Académique Documents

Professionnel Documents

Culture Documents

Animal Tallow

Transféré par

big johnCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Animal Tallow

Transféré par

big johnDroits d'auteur :

Formats disponibles

8.

PROFILE ON ANIMAL TALLOW PROCESSING

8-2 TABLE OF CONTENTS

PAGE

I.

SUMMARY

8-3

II.

PRODUCT DESCRIPTION & APPLICATION

8-3

III.

MARKET STUDY AND PLANT CAPACITY A. MARKET STUDY B. PLANT CAPACITY & PRODUCTION PROGRAMME

8-4 8-4 8-7

IV.

RAW MATERIALS AND INPUTS A. RAW & AUXILIARY MATERIALS B. UTILITIES

8-8 8-8 8-8

V.

TECHNOLOGY & ENGINEERING A. TECHNOLOGY B. ENGINEERING

8-9 8-9 8-10

VI.

MANPOWER & TRAINING REQUIREMENT A. MANPOWER REQUIREMENT B. TRAINING REQUIREMENT

8-11 8-11 8-12

VII.

FINANCIAL ANLYSIS A. TOTAL INITIAL INVESTMENT COST B. PRODUCTION COST C. FINANCIAL EVALUATION D. ECONOMIC BENEFITS

8-13 8-13 8-14 8-15 8-16

8-3 I. SUMMARY

This profile envisages the establishment of a plant for the processing of animal tallow with a capacity of 150 tonnes per annum.

The present demand for the proposed product is estimated at 21,645 tonnes per annum. The demand is expected to reach at 36,041 tonnes by the year 2020.

The plant will create employment opportunities for 22 persons.

The total investment requirement is estimated at Birr 9.5 million, out of which Birr 5.6 million is required for plant and machinery.

The project is financially viable with an internal rate of return (IRR) of 14 % and a net present value (NPV) of Birr 2.39 million, discounted at 8.5%.

II.

PRODUCT DESCRIPTION AND APPLICATION

Animal tallow is tallow extracted from solid fat or suet" of cattle, sheep or horses by dry or wet rendering. The chief constituents of, for example, beef tallow are stearin, palmitin and olein.

Animal tallow is used in soap industries, leather dressing, candle, greases, manufacture of stearic and oleic acids, animal feed and as adherent in tire moulds.

Animal tallow is a by-product of the meat-processing industry obtained by rendering the body fat from cattle and sheep.

Tallow from different sources may vary considerably in colour, titer (solidification point of fatty acids), tree fatty acid content, specification value (alkali required for specifications), and iodine value (measure of un saturation. The better grades of tallow, judged principally from titer and colour after laboratory bleaching, are used for the preparation of fine toilet soaps; poorer grades are used for laundry soaps.

8-4 Generally, beef or mutton fat acid a titer > 4.4oC is classified as tallow.

In this profile, semi-processed animal tallow (rendered and bleached tallow) is planned to be produced, since the capacity, of the envisaged plant is small. Usually, high quality animal tallow production requires bigger capacity and high investment cost.

III.

MARKET STUDY AND PLANT CAPACITY

A.

MARKET STUDY

1.

Past Supply and Present Demand

Animal tallow is mostly used in soap production. The demand for the product is therefore derived from the demand for soap. Accordingly, the estimated demand for soap is used in determining the demand for animal tallow.

Soap is a necessity product for urban households so much so that its demand is mainly associated with urbanization. The countrys requirement for soap has been met through both domestic production and import. Table 3.1 shows the supply of the product from domestic production and imports during 1997-2005. During the period under reference, total supply averaged at 40,024 tonnes, of which 14,497 tonnes constituted domestic production and the remaining 25,527 tonnes imports. Thus, domestic production, on the average, accounted for 37 percent of the country's requirement for soap, indicating much of the demand for the product (63%) is still met through imports.

8-5 Table 3.1 SUPPLY OF SOAP (TONNES) Market share (%) Year Domestic Production 1997 1998 1999 2000 2001 2002 2003 2004 2005 Average 12,908 9,787 13,135 17,194 14,766 19,249 11,632 14,975 16,825 14,497 20,417 16,471 21,081 21,287 26,811 27,249 27,715 25,557 43,154 25,527 Import Total Supply 33,325 26,258 34,216 38,481 41,577 46,498 39,347 40,532 59,979 40,024 Domestic Production 39 37 38 45 36 41 30 37 28 37 Imports 61 63 62 55 64 59 70 63 72 63

Sources: Customs Authority, External Trade Statistics, various years CSA, Statistical Abstract, Various years.

Assuming supply was driven by demand, the average annual supply of soap for the period under reference, which constitutes domestic production and imports, is considered as the effective demand for the product for the year 2005. Since the consumption of soap is mainly associated with the urban population, the demand for the product is assumed to grow at the rate of 4% that corresponds to the annual growth rate of the urban population. The present demand for soap (i.e., for 2007) is, thus, estimated at 43,289 tonnes. According to the estimates of engineers involved in this study, animal tallow accounts for about 50 per cent of the inputs used in the production of soap. The current demand for animal tallow (i.e., for 2007) is, therefore, estimated at 21,645 tonnes.

8-6 2. Projected Demand

Since the demand for animal tallow is derived from the demand for soap, the 4% annual growth rate of the urban population used in projecting the demand for soap is applied in projecting the demand for animal tallow. In projecting the demand for animal tallow, it is also assumed that existing suppliers will maintain the 38% market share that corresponds to the market share of domestic producers in the total supply of soap. Table 3.2 presents the projected unsatisfied demand for animal tallow. Table 3.2 PROJECTED DEMAND FOR ANIMAL TALLOW (TONNES)

Projected Year 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018 2019 2020 Demand 22,511 23,411 24,348 25,322 26,334 27,388 28,483 29,623 30,808 32,040 33,321 34,654 36,041

Existing Supply 8329 8662.16 9008.64 9368.99 9743.75 10133.5 10538.8 10960.4 11398.8 11854.8 12328.9 12822.1 13335

Unsatisfied Demand 14,182 14,749 15,339 15,953 16,591 17,254 17,945 18,662 19,409 20,185 20,993 21,832 22,706

3.

Pricing and Distribution

Based on current market price for the product, a factory-get price of Birr 20 per kg is recommended for the envisaged plant. The product can be directly supplied to the end users.

8-7

B.

PLANT CAPACITY AND PRODUCTION PROGRAMME

1.

Plant Capacity

The production capacity of the envisaged plant is 150 tonnes per year based on 300 working days per year and single shift of (8 hrs) per day. The capacity can be increased by increasing the number of working hours per day.

2.

Production Programme

During the first two years of production, full capacity utilization may not be attained. This is because of lack of manufacturing and marketing experiences. Therefore, in the first and second year of only 70% and 85% of the plant capacity will be utilized. In the third year and thereafter, full capacity can be attained. The production programme of the project is indicated in Table 3.3.

Table 3.3 PRODUCTION PROGRAMME

Sr. No. 1 2

Product 2008 Animal tallow Capacity utilization rate (%) 105 70

Production Year 2009 127.5 85 2010-2018 150 100

8-8

IV.

MATERIALS AND INPUTS

A.

RAW & AULIXILIARY MATERIALS

The major raw & auxiliary materials of the proposed project are crude tallow and wastes of slaughtering house such as bones and other fat containing materials. In addition, bleaching earth is required to improve the colour of the semi-processed tallow. The annual raw and auxiliary material requirement and its cost is indicated in Table 4.1. The total annual cost of raw materials, at full capacity operation, is estimated at Birr 749.7 thousand.

Table 4.1 RAW AND AUXILIARY MATERIALS REQUIREMENT & COST

Sr.

Raw Material

Qty. (Tonnes)

Cost ('000 Birr)

No. 1 2 3 Crude Tallow Slaughter house wastes Bleaching earth Grand Total 146.3 643 3

FC

LC 512.05 225.05

Total 512.05 225.05 12.6 749.7

10.5 10.5

2.1 739.2

B.

UTILITIES

Electricity, furnace oil and water are major utilities of the project. Annual utility requirement and its cost are indicated in Table 4.2. The total annual cost of utilities, when the plant is operating at full capacity, is estimated at Birr 351.9 thousand.

8-9

Table 4.2 ANNUAL UTILITY REQUIREMENT AND ITS COST

Sr. No. 1

Product

Qty.

Unit Price

Cost ('000 Birr) 52.1

Electricity (kWh)

110,000

0.4736

2 3

Furnace oil (kg) Water (m3) Total

30,000 25,000

5.41 5.5

162.3 137.5 351.9

V.

TECHNOLOGY AND ENGINEERING

A.

TECHNOLOGY

1.

Process Description

The site of the meat processing products (crude tallow, bones and other fat containing products) shall first be reduced with bone crushers and extruders. It is then conveyed to fat rendering unit. In this unit, the raw materials are cooked in a closed vertical tank under pressure by direct steam injection, typically at 380-500 kpa (3.8-4.9 atm.) for 3 to 6 hrs. The tallow is drawn off from the top of the vessel after it has been allowed to settle for several hours. This process is called rendering.

After rendering, the fat is usually further processed outside the meat processing plant. Depending on the desired product, the fats may be hydrogenated, bleached, deodorized, plasticized, etc. In this project, the rendered fat shall only be bleached and sent as semi-

finished product to laundry soap processing factories.

8-10 The bleaching process may take in batch bleacher by adding powdered bleaching earth which adsorbs the materials responsible for the colour of tallow. After bleaching, melted tallow shall be separated from bleaching earth by filter press.

B.

ENGINEERING

1.

Machinery & Equipment

The list of machinery and equipment is indicated in Table 5.1. The total cost of machinery and equipment is estimated at Birr 5.6 million, out of which Birr 4.48 million is in foreign currency.

Table 5.1 MACHINERY & EQUIPMENT REQUIRMENT

Sr. No. 1. 2. 3. 4. 5. 6. 7. 8. Bone crusher Extruder

Description

Rendering vessel with accessories Bleacher Filter press Boiler Storage tanks Wheel barrows

2.

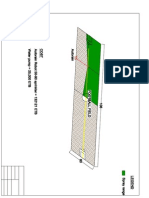

Land, Building and Civil Work

The total land required by the project is about, 5,000 m2, out of which 1,100 m2 is a built-up area. The lease value of land is estimated at Birr 40,000 at a rate of 0.1 Birr/m2 per year for 80 years. The cost of building is estimated at Birr 2.53 million assuming a building construction rate of Birr 2,300 per m2 for building to be constructed of hollow block wall, steel truss and

8-11 EGA sheet roof and cement screed floor. The total cost of land, building and civil works is estimated at Birr 2.57 million.

3.

Proposed Location

The location will be determined by the presence of cattle population and proximity to market for the product or the soap factory that can use the animal tallow can be established following the establishment of this plant. The envisaged plant is proposed to be located in Banatsemay woreda, Kayafer town.

VI.

MANPOWER AND TRAINING REQUIREMENT

A.

MANPOWER REQUIREMENT

The total manpower requirement is 22 persons. The list of manpower and the annual labour cost is indicated in Table 6.1. The total annual labour cost is estimated at Birr 168,750.

8-12

Table 6.1 MANPOWER REQUIREMENT AND LABOUR COST

Sr. No. 1. 2. 3. 5. 6. 7. 10. 11. 12.

Manpower

No. of Persons

Monthly Salary (Birr) 1,500 700 900 900 450 800 2400 1,800 1,800

Annual Salary (Birr) 18,000 8,400 10,800 10,800 5,400 9,600 28,800 21,600 21,600 13,5000 33,750 168,750

General manager Secretary Sales /purchasing officer Accountant Cashier Production supervisor Operator technician Labourers General service Sub-Total Benefit (25% BS) Total

1 1 1 1 1 1 4 6 6 22

B.

TRAINING REQUIREMENT

On-the-job training of manpower particularly production supervisor and machine operators will take place by the experts of machinery supplier. The cost of training is estimated at Birr 25,000.

8-13 VII. FINANCIAL ANALYSIS

The financial analysis of the animal tallow processing project is based on the data presented in the previous chapters and the following assumptions:-

Construction period Source of finance

1 year 30 % equity 70 % loan

Tax holidays Bank interest Discount cash flow Accounts receivable Raw material local Work in progress Finished products Cash in hand

5 years 8% 8.5% 30 days 30days 5 days 30 days 5 days

A.

TOTAL INITIAL INVESTMENT COST

The total investment cost of the project including working capital is estimated at Birr 9.5 million, of which 17 per cent will be required in foreign currency.

The major breakdown of the total initial investment cost is shown in Table 7.1.

8-14

Table 7.1 INITIAL INVESTMENT COST

Sr. No. 1 2 3 4 5 6 7 Cost Items Land lease value Building and Civil Work Plant Machinery and Equipment Office Furniture and Equipment Vehicle Pre-production Expenditure* Working Capital Total Investment cost Foreign Share

Total Cost (000 Birr) 40.0 2,530.0 5,600.0 75.0 450.0 653.8 154.8 9,503.6 17

* N.B Pre-production expenditure includes interest during construction ( Birr 503.80 thousand ) training (Birr 25 thousand ) and Birr 125 thousand costs of registration, licensing and formation of the company including legal fees, commissioning expenses, etc.

B.

PRODUCTION COST

The annual production cost at full operation capacity is estimated at Birr 2.54 million (see Table 7.2). The material and utility cost accounts for 43.41 per cent, while repair and

maintenance take 3.94 per cent of the production cost.

8-15 Table 7.2 ANNUAL PRODUCTION COST AT FULL CAPACITY ('000 BIRR) Items Raw Material and Inputs Utilities Maintenance and repair Labour direct Factory overheads Administration Costs Total Operating Costs Depreciation Cost of Finance Total Production Cost Cost 749.70 351.9 100 101.25 0 67.5 1,370.35 816 351.5 2,537.85 % 29.54 13.87 3.94 3.99 0.00 2.66 54.00 32.15 13.85 100

C.

FINANCIAL EVALUATION

1.

Profitability

According to the projected income statement, the project will start generating profit in the first year of operation. Important ratios such as profit to total sales, net profit to equity (Return on equity) and net profit plus interest on total investment (return on total investment) show an increasing trend during the life-time of the project. The income statement and the other indicators of profitability show that the project is viable.

2.

Break-even Analysis

The break-even point of the project including cost of finance when it starts to operate at full capacity ( year 3) is estimated by using income statement projection. BE = Fixed Cost Sales Variable Cost = 70 %

8-16 3. Pay Back Period

The investment cost and income statement projection are used to project the pay-back period. The projects initial investment will be fully recovered within 6 years.

4.

Internal Rate of Return and Net Present Value

Based on the cash flow statement, the calculated IRR of the project is 14 % and the net present value at 8.5% discount rate is Birr 2.39 million.

D.

ECONOMIC BENEFITS

The project can create employment for 22 persons.

In addition to supply of the domestic

needs, the project will generate Birr 2.12 million in terms of tax revenue.

Vous aimerez peut-être aussi

- Herb Production OrganicDocument20 pagesHerb Production OrganicShoshannah33% (3)

- Nursery Manual For Native Plants PDFDocument309 pagesNursery Manual For Native Plants PDFbig john100% (1)

- Lowland OilcropsDocument14 pagesLowland Oilcropsbig johnPas encore d'évaluation

- Tea and IrrigationDocument14 pagesTea and Irrigationbig johnPas encore d'évaluation

- Co-Op Bulk Spice List in Order by Alphabetic Spice NameDocument3 pagesCo-Op Bulk Spice List in Order by Alphabetic Spice Namebig johnPas encore d'évaluation

- The Date Palm Journal PDFDocument240 pagesThe Date Palm Journal PDFbig johnPas encore d'évaluation

- Chewaka Store ModelDocument1 pageChewaka Store Modelbig johnPas encore d'évaluation

- Tea and IrrigationDocument14 pagesTea and Irrigationbig johnPas encore d'évaluation

- Football Field Layout1Document1 pageFootball Field Layout1big johnPas encore d'évaluation

- OrangeDocument23 pagesOrangebig john100% (1)

- Jam and JellyDocument28 pagesJam and Jellybig johnPas encore d'évaluation

- Participatory Irrigation Management in AlbaniaDocument25 pagesParticipatory Irrigation Management in Albaniabig johnPas encore d'évaluation

- PomegranatesDocument5 pagesPomegranatesbig johnPas encore d'évaluation

- Grape JuiceDocument16 pagesGrape Juicebig johnPas encore d'évaluation

- Tuta AbsolutaDocument25 pagesTuta Absolutabig johnPas encore d'évaluation

- BS Year1 No14 - Apr.02 1925Document4 pagesBS Year1 No14 - Apr.02 1925big johnPas encore d'évaluation

- Horticulture Report FinalDocument57 pagesHorticulture Report Finalbig john100% (1)

- FCKupload File FAO Syria Crisis Report enDocument106 pagesFCKupload File FAO Syria Crisis Report enbig johnPas encore d'évaluation

- CIB, ContractDocument89 pagesCIB, Contractbig johnPas encore d'évaluation

- CIB, ContractDocument89 pagesCIB, Contractbig johnPas encore d'évaluation

- Tomato MarketingDocument8 pagesTomato Marketingbig johnPas encore d'évaluation

- Ethiopia Irrigation Diagnostic July 2010 2Document59 pagesEthiopia Irrigation Diagnostic July 2010 2big john100% (1)

- 36 Tomato Sauce, Ketchup and PureesDocument9 pages36 Tomato Sauce, Ketchup and Pureesbig johnPas encore d'évaluation

- Commodity TeaDocument4 pagesCommodity Teabig johnPas encore d'évaluation

- Final EgyptDocument258 pagesFinal Egyptbig johnPas encore d'évaluation

- Unu Strategic Plan 2011-2014 enDocument20 pagesUnu Strategic Plan 2011-2014 enbig johnPas encore d'évaluation

- Tomato Paste and JuiceDocument14 pagesTomato Paste and JuiceRamanathan Meyyappan100% (1)

- 101 Iced Tea RecipesDocument109 pages101 Iced Tea RecipesNessa Santiago100% (3)

- Dried Spray FruitDocument130 pagesDried Spray Fruitbig john100% (2)

- Agribusiness Organization and Management SeminarDocument24 pagesAgribusiness Organization and Management Seminarbig john100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Cost II - All Theoretical PDFDocument9 pagesCost II - All Theoretical PDFkarimhishamPas encore d'évaluation

- Journal Entries:: CHAPTER 9 - Installment Sales Solutions To Problems Problem 9 - 1Document15 pagesJournal Entries:: CHAPTER 9 - Installment Sales Solutions To Problems Problem 9 - 1Maurice AgbayaniPas encore d'évaluation

- ABM 12 - Accounting-Module 2 SCIDocument6 pagesABM 12 - Accounting-Module 2 SCIWella LozadaPas encore d'évaluation

- Differential Analysis and Product PricingDocument60 pagesDifferential Analysis and Product Pricingmentari cahyaPas encore d'évaluation

- 20221218145704D6181 - Datar - 17e - Accessible - Fullppt - 18 - Process Costing WeightedDocument27 pages20221218145704D6181 - Datar - 17e - Accessible - Fullppt - 18 - Process Costing WeightedMateus AriatamaPas encore d'évaluation

- Introduction To Cost Accounting/CostingDocument36 pagesIntroduction To Cost Accounting/CostingHarisvan To SevenPas encore d'évaluation

- Chapter 03Document22 pagesChapter 03Nelly YulindaPas encore d'évaluation

- Background Artisans Shirtcraft Manufactures and Sells Hand Painted Shirts of Original DesignDocument3 pagesBackground Artisans Shirtcraft Manufactures and Sells Hand Painted Shirts of Original Designtrilocksp SinghPas encore d'évaluation

- 9706 Accounting: MARK SCHEME For The May/June 2014 SeriesDocument6 pages9706 Accounting: MARK SCHEME For The May/June 2014 SeriesDanny DrinkwaterPas encore d'évaluation

- Assignment FinalDocument6 pagesAssignment Finalcecille maningoPas encore d'évaluation

- Chapter 5Document14 pagesChapter 5RB100% (3)

- MAF Assignment QuestionDocument13 pagesMAF Assignment QuestionKietHuynhPas encore d'évaluation

- Process Manufacturing AjinomotoDocument2 pagesProcess Manufacturing AjinomotoCheong Zhe Yoing0% (1)

- Financial Accounting: Tools For Business Decision Making: Ninth EditionDocument70 pagesFinancial Accounting: Tools For Business Decision Making: Ninth EditionJesussPas encore d'évaluation

- FABM2 Q1 Module 5 Analysis and Interpretation of Financial Statements - editEDDocument31 pagesFABM2 Q1 Module 5 Analysis and Interpretation of Financial Statements - editEDMecaila libaton100% (2)

- Quiz 2 - Cost Terms, Concepts and ClassificationDocument9 pagesQuiz 2 - Cost Terms, Concepts and Classificationralphalonzo100% (1)

- Entrepreneurship Quarter2 Week1 4editDocument32 pagesEntrepreneurship Quarter2 Week1 4editMarcht PatarayPas encore d'évaluation

- InventoriesDocument17 pagesInventoriesYash AggarwalPas encore d'évaluation

- Fundamental Accounting Principles 24th Edition Ebook PDFDocument61 pagesFundamental Accounting Principles 24th Edition Ebook PDFwilliam.dailey153100% (45)

- Practice Exercises: Discussion QuestionsDocument11 pagesPractice Exercises: Discussion QuestionsDesi TravelsPas encore d'évaluation

- Midterm ExaminationDocument10 pagesMidterm ExaminationJo KePas encore d'évaluation

- Cost and Cost ConceptsDocument2 pagesCost and Cost ConceptsCamie YoungPas encore d'évaluation

- Case 1: Balungao Company Engaged You To Examine Its Books and Records For TheDocument2 pagesCase 1: Balungao Company Engaged You To Examine Its Books and Records For Thekat kalePas encore d'évaluation

- HorngrenIMA14eSM ch16Document53 pagesHorngrenIMA14eSM ch16Piyal HossainPas encore d'évaluation

- SAMPLE 1-One-Page Sample Business PlanDocument1 pageSAMPLE 1-One-Page Sample Business PlanClariz Angelika EscocioPas encore d'évaluation

- Reviewer For FinalsDocument4 pagesReviewer For FinalsRenz AlconeraPas encore d'évaluation

- Wiley Sec D 2021 MCQDocument673 pagesWiley Sec D 2021 MCQAbd-Ullah AtefPas encore d'évaluation

- Chapter 11,12,13Document20 pagesChapter 11,12,13Nikki GarciaPas encore d'évaluation

- BasicchartofaccountsDocument6 pagesBasicchartofaccountsPanith MeasPas encore d'évaluation

- Wey Fin 11e SM Ch06Document66 pagesWey Fin 11e SM Ch06Muhammad Farhan AliPas encore d'évaluation