Académique Documents

Professionnel Documents

Culture Documents

9A14401 Production Technology

Transféré par

sivabharathamurthyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

9A14401 Production Technology

Transféré par

sivabharathamurthyDroits d'auteur :

Formats disponibles

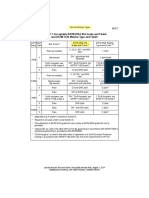

Code: 9A14401

1

PRODUCTION TECHNOLOGY

(Mechatronics)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013

Time: 3 hours

Answer any FIVE questions All questions carry equal marks *****

Max. Marks: 70

1. (a) Explain skeleton pattern briefly with a neat sketch and compare it with sweep pattern. (b) What are the function of a runner and a riser in gating systems? 2. Describe the operation of a cupola furnace for melting last iron.

3. (a) What are the different types of flames used in gas welding process? (b) What is the principle of thermit welding? 4. Discuss in detail about the destructive and nondestructive testing of welds.

5. (a) What is injection moulding? What are its applications? (b) Differentiate between hot working and cold working processes. 6. (a) Explain the coining operation with a neat sketch. (b) Describe briefly the deep drawing operation with a neat sketch. 7. (a) Differentiate between forward extrusion and backward extrusion. (b) Write a note on impact extrusion process. 8. What are the reasons for occurring of defects in forging and give the suitable remedies for preventing defects?

*****

Code: 9A14401

2

PRODUCTION TECHNOLOGY

(Mechatronics)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013

Time: 3 hours

Answer any FIVE questions All questions carry equal marks ***** 1. (a) What are pattern allowances? Explain each in detail with a neat sketch. (b) Define gating ratio. What is its significance? 2.

Max. Marks: 70

What is meant by crucible furnace? What are their types? Explain any two in detail with a neat sketch.

3. (a) Describe the functioning of an arc welding machine with a neat sketch. (b) Mention the various types of gases commonly used in gas welding. 4. (a) Distinguish between soldering and brazing. (b) Discuss the sequence of operations in friction welding. 5. (a) What do you mean by recrystallization temperature and grain growth in hot working? (b) Discuss briefly the factors affecting the rolling process. 6. Explain the following with neat sketches. (a) Wire drawing. (b) Tube drawing.

7. (a) Explain the cold extrusion process with a neat sketch. (b) Write the applications of extrusion. 8. Explain the sequence of operations involved in upset forging. Write down the applications of forging.

*****

Code: 9A14401

3

PRODUCTION TECHNOLOGY

(Mechatronics)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013

Time: 3 hours

Answer any FIVE questions All questions carry equal marks ***** 1.

Max. Marks: 70

Describe the complete casting process with neat sketches. Clearly explain all the steps involved in it.

2. (a) Explain the centrifugal casting with a neat sketch and state its applications. (b) What is the need of special casting process? Explain any one. 3. Stating the principle of flame cutting described the method of oxygen cutting and differentiates with respect to are cutting.

4. (a) Compare laser beam welding with friction welding. (b) What is meant by welding defect? Explain any two. 5. Describe the forces and geometrical relationships in rolling and explain the effect of variables on rolling load and process.

6. (a) Explain the bending operation with a neat sketch. (b) Derive an expression for bending force. 7. Classify the extrusion processes.

8. (a) Differentiate between smith forging and drop forging. (b) Derive the forces required in forging.

*****

Code: 9A14401

4

PRODUCTION TECHNOLOGY

(Mechatronics)

B.Tech II Year II Semester (R09) Regular & Supplementary Examinations, April/May 2013

Time: 3 hours

Answer any FIVE questions All questions carry equal marks *****

Max. Marks: 70

1. (a) Give an account of different pattern materials. (b) What are the advantages, disadvantages and limitations of casting process? 2. Compare investment casting and shell moulding from the point of process, product and application.

3. (a) Explain the resistance welding process with a neat sketch. (b) Discuss about the filler and flux materials used in arc welding process. 4. Explain the TIG and MIG system of welding. Give the applications of each.

5. (a) What is strain hardening? (b) How rolling mills are classified? Explain with their application. 6. (a) Differentiate between coining and embossing. (b) With a neat diagram explain the process of spinning. 7. Explain the hydro static extrusion process with a neat sketch and mention its advantages.

8. (a) Explain the different forging tools used for forging operations. (b) Write the advantages and disadvantages of forging.

*****

Vous aimerez peut-être aussi

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysD'EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysPas encore d'évaluation

- Printed Batteries: Materials, Technologies and ApplicationsD'EverandPrinted Batteries: Materials, Technologies and ApplicationsSenentxu Lanceros-MéndezPas encore d'évaluation

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduPas encore d'évaluation

- R7210301 Production TechnologyDocument1 pageR7210301 Production TechnologysivabharathamurthyPas encore d'évaluation

- Production TechnologyDocument4 pagesProduction TechnologysandchinniPas encore d'évaluation

- Code: R7210301 B.Tech II Year I Semester (R07) Supplementary Examinations, May 2013Document1 pageCode: R7210301 B.Tech II Year I Semester (R07) Supplementary Examinations, May 2013sivabharathamurthyPas encore d'évaluation

- rr311401 Manufacturing TechnologyDocument4 pagesrr311401 Manufacturing TechnologySRINIVASA RAO GANTAPas encore d'évaluation

- 29-05 Manufacturing Technology (MT)Document1 page29-05 Manufacturing Technology (MT)a11972003Pas encore d'évaluation

- rr310301 Production TechnologyDocument6 pagesrr310301 Production TechnologySRINIVASA RAO GANTAPas encore d'évaluation

- r05310303 Production TechnologyDocument4 pagesr05310303 Production TechnologySrinivasa Rao GPas encore d'évaluation

- rr322003 Foundry - WeldingDocument5 pagesrr322003 Foundry - WeldingSRINIVASA RAO GANTAPas encore d'évaluation

- 2-1 PT (Nov 2009 Regular)Document4 pages2-1 PT (Nov 2009 Regular)micmechPas encore d'évaluation

- JNTU Old Question Papers 2007Document4 pagesJNTU Old Question Papers 2007Srinivasa Rao G100% (1)

- ME204Document2 pagesME204raja93satPas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelPas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVraj ShahPas encore d'évaluation

- R10 JanuaDry - 2014Document4 pagesR10 JanuaDry - 2014sivaenotesPas encore d'évaluation

- R7210301 Production TechnologyDocument1 pageR7210301 Production TechnologysivabharathamurthyPas encore d'évaluation

- r05322003 Metal FormingDocument8 pagesr05322003 Metal FormingSRINIVASA RAO GANTAPas encore d'évaluation

- MP Previous Qp-Me3393Document21 pagesMP Previous Qp-Me3393azhagan.mecPas encore d'évaluation

- MII Manufacturing TechnologyDocument5 pagesMII Manufacturing TechnologyRameez FaroukPas encore d'évaluation

- U93567263bte Study Resources)Document3 pagesU93567263bte Study Resources)Tejas GanganePas encore d'évaluation

- rr322002 Metal FormingDocument8 pagesrr322002 Metal FormingSRINIVASA RAO GANTAPas encore d'évaluation

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityMaulik PatelPas encore d'évaluation

- L-2ff-2/IPE Date: 01/0412019: Section - ADocument24 pagesL-2ff-2/IPE Date: 01/0412019: Section - Ajenalyncelzomedina19Pas encore d'évaluation

- PU Paper Manufacturing Science KME-403 - NewDocument2 pagesPU Paper Manufacturing Science KME-403 - Newdaso khagoPas encore d'évaluation

- 114 DM 112016Document2 pages114 DM 112016Ravindra JeeviPas encore d'évaluation

- 114 DM 112016Document2 pages114 DM 112016Ravindra JeeviPas encore d'évaluation

- Code No: 35041Document4 pagesCode No: 35041SRINIVASA RAO GANTAPas encore d'évaluation

- rr312101 Aircraft Production TechnologyDocument4 pagesrr312101 Aircraft Production TechnologySRINIVASA RAO GANTAPas encore d'évaluation

- DesDocument33 pagesDesKiran RatnaPas encore d'évaluation

- Advance Welding TechniqueDocument4 pagesAdvance Welding TechniqueGunabalan SellanPas encore d'évaluation

- MT R07, Sup, AprilMay - 2012Document34 pagesMT R07, Sup, AprilMay - 2012N Dhanunjaya Rao BorraPas encore d'évaluation

- PRODUCTIONTECHNOLOGYDocument4 pagesPRODUCTIONTECHNOLOGYSamiullah MohammedPas encore d'évaluation

- Rr321803 Foundry TechnologyDocument5 pagesRr321803 Foundry TechnologySrinivasa Rao GPas encore d'évaluation

- Jntuworld: R09 Set No. 2Document4 pagesJntuworld: R09 Set No. 2saiteja1234Pas encore d'évaluation

- QP April2011 32 Mec MseDocument4 pagesQP April2011 32 Mec MseSurendra Babu Koganti0% (1)

- rr321803 Foundry TechnologyDocument6 pagesrr321803 Foundry TechnologySRINIVASA RAO GANTAPas encore d'évaluation

- 9A03503 Machine ToolsDocument4 pages9A03503 Machine ToolssivabharathamurthyPas encore d'évaluation

- Manufacturing Process Model Question Paper (2014)Document2 pagesManufacturing Process Model Question Paper (2014)Kailas Sree ChandranPas encore d'évaluation

- M&SE Dec 2011Document4 pagesM&SE Dec 2011simalaraviPas encore d'évaluation

- Code No: 25056Document8 pagesCode No: 25056SRINIVASA RAO GANTAPas encore d'évaluation

- Answer ALL Questions Part-A 10x2 20: Department of Mechanical Engineering Internal Exam-IiiDocument1 pageAnswer ALL Questions Part-A 10x2 20: Department of Mechanical Engineering Internal Exam-IiitagoreboopathyPas encore d'évaluation

- 2011 Nov Dec R2010Document2 pages2011 Nov Dec R2010anon_318963451Pas encore d'évaluation

- ME 2201 - MANUFACTURING TECHNOLOGY - I 3rd MechDocument3 pagesME 2201 - MANUFACTURING TECHNOLOGY - I 3rd Mechkarthiksubramanian94Pas encore d'évaluation

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)Viswanath ViswaPas encore d'évaluation

- B Tech Mech With Credits Regular WEF 2016 S Y B Tech Mech Sem IV 959411107021149111 11Document2 pagesB Tech Mech With Credits Regular WEF 2016 S Y B Tech Mech Sem IV 959411107021149111 11Divy PatelPas encore d'évaluation

- Au Qp-Adv in Casting and Welding-Dec2020Document3 pagesAu Qp-Adv in Casting and Welding-Dec2020Ohmsakthi vel RPas encore d'évaluation

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 pagesE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RPas encore d'évaluation

- Metrologyand Surface EngineeringDocument4 pagesMetrologyand Surface EngineeringshivkrnPas encore d'évaluation

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityBhagirath sinh ZalaPas encore d'évaluation

- B-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Document6 pagesB-Tech. Mechanical UNIT-1: Bme 206 Manufacturing Technology - 1Michael ButlerPas encore d'évaluation

- X20818 (Me6008 Ptme6008)Document3 pagesX20818 (Me6008 Ptme6008)saranPas encore d'évaluation

- Estelar: Faculty of EngineeringDocument1 pageEstelar: Faculty of EngineeringPrasad Apv100% (1)

- MP IatDocument4 pagesMP Iatazhagan.mecPas encore d'évaluation

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsD'EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoPas encore d'évaluation

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeD'EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticePas encore d'évaluation

- SSC Social Textbook (AP)Document100 pagesSSC Social Textbook (AP)sivabharathamurthyPas encore d'évaluation

- R7410506 Mobile ComputingDocument1 pageR7410506 Mobile ComputingsivabharathamurthyPas encore d'évaluation

- Control Systems (CS) Notes As Per JntuaDocument203 pagesControl Systems (CS) Notes As Per Jntuasivabharathamurthy100% (3)

- 9A13701 Robotics and AutomationDocument4 pages9A13701 Robotics and AutomationsivabharathamurthyPas encore d'évaluation

- 07A4EC01 Environmental StudiesDocument1 page07A4EC01 Environmental StudiessivabharathamurthyPas encore d'évaluation

- R7311506 Operating SystemsDocument1 pageR7311506 Operating SystemssivabharathamurthyPas encore d'évaluation

- 9A05707 Software Project ManagementDocument4 pages9A05707 Software Project ManagementsivabharathamurthyPas encore d'évaluation

- R7311006 Process Control InstrumentationDocument1 pageR7311006 Process Control InstrumentationsivabharathamurthyPas encore d'évaluation

- Code: R7311306: (Electronics & Control Engineering)Document1 pageCode: R7311306: (Electronics & Control Engineering)sivabharathamurthyPas encore d'évaluation

- R5410201 Neural Networks & Fuzzy LogicDocument1 pageR5410201 Neural Networks & Fuzzy LogicsivabharathamurthyPas encore d'évaluation

- R7312301 Transport Phenomena in BioprocessesDocument1 pageR7312301 Transport Phenomena in BioprocessessivabharathamurthyPas encore d'évaluation

- R7311205 Distributed DatabasesDocument1 pageR7311205 Distributed DatabasessivabharathamurthyPas encore d'évaluation

- 9A02505 Electrical Machines-IIIDocument4 pages9A02505 Electrical Machines-IIIsivabharathamurthyPas encore d'évaluation

- 9A15502 Digital System DesignDocument4 pages9A15502 Digital System Designsivabharathamurthy100% (1)

- R7310206 Linear Systems AnalysisDocument1 pageR7310206 Linear Systems AnalysissivabharathamurthyPas encore d'évaluation

- R7310406 Digital CommunicationsDocument1 pageR7310406 Digital CommunicationssivabharathamurthyPas encore d'évaluation

- R7310106 Engineering GeologyDocument1 pageR7310106 Engineering GeologysivabharathamurthyPas encore d'évaluation

- 9A23501 Heat Transfer in BioprocessesDocument4 pages9A23501 Heat Transfer in BioprocessessivabharathamurthyPas encore d'évaluation

- R5310204 Power ElectronicsDocument1 pageR5310204 Power ElectronicssivabharathamurthyPas encore d'évaluation

- 9A21506 Mechanisms & Mechanical DesignDocument8 pages9A21506 Mechanisms & Mechanical DesignsivabharathamurthyPas encore d'évaluation

- 9A14503 Principles of Machine DesignDocument8 pages9A14503 Principles of Machine DesignsivabharathamurthyPas encore d'évaluation

- 9A10505 Principles of CommunicationsDocument4 pages9A10505 Principles of CommunicationssivabharathamurthyPas encore d'évaluation

- 9A04504 Digital IC ApplicationsDocument4 pages9A04504 Digital IC ApplicationssivabharathamurthyPas encore d'évaluation

- R7411307 Instrumentation & Control in Manufacturing SystemsDocument1 pageR7411307 Instrumentation & Control in Manufacturing SystemssivabharathamurthyPas encore d'évaluation

- 9A03505 Heat TransferDocument4 pages9A03505 Heat TransfersivabharathamurthyPas encore d'évaluation

- R7412310 Nano BiotechnologyDocument1 pageR7412310 Nano BiotechnologysivabharathamurthyPas encore d'évaluation

- R7412311 Metabolic EngineeringDocument1 pageR7412311 Metabolic EngineeringsivabharathamurthyPas encore d'évaluation

- R7411306 Robotics & AutomationDocument1 pageR7411306 Robotics & AutomationsivabharathamurthyPas encore d'évaluation

- R7411509 Distributed DatabasesDocument1 pageR7411509 Distributed DatabasessivabharathamurthyPas encore d'évaluation

- R7411510 Neural NetworksDocument1 pageR7411510 Neural NetworkssivabharathamurthyPas encore d'évaluation

- Q-PANEL Standard Substrate Applications GuideDocument2 pagesQ-PANEL Standard Substrate Applications GuideGhulam HussainPas encore d'évaluation

- Armox 600T: General Product DescriptionDocument2 pagesArmox 600T: General Product Descriptionehudingram6535Pas encore d'évaluation

- MCQ On Press Tool Design - Amit MahtoDocument3 pagesMCQ On Press Tool Design - Amit MahtoPrashant SinghPas encore d'évaluation

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiPas encore d'évaluation

- Check List For FSG-35Document3 pagesCheck List For FSG-35Rayudu VVSPas encore d'évaluation

- Metal FormingDocument7 pagesMetal FormingAl Fredo100% (3)

- General Seminar Case HardeningDocument18 pagesGeneral Seminar Case HardeningSharath DargaPas encore d'évaluation

- Petroled Luminary Technical SheetDocument2 pagesPetroled Luminary Technical SheetDiseño Lexu LightPas encore d'évaluation

- Universal Cutter Grinder: ORDER NO.U2 CODE NO.1022-001Document11 pagesUniversal Cutter Grinder: ORDER NO.U2 CODE NO.1022-001Cristian FuentesPas encore d'évaluation

- coatosil-mp-200-TDS - TR DÍNHDocument3 pagescoatosil-mp-200-TDS - TR DÍNHAPEX SONPas encore d'évaluation

- Support TSK CheckingDocument14 pagesSupport TSK CheckingRhangga Frandika STPas encore d'évaluation

- FilmDocument2 pagesFilmDhileepan KumarasamyPas encore d'évaluation

- ColdHeadingForFastenerManufactureDocument40 pagesColdHeadingForFastenerManufactureKeerthi Kumar100% (1)

- FGHFGHFDocument2 pagesFGHFGHFJob ShortsPas encore d'évaluation

- 15KLD STP FBBR LayoutDocument1 page15KLD STP FBBR LayoutBiswajit SahooPas encore d'évaluation

- Olympus Ch20i BrochureDocument15 pagesOlympus Ch20i BrochureVek MPas encore d'évaluation

- Me310 HW 3Document3 pagesMe310 HW 3HafizSikandarPas encore d'évaluation

- 77 Cast Iron Electrode InstructionsDocument2 pages77 Cast Iron Electrode Instructionsjoaquin r.Pas encore d'évaluation

- Plates and Shts-Diff.Document1 pagePlates and Shts-Diff.cirius_coolPas encore d'évaluation

- Vol 1 PDFDocument2 pagesVol 1 PDFأبومحمدالزياتPas encore d'évaluation

- Dissimilar WeldDocument24 pagesDissimilar WeldBenjapon bt7Pas encore d'évaluation

- Production of Automotive Components: Jerome GDocument24 pagesProduction of Automotive Components: Jerome GMr. Jerome Nithin Gladson100% (1)

- Regional DocumentDocument8 pagesRegional DocumentIBRPas encore d'évaluation

- Ppac Important QuestionsDocument3 pagesPpac Important QuestionsALLEN TOMPas encore d'évaluation

- Artikel Edukasi Dampak Negatif Circle Pertemanan - NovaDocument6 pagesArtikel Edukasi Dampak Negatif Circle Pertemanan - NovaNova YasminePas encore d'évaluation

- Company Profile PBJ NewDocument21 pagesCompany Profile PBJ NewDavidPrasojoPas encore d'évaluation

- 12bDocument14 pages12bphanisai100% (1)

- RCSC Table 2.1 Nut and Washer TypesDocument1 pageRCSC Table 2.1 Nut and Washer TypesAdam JonesPas encore d'évaluation

- Mec 126 Lecture NoteDocument11 pagesMec 126 Lecture Notemboniface763Pas encore d'évaluation

- Assignment 4Document2 pagesAssignment 4Lhekha RaviendranPas encore d'évaluation