Académique Documents

Professionnel Documents

Culture Documents

New Application Ez - David - Cowan

Transféré par

Ho TenDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

New Application Ez - David - Cowan

Transféré par

Ho TenDroits d'auteur :

Formats disponibles

New applications for enzymes in oil processing

Dr David Cowan, Novozymes Customer Solutions

27/06/2011

27/06/2011

NOVOZYMES PRESENTATION

Agenda

Current Applications Where to from here my perspective

27/06/2011

NOVOZYMES PRESENTATION

Mechanisms of Current Applications

Interesterification

Hydrolysis

Several near future applications based on synthesis and modification 2 examples

If an alcohol or fatty acid is substituted for water we can make esters or exchange fatty acids

27/06/2011

NOVOZYMES PRESENTATION

Mixing esters or fatty acids with glycerol allows for condensation reactions to occur under vacuum

27/06/2011

NOVOZYMES PRESENTATION

Application 1: removal of FFA

OH-group

Fatty acid group

Tri-glyceride

Di-glycerides

Mono-glycerides

Fatty acids and Glycerol

REMEDIATION BY CONDENSATION

27/06/2011

NOVOZYMES PRESENTATION

Conditions for reaction

Operating under vacuum to allow removal of generated water increases reaction rate and moves the equilibrium to FFA removal

Increased enzyme dosage increases reaction speed and as enzymes (liquid and immobilized) can be recovered, re-use is possible

27/06/2011

NOVOZYMES PRESENTATION

New applications

Fish oil for use in high DHA/EPA products contains 5-10% FFA. Removing this by alkali neutralization gives a double loss due to oil entrained in soaps. Conversion back to TAG reduces losses and makes a better utilization of scarce resources.

Palm oil extracted from fruit bunches also contains FFA coming from microbial degradation of the lipids. MAG & DAG in this oil is associated with 3-MCPD formation, so condensation of FFA back onto these could reduce the pre-cursors for the formation of this unwanted compound.

27/06/2011

NOVOZYMES PRESENTATION

Non Food grade oils

Condensation of waste oil using Lipozyme Calb at 70C, 0.1% w/w enzyme and 2% w/w glycerol

Waste oils (brown grease) can be readily converted in a batch system but oil quality needs to be considered. Oils often contain high levels of acidity (Non FFA) and oxidation products which can reduce enzyme activity. Pre-treatments may be required to reduce these to get acceptable enzyme working life.

27/06/2011

NOVOZYMES PRESENTATION

Application 2: Production of DAG

Glycerolysis of a tri-glyceride can be used to re-distribute fatty acids to produce a mixture of MAG, DAG and TAG. Lipase used can be non-specific or with Sn1,3 specificity Immobilised enzyme may be preferred due to high glycerol addition rate.

10

27/06/2011

NOVOZYMES PRESENTATION

Production of DAG/MAG

Glycerolysis with Lipozyme 435 (2%) and various glycerol addition rates at 80C/24 hours

Glycerolysis with Lipozyme 435 (2%) and glycerol (3.4M) at 80C, 0-24 hours

11

27/06/2011

NOVOZYMES PRESENTATION

Alternative routes

MAG and DAG can also be synthesised by combining glycerol and fatty acids Using liquid enzymes reduces the conversion to DAG but does not eliminate it . Presence or absence of a solvent alters the relative proportions of MAG and DAG

Yang, Rebsdorf, Engelrud, and Xu, Monoacylglycerol synthesis via enzymatic glycerolysis in an efficient reaction system, J. Food Lipids 12, 299-312, 2005.

12

27/06/2011

NOVOZYMES PRESENTATION

Reactions involving alcohols

13

27/06/2011

NOVOZYMES PRESENTATION

Previous observations for Biodiesel production Observations

Methanol toxic to immobilised enzyme Ethanol gives higher yield as more bulky alcohol Enzyme re-cycling required for process economy Prospects limited for enzymatic bioiesel

Remedies

Systems utilising phased addition or co-solvents Methyl esters are generally regarded as being biodiesel Normally immobilised enzymes suggested but these are normally high cost due to support. Joint research with external partners to resolve problems

14

27/06/2011

NOVOZYMES PRESENTATION

Full enzymatic process

Callera Ultra

Trans esterification reactor

CalleraTM Trans

Two stage system using liquid lipase for trans-esterification followed by immobilised enyme for FFA removal

15

27/06/2011

NOVOZYMES PRESENTATION

Outline for batch system

Liquid formulated lipase (Callera Trans) is added at 0.5% (w/w) of oil 1.5 molar mass equivalents of methanol to fatty acids, both FFA and fatty acids bound in triglycerides (alternatively, ethanol can be used) Temperature: 3540 C (95104 F) Reaction time:0-6 hours

Novozymes A/S Luna No. 2011-13233-01

NB: A CSTR continuous system is also available

16

27/06/2011

NOVOZYMES PRESENTATION

The FFA esterification process

Glycerol-free FAME with 5% FFA

and turn it into a FFA-esterification pretreatment unit for chemical plants

17

27/06/2011

NOVOZYMES PRESENTATION

The work with FFA esterification showed us that:

FFA in raw materials equals YIELD We have an enzyme that loves FFA

C.antarctica lipase B

CalleraTM Ultra

To drive the reaction the water needs to be removed. 1 kg FFA produces approximately 1.05 kg FAME and 0.06 kg water We need to remove the water

FAeSTER process eliminate water continuously Air loop drying technology Flash drying

18

27/06/2011

NOVOZYMES PRESENTATION

Principles of the water flash removal

Esterification in three steps (4% FFA)

Drying to 100ppm. Reaction 5% Callera Ultra, 35oC

Time (min)

Ref. S.Fedosov. Aarhus University Unpublished data

Water (ppm)

FA (%)

19

27/06/2011

NOVOZYMES PRESENTATION

Adapting the FFA removal step for oil pretreatment

Ref. S.Fedosov. Aarhus University, unpublished data

20

27/06/2011

NOVOZYMES PRESENTATION

Ethylation of Fish oils

In order to separate DHA & EPA from other fatty acids in fish oils, the tri-glyceride is first converted to ethyl esters and then the separation made using short path distillation Residual FFA in the oils will neutralise the catalyst producing soaps and yield loss The high temperature used in the reaction can promote polymerization and tans fat production

Adaptation of Biodiesel process

Reaction conditions: 35C, 5 eqv. ethanol to triglyceride, EtOH added in 5 portions over 1 h. 1.2% Lipozyme TL 100 of oil, neutralized with 0.025 M KOH (1 ml per 100 g oil). FAE content measured by GC. Fish oil kindly provided by Berg Lipid Tech AS. Ref. PRBA

22

27/06/2011

NOVOZYMES PRESENTATION

Optimisation by enzyme switch

Use of alternative enzyme improves overall yield of FAEE, indicating different fatty acid preferences for lipases Step wise addition of ethanol avoids enzyme inactivation Plateaus in the conversion indicate possibility to reduce reaction time to an acceptable level

ELN-11-JHAN-0009

23

27/06/2011

NOVOZYMES PRESENTATION

Conclusion & Summary

Enzyme applications are more widespread than degumming and interesterification and new possibilities are under development Renewed interest in yield improvement and improving sustainability is driving many of these developments We can also expect the development and introduction of new enzymes within the degumming, speciality fats and interesterification applications as success there drives new developments and attracts new players

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Prepositions of Place 1Document1 pagePrepositions of Place 1Michelle AhydePas encore d'évaluation

- R134 ADocument1 pageR134 AHo TenPas encore d'évaluation

- Simple PastDocument14 pagesSimple PastHo TenPas encore d'évaluation

- Emotion, Character, and ResponsibilityDocument184 pagesEmotion, Character, and ResponsibilityHo Ten100% (1)

- Optimization of Amylase ProductionDocument8 pagesOptimization of Amylase ProductionHo TenPas encore d'évaluation

- Flash Card Comparison: Product Planning & Application Engineering Team Memory Division Samsung Electronics Co., LTDDocument3 pagesFlash Card Comparison: Product Planning & Application Engineering Team Memory Division Samsung Electronics Co., LTDHo TenPas encore d'évaluation

- Flamand 4 - OkDocument3 pagesFlamand 4 - OkHo TenPas encore d'évaluation

- Level 3 Passage 1Document3 pagesLevel 3 Passage 1Ho TenPas encore d'évaluation

- Contes 4 - OkDocument3 pagesContes 4 - OkHo TenPas encore d'évaluation

- 187407Document32 pages187407Ho TenPas encore d'évaluation

- ESL Independent Study Lab - ReadingDocument5 pagesESL Independent Study Lab - ReadingHo TenPas encore d'évaluation

- CBR-970 (A) - Firmware Upgrade GuideDocument3 pagesCBR-970 (A) - Firmware Upgrade GuideHo TenPas encore d'évaluation

- Production-Purification and Characteristic of AmylaseDocument8 pagesProduction-Purification and Characteristic of AmylaseHo TenPas encore d'évaluation

- Optimization of Amylase ProductionDocument8 pagesOptimization of Amylase ProductionHo TenPas encore d'évaluation

- Fungal AmylaseDocument8 pagesFungal AmylaseangelinaanavarroPas encore d'évaluation

- Fungal AmylaseDocument8 pagesFungal AmylaseangelinaanavarroPas encore d'évaluation

- Contract AppendixDocument2 pagesContract AppendixHo TenPas encore d'évaluation

- FAO Value Chain of Fresh Milk NgaDocument16 pagesFAO Value Chain of Fresh Milk NgaHo TenPas encore d'évaluation

- The Complete Book On Cultivation and Manufacture of TeaDocument11 pagesThe Complete Book On Cultivation and Manufacture of TeaHo Ten0% (1)

- CBR-970 (A) - Firmware Upgrade GuideDocument3 pagesCBR-970 (A) - Firmware Upgrade GuideHo TenPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Project SynopsisDocument8 pagesProject Synopsistaran jot100% (1)

- Gat Test 26-3-22 PDFDocument8 pagesGat Test 26-3-22 PDFRitesh Raj PandeyPas encore d'évaluation

- Arlan Alvar: Compex Certified E&I Ex Inspector (Qa/Qc) Available For New OpportunityDocument3 pagesArlan Alvar: Compex Certified E&I Ex Inspector (Qa/Qc) Available For New OpportunityDo naPas encore d'évaluation

- G20 Business Letter We Mean Business CoalitionDocument26 pagesG20 Business Letter We Mean Business CoalitionComunicarSe-ArchivoPas encore d'évaluation

- Final Et NotesDocument123 pagesFinal Et NotesyounusmohamadPas encore d'évaluation

- Photoassociation Spectroscopy of A Spin-1 Bose-Einstein CondensateDocument5 pagesPhotoassociation Spectroscopy of A Spin-1 Bose-Einstein Condensatee99930Pas encore d'évaluation

- Versati 3 Split Service Manual MinDocument155 pagesVersati 3 Split Service Manual MinPatrick HorsfieldPas encore d'évaluation

- Instr 12205 Elements Transmitters Transducers DisplacersDocument103 pagesInstr 12205 Elements Transmitters Transducers DisplacersKumar SomasundaramPas encore d'évaluation

- Cahier Technique No. 193 ScheneiderDocument36 pagesCahier Technique No. 193 ScheneiderSarahí Fernández SánchezPas encore d'évaluation

- OMS 605 User Manual ENUDocument86 pagesOMS 605 User Manual ENUlatifPas encore d'évaluation

- Renewable RevolutionDocument52 pagesRenewable RevolutionDaisyPas encore d'évaluation

- Pompe Perkins 3340f261t PDFDocument2 pagesPompe Perkins 3340f261t PDFKamel BelhibaPas encore d'évaluation

- En 16252-2012Document42 pagesEn 16252-2012Fabio Manente100% (1)

- AQA QMS Pvt. LTD.: S No Company Name Membership NoDocument11 pagesAQA QMS Pvt. LTD.: S No Company Name Membership NoDevasyrucPas encore d'évaluation

- Cambridge International AS Level: Environmental Management 8291/12Document12 pagesCambridge International AS Level: Environmental Management 8291/12zohaibPas encore d'évaluation

- Vibration Isolation Selection GuideDocument5 pagesVibration Isolation Selection GuidearifzakirPas encore d'évaluation

- BOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Document32 pagesBOMAG - Brochure - BF600-700-800-3 - PRE107416 - 2103Jason TanPas encore d'évaluation

- Ncom N102Document16 pagesNcom N102RixroxPas encore d'évaluation

- Air Compressor Presentation 1.1Document20 pagesAir Compressor Presentation 1.1ROBERTO FELIX RUEDASPas encore d'évaluation

- StandardsDocument76 pagesStandardsSohaib ZafarPas encore d'évaluation

- TERAL End SuctionDocument6 pagesTERAL End Suctionmarpaung saberindoPas encore d'évaluation

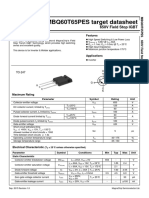

- MBQ60T65PES Target Datasheet: 650V Field Stop IGBTDocument1 pageMBQ60T65PES Target Datasheet: 650V Field Stop IGBTamrPas encore d'évaluation

- Notification 1 2017 For CGST Rate ScheduleDocument74 pagesNotification 1 2017 For CGST Rate ScheduleIti CglPas encore d'évaluation

- Syllabus: Certificate in Subsea EngineeringDocument6 pagesSyllabus: Certificate in Subsea EngineeringJerome LIKIBIPas encore d'évaluation

- Refrigerator User Manual: ASD241B ASD241S ASD241X ASD241W ASL141B ASL141S ASL141W ASL141XDocument29 pagesRefrigerator User Manual: ASD241B ASD241S ASD241X ASD241W ASL141B ASL141S ASL141W ASL141XBooksPas encore d'évaluation

- Auto ElectricianDocument3 pagesAuto Electricianmnrao62Pas encore d'évaluation

- Unit 4: Fault Analysis EssentialsDocument9 pagesUnit 4: Fault Analysis EssentialsBALAKRISHNAN100% (2)

- Special Working Rules For Bahadurgarh Station 1. General and Subsidiary Rules:-A)Document12 pagesSpecial Working Rules For Bahadurgarh Station 1. General and Subsidiary Rules:-A)sahil4INDPas encore d'évaluation

- Safety Rule Book For Persons in Charge of Work On Mechanical Systems Associated With JSP 375 Volume 3 Chapter 4Document43 pagesSafety Rule Book For Persons in Charge of Work On Mechanical Systems Associated With JSP 375 Volume 3 Chapter 4Dimkovski Sase KazakPas encore d'évaluation

- Dual Cab Locomotive HandbookDocument80 pagesDual Cab Locomotive HandbookRah Mli80% (5)