Académique Documents

Professionnel Documents

Culture Documents

Sec-I 128

Transféré par

Panchal ShaileshCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Sec-I 128

Transféré par

Panchal ShaileshDroits d'auteur :

Formats disponibles

2007 SECTION I

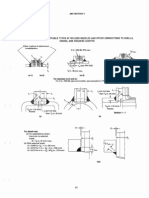

TABLE PW-33 ALIGNMENT TOLERANCE OF SECTIONS TO BE BUTT WELDED

Direction of Joints in Cylindrical Shells Section Thickness, in. (mm)

Up to ~ (B), incl. Over ~ (13) to \ (9), incl. Over \ (9) to l~ (38), incl. Over 1 ~ (38) to 2 (50), incl. Over 2 (50)

for complete weld penetration. The weld shall meet the reinforcement requirements of PW-35.

Longitudinal in. (mm)

Circumferential in. (mm)

Ye Ye Ye

~t

<3.0) <3.0)

(3.0)

~6 (5)

~t ~t

Lesser of ~6 t or ~ (0)

Yet

Lesser of

\ (9)

Ye t or

FINISHED LONGITUDINAL AND CIRCUMFERENTIAL JOINTS PW-35.1 Butt welds shall have complete joint penetration. To assure that the weld grooves are completely filled so that the surface of the weld metal at any point is not below the surface of the adjoining base materials, weld metal may be added as reinforcement on each face of the weld. The thickness of the weld reinforcement on each face shall not exceed the following:

Maximum Reinforcement, in. (nun) Circumferential Joints in Pipe and Tubing Other Welds

PW-35

prepared by grinding or other suitable means so that they may be satisfactorily incorporated into the final weld. Tack welds, whether removed or left in place, shall be made using a fillet weld or butt weld procedure qualified in accordance with Section IX. Tack welds to be left in place shall be made by welders qualified in accordance with Section IX and shall be examined visually for defects and, if found to be defective, shall be removed. PW-31.4 When joining two parts by the inertia and continuous drive friction welding processes, one of the two parts must be held in a fixed position and the other part rotated. The two faces to be joined must be essentially symmetrical with respect to the axis of rotation. Some of the basic types of applicable joints are solid round-to-solid round, tube-to-tube, solid round-to-tube, solid round-toplate, and tube-to-plate. ALIGNMENT TOLERANCE, SHELLS AND VESSELS (INCLUDING PIPE OR TUBE USED AS A SHELL) PW-33.1 Alignment of sections at edges to be butt welded shall be such that the maximum offset is not greater than the applicable amount as listed in Table PW-33, where t is the nominal thickness of the thinner section at the joint. PW-33.2 Joints in spherical vessels and within heads and joints between cylindrical shells and hemispherical heads shall meet the requirements in PW-33.1 above for longitudinal joints in cylindrical shells. PW-33.3 Any offset within the allowable tolerance provided above shall be faired at a 3 to 1 taper over the width of the finished weld, or if necessary, by adding additional weld metal beyond what would otherwise be the edge of the weld. PW-34 ALIGNMENT, TUBE AND PIPE PW-34.1 When tubes or pipes are welded together, the alignment shall be such that the inside surfaces provide

90

Nominal Thickness, in. (mm) Up to ~ (3) Over ~ (3) to X6 (5), incl. Over X6 (5) to (13), incl. Over (13) to 1 (25), incl. Over 1 (25) to 2 (50), incl. Over 2 (50) to 3 (75), incl. Over 3 (75) to 4 (100), incl. Over 4 (100) to 5 (125), incl. Over 5 (125)

132 (2.5)

~ (3.0) ~2 (4.0) X6 (5.0) ~ (6.0) [Note (1)] [Note (l)] [Note (l)] [Note (l)]

Jt

Jt

~ ~2 ~2 ~ ~6

132 (2.5) 132 (2.5) 132 (2.5) 132 (2.5)

(3.0) (4.0)

(5.5) (6.0) (8.0)

NOTE: (1) The greater of ~ in. (6 nun) or ~ times the width of the weld in inches (mm).

PW-33

As-welded surfaces are permitted; however, the surface of the welds shall be sufficiently free from coarse ripples, grooves, overlaps, abrupt ridges, and valleys to avoid stress raisers. Undercuts shall not exceed ~2 in. (0.8 mm) or 10% of the wall thickness, whichever is less, and shall not encroach on the required section thickness. The surfaces of the finished weld shall be suitable to permit proper interpretation of radiographic and other required nondestructive examinations. If there is a question regarding the surface condition of the weld when interpreting radiographic film, the film shall be compared to the actual weld surface for determination of acceptability. PW-35.2 The weld reinforcement need not be removed except to the extent necessary to meet the thickness requirements in PW-35.1. PW-35.3 Backing strips used at longitudinal welded joints shall be removed and the weld surface prepared for radiographic examination as required. Inside backing rings may remain at circumferential joints of cylinders, provided they meet the requirements of PW-41. PW-35.4 The welded joint between two members joined by the inertia and continuous drive friction welding

Vous aimerez peut-être aussi

- AWS D1.1-D1.1M-2015 (WeldingWorld) 250Document1 pageAWS D1.1-D1.1M-2015 (WeldingWorld) 250Ali Clubist100% (1)

- SUBTEXT On Weld Defect For AWS Standard.Document2 pagesSUBTEXT On Weld Defect For AWS Standard.fammacat100% (1)

- Beeman Gs 1000 ManualDocument4 pagesBeeman Gs 1000 Manualanbsc2100% (1)

- Yamaha Acoustic GuitarsDocument18 pagesYamaha Acoustic Guitarsrusf123100% (5)

- RME ReviewerDocument354 pagesRME ReviewerRene100% (1)

- Asme PCCDocument6 pagesAsme PCCajaysharma_1009100% (2)

- Determining Weld SizeDocument22 pagesDetermining Weld SizeJose Luis Olivares Lopez100% (1)

- PipelineDocument3 pagesPipelineKrystle FlowersPas encore d'évaluation

- BS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 4.3.2.2 Intermittent Fillet WeldsDocument5 pagesBS EN 1993-1-8:2005 EN 1993-1-8:2005 (E) : 4.3.2.2 Intermittent Fillet Weldsmn4webPas encore d'évaluation

- Aluminum Welding ProceedureDocument14 pagesAluminum Welding ProceedureGregEverett2Pas encore d'évaluation

- Nozzle Welding DesignDocument12 pagesNozzle Welding DesignAlvin Smith100% (2)

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshPas encore d'évaluation

- Pressure Vessels Lectures 87Document1 pagePressure Vessels Lectures 87Adeel NizamiPas encore d'évaluation

- Press Working Operations - Sheet MetalDocument16 pagesPress Working Operations - Sheet MetalIrwan Rony100% (2)

- Detailing of RCC Slabs PresentantionsDocument31 pagesDetailing of RCC Slabs PresentantionsMligo ClemencePas encore d'évaluation

- Standard HFRW PDFDocument3 pagesStandard HFRW PDFGuidoColomboPas encore d'évaluation

- NDT AcceptanceDocument62 pagesNDT Acceptancebommakanti srinivasPas encore d'évaluation

- HSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fDocument14 pagesHSS Radius 742c7a4e 5e10 4b0b 8ba8 A8516cdafd9fTerraManPas encore d'évaluation

- 6 Connections ModifiedDocument59 pages6 Connections Modifiedkebede amezenePas encore d'évaluation

- Asci 358-18 Table 6.1.22Document3 pagesAsci 358-18 Table 6.1.22Jan stevens Vargas cardonaPas encore d'évaluation

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShankar Pl GowdaPas encore d'évaluation

- Acceptance Criteria of Weld DefectsDocument17 pagesAcceptance Criteria of Weld DefectsvikasPas encore d'évaluation

- Module 5-ADocument9 pagesModule 5-Adash1991Pas encore d'évaluation

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaPas encore d'évaluation

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausPas encore d'évaluation

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesTanveer Rajput EngrPas encore d'évaluation

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesNavanitheeshwaran Sivasubramaniyam100% (3)

- ECDocument40 pagesECJosé CarlosPas encore d'évaluation

- Design For Hot Dip GalvanisingDocument9 pagesDesign For Hot Dip GalvanisingSreedhar Patnaik.MPas encore d'évaluation

- FASTENERSDocument34 pagesFASTENERSEmrePas encore d'évaluation

- Free English GrammarDocument20 pagesFree English GrammarrajeshPas encore d'évaluation

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesdhasdjPas encore d'évaluation

- Connection of Flange Plate With WebDocument11 pagesConnection of Flange Plate With WebyhproPas encore d'évaluation

- Unit 3 Tension Members: StructureDocument28 pagesUnit 3 Tension Members: StructureRaj BakhtaniPas encore d'évaluation

- NDT-Acceptance Various CodesDocument17 pagesNDT-Acceptance Various CodesShanmuga NavaneethanPas encore d'évaluation

- 4.0 Reinforcing DeailingDocument16 pages4.0 Reinforcing DeailingRupesh Chaudhary EsRan TharuwaPas encore d'évaluation

- Is 4049 Part 1Document7 pagesIs 4049 Part 1Otavio123Pas encore d'évaluation

- Bs 1881-Part-109 Concrete Making Test Beams From Fresh ConDocument7 pagesBs 1881-Part-109 Concrete Making Test Beams From Fresh Conhajimak100% (1)

- Seccion 16 Abs SoldaduraDocument9 pagesSeccion 16 Abs SoldaduraRoberto DavilaPas encore d'évaluation

- Column Beam Seismic ConnectionDocument8 pagesColumn Beam Seismic ConnectionPrakash Singh RawalPas encore d'évaluation

- Introduction-Design-Guide 2Document16 pagesIntroduction-Design-Guide 2Sutha100% (1)

- #002bolted Connection-2019Document51 pages#002bolted Connection-2019PAVANPOREPas encore d'évaluation

- Design of Welded Connections - AWSDocument43 pagesDesign of Welded Connections - AWSnunosobral100% (1)

- 14 DetailingDocument18 pages14 DetailingRushiPas encore d'évaluation

- Weldox PrefabricationDocument6 pagesWeldox Prefabricationmuamer1Pas encore d'évaluation

- Transverse Reinforcement For BeamDocument3 pagesTransverse Reinforcement For BeamsudarsancivilPas encore d'évaluation

- Pressure Vessels Lectures 96Document1 pagePressure Vessels Lectures 96Adeel NizamiPas encore d'évaluation

- Direct Design Method "DDM"Document139 pagesDirect Design Method "DDM"Fahad AsgharPas encore d'évaluation

- IRECN Bridge Bearing-3Document21 pagesIRECN Bridge Bearing-3vpmohammed100% (1)

- Mat Chapter 31Document27 pagesMat Chapter 31hemant_durgawalePas encore d'évaluation

- Reinforcement DetailingDocument23 pagesReinforcement Detailingyash khandol100% (1)

- Basic Rules For Design of BeamsDocument8 pagesBasic Rules For Design of BeamsJaswanth JPas encore d'évaluation

- Inspection and Maintenance of Steel Girders-5Document10 pagesInspection and Maintenance of Steel Girders-5vpmohammedPas encore d'évaluation

- 8, BNBC Short NotesDocument25 pages8, BNBC Short NotesLutfor RahmanPas encore d'évaluation

- Bifurcation Methodology: Basic Welding ProcedureDocument7 pagesBifurcation Methodology: Basic Welding ProcedureNischal PokharelPas encore d'évaluation

- Steel Vessels Under 90 Meters (295 Feet) in Length 2017: Rules For Building and ClassingDocument9 pagesSteel Vessels Under 90 Meters (295 Feet) in Length 2017: Rules For Building and Classingamr_tarek_26Pas encore d'évaluation

- Lecture 2 2021-Concrete Reinforcement Details L1Document26 pagesLecture 2 2021-Concrete Reinforcement Details L1Zahim HarkiPas encore d'évaluation

- Ibr BookDocument33 pagesIbr BookRaja JayachandranPas encore d'évaluation

- Cylindrical Compression Helix Springs For Suspension SystemsD'EverandCylindrical Compression Helix Springs For Suspension SystemsPas encore d'évaluation

- Sec-I 140Document1 pageSec-I 140Panchal ShaileshPas encore d'évaluation

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Coiijt'D)Panchal ShaileshPas encore d'évaluation

- Sec-I 139Document1 pageSec-I 139Panchal ShaileshPas encore d'évaluation

- Sec-I 138Document1 pageSec-I 138Panchal ShaileshPas encore d'évaluation

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshPas encore d'évaluation

- Sec-I 136Document1 pageSec-I 136Panchal ShaileshPas encore d'évaluation

- Table Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsDocument1 pageTable Pw-39 (Cont'D) Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and AttachmentsPanchal ShaileshPas encore d'évaluation

- Sec-I 133Document1 pageSec-I 133Panchal ShaileshPas encore d'évaluation

- Sec-I 129Document1 pageSec-I 129Panchal ShaileshPas encore d'évaluation

- Sec-I 130Document1 pageSec-I 130Panchal ShaileshPas encore d'évaluation

- Sec-I 131Document1 pageSec-I 131Panchal ShaileshPas encore d'évaluation

- Sec-I 132Document1 pageSec-I 132Panchal ShaileshPas encore d'évaluation

- Sec-I 126Document1 pageSec-I 126Panchal ShaileshPas encore d'évaluation

- Sec-I 127Document1 pageSec-I 127Panchal ShaileshPas encore d'évaluation

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Cont'D)Panchal ShaileshPas encore d'évaluation

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersDocument1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Cot/Inections To Shells, Drums, and HeadersPanchal ShaileshPas encore d'évaluation

- FIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Document1 pageFIG. PW-16.1 Some Acceptable Types of Welded Nozzles and Other Connections To Shells, Drums, and Headers (Co NT'D)Panchal ShaileshPas encore d'évaluation

- FIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingDocument1 pageFIG. PW-19.4 (A) Some Acceptable Types of Diagonal Braces For Installation by WeldingPanchal ShaileshPas encore d'évaluation

- Sec-I 121Document1 pageSec-I 121Panchal ShaileshPas encore d'évaluation

- Sec-I 117Document1 pageSec-I 117Panchal ShaileshPas encore d'évaluation

- Sec-I 119Document1 pageSec-I 119Panchal ShaileshPas encore d'évaluation

- FIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IDocument1 pageFIG. PW-15 Examples of Weld Strength Calculations: 2007 Section IPanchal ShaileshPas encore d'évaluation

- Design: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessDocument1 pageDesign: FIG. PW-9.1 Butt Welding of Plates of Unequal Thici NessPanchal ShaileshPas encore d'évaluation

- Sec-I 113Document1 pageSec-I 113Panchal ShaileshPas encore d'évaluation

- Sec-I 116Document1 pageSec-I 116Panchal ShaileshPas encore d'évaluation

- Sec-I 114Document1 pageSec-I 114Panchal ShaileshPas encore d'évaluation

- Sec-I 112Document1 pageSec-I 112Panchal ShaileshPas encore d'évaluation

- Manufacturer'S Data Report Forms: 2007 Section IDocument1 pageManufacturer'S Data Report Forms: 2007 Section IPanchal ShaileshPas encore d'évaluation

- D300D Articulated Truck Electrical System: 5MG1-UPDocument2 pagesD300D Articulated Truck Electrical System: 5MG1-UPCarlos IrabedraPas encore d'évaluation

- SJ 9 PDFDocument52 pagesSJ 9 PDFNicolas X FloresPas encore d'évaluation

- 9-4130 - Loose Stepper MotorDocument2 pages9-4130 - Loose Stepper MotorarasPas encore d'évaluation

- 2018 Index of Military Strength Air Domain EssayDocument15 pages2018 Index of Military Strength Air Domain EssayThe Heritage FoundationPas encore d'évaluation

- Clubhouse Rental FormDocument8 pagesClubhouse Rental FormAmanda MillerPas encore d'évaluation

- Business Plan ScrunshineDocument2 pagesBusiness Plan ScrunshineEnjhelle MarinoPas encore d'évaluation

- Business ListingDocument16 pagesBusiness ListingSarika YadavPas encore d'évaluation

- Antenna PrimerDocument14 pagesAntenna PrimerStephen Dunifer100% (3)

- BC-2800 - Service Manual V1.1 PDFDocument109 pagesBC-2800 - Service Manual V1.1 PDFMarcelo Ferreira CorgosinhoPas encore d'évaluation

- Electronic Vehicle and Fueled Vehicle in Iloilo CityDocument7 pagesElectronic Vehicle and Fueled Vehicle in Iloilo CityGm MuyaPas encore d'évaluation

- Dispersant Manual WebDocument108 pagesDispersant Manual Webcamilinrodriguezzzz100% (1)

- Validation Protocol For Efficacy of Chemical DisinfectantsDocument8 pagesValidation Protocol For Efficacy of Chemical DisinfectantsMohamed KamalPas encore d'évaluation

- Urea ProjectDocument17 pagesUrea ProjectAbdo Shaaban100% (2)

- 3-Phase Brushless DC Motor Controller/Driver With Back-Emf SensingDocument12 pages3-Phase Brushless DC Motor Controller/Driver With Back-Emf SensingPero01Pas encore d'évaluation

- Neon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationDocument24 pagesNeon Green and Blue Bold Cut Out Graphic Science Subject For Middle School Pollution PresentationJimi CohenPas encore d'évaluation

- Gambar SuspensiDocument1 pageGambar SuspensiMashiro HikariPas encore d'évaluation

- VIJAYDocument61 pagesVIJAYYOGESH CHAUHANPas encore d'évaluation

- RRP NoticeDocument6 pagesRRP NoticeLucky TraderPas encore d'évaluation

- A320 CBT Fuel System: Table of ContentDocument8 pagesA320 CBT Fuel System: Table of ContentAman VermaPas encore d'évaluation

- NS0 157Document42 pagesNS0 157Muthu LPas encore d'évaluation

- Essay On The Traffic Conditions in Big CitiesDocument3 pagesEssay On The Traffic Conditions in Big CitiesCeciliaPas encore d'évaluation

- Divinity Original Sin 2 GrenadesDocument2 pagesDivinity Original Sin 2 Grenadesbeans54Pas encore d'évaluation

- Describe in Detail The Method You Use To Parallel The Alternator and Share LoadDocument4 pagesDescribe in Detail The Method You Use To Parallel The Alternator and Share LoadDen EdiPas encore d'évaluation

- Class 6 Ioel 2017Document8 pagesClass 6 Ioel 2017A GuptaPas encore d'évaluation

- Troubleshooting Data: Plug Seen From The Cable SideDocument2 pagesTroubleshooting Data: Plug Seen From The Cable SideTomyPas encore d'évaluation

- Domino's PizzaDocument37 pagesDomino's PizzaAristianto Pradana0% (3)

- RF Power Meter v2: Preliminary Operator's ManualDocument10 pagesRF Power Meter v2: Preliminary Operator's Manualsalvatore dalessandroPas encore d'évaluation