required. Larger cement companies can contribute to the overall industry effort, supporting smaller companies and transferring experience from one area to another. More proactive options include cement companies engaging their suppliers and downstream partners, maintaining LCA profiles of alternative products and applications, and using LCA for communications.

vi

(W H A T L C A C A N T E L L U S A B O U T T H E C E M E N T I N D U S T R Y )

Table of Contents

Introduction ......................................................................................................................... 1 1.1. Objectives ................................................................................................................... 1 1.2. Scope ......................................................................................................................... 1 1.3. Technical Approach .................................................................................................... 1 2. State of LCA Practice.......................................................................................................... 3 2.1. What is Life Cycle Assessment? ................................................................................. 3 2.2. LCA method................................................................................................................ 4 2.3. State of Practice ......................................................................................................... 7 3. LCA and Cement .............................................................................................................. 10 3.1. Applying LCA to Cement........................................................................................... 10 3.2. European Experience ............................................................................................... 11 3.3. Experience in Australia with LCA of Building Materials ............................................. 11 3.4. Canadian LCA Work on Concrete Roads.................................................................. 13 3.5. LCA Experience in the USA ...................................................................................... 14 4. Tools for LCA .................................................................................................................... 16 4.1. Suggested LCA-Analysis Tools for the Cement Industry ........................................... 17 4.2. Other LCA-related Software Tools ............................................................................ 17 4.3. Databases................................................................................................................. 18 5. Analysis ............................................................................................................................ 20 5.1. Status of LCA............................................................................................................ 20 5.2. Cement and Eco-efficiency ....................................................................................... 20 5.3. Meeting Market and Societal Expectations for LCA................................................... 21 5.4. How Should the Cement Industry Use LCA?............................................................. 22 6. Findings and Recommendations ....................................................................................... 27 6.1. Findings .................................................................................................................... 27 6.2. Recommendations .................................................................................................... 27 6.3. Conclusion ................................................................................................................ 28 7. References ....................................................................................................................... 30 8. Bibliography ...................................................................................................................... 33 APPENDIX A: LCA Annotated Bibliography Cement and Applications .................................... 1 APPENDIX B: LCA Annotated Bibliography Alternative Products............................................ 1 APPENDIX C: LCA Software and Databases ............................................................................. 1 APPENDIX D: Users Guide to Understanding an LCA Study .................................................... 1 APPENDIX E: Case Study Taiheiyos use of LCA for Technology Evaluation ......................... 1 APPENDIX F: Case Study Norcems Use of LCA to Communicate Environmental Performance............................................................................................................................... 1 1.

List of Tables

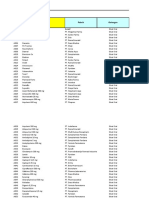

Table 2-1. Example Life Cycle Inventory (LCI) results for 1 kg of Cement from a plant in Sweden (Source: Bjorkland5). ........................................................................................................... 5 Table 2-2. Example Life Cycle Impact Assessment Indicator Results (Source: Eyerer and Reinhardt6). ......................................................................................................................... 6 Table 4-1. LCA-analysis Tools Suitable for the Cement Industry (compare to Table 4-2) ......... 17 Table 4-2. Important LCA-related Software Tools (compare to Table 4-1)................................ 18 Table 4-3. Relevant Databases ................................................................................................ 19 Table C-1. Eco-Tools & Databases Summary ........................................................................... 2 Table C-2. LCA Tools Suitable for the Cement Industry ............................................................. 4 Table C-3. Important Downstream Tools .................................................................................... 7 Table C-4. Relevant Databases.................................................................................................. 8 Table E-1. Global warming ......................................................................................................... 3 Table E-2. Depletion of energy resources .................................................................................. 3

vii

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

Table E-3. Depletion of mineral resources.................................................................................. 3 Table E-4. Shortage of landfill sites ............................................................................................ 3 Table E-5. Economic Effects of Environmental Conservation Efforts .......................................... 5 Table F-1. Main Impacts of Cement Production (Vold and Ronning 1) ....................................... 2

List of Figures

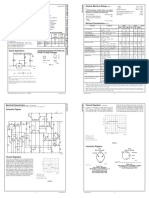

Figure 1-1. The product life cycle extends from primary extraction through various economic activities of value creation to product end-of-life disposal. ................................................... 2 Figure 5-1. Uses of LCA vary from internal company uses to more industry-level and external applications, and range from more tactical to more strategic areas. The value to the cement industry of each use is low (green), mid (yellow) or high (red). .......................................... 22 Figure E-1. Global Warming ....................................................................................................E-2 Figure E-2. Depletion of Mineral Resources ............................................................................E-2 Figure E-3. Depletion of Energy Resources.............................................................................E-3 Figure E-4. Shortage of Final Landfills.....................................................................................E-3

viii

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

1. Introduction

The cement industry is faced with many challenges that span the product life cycle. On the one hand, the cement industry itself is challenged by a number of significant sustainability and environmental issues like carbon dioxide emissions and production energy requirements. On the other hand, studies indicate that certain aspects of the cement industry (e.g., products for durable end-use applications, disposal of hazardous waste) can contribute greatly to sustainable development. The goal of this substudy is to identify opportunities for the use of LCA that will guide the cement industry in contributing to sustainable development objectives.

1.1.

Objecti v es

This substudy has two main objectives: 1. Document LCA status and cement industry experience with LCA. This substudy illustrates the use of LCA by cement companies, industry associations, and other interested parties. It demonstrates the use of LCA in areas such as comparisons of differing production technologies, comparisons of cement to alternative construction materials, and product environmental labeling. 2. Identify the potential relevance and value of LCA to designing a sustainable future for the cement industry. This substudy provides a concise report of the applicability of LCA to the cement industry. Additionally, it identifies how these applications might provide business benefits to the industry.

1.2.

Scope

This substudy reviews the use of LCA by and for the cement industry. It does not provide an LCA analysis, nor does it provide specific suggestions or guidance arising from technical or environmental assessments. Numerical and other specific information, where provided, are illustrative of the types of uses and results possible from LCA. The cradle-to-grave life cycle of cement includes production processes beginning at earth and continuing through cement production (as covered in the WBCSD study scope), extending to cement applications, their use, and end-of-life (Figure 1-1). LCA considers some or all of this entire life cycle. The scope of this substudy therefore encompasses consideration of concrete, various concrete applications (residences, roads, other structures, etc.), and end-of-life of concrete and cement, in addition to raw materials sourcing and production. This substudy is global in scope, but also respects that there are regional industrial practices that affect global environmental impacts and company priorities.

1.3.

Technical Approach

The information in this substudy was compiled through a number of approaches. A literature search of printed and Internet sources was undertaken. Surveys were submitted to cement companies, followed by interviews. Additional interviews and research were conducted with other individuals in cement companies, industry associations, cement users and other stakeholders. Experts familiar with LCA and with cement, located in North America, Europe, South America and Asia contributed to the content of this report. The first part of the report explains what LCA is and how it has developed up to this time. The second part discusses the use of LCA in the cement industry, including experiences in Europe, Australia and North America; and case studies of LCA use in cement companies. An account of LCA in the aluminum industry provides possible lessons applicable to the cement industry. Part three is an evaluation of LCA tools and databases, with an assessment of their applicability

1

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

specifically to the cement industry. The fourth part offers an analysis and synthesis of the research. It details areas for using the tool, applicable to companies and the industry. Part five summarizes the findings of this substudy and suggests several paths forward for the use of LCA in the cement industry. Appendix D, Users Guide to Understanding an LCA Study, is a tool that allows companies to summarize an existing LCA study and helps identify important features such as the functional unit, system boundaries and final conclusions.

Cradle

Resource extraction Resource (e.g., limestone quarry) E i

Materials Materials production plant) P (e.g., d cement i

Gate

Product manufacture Product (e.g., fconcrete M i structure)

Product Use (e.g., bridge 50 year life) U

End -of-life End -of-Life

Recycling

(e.g., demolition)

Grave

Figure 1-1. The product life cycle extends from primary extraction through various economic activities of value creation to product end-of-life disposal.

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

2. State of LCA Practice

2.1. What is Life Cycle Assessment?

LCA is a systems analysis tool for compiling and assessing environmental information. The basic life cycle includes production processes beginning at resource extraction from the earth (the cradle) and continues through cement production, to cement applications like concrete structures, their use, and end-of-life (see Figure 1-1). Originally devised to assess and improve the environmental performance of final products (e.g., buildings, roads), LCA has found wide application in process analysis, too. Guidelines for LCA were first established by the Society of Environmental Toxicology and Chemistry (SETAC), and since 1997, the ISO 14040 series of international standards have defined the method, providing rules and formal guidance for its use and applicability. Typically, LCA is used to evaluate the environmental performance of functionally comparable systems. This may be a comparison of two competing products (e.g., concrete structure vs. steel structure), or a comparison of an existing system to a new option that may have environmental advantages (e.g., improved technology for destroying hazardous waste). The tool is also used, frequently and simply, to evaluate a stand-alone system to identify and quantify areas of potential interest or improvement. The ISO 14040 series of standards from the International Organisation for Standardisation provides internationally agreed to principles for LCA studies (ISO 14040,1 ISO 14041,2 ISO 14042,3 ISO 140434). To meet needs in various countries and industrial sectors, the basic standard was developed in 1997 to provide a framework for assessing the environmental aspects and potential impacts associated with a product or service.

4) Interpretation

3) Impact Assessment

materials

1) Goal and Scope

use use end-of-life end-of-life

energy

water

air

materials materials

manufacture manufacture

2) Life Cycle Inventory

waste

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

Fundamentally, LCA is for product-focused environmental decision-making; however, the tool is representative of a broader conceptual framework that includes the application of the life-cycle discipline at various levels, but also extends to a general discipline of thinking and for decisionmaking. Terms that commonly arise in the life-cycle framework include: product stewardship, life cycle management, extended producer responsibility and integrated product policy.

2.2.

LCA method

The LCA method can be summarized as four steps (Figure 2-1). Each step is described in the international standards (ISO 14040, ISO 14041). These steps are iterative, where the level of detail and effort will depend on the goals of the study.

Step 1: Goal and Scope

This step defines the goal and scope of a study. Defining the goal of an LCA study is an important first point. The execution of the LCA method will vary according to goal. A number of important factors related to the goal need to be considered: Whether the work is internal or external. For example, if the work is intended for an internal audience of company decisions-makers, the level of rigor and quality will not be as arduous as a study that is to be used externally, perhaps to inform policy-makers. Whether the goals are strategic or tactical. This affects the level of risk involved, and determines the required certainty that is desired. A tactical goal, such as deciding between two materials, involves little risk and a streamlined study would be adequate to make the decision. A full study would be required when the goal of the study is to assist in making strategic decisions, where there are significant revenue or cost implications. Whether a critical review will be desirable, or even necessary, which at the most involves an independent third-party panel of experts to review the work (ISO 14040). The scope of a study sets-up how and where data are to be compiled, including the system boundaries and functional unit for the study. System boundaries are defined according to the intended goal. System boundaries determine what will be considered in the study and what will be left out. Central to this is the functional unit for a studythis explicitly defines the service or function provided by the system (e.g., structural integrity for 50 years, or hazardous waste disposal to defined criteria). The results of the LCA study will relate directly to the functional unit; for example, if the functional unit is 1 kg of a product, the results would include the amount of pollutants released for every kg of product that is made. Unit processes are defined, usually with a process flow diagram, to define the physical sequence of mass and energy activities across the life cycle (see Figure 1-1). For simple, macro-level studies there may be only several unit processes; for complex studies, particularly if primary data are to be collected, the number of unit processes may be in the hundreds.

Step 2. Life Cycle Inventory

This step is called the Life Cycle Inventory (LCI) analysis (ISO 14041), and involves compiling an inventory of relevant inputs and outputs of a product system, covering multiple environmental aspects. The data inventory takes place for each unit process defined in the system. Depending on the study and aims, data may be collected first-hand from measurements and estimates of key

4

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

activities, or will be based on information drawn from existing LCA databases. Different levels of consideration are possible, including individual processes and sub-systems (such as energy supply or transport, etc.). A complete study may consist of several different layers of analysis from specific activities, up to the whole life cycle of a product. The LCI portion of the study is often considered in stages. A cradle-to-gate inventory for cement would include all resources and energy required to produce cement, to the gate of the plant (see Figure 1-1). A cradle-to-grave inventory would cover all unit processes extending from original resources on to final disposal in the earth. Data analysis considers environmental inputs and outputs (see Table 2-1 for an example of life cycle inventory data for cement production). Tools and software are available to assist, but smaller studies are performed using conventional spreadsheets. In a fully executed LCA study, all the environmental inputs and outputs associated with each material are tracked (e.g., machine grease is tracked back to crude oil, and traced forward to water emission). Table 2-1. Example Life Cycle Inventory (LCI) results for 1 kg of Cement from a plant in Sweden (Source: Bjorkland5).

OUTPUTS Air Emissions Explosives 0.27 g Carbon dioxide 800 g Grinding media 0.09 g Particulate 0.16 g Iron sulfate 9.2 g Nitrogen oxides 1.9 g Quartzite 46 g Hydrocarbons 0.016 g Waste oil 12 g Ashes 0.0020 g Limestone 1400 g Cadmium 0.000010 g Gypsum 46 g Methane 0.31 g Carbon monoxide 0.78 g Chromium 0.000017 g Energy Copper 0.0000026 g Coal 0.86 MJ Mercury 0.0000035 g Coke 1.5 MJ Nitrous oxide 0.00000015 g Diesel 0.058 MJ PAH 0.00000034 g Fossil fuel 0.93 MJ Lead 0.0000087 g Oil 0.016 MJ Phenol 0.00000042 g Waste fossil fuel 0.53 MJ Sulfur dioxide 0.45 g Electricity 0.47 MJ Thallium 0.00010 g Volatile organic carbons 0.13 g Zinc 0.000013 g Water Emissions COD 0.000087 g Total nitrogen 0.000014 g Oil 0.000030 g Note: Not all flows have been tracked back to the Earth. LCI results are for illustrative purposes only, and are not intended to be representative of LCI study results.

Raw Materials

INPUTS

As a distinct methodological element of LCA, LCI has demonstrated considerable benefit. In a sense, the LCI method is an accounting system for mass and energy flows. It builds upon conventional process management techniques based in chemical, metallurgical engineering and the like, but LCI demands a consistency of accounts across many operations and life-cycle activities. Managers and engineers recognize that LCI can help them keep more accurate and more comprehensive inventories of energy consumption and raw materials usage and doing so while providing a zoom lens from unit process, to complete facilities, to corporate divisions, to the level of the company or across the industry. This process can help identify savings in

5

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

energy and materials usage, which relate very directly to process optimization and to economic savings.

Step 3: Impact Assessment

Life Cycle Impact Assessment (ISO 14042) evaluates the possible environmental impacts associated with measured environmental inputs and outputs. It is important to note here that LCA is not a single-issue tool; rather, the analysis encompasses numerous environmental issues (e.g., energy, water pollution, climate change), thus allowing for broad consideration of the impacts of the system (see Table 2-2). The results of an LCI study will be a quantitative profile of environmental parameters. Information may be first examined at a disaggregated level right from the inventory (e.g., carbon dioxide, nitrogen oxide) or may be grouped or aggregated according to environmental indicator categories like greenhouse gases or toxicity (Table 2-2). Many studies are taken to a point where results are expressed as selected environmental indicators or scores, be it for largescale system comparisons, technology scenarios or internal improvement assessments. Ranking and scoring are optional elements, guidance for which is provided in ISO 14042. At this step, LCA can be extended beyond quantitative measurement and analysis to a point where an evaluation or judgment is made. At its simplest, this may be an assessment of what is better or what is worse; for example deciding between two production processes. The intent is to provide insights into priorities, based on data, but the value judgment has no scientific basis. LCA provides structure and direction to help decision-makers focus on key priorities for environmental sustainability. Sets of indicators have been developed, addressing commonly agreed and important environmental impact categories. Note, however, that additional environmental and other analysis will still be necessary to complete any decision. The judgment of relative importance of specific issues is always a challenge. Depending on the goals and scope of a specific LCA study, different indicators will exhibit different value. If the decision is narrow and local versus global and strategic, the consideration of Global Warming Potential versus toxicity versus water use will differ. Table 2-2. Example Life Cycle Impact Assessment Indicator Results (Source: Eyerer and Reinhardt6).

Indicator Value Unit Primary Energy Requirement 4355 MJ/t cement (Measure of energy input) Global Warming Potential 872 kg CO2-equivalent/t cement (Measure of greenhouse gas emissions) Acidification Potential 1.68 kg SO2- equivalent/t cement (Measure of air pollution, acid rain) Photo-oxidant Potential 0.07 kg C2H2- equivalent/t cement (Measure of air pollution, smog) Nutrification Potential 0.20 kg PO2- equivalent/t cement (Measure of water pollution) Note: Indicator results are for illustrative purposes only, and are not intended to be representative of LCA study indicator results.

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

Step 4: Interpretation

Interpretation (ISO 14043) is the final phase of an LCA. In the interpretation, the analyst looks for significant environmental aspects (e.g., energy use, greenhouse gases), significant contributions to indicators or scores, and significant unit processes in the system. For example, if the results of an impact assessment had indicated a particularly high value for the Global Warming Potential indicator, the analyst could refer back to the inventory to determine which outputs are contributing to the high value, and which unit processes those outputs are coming from. This is also used as a form of quality control. It helps provide more certain conclusions and recommendations. The procedure typically involves examination of the sensitivity of results, performance of a scenario analysis, a review data quality, and a comparison of the results to the original goals of the study.

2.3.

State of Practice

Value of a Product Approach

In applying LCA the product provides a tangible focal point for environmental consideration of process and product choices. The product perspective is already a framework in which decisions have been made: we have markets for products, businesses make products, and Case Study: Norcem: Life Cycle consumers use products. A product-oriented Perspective in Environmental approach to environmental management Management and Communication builds on the strengths and infrastructures that are already intact in traditional product Norcem is a cement producer located in Norway, part of the Northern Europe Region of orientations, but simultaneously extends the Heidelberger Zement. Norcem has used life consideration of environmental issues to the cycle assessment (LCA) to their advantage in whole product life cycle. End-product sectors with significant activity and application of LCA include: Automotive Buildings and construction Packaging Paper products Electronics Appliances Detergents and chemicals Military equipment Food Waste management In product-focused environmental management, the product represents the tangible outcome of a production system that delivers value (as cement is to the cement industry). However, in the functional unit approach, services can also be analyzed with LCA sectors like waste management use the tool as a decision-making tool to help understand and evaluate long-term technological options for management and policy.

a number of different applications. From 19941997 they participated in a Nordic cement and concrete project that aimed to establish the impacts of cement and concrete life cycle and identify opportunities for improvement. The project was carried out through several LCA studies of concrete products. In 1998, while Norcem was part of the Scancem group, Scancem used a life cycle approach in their environmental report. The report highlighted the importance of the use phase in the cement life cycle, and showed how LCA had been used to target improvements in operations. Recently Norcem has been involved in a program to create environmental product declarations for different sectors. The declarations use life cycle data and a standard format so that consumers can compare different products to each other. In addition to these activities Norcem has used LCA internally to track data that is required for their certification to the European Eco Management and Auditing Scheme (EMAS) and ISO 14001. The use of LCA in all of these ways has been beneficial both for Norcem and their customers. For more information, see Appendix F.

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

When a product-orientation is applied, the consideration of environmental issues is extended in new ways. Conventional frameworks for environmental management include the facility (e.g., in permits for emissions control), the sector (e.g., in regulations for an industry), the medium (to air or water or soil), habitat, and more recently substance (e.g., chlorine). By using the product as a focus for information, both existing and new datasets may be required. Production, use and disposal information about a product demand extensive data sets (the data requirements of LCA are addressed in Part III: Tools for LCA).

Ability to See Trade-offs

Single issues (like solid waste or energy) can be seen in perspective and aligned against broader priorities (like resource utilization, climate change, or toxics reduction). The product life cycle also helps identify potential problem shifting, whereby a problem waste might otherwise be combusted to air but subsequently precipitated to surface water, eliminating the waste but not the real problem. LCA provides a way to see trade-offs between issues and across different activities. For industry (but also government regulators) this systems focus provides a constructive perspective for environmental management.

Limitations

The strengths of the method also play into its weaknesses. Systems analysis, structured around the functional unit, tends to obscure important factors necessary to determine real environmental impacts. Both spatial and temporal specificity are usually lost during the inventory; thus the life-cycle impact assessment step can only approximate potential environmental impacts, and does not address or estimate real impacts. This challenge is an area of continuing LCA research. In the early days of LCA the tool was seen as a panacea, a means of providing conclusive environmental evaluations on products and systems. Since the mid-1990s, particularly after the Comprehensive European release of the first ISO standard in 1997, the tool has Database for LCA found a more realistic position in the environmental toolbox. Early use of LCA for comparative assertions led to A reference quality European guidance defined in ISO 14040 to prevent misuse of the LCA database for concrete tool. LCA understood today to be one source of products is due for release in information that can feed into sustainability decisions. autumn 2001. The work will Economic contexts, social priorities and other deliver an inventory dataset, environmental data are also required to complete the software tool and Life Cycle picture Impact Assessment results. The One of the more challenging parts of an LCA study is the final determination of significant environmental issues. Although the method structures this step, using data and indicators, the value-choices in the judgment are ultimately provided by the sponsors or analysts of the study. This is true of any tool, like cost benefit analysis or engineering design, where if objectives are clear, the decision can be transparent and conclusive. If however goals and objectives are not clear, there will be a degree of uncertainty inside the study, leading to reduced conclusiveness or credibility in results.

exercise promotes the need to understand LCA of cement as part of the life-cycle of concrete. Ten different functional units are being examined (e.g., residential, roads). This work will effectively replace existing national-level European LCA data on cement. The work is coordinate by CEMBUREAU, which actively advocates the use of LCA for environmental information on construction products. (CEMBUREAU 1999(1), 8 Chandelle 2001(1), )

8

7

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

Level of effort

The systems analysis that LCA provides is rigorous, science-based and whole systems focused. Applications of the tool vary from simple, in-house analyses requiring several days of effort, to large externally communicated studies that can take months to complete. Use of commercial software and databases can greatly facilitate study execution. Regardless, LCA results provide information that assists in defining key environmental issues, identifying important processes or activities across the system, and help provide structure in determining best options from an ecoefficiency perspective. Investment in level of effort for a study needs to be balanced against need: if a higher degree of certainty and confidence in results is necessary, perhaps because the LCA study will feed into an important decision, then investment in better data, more comprehensive definitions of unit processes, and possibly an external critical review of the study might be well worth the additional investment. A particular kind of LCA study is the development of basic materials data by an industry. Several regional cement groups have already completed first-generation cement LCI datasets (see for example the box called Comprehensive European Database for LCA). The level of effort necessary to establish a basic materials database is substantial: requiring in the order of one-years time of one or more full-time professionals plus support from multiple facility personnel and corporate managers. This kind of foundation initiative demands the highest degrees of analytical rigor and critical review, to ensure consistency to standards, transparency and credibility of data. Moreover, it is desirable to ensure means to update the data as technologies and practices evolve, and as further information becomes available. Lastly, to achieve results, it is important to have a communication strategy for the data, to publish the information clearly and meaningfully, and allow means to monitor and support its appropriate use.

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

3. LCA and Cement

3.1. Applying LCA to Cement

Given the whole life-cycle concept of LCA (see Figure 1-1), one might presume that LCA is useful only in the context of concrete products and structures. However, experience and practice show a broader utility of LCA for the industry. Research in this project unearthed about 80 publications related to LCA of cement. Some of these addressed cement and/or alternative materials; others used the method for a variety purposes. Many of the available references are academic reports, which focus on the method and application of LCA to cement and other building materials. Appendix D, which is intended as a guide to the reader or user of a pre-existing LCA study, highlights some areas of focus that are important for doing an LCA study. The ISO 14040 series standards define requirements in detail. Some areas of consideration that are of particular interest to the cement industry are: System boundaries, for example whether the full life cycle of cement including raw materials, production, application and final end-of-life is included (see Figure 1-1); Co-product allocations, like co-generation of energy or the provision of waste management services in conjunction with traditional cement manufacture; Careful accounting of fuels, including combustion emissions and pre-combustion emissions occurring upstream (this is important in the use of LCA approaches in GHG accounts); Definitions and categories of waste, for LCA of a Building example the manner in which overburden and waste rock are treated in waste LCA results for a building constructed of accounts during raw-material extraction; Portland cement concrete provide an Recycling of concrete or cement, and the informative picture of the role of cement in manner in which this is included in contributing to environmental issues. What assumptions regarding the full life cycle becomes apparent is that cement does play of a building or similar application. an important role in contributing to

LCA to analyze cement applications

Because cement is a commodity, its life cycle is embedded in cement-applications most commonly this is Portland cement concrete used in structural applications. Thus it is the end application that is of primary life-cycle interest (e.g., building or bridge), and in this context, the cement is part of the greater system (for an example see box on LCA of a Building).* Thus there is a body of LCA studies that examine the role of cement in buildings, roads and other applications (see Appendix A for a listing, and Appendix B for alternative

*

environmental impacts associated with building materials and construction; although steel rebar, if used, can also be substantial. But what is more informative is that the majority of total life-cycle environmental burdens of a building are almost invariably due to building use, not materials or construction. Studies conducted by the Scancem Group (now part of the Heidelberger Group) showed that when the materials complete life cycle is analyzed...it can be seen that their environmental effects during their 34 usage are completely dominant. The numerous systems of a building, especially heating, ventilation and air conditioning, generate significant need for energy and are the source of the majority of associated emissions.

Note: In accordance with the terms of the WBCSD cement project, this sub-study did not comprehensively examine the full-life cycle of cement applications; rather the research focus was on cement production.

10

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

materials). In these cases, it is the quantitative results that may be useful to decision-makers who are seeking to differentiate the environmental performance characteristics between options.

Use of LCA for other areas of assessment in the cement industry

Another category of LCA application considers areas or technologies relevant to cement but without assessing cement product itself. This kind of use of LCA draws on the power of the method to provide a rigorous systems analysis, often to compare two options (see box on Alternative Fuel Resources).

3.2.

European Experience

LCA Evaluates Alternative Fuel Resources (AFR) In a number of jurisdictions, based on regional conditions and environmental priorities, LCA studies have revealed the benefits of processing AFR in cement plants. CEMBUREAU reported that the use of waste in European cement kilns saves the equivalent of 2.5 million tonnes of coal per year, based on an LCA analysis of environmental benefits of fuel 9 substitution.

LCA activities in Europe have been on going since the early 1990s, but the focus has been varied and the utility mixed. Several early studies on cement were completed in response to market claims concerning the environmental impacts. However, in the period before 1997, prior to the ISO 14040 standard, LCA results often did not prove to be conclusive. In fact, the use of LCA may have confused debates concerning the relative greenness of materials and buildings. This experience is not unique to cement, but is typical also of other sectors (e.g., packaging and automotive), where early LCA activity proved difficult.

What was accomplished, that pertains to the In Switzerland, following an LCA project, present value of the tool, is the development of regulations concerning the treatment of expertise in a number of centers (academic and hazardous waste were changed to private consultants), plus the establishment of provide greater allowance for processing 10 AFR in cement kilns. first-generation databases and LCA tools. Most cement industry associations at the national level made efforts to develop representative generic LCA data sets describing the cradle-to-gate production of cement; several went so far as to include concrete and end products. The value of developing and making available generic LCA data is highlighted below in Part IV: Analysis. Of particular significance today is the new CEMBUREAU lead LCA project, due for completion in the autumn 2001 (see box on Comprehensive European Database for LCA).

3.3.

Experience in Australia with LCA of Building Materials

Australia has become a leading region in the use of LCA for examining building materials, as part of broader efforts to improve the environmental performance of buildings.

Sydney Summer Olympic Games

One of the main pressures to use LCA arose from the 2000 Olympic Summer Games in Sydney. Sydneys bid for the games included specifications for environmental performance. When Sydney won the games, these specifications became the Environmental Guidelines of the Summer Olympic Games.46 The requirements were also incorporated into the New South Wales (NSW) State Environmental Planning Policy for Olympic Games Projects11.

11

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

One of the outcomes of the green games was the LCA of Stadium Australia, the structure erected to host the opening and closing ceremonies and the track and field events. The LCA looked at all the major life cycle stages: raw material acquisition, manufacturing, transportation, use and maintenance, demolition and final disposal. The study assumed a 50-year life span for the stadium.13 The LCA was initially used (in conjunction with cost/benefit analysis) to decide between three possible stadium designs, and to make decisions about materials. The LCA inventory results of the actual design showed compliance with the Environmental Guidelines and quantified the advantages that the stadium had over a conventional design12. Of the main materials used to build the stadium, reinforced concrete was the most prominent material by mass (79%) and energy for procurement (39%). Within the concrete product system, it was found that the most energy intensive materials were the steel reinforcing and the cement. In the use phase, the thermal mass of the concrete is expected to contribute to the energy efficiency of the passive ventilation in the stadium. The most challenging aspect of the LCA was data collection. The data was collected by means of a quantitative survey that accounted for the raw materials, energy, water and waste associated with each material. It was recognized from the beginning that the data would have to be obtained from numerous different sources. For many companies in this industry it was the first time they had participated in an LCA inventory. To ensure participation by all parties, the data requirements were included in contractual agreements between Multiplex and their subcontractors, suppliers and manufacturers.11 Proprietary data was kept private and only aggregated data for life cycle stages was released to the public.12 This project is expected to act as an example for large-scale LCA studies in the future. It has raised awareness of environmental impacts within the building and construction industry.12,13,46 As a result, requests for life cycle information are becoming more common in contracts and specifications.11

Related Initiatives

The Queensland government supports the use of a life cycle perspective in the building and construction industry through Ecologically Sustainable Strategic Asset Management (ESSAM). The government has established an ESSAM Guideline that ensures that environmental considerations are included in all steps of asset management: planning, material procurement, construction, maintenance, refurbishment and disposal. The guideline is being tested for implementation throughout the Queensland government.14 The Australian Greenhouse Office is seeking to reduce energy use associated with buildings. They are working with the Australian Building Energy Council, which represents the building and construction industry. They have conducted extensive research and consultation and are moving forward with two initiatives. The first is a voluntary code of practice for the building and construction industry. The code will include practical guidance and will be developed over the period 2000-2001.15 The second is an amendment to the Australian Building Code to include minimum energy requirements, in an effort to eliminate the worst practices in building design. These measures are intended to encourage the adoption of energy efficient and environmentally conscious methods at each stage of the building life cycle.16

12

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

3.4.

Canadian LCA Work on Concrete Roads

Case Study: Concrete Roads in Brazil

Similar to LCA are other methods employing the life-cycle approach. Costing is one such area. The life cycle cost advantages of using cement concrete roads have made them a popular choice in Brazil. Some of these advantages include: Durability (typically greater than 25 years); Low maintenance requirements (up to 20 years before requiring maintenance); Fuel savings, especially for heavy trucks (one study showed a fuel economy increase of about 20% over conventional material surfaces); Better light reflection on the bright concrete surface, resulting in savings of approximately 30% savings in electricity for lamps, lampposts 17 and signs. Votorantim is working together with the Brazilian Portland Cement Association (ABCP) to promote concrete roads. Votorantim CEO Luiz Vilar de Carvalho proposed the program and provided financial incentives, and both BPCA and Votorantim purchased equipment that would allow concrete roads to be 18 constructed.

Roads play a particularly important role in Canadas infrastructure, due to the vast distances in the country. Construction and maintenance of roads, and the vehicles that use these roads, consume large amounts of energy and produce damaging emissions. Various organizations in Canada are investigating the possibility of reducing fuel consumption by expanding the use of concrete roads. Their work takes a life cycle approach, similar to LCA, to assess impacts and costs of roads. The Athena Sustainable Materials Institute completed a study in 1998 entitled Life Cycle Embodied Energy and Global Warming Emissions for Concrete and Asphalt Roadways.19 It looked at the construction and maintenance of major freeways, major highways and secondary highwaysfocusing on the manufacture, transportation and construction effects of cement, concrete, steel reinforcement and asphalt. The study concluded that, compared to asphalt, concrete would require the least energy for construction and maintenance. Advantages were most significant for thicker pavements and high traffic roads.19

In 2000, the Canadian government undertook One outcome of this project was concrete a complementary initiative looking at the lifepaving of the Castello Branco marginal roads. cycle use of roads. The Center for Surface Paving of the two 4-lane roads with concrete Transportation Technology at the National was completed in May 2001. The project used 3 Research Council carried out the study for the 90,000 m of concrete, corresponding to 34,000 tonnes of cement, of which up to 34% Cement Association of Canada. The study, was made up of blast furnace slag. An Effect of Pavement Surface Type on Fuel economic assessment of the project showed Consumption, looked at concrete, asphalt and that compared to asphalt: asphalt/concrete composite roads while Initial construction costs were reduced by varying a number of conditions (pavement 6.3%; roughness, vehicle type, load on the vehicle, The net present value of maintenance is 85% speed, season, temperature, direction on the lower; road). The researchers used short, uniform Maintenance of concrete causes less disruption road segments and liquid tankers with special 17 to traffic. tracking equipment to test road performance. They found that at the fastest speed and Recognition of the life cycle economic benefits under the heaviest load there were statistically of concrete roads will ensure their continued significant advantages in the fuel consumption construction in Brazil. values for the concrete roads. Specifically, at a speed of 100 km/h, a fully loaded tractor semi-trailer uses 11% less fuel on a concrete road than on an asphalt road. Moreover, concrete roads showed the least change in roughness throughout the seasons.20

13

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

As a result of these two projects, the Canadian government has recognized the potential benefits of using cement concrete for road construction. In fact, in the Government of Canada Action Plan 2000 on Climate Change21 it suggested increasing awareness of the advantages of concrete roads for improving vehicle mileage. As of 2001, Canada has dedicated $3.5 million dollars over the next five years to educate provincial transportation departments about the advantages of concrete highways.22 As well, the province of Quebec has already mandated that a portion of the highways in high volume corridors be concrete23. Roadways suitable for concrete paving will be identified using Life Cycle Costing Analysis (LCCA) and multicriteria analysis. LCCA will be used to determine the return on investment for asphalt and concrete pavements, and non-quantifiable criteria, such as winter maintenance, will be assessed using multicriteria analysis24.

3.5.

LCA Experience in the USA

Coordinated by the Portland Cement Association (PCA), the USA cement industry has been collecting LCA information on cement manufacturing since 1994, and on concrete production and construction since 1996. More specifically, the data are life-cycle inventory profiles, as they do not include explicit impact assessment of the environmental inputs and outputs. Data for the complete concrete life cycle inventories are supplied by member associations of the Environmental Council of Concrete Organizations (including aggregate, ready-mix concrete, precast concrete, masonry block, etc.). There are now ten trade associations, and through them, more than 200 companies participating, as the initiative has completed its second round of data collection. The data set for cement manufacturing will be updated every three years in concert with the economic research functions at the PCA. There is no current PCA or ECCO initiative for updating the data set for concrete production and construction. 25-28,29) Data have been used for a cross-section of applications, generally aimed at providing market support. The PCA with Construction Technology Laboratories, Inc. has undertaken LCA studies examining cement applications in concrete, including research on buildings and roads that has been published. 27 Further activities are planned, to better understand and direct the life-cycle use of concrete.29,30 For external parties, the PCA provided the data to the BEES project of the National Institute for Standards and Testing (NIST), a USA government initiative in support of environmentally preferable purchasing (EPP). The Athena Sustainable Materials Institute has been supported also with PCA data that are now used in a computer model aimed for use by architects interested in environmental performance evaluations of residential housing (see Table 4-3). In at least one case the LCA data were provided directly by a cement company to an architectural firm engaged in green building analysis. The industry keeps a close watch on green building initiatives in the USA.29 Internally, the PCA calculates industry average values for the industry to provide benchmark information to cement companies to assist in directing areas for process improvement. Ann Dougherty at the PCA expects to see significant progress in the industry over the next decade, as measured and documented by LCA techniques, as new equipment and operational controls continue to be implemented.

14

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

Case Study: Can cement borrow from the experience of the aluminum industry?

Beginning in the late 1980s and early 1990s, three aluminum companies (Alcan, Alcoa and Reynolds) started to use LCA. Original efforts were prompted by market claims made about aluminum cans by competing industries and other parties. After developing generic LCA data in a number of regions for beverage cans and automotive applications, the companies began to realize a greater utility of LCA and LCA data. The interest in LCA was expanded from simply meeting customer needs for LCA, to developing LCA into a more powerful tool useful for process benchmarking and technology evaluation. After some education from the global companies to others in the sector, the industry organized itself more broadly. Like the cement industry, aluminum producers employ processes that are very similar at plants around the world with similar resource inputs. A few fundamental technologies such as "prebake" or "soderberg" electrolysis that differ primarily only by age and capacity are employed to convert bauxite ore into primary aluminum and aluminum castings, extrusions or rolled products. Aluminum companies now compare environmental performance across mining, metallurgical and processing facilities; comparing individual plants to industry average and best-in class performance, leading to identification of improvement opportunities for eco-efficiency. Today the aluminum sector has a highly integrated LCA capacity, coordinated through the International Aluminum Institute, and including the majority of companies and production worldwide. Comprehensive data coverage has been built for energy and greenhouse gases; now in its third generation, it is being expanded to included additional environmental aspects for all sites. The sector is not only ready and able to provide detailed LCA data suitable for customer needs-but has also found extensive value in the tool for environmental management and business needs. 31 32 Sources: Young, Martchek

15

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

4. Tools for LCA

There are more than 30 LCA or LCA-type software tools available. Some are more applicable than others for use by the cement industry. A survey was conducted to evaluate the availability and relevance of these tools, and to produce a subset that can be suggested as useful. The software and database survey (Appendix C) considered various sources including web pages of software vendors, other literature, prior reviews of software, and professional contacts. Tools examined presented a broad range of capabilities related to LCA. One factor is the intended user of the tools: product designers, LCA practitioners, environmental managers, process engineers, or downstream users such as planners, architects, and builders. Another consideration is the type of LCA being performed, for example, a simple screening study versus as larger project involving intensive primary data collection. For example, with todays software tools and databases, a practitioner can complete a quick study in less than a day, using secondary data as an estimate of the real system they are studying. This type of study, however, may not be sufficiently conclusive to support situations involving significant business risk, such as investment in new technologies or advertising product attributes. It was judged that the most useful tools to the cement industry are those that contain high quality databases, comply with the ISO 14040 series of LCA standards, and can be used to fulfill the full LCA methodology from goals and scope definition, to inventory to Life Cycle Impact Assessment and final Interpretation. However, it is important that the cement industry understands that LCA-type tools intended to evaluate downstream applications of end-products can and do have an impact on how the marketplace views cement in its various applications; these tools are discussed separately below.

16

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

Table 4-1. LCA-analysis Tools Suitable for the Cement Industry (compare to Table 4-2)

Name GaBi 3 LCAiT 4.0 NIRE LCA 2 SimaPr o 4.0 TEAM 3.0 Vendor IKP Uni. Stuttgart/PE, Germany Chalmers Ind. (CIT), Sweden NIRE, Japan Pre, The Netherlands Ecobilan/Ecobalance/ PriceWaterhouse Coopers, Europe/USA Tool a a a a a Database a a a a a a a a a a a a ISO a a DQA a Impacts a a Stats a More Info

http://www.gabisoftware.com http://www.lcait.com http://www.nire.go.jp http://www.pre.nl http://www.ecobilan.c om

Legend: ISO actively supports studies to comply with the ISO 14040 standards on LCA DQA includes data quality assessment indicators or evaluation Impacts includes features for Life Cycle Impact Assessment Stats includes features for statistical analysis

4.1.

Suggested LCA-Analysis Tools for the Cement Industry

Based on findings in this study, five strong LCA tools can be positively suggested for use by the cement industry (Table 4-1). The absence of a specific tool from the suggested list should not be perceived as a negative recommendation. In general, each of these five software tools should be applicable and useful to cement companies. While some are weaker in the functions they offer, others have weaker databases, or databases only useful to a particular country or region. Many of the software providers offer add-on datasets to their standard databases.

4.2.

Other LCA-related Software Tools

There are currently many life cycle based (LCA-related) tools being used by planners, engineers and architects to evaluate downstream cement applications, for example comparing concrete to wood to steel structures. These tools, in most cases, are not as powerful as the LCA-analysis tools mentioned above, as they do not allow the user to perform the Life Cycle Inventory step (see Part 2) based on primary data. Instead, they provide pre-defined data of fixed data quality and applicability. The intent of the LCA-related tools is to allow non-LCA experts quickly to compare generic products or processes to support decisions during the design process. This substudy positively identified three important LCA-type software tools useful for assessing products containing cement (Table 4-1). It should be recognized that none of these tools is intended to perform an LCA study compliant with the ISO 14040 standards. Because downstream actors are using these tools to judge the environmental benefits of cement, whether directly or indirectly in cement applications, it is important that the cement industry be familiar with these more user-friendly tools.

17

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

Table 4-2. Important LCA-related Software Tools (compare to Table 4-1)

Name BEES Vendor National Institute for Standards and Testing, USA. IKP, University of Stuttgart, Germany BRE, United Kingdom Tool a Database a ISO DQA Impacts a Stats More Info

http://www.bfrl.nist.gov /oae/ software/bees.html

Build-IT

http://www.ikpgabi.unistuttgart.de/

ENVEST

http://www.bre.co.uk/s ustainable/ envest.html

Legend: ISO actively supports studies to comply with the ISO 14040 standards on LCA DQA includes data quality assessment indicators or evaluation Impacts includes features for Life Cycle Impact Assessment Stats includes features for statistical analysis

4.3.

Databases

Databases are fundamental to the quality of an LCA study and crucial to the timely completion of an LCA project. LCA databases typically include a cross-section of energy, materials and process data that, together, provided a generic foundation suitable to LCA in a diversity of industries. Process information will include common extractive and chemical technologies, plus transport, fuels, electric power and possibly waste management. Many stand-alone LCA databases include data relevant to cement. The substudy generated a short selection of databases that are suggested to be widely applicable to the cement industry (Table 4-3). In some cases the data are provided within an LCA software tool (see Table 4-1); in other cases, the data are purchased separately. An important distinction is between industryprovided data and independent databases, which include consultant, academic and government generated data. Industry-provided data tend to be comprehensive datasets compiled by survey of facilities in a region (see under heading on Level of Effort in section 2.3). Data are usually industry average information, published by the association, with some indication of variability and representativeness; although sometimes data are provided specifically from one site or company. Independent databases are more likely to contain data from several sources and give a more rounded view of an industry. Finally, note that considerable effort in the LCA community is underway in the area of data exchange: it is anticipated that within two to five years, there will be viable standard enabling users effectively to transfer LCA data from one platform to another, thus allowing for a more fluid use of LCA data universally. A more complete listing of tools and databases, and their characteristics, is provided in Appendix C.

18

( WHAT LCA CAN TELL US ABOUT THE CEMENT INDUSTRY )

Table 4-3. Relevant Databases

Name IVAM LCAdata 3.0. Athena Vendor IVAM Environmental Research Athena Institute for Sustainable Materials Comments Very strong database Used alone or with Athena software tool (see Appendix C). Canadian based data, expanding to USA and UK. Japanese language and content More Info

http://www.ivambv.uva. nl/ uk/index.htm http://www.athenasmi. ca/

Use Nordic Countries Canada and USA

JEMAI

BEES

BRE Environmental Profiles

Japan Environmental Management Association for Industry Building and Fire Research Laboratory, National Institute of Standards and Technology BRE & Department of

Energy, Transport & Regions UK

http://www.jemai.or.jp/in dex-e.asp

Japan

USA government in support of environmentally preferable purchasing

http://www.bfrl.nist.gov/ oae/software/bees.html

USA

UK Industry inventory and other databases, used by BRE for different LCA tools

http://collaborate.bre.co. uk/ envprofiles/

United Kingdom

19

( TOWARD A SUSTAINABLE CEMENT INDUSTRY )

5. Analysis

5.1. Status of LCA