Académique Documents

Professionnel Documents

Culture Documents

Welcome To International Journal of Engineering Research and Development (IJERD)

Transféré par

IJERDTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Welcome To International Journal of Engineering Research and Development (IJERD)

Transféré par

IJERDDroits d'auteur :

Formats disponibles

International Journal of Engineering Research and Development e-ISSN: 2278-067X, p-ISSN: 2278-800X, www.ijerd.

com Volume 6, Issue7 (April 2013), PP.74-79

Modeling and Analysis of 2nd Stage HP Stator Blade using FEA

Jonna. Swathi1, Tippa Bhimasankara Rao2

2 1 PG Student, Department of Mechanical Engineering, Nimra Institute of Science and Technology HOD, Department of Mechanical Engineering, Nimra Institute of Science and Technology, Vijayawada, AP, INDIA

Abstract:- Advances in materials, cooling technology and design techniques have allowed MS7001 turbines to

be operated with higher firing temperatures and airflows, which result in higher turbine output and efficiency. Improvements in combustion technology have also made significantly lower emission levels a reality. Advanced design technology is usually introduced for new unit production and subsequently applied to customer-operated gas turbines by a gas turbine uprate program. Many new uprate programs have been introduced for installed GEdesigned heavy duty gas turbines, including the MS7001A, B, C, E, and EA models. Each uprate program provides increased output, improved heat rate and efficiency, improved reliability, reduced maintenance costs, longer inspection intervals, and longer expected parts lives. Additional benefits result because uprates are based on current production components parts that are not specifically unique to older machines and thus readily available. This Project deals with about 2nd Stage HP stator blade. 3D model of blade is done CATIA by taking point data, Meshed in Hyper mesh and Analysis done in ANSYS. Structural analysis is carried on Blade as per given load condition by varying material properties. Study of process making of Blade is studied. Keywords: -Rotor, Stator.

I.

INTRODUCTION

Todays requirements of advanced steam turbine design place special emphasis on the design simplicity, fewer parts, enhanced reliability and maintainability. Such requirements, when coupled with the ever-increasing demand on the higher efficiency level for both existing and new design concepts, offer the most challenging problem to the design engineers. Modern turbine-design entails integrated program system, which accounts for many of the above design requirements from the very beginning of a project and allows the best compromise satisfying the specified constraints to be reached. The principal target is to reduce the design-cycle-time quite drastically, and to enable the designers to perform conceptual studies for any desired ranges of design parameters whilst maintaining the highest level of design quality and reliability. Regarding fine-tuning in the final design stage, hitherto the benefits taken from advances in computational fluid dynamic (CFD) to boost the stage efficiency are quite significant. The improvements were, however, mainly achieved in the standard aerodynamic flow path design to the point where further potential for efficiency improvement on such issues seems to be relatively small. However, as part of continuing technological advance towards the design of new generations of highly efficient turbines, significant efforts have to be concentrated on a number of design details on components placed outside the standard blading flow channel where still some room is left for further efficiency improvement.

II.

TYPES OF TURBINES AND DESCRPTION

There are two types of turbines: HP TURBINE: The axial flow, two-stage reaction type HP Turbine was designed to deliver high efficiency over a broad power range. It consists of two turbine wheels, first and second stage turbine nozzle assemblies, and turbine casings. Both stages of HPT nozzles are air cooled (convection and film) by compressor discharge air flowing through each vane. Both stages of HPT buckets are cooled by compressor air flowing through the dovetail and shanks into the buckets. LP TURBINE: The power turbine uses the same general arrangement, materials and mechanical structure as that of the GE Oil & Gas PGT25+ model whose installed fleet consists of over 80 units and more than 500,000 operating hours. The flow-path profile and airfoils were redesigned to allow 20% higher airflow than the PGT25+. Turbine uprate packages have been introduced because of strong customer interest in extending intervals between maintenance, improving efficiency, and increasing output. The main items that must be considered when evaluating a unit for an advanced technology uprate option are as follows Performance Improvements (Output/Heat Rate) Maintenance/Inspection Interval Extensions Availability/Reliability Improvements Emissions Reduction/Regulatory Agencies Life Extension This paper covers new uprates that have been successfully developed using engineered components developed for current new unit production. Uprate benefits are discussed, including turbine performance and maintenance improvements. Each

74

Modeling and Analysis of 2nd Stage HP Stator Blade using FEA

owner of GE heavy-duty gas turbines should evaluate the economics of the various uprates for the specific application. In many cases, the economic evaluation will justify one of the available uprates at the next major overhaul and, in some cases, earlier. When more power generating capacity is required, uprating can provide a cost-effective alternative to purchasing and installing new units. At the same time, the improved parts can provide extended life to the existing turbine.

Fig.1 the MS7001EA simple-cycle single-shaft, heavy-duty gas turbine.,Fig.2 7EA HGP and rotor materials Many improvements have been made to the current production 7EA in the above figure that can be utilized in older fielded units. Combustion systems, turbine buckets, nozzles, and compressor components have been redesigned using improved materials that increase component life and reduce repairs. While GE moves forward to address marketplace needs, it will continue to improve its products and serve as a world-class high quality supplier of power generation equipment. As a leader in the gas turbine industry, GE is committed to applying the latest available technology parts to the large installed base of GE-designed gas turbines.

III.

THE MAJOR COMPONENTS AND SYSTEMS OF A GAS TURBINE GENERATOR SET INCLUDE

Gas turbine Reduction-drive gear box Generator Start system Fuel system Lubricating oil system Turbotronic for control system On skid electrical wiring Skip with drip pads Piping and manifolds

IV.

PROCEDURE STEPS IN MANUFACTURING OF 2ND STAGE CSB, HPC BLADE

Billet: At this stage stamping of billet as per 104.03TY16 with cold rolled aerofoil. Profile allowance is proportional in all the sections with coefficient deformations. As per the technology additionally equidistant in A1-A1 section on concave by 0.1mm and on convex by 0.4mm with smooth transition up to 0.1mm on concave and convex in the final section. Milling: It is used to mill the neck and aerofoil tip by maintaining dimensions. Centering: Centering has to be done on the blade profile by dividing in to sections along vertical and horizontal direction , then carry out the centering of the faces of the part simultaneously by maintaining desired dimensions . Inspection: Check the aerofoil profile in the device pompkol-4 with block by randomly selection of 10% of parts of the beverage. Displacement of aerofoil profile parallel to x-x axis in section A1 and A2 0.25 mm max in all other sections 0.35mm max. Difference in edges thickness in sections A1 and A2 0.1mm max. Filling: Here we are using cero band filling by placing the scaling gasket on the neck of the blade. Load the part in the cartridge and fasten it. Carry out the filling of part by alloy B. Cooling of cartridge in air until the hardening of alloy B. Carryout the subsequent cooling in the running waste. Disassemble the cartridge and take out the briquette. Turning: Turning is used for root preparation; it has to be done on the face of the neck of the blade .Here we have to take in to consider of non-perpendicularity surface relative to surface B 0.03max. Face run-out of surface relative to B0.05mm max. Ensure by machines in one section. Displacement of placement from the design portions parallel to axis X and Y 0.1mm max and non-perpendicularity of surface relative to the plane X Y at the length of 100 mm -0.01mm max. Before starting the centers of fixture and tailstock of machine up to 0.02mm along the mandrel. Smelting: It has to be done by putting the briquettes in the basket and lower in the tub fill it hot water. After the full removal of BA.. Take out the part and wash the parts in the hot water. Blow off the part by air until full removal of moisture put the blade in the container. Now again milling has to be done on both sides of surfaces of shroud from concave and convex sides flush with aerofoil profile by maintain the dimensions. Projection of machined surfaces relative basic profile should be within the limits of 0.10.3mm. Digging is not permitted. Trimming: It is nothing but removal of unwanted materials of edges and burrs. Check the quality of re-sharpening of cutting surfaces of die. Inspection should be carried out before starting the operation, the contour of aerofoil should be cut incase of quality of surface of parts not matching with inspection etalon i.e. finishing of edges and

75

Modeling and Analysis of 2nd Stage HP Stator Blade using FEA

excess of burr. Carry out the re-sharpening of cutting surfaces. Radius of indicator E6015-6906. Let at 0 at any section of blade at inlet and outlet edges should not be more than + or 0.1mm. On the end of face of pair of blades not more than -0.2mm. Fatigue test: This instruction gives the order for the periodic inspection on fatigue for the finally manufactured aerofoil of the compressor blades of the engine AL31FP. This instruction determines the order of test procedure for checking the stability of manufacturing technology of the blades. The technology documentation for conducting the fatigue tests is developed according to the given instruction.

V.

MODELLING AND ANALYSIS

Fig.3 Model of HP stator blade

Table.1 Inputs given for the model

Fig.4 Meshing of model in ANSYS

Fig.5 Applying loads in ANSYS

VI.

Static Structural Analysis of blade

RESULTS AND DISCUSSIONS

Table.2 static analysis of blade CASE 1: For Alloy-Steel

Fig.6 Stress values CASE 2: For Ni-Alloy

Fig.7 Deformation values

76

Modeling and Analysis of 2nd Stage HP Stator Blade using FEA

Fig.8 Stress values CASE 3: For Titanium Fig.9 Deformation values

Fig.10 Stress values Harmonic Analysis of blade

Fig.11 Deformation values

Table.3 Harmonic analysis of blade

Fig.12 CASE 1: For Alloy-Steel Modal Analysis of the blade Case 1: For Alloy Steel

Fig.13 CASE 2: For Ni-Alloy

Fig.14 CASE 3: For Titanium

Table.4 Natural frequencies of Alloy steel blade

Fig.15, 16, 17, 18, 19&20

Different mode shapes of the Alloy steel blade

77

Modeling and Analysis of 2nd Stage HP Stator Blade using FEA

Case 2: For Ni-Alloy

Table.5 Natural frequencies of Ni-Alloy blade

Fig.21 Graph for modal analysis

Fig.22, 23, 24, 25, 26&27 Case 3: For Titanium

Different mode shapes of the Ni-Alloy blade

Table.6 Natural frequencies of Titanium-Alloy blade

Fig.28 Graph for modal analysis

78

Modeling and Analysis of 2nd Stage HP Stator Blade using FEA

Fig.29, 30, 31, 32, 33&34 Different mode shapes of the Titanium-Alloy blade Results obtained

Table.7 Obtained results

VII.

CONCLUSION

By doing the analysis of 2nd stage hp stator blade with different materials we can observe that the stress induced is more in Alloy-Steel compared to other two materials of Ni-Alloy & Titanium by considering the cost and availability of materials Alloy-steel is more preferable than Titanium or we may use Ni-Alloy instead of Alloy-Steel. And the deformation is observed more in Titanium compared to Alloy-Steel & Ni-Alloy so by seeing the results after analysis Alloy-Steel is best material for 2nd stage hp stator blade and further we may use Ni-Alloy instead of it.

VIII.

[1]. [2]. [3]. [4]. [5]. [6]. [7]. [8]. [9]. [10]. [11].

REFERENCES

Beltran, A.M., Pepe, J.J., Schilke, P.W., Advanced Gas Turbines Materials and Coatings, GER -3569E, GE Energy, August 1994. Brandt, D.E., and Wesorick, R.R., GE Gas Turbine Design Philosophy, GER -3434D, GE Energy, August 1944. Brooks, F.J., GE Gas Turbine Performance Characteristics, GER- 3567E, GE Energy, August 1994. Davis, L.B., Dry Low NOx Combustion Systems for Heavy-Duty Gas Turbines, GER-3568E, GE Energy, August 1994. Johnston, J.R., Robert, Performance and Reliability Improvements for Heavy-Duty Gas Turbines, GER-3571E, GE Energy, August 1994. Junge, R.M., The MS7001E Heavy-Duty Gas Turbine, Gas Turbine Engineering and Manufacturing Department, Gas Turbine Division, Schenectady, NY, 1979. Kelley, L.A., Luessen, H.P., Uprate Options for the MS7001 and MS9001 Gas Turbines, GER -3667, GE Energy, 1991. P. LAMPART1, . HIRT2 on Complex multidisciplinary optimization of turbine blading systems. R. Greim, S. Havakechian on Recent advances in the aerodynamic design of steam turbine components. JERZY SWIRYDCZUK on UNSTEADY PERFORMANCE OF AN HP TURBINE STAGE OPTIMISED FOR STEADY FLOW CONDITIONS. Menter F R 1994 AIAA Journal 32 1598.

79

Vous aimerez peut-être aussi

- SteamDocument6 pagesSteamGunjan KumarPas encore d'évaluation

- Centrifugal Compressors TheoryDocument17 pagesCentrifugal Compressors Theoryvirendkumar75% (4)

- Improved Power Plant PerformanceDocument3 pagesImproved Power Plant Performanceshams100% (1)

- Computational Fluid Dynamics Analysis of A Turbocharger SystemDocument4 pagesComputational Fluid Dynamics Analysis of A Turbocharger Systemmuthu vPas encore d'évaluation

- 5 Development and Operating Experience PDFDocument10 pages5 Development and Operating Experience PDFVijaya100% (2)

- Ge Power Ststem Manuals PDFDocument157 pagesGe Power Ststem Manuals PDFveejai_kumar100% (1)

- Structural Analysis of Micro Turbine by Using CFD Dr.R.Rajappan, K ChandrasekarDocument8 pagesStructural Analysis of Micro Turbine by Using CFD Dr.R.Rajappan, K ChandrasekarSaad Al HelyPas encore d'évaluation

- 4 Turbine and Condenser ModernizationDocument8 pages4 Turbine and Condenser ModernizationmohantyomPas encore d'évaluation

- High Performance RetrofitDocument8 pagesHigh Performance RetrofitJose Fernando Barrera ValderramaPas encore d'évaluation

- Generator Cooling MethodsDocument16 pagesGenerator Cooling MethodsKVVPas encore d'évaluation

- USC Steam Turbine TechnologyDocument17 pagesUSC Steam Turbine TechnologyteijarajPas encore d'évaluation

- Optimization of Diesel Engine Cylinder Liner Undercut 6Document7 pagesOptimization of Diesel Engine Cylinder Liner Undercut 6International Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- SGT-800 Maintainability ImprovementsDocument13 pagesSGT-800 Maintainability Improvementsalexandr_popov_2Pas encore d'évaluation

- Subaru FA20 D-4S Engine PaperDocument18 pagesSubaru FA20 D-4S Engine Paperstefan.vince536100% (1)

- Compressor Maint ListDocument3 pagesCompressor Maint Listsantosh kumar100% (1)

- Design and Analysis of Gas Turbine Rotor Blade Using Finite Element MethodDocument22 pagesDesign and Analysis of Gas Turbine Rotor Blade Using Finite Element MethodTJPRC PublicationsPas encore d'évaluation

- 70 Ijmperdapr201870Document8 pages70 Ijmperdapr201870TJPRC PublicationsPas encore d'évaluation

- Lesson 13 TurbomachineryDocument33 pagesLesson 13 TurbomachineryThomas ParentPas encore d'évaluation

- Gas TurbineDocument6 pagesGas TurbineRicardo Carpio OssesPas encore d'évaluation

- Study On Design of Casing of Steam TurbineDocument3 pagesStudy On Design of Casing of Steam Turbinesevero97Pas encore d'évaluation

- Pneumatic Mobile CraneDocument21 pagesPneumatic Mobile CraneMayilai AshokPas encore d'évaluation

- STEAM TURBINE 3 Design and MaterialsDocument19 pagesSTEAM TURBINE 3 Design and MaterialsHandayani Kesumadewi100% (2)

- LMZ ModernisationDocument62 pagesLMZ ModernisationAnonymous gr5Pr9AVPas encore d'évaluation

- Twin Lobe CompressorDocument14 pagesTwin Lobe Compressorpbs9890271109100% (1)

- Static and Thermal Analysis of Piston With Different Thermal CoatingsDocument13 pagesStatic and Thermal Analysis of Piston With Different Thermal CoatingsPinsteritPas encore d'évaluation

- Gas Turbine Control System ThesisDocument6 pagesGas Turbine Control System Thesisafcnenabv100% (2)

- 6 Testing and Qualification of Two-Stage Turbocharging SystemsDocument16 pages6 Testing and Qualification of Two-Stage Turbocharging SystemsMuzaffar Ali QuaziPas encore d'évaluation

- CHAPTER 8 Sizing and CostingDocument20 pagesCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- 10 11648 J Ijfmts 20190501 11Document9 pages10 11648 J Ijfmts 20190501 11Akhmad M. HasyimPas encore d'évaluation

- 4 Fast Cycling CapabilityDocument13 pages4 Fast Cycling CapabilityktsnlPas encore d'évaluation

- Research Paper On Frictionless Compressor TechnologyDocument4 pagesResearch Paper On Frictionless Compressor Technologygw155nahPas encore d'évaluation

- Siemens SGT5 4000F Performance MeasuremeDocument9 pagesSiemens SGT5 4000F Performance MeasuremerudiyanarefacePas encore d'évaluation

- Reverse Flow Core Intercooled Engines: Rodrigo Orta GuerraDocument5 pagesReverse Flow Core Intercooled Engines: Rodrigo Orta GuerraVishnu RamPas encore d'évaluation

- J. Marx Pratt Aircraft Hartford, CT: Installation Features of Advanced, Very High Bypass Turbofan Propulsion SystemsDocument7 pagesJ. Marx Pratt Aircraft Hartford, CT: Installation Features of Advanced, Very High Bypass Turbofan Propulsion Systemskilcoo316Pas encore d'évaluation

- AHS2011 HECC Design Final PDFDocument15 pagesAHS2011 HECC Design Final PDFKarl GlorstadPas encore d'évaluation

- Design of A High-Performance Centrifugal Compressor With New Surge Margin Improvement Technique For High Speed TurbomachineryDocument11 pagesDesign of A High-Performance Centrifugal Compressor With New Surge Margin Improvement Technique For High Speed TurbomachineryBrahimABDPas encore d'évaluation

- Commercial Operation of 600 MW UnitDocument5 pagesCommercial Operation of 600 MW Unitwaleed emaraPas encore d'évaluation

- CFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarDocument11 pagesCFD Analysis of Non-Symmetrical Intake Manifold For Formula SAE CarGtatlisPas encore d'évaluation

- 5 1526381038 - 15-05-2018 PDFDocument7 pages5 1526381038 - 15-05-2018 PDFAnonymous lPvvgiQjRPas encore d'évaluation

- Solutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas IndustryDocument7 pagesSolutions For Reduced Life Cycle Costs of Centrifugal Compressors in Oil and Gas Industryzeinab_jahani5799Pas encore d'évaluation

- GE Jenbacher High Efficiency ConceptDocument9 pagesGE Jenbacher High Efficiency Conceptjulihardo parulian simarmataPas encore d'évaluation

- Literature Review On Gas TurbineDocument6 pagesLiterature Review On Gas Turbinefuhukuheseg2100% (1)

- Pitch Control Critical For Wind PowerDocument6 pagesPitch Control Critical For Wind Powermehdi amelPas encore d'évaluation

- 30508Document36 pages30508Raphael Felipe Gama RibeiroPas encore d'évaluation

- pgt10 Gas TurbineDocument8 pagespgt10 Gas TurbineKarim Zianni100% (1)

- GE 9HA Gas TurbineDocument4 pagesGE 9HA Gas TurbinejparmarPas encore d'évaluation

- Fu 1Document44 pagesFu 1Joy BhattacharyaPas encore d'évaluation

- BHELDocument4 pagesBHELNageswara Reddy GajjalaPas encore d'évaluation

- International Journal of Engineering Research and Development (IJERD)Document7 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDPas encore d'évaluation

- 1999-01-0266 Technology For Future Air Intake SystemsDocument11 pages1999-01-0266 Technology For Future Air Intake SystemsJoão SoeiroPas encore d'évaluation

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesD'EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideD'EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideÉvaluation : 4 sur 5 étoiles4/5 (8)

- Major Process Equipment Maintenance and RepairD'EverandMajor Process Equipment Maintenance and RepairÉvaluation : 4 sur 5 étoiles4/5 (4)

- Machinery Component Maintenance and RepairD'EverandMachinery Component Maintenance and RepairÉvaluation : 5 sur 5 étoiles5/5 (1)

- Router 1X3 - RTL Design and VerificationDocument10 pagesRouter 1X3 - RTL Design and VerificationIJERDPas encore d'évaluation

- Moon-Bounce: A Boon For VHF DxingDocument5 pagesMoon-Bounce: A Boon For VHF DxingIJERDPas encore d'évaluation

- Biomimicry in ArchitectureDocument10 pagesBiomimicry in Architecturerodolfo barbosaPas encore d'évaluation

- Investigations On Properties of Light Weight Cinder Aggregate ConcreteDocument10 pagesInvestigations On Properties of Light Weight Cinder Aggregate ConcreteIJERDPas encore d'évaluation

- Emotion Detection From TextDocument12 pagesEmotion Detection From TextIJERDPas encore d'évaluation

- Ha1005 PDFDocument18 pagesHa1005 PDFhidraulic50% (2)

- LF Student Workbook 05.5Document42 pagesLF Student Workbook 05.5indikumaPas encore d'évaluation

- 4.heater TreaterDocument53 pages4.heater TreaterMohamed Elabbasy100% (1)

- Materijali I Konstrukcije Materials and Structures: GRA ĐevinskiDocument204 pagesMaterijali I Konstrukcije Materials and Structures: GRA ĐevinskiAnonymous FJG4UKm5HPas encore d'évaluation

- Robots User Manual (CE) - EnglishDocument170 pagesRobots User Manual (CE) - EnglishVlad-Andrei Cucuteanu100% (3)

- Chapter 15 BennetDocument91 pagesChapter 15 BennetpapipapiiPas encore d'évaluation

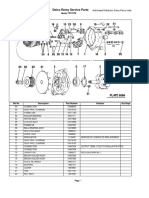

- Delco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaDocument2 pagesDelco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaWilson AcostaPas encore d'évaluation

- Working Example - RC Shear Walls Design Spreadsheet To Bs8110 - Version 1.0Document5 pagesWorking Example - RC Shear Walls Design Spreadsheet To Bs8110 - Version 1.0alok100% (3)

- SC-01 Safety Code On Storage, Handling & Use of Gas CylindersDocument8 pagesSC-01 Safety Code On Storage, Handling & Use of Gas CylindersSandeep ShettyPas encore d'évaluation

- Electrical Equipment: Passenger Compartment Connection UnitDocument233 pagesElectrical Equipment: Passenger Compartment Connection UnitEeeps100% (2)

- TFP110 08 2018Document6 pagesTFP110 08 2018SamiYousifPas encore d'évaluation

- Jednostavni PrimeriDocument13 pagesJednostavni Primeridaka crtamPas encore d'évaluation

- CIP HeaterDocument2 pagesCIP HeaterTutoriais 2.0Pas encore d'évaluation

- Srikage &creepDocument10 pagesSrikage &creepsandeepuaePas encore d'évaluation

- Surface Vehicle Standard: (R) Hydraulic Hose FittingsDocument34 pagesSurface Vehicle Standard: (R) Hydraulic Hose FittingsLUCIANO SOTOPas encore d'évaluation

- PVT (Hydrocarbon Phase Behaviour)Document18 pagesPVT (Hydrocarbon Phase Behaviour)Oscar Mauricio TellezPas encore d'évaluation

- Liquefied Petroleum Gas Cylinder Level Indicator and Transporting DeviceDocument105 pagesLiquefied Petroleum Gas Cylinder Level Indicator and Transporting DeviceAyorinde Oladele Tiwalade100% (1)

- CM P1 11604 en SKF Vibration Sensors CatalogDocument140 pagesCM P1 11604 en SKF Vibration Sensors CatalogMarcelo MallmannPas encore d'évaluation

- Krishnajn@iitb - Ac.in: Quiz Schedule For The Semester Day Thursday Thursday ThursdayDocument1 pageKrishnajn@iitb - Ac.in: Quiz Schedule For The Semester Day Thursday Thursday ThursdayritwikPas encore d'évaluation

- 6stroke EngineDocument5 pages6stroke EngineMitesh KumarPas encore d'évaluation

- Flow Types: - Base of SpillwayDocument6 pagesFlow Types: - Base of Spillwaygizem cenikPas encore d'évaluation

- The Addition and Resolution of Vectors Lab PracticeDocument2 pagesThe Addition and Resolution of Vectors Lab PracticeLuis Alberto Martínez BenítezPas encore d'évaluation

- Simulink Model For Teaching The 'Stick-Slip' Friction Phenomenon in 'Machine Vibration and Noise' CourseDocument10 pagesSimulink Model For Teaching The 'Stick-Slip' Friction Phenomenon in 'Machine Vibration and Noise' Courseeko123Pas encore d'évaluation

- Rebound HammerDocument6 pagesRebound Hammerahmadfarriz100% (1)

- IMI CCI Product DRAG-Control-Valves AW LRESDocument4 pagesIMI CCI Product DRAG-Control-Valves AW LRESOscarGomezMecanicoPas encore d'évaluation

- MCR Training ManualDocument71 pagesMCR Training ManualCluis Ke100% (1)

- 029-Din en 1983 2006 Industrial Valves - Steel Ball ValvesDocument20 pages029-Din en 1983 2006 Industrial Valves - Steel Ball ValvesQuality MSIPL100% (5)

- OHP Assignment 19122016 060442AMDocument3 pagesOHP Assignment 19122016 060442AMPARMAR MAHENDRAPas encore d'évaluation

- 500MWDocument18 pages500MWAlok Ranjan TripathiPas encore d'évaluation