Académique Documents

Professionnel Documents

Culture Documents

Automated Delivery Vehicle

Transféré par

OxusBandCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Automated Delivery Vehicle

Transféré par

OxusBandDroits d'auteur :

Formats disponibles

1

Automated Delivery Vehicule

Gabriel Zarate Azamar1, Camilo Itzame Martinez Marquez1, Dr. Roberto Castaeda Sheissa1

1

Facultad de Instrumentacin Electrnica, Universidad Veracruzana, Xalapa, Ver. 91000, Mxico.

Abstract - This work presents the prototype of a vehicle that is capable, in an independent way, to perform the role of a messenger. This vehicle, employing ultrasonic sensors, is capable to detect obstacles and modify its trajectory in order to avoid them. Besides, it has an RF connection, which allows it to be in contact to a central office, which will be monitoring the trajectory and operation. I. INTRODUCTION The prototype is conformed by two central modules, the mobile unit and the station unit. The mobile unit is, actually, the messenger that receives and drops the packages at the right destination. The station unit is the operational base where indications are provided to the messenger, and its operation is constantly monitored. The block diagrams for both modules are shown in Figures 1 and 2.

Lector foto electrnico

Nowadays, where economic issues are a concern to most of the companies, the need to optimize resources is an everyday task. One of the priorities is to optimize the internal functionality. As such, the internal parcel services are the cornerstone to guarantee an even workflow. These parcel services can be as simple as sending internal memorandums or as complex as moving complete prototypes or special hardware. For certain companies where their parcel requirements are not so demanding it is possible to automate the process. This automation would translate in savings for reducing the cost of using humans on the delivering/pick-up process. Also, further tasks could be assigned as needs grow. As for the environmental side, an automated device could pollute several orders less than a human being. Although in order to achieve this goal several variables should be taken into account to guarantee a green design. II. PROTOTYPE DESCRIPTION

Mdulo Transceptor RF

Unidad de Control Sonar Ultrasnico

Figure 1. Block diagram for the mobile unit.

The idea to employ mechanic and electronic devices is to ease and speed-up certain tasks. Nevertheless, as technology keeps its pace more complex devices are created and humans are replaced by them. Based on this fact, this work proposes the development of an automated parcel system. This system employs components not so expensive and easy to acquire on any electronics store. The implementation of a system of this kind, using a low cost development and manufacturing process, would be a solution to the need of having an internal parcel service that minimizes the human factor involved. Although this problematic has been addressed on previous works, the ends of this project is to implement a vehicle capable to cover a previously defined route in an autonomous fashion not being a line follower. Considering some previous works related to this kind of prototypes, it is pretended to use some of the components that proven useful [1]. 1

Figure 1 shows the block diagram for the mobile unit. At first instance it can be seen the photo-electronic scanner module, this module recognize the presence of a package and its destination, which requests to the central base. Once the route has been received, the vehicle starts moving following the route and the sonar module is started for the detection of a possible obstacle. The control unit is made of a series of PIC microcontrollers from the 16 and 18 families, which receive signals from the photo-electronic modules and the sonar, process those signals, provide the directives to follow the route, and take the required measurements to avoid obstacles helped by the central base. The RF transceiver module provides the vehicle means to communicate to the base, receive the route data, send data of its functioning, alert signals and, if necessary, being driven back to the base.

Mdulo Transceptor RF

Base Remota

Interfaz de Usuario Figure 2. Block diagram for the stacionary unit.

The station unit has an RF transceiver that receives data and signals from the mobile unit, send rout data. The remote base is comprised of a personal computer (PC) that receives data from the RF transceiver y show them to the operator through a user interface. A. PHOTO-ELECTRONIC SCANNER It consists on four infrared sensors, one that determines the presence of a package and the remaining three read the destination code. The first sensor is located on the vehicles tray, where once a package is placed on it, the light beam is interrupted and the sensor state changes, once this signal is received, the microcontroller gets ready to read the destination code and send the route request to the base. The other three sensors are placed in such a way that, using binary code, sets the package destination (for experimental reasons only three sensors are set for the destiny, therefore, only seven possible destinations are possible1). B. ULTRASONIC SONAR Two ultrasonic sensors LV MaxSonar EZ1 are used to build the ultrasonic sonar, which performs a 180 sweep at the front of the vehicle in order to locate a possible obstacle. Each sensor is mounted on a step motor, this way each sensor performs the sweep locating nearby objects that may cause a block on the route of the vehicle. Each sensor is physically above the other in order to avoid interference between them and their readings; this way it is possible to move one sensor from left to right and the other one from right to left. Once the sensor has reached the limit the oppose movement is performed for the both. The nominal sensing range is beyond 6 meters 2 , for this particular application the minimal critical range distance is 14 centimeters and the maximum detecting distance is 5 meters

1

C. CONTROL UNIT This control unit is in charge to control every module of the vehicle. One controller is employed to control the movement of the vehicle motors, receive instructions from the central microcontroller and execute the trajectory directives. Other microcontroller receives, process and conditions the data received from the sonar. Control the step motors where sensors are mounted and the sonar readings. The analog signal from the sensors enters the A/D converter to be processed, once digitalized, this signal serve as a reference to detect if an obstacle has been detected in the vehicles path, its location and, in case the obstacle is in motion, calculate its trajectory. All the data is processed by the same microcontroller in order to avoid overloading the central microcontroller, which just receives the processed data that will help to take a decision. Finally, the central microcontroller function is to drive the vehicle, read data from the photo-electronic module, request the destination route and command the motors microcontroller the sequence to follow to complete the route successfully. Likewise, receive information from the sonars microcontroller and make decisions, based on the data provided by them. Also, the central microcontroller provides information to the central base (functioning, alerts, and switch to remote control mode). D. RF TRANSCEIVER MODULE On the mobile unit, this module is build by an XBEE module, which sends and receives data about the route and the functioning record of the vehicle, besides, allows the base to monitor the rout of the vehicle and, if necessary, switches the vehicle to remote control mode. For the stationary unit, the RF module has two XBEEs. One is employed to communicate to the mobile unit, to receive the destination code and send the route to be followed, to monitor the failure signals or alerts sent by the vehicle. The other XBEE helps to monitor the correct rout of the vehicle 3 by means of a basic triangulation scheme based on signal-distance ratio. E. REMOTE BASE This base, basically, is a personal computer connected to the XBEE modules. It contains all the predefined routes for every destination, the site map of the work area, check the correct execution of the rout, and attends the emergency signals from the device. This unit performs the signals strength measurements and calculates the position of the vehicle in order to

3 At the moment of writing this paper, the triangulation scheme continues to be tested.

000 remains reserved to indicate the vehicle to return to the base. Manufacturer states that maximum distance is up to 6.45m.

determine if the route is being covered correctly. F. USER INTERFACE The interface is developed to present all the relevant data from the device; such as: distance covered, received alerts, current destination and, if needed, allows the user to drive the vehicle remotely. III. DEVELOPMENT

4

Eight MOC3011opto-couplers [4]. One 24FC512 EEPROM memory [5]. The microcontroller, drives the motors and, at the same time executes periodic speed sensing measurements to find out the distance travelled. The opto-couplers isolate the microcontroller from the power drivers, to avoid them to require excessive current to the microcontroller. The gearboxes provide the needed torque to move the vehicle, whether it has a package on its tray or travels without any cargo. The microcontroller is connected to an EEPROM memory, the measured speed and the distance travelled calculations will be registered in it, whether they get processed by the central microcontroller or for further data processing. Next to the upper level, the central level is where the most development work was performed, since this is where the obstacle detection takes place, also, define the position of the obstacle and determine if the obstacle is moving and, in that case, it calculates its trajectory. The hardware employed was the following: One 18F4550 PIC microcontroller [6]. Two LV MaxSonar EZ1sensors [7]. Two generic step motors. Eight 2N2222transistors [8]. One 24FC512 EEPROM memory [5]. The microcontroller sends the sequence to activate the motors, and also the signal to enable each sensor and to perform a measurement; this signal is conditioned by a small power stage made by transistors. Besides, the microcontroller executes the following object detection algorithm5:

In the construction process of the prototype the integration of several knowledge areas was intended. Such areas include: mechanics, electronics and informatics, all them helped to optimize the construction. This work was done based on project planning, research process (finding the available material about this subject, cost planning, select the required components based on its availability), developing control algorithms for each unit, developing the user interface, the design and construction of the chassis of the vehicle. The different stages of the development were carried out in a parallel time basis in order to achieve the highest level of integration possible. The selection of the technology employed in this project was done considering costs, versatility and availability. This work aims to provide a device easy to assemble at the lowest cost possible. A. MOBILE UNIT DEVELOPMENT The mobile unit, as said before, has four modules: photo-electronic scanner, ultrasonic sonar, control unit and RF transceiver. Nevertheless, for development purposes, the prototype was divided in levels: first level or lower level, is the one that controls the motor operations and speed sensor; the second level or central level, is where the sonar actions are developed; the third level or upper level, carries the photo-electronic scanner and central microcontroller. It should be noticed that each level has its own microcontroller and all of them are linked together to conform the control unit. Located at the lower level: motors, gearboxes, speed sensor and the microcontroller responsible of them all. To operate, this level employs the following resources: Four 6v DC motors (Any 6v DC motors). Two DOUBLE GEARBOX (TAMIYA gearboxes). One TRACK & WHEEL SET (TAMIYA caterpillars). One 16F877A PIC microcontroller [2]. Two TA7279P DRIVERS [3].

4 At the moment of writing this paper, the user interface is still on developing stage.

Every algorithm used on this prototype was written on C language.

Inicializar funcionamiento del sonar

Inicializacin de variables

0

N Pasos = Pasos -1 1

just monitors the object; at 50 centimeters or less, it is considered to be within the collision critical threshold (figure 6), then the calculated data is saved on memory and a warning signal is dispatched to the central unit. The central unit evaluates the saved data and performs the adequate preventive action. Notice that this logic applies for just one sensor, but, in order to optimize the object detection, two sensors are employed. Therefore, the algorithm is duplicated (in an integral way) in the microcontroller.

Direccin de g iro = a 0?

Zona de deteccin

S Pasos = Pasos

Zona de riesgo

Figure 3. Oject detection algoritm flowchart.

The motor step turns until it sums 48, which equals to 180 (fig. 3), this is necessary to cover the entire vehicles front. Starts to the right summing one step at a time, once the sum reaches 48 it can be said that 180 have been covered and direction is changed (fig. 4); at each step of the motor, the sensor provides the measured distance to the closest object.

2

Fig6.Consideredriskzones.

Si Pasos = 48? Direccin de giro = 1

Figure4.Objectdetectionalgoritmflowchart(cont.)

Doing the sensing this way, allows performing some comparisons in order to determine if it is possible the object could collide with the vehicle at some point. Depending on the distance to the object, the microcontroller responsible of the sonar will take one of the following actions: when the object is at about 100 centimeters, it is said that it is the threshold to consider the object (figure 6), at this distance the microcontroller 4

In order to guarantee that the step counters will always start at their set position (0 at 0 and 48 at 180), special switches were placed to reset the counters at zero point. Finally, at the upper level, the central microcontroller is found. It process data from the photo-electronic scanner, communicates to the base for information about the rout and, in conjunction with it, makes the decision for the obstacle evasive procedures. The design of this level required the following hardware: One 18F4550 PIC microcontroller [6]. Four QRD 1114infrared sensors [9]. One XBEE transceiver module [10]. The control unit of this level, read the data from the cargo tray (package loaded and destination), then performs central unit functions; receive data from the base to compute the route, make the necessary decisions to evade obstacles, inform the base about any malfunction. As for the algorithm on this level, although it is still in constant review, it has performed as expected doing the basic tasks that it was designed for. The central microcontroller, once an alert is received from the microcontroller in charge of the sonar, process the data provided by the sonar microcontroller from the EEPROM memory. The information in there is the latest received from the sensor that includes: object location, distance to the object, and if it is a moving object,

indicates its trajectory. This data will allow the central microcontroller, and the central base, to perform the adequate evasive maneuvers. At the time of the writing of this work, the algorithm is capable to handle alerts for static objects; as for moving objects, it is only capable to stop its motion and wait until the object is out of the sweeping range of the sensors. IV. FUTURE IMPROVEMENTS

Fig7.PrototypeVersion0.1.

Although some units of the prototype and the base are in optimization phase, it is already possible to provide some ideas that would lead to the improvement of the design. For the evasive algorithm, it needs an improvement but also the positioning hardware should be improved. Some tests have been done for triangulating the position of the vehicle using radio frequency, that way it could be assured if the trajectory is the adequate or needs to be adjusted. Another idea is to add a barcode scanner and place some special signals throughout the working spaces where it operates. This way it would be possible to recognize where it has been, and recognize any modification to its original route. One option that appears possible, but would require further development, is to attach a video camera and let the microcontroller or some additional hardware to perform the required signal processing. V. CONCLUSSIONS

This work has shown the viability to develop and build a project aimed to satisfy specific constraints using low cost materials. This could allow building several units to satisfy the needs of a customer, with a high rate on the return of the investment ratio. Although the selected sensor not performed as expected, adding a second sensor helped to increase the accuracy of the sensing and the measurements performed. Even that this project is still in the testing phase, it can be said that the first version of the prototype helped to verify the feasibility of this project. For future revisions performance comparisons should be performed in order to select the most capable to increase the vehicles efficiency.

REFERENCES [1] Claudia Carpinteyro Lozano, Sofa Corral Scherer, Karen Crdova Ugalde, Alejandro Hernndez Rodrguez, Optimizacin del transporte de archivos e instrumentos del rea empresarial, Instituto Educativo Olinca. [2] Microchip Technology Inc., PIC16F87XA Microcontroller Datasheet. [3] Toshiba, TA7279A Dual Bridge Driver Datasheet. [4] Motorola Inc., MOC3011 Optoisolator Triac Driver Output Datasheet. [5] Microchip Technology Inc., 24FC512 CMOS EEPROM Datasheet. [6] Microchip Technology Inc., PIC18F4550 Microcontroller Datasheet. [7] MaxBotix Inc., LV-MaxSonar-EZ1 High Performance Sonar Range Finder Datasheet. [8] Philips Semiconductors, 2N2222 NPN Switching Transistors Datasheet. [9] Fairchild Semiconductor Corporation, QRD1114 Reflective Object Sensor Datasheet. [10] MaxStream, XBee OEM RF Modules Datasheet.

Vous aimerez peut-être aussi

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Lm80-p0436-51 Apq8016 Processor Design GuidelinesDocument86 pagesLm80-p0436-51 Apq8016 Processor Design GuidelinesGustavo FélixPas encore d'évaluation

- Review On SIW TechnologyDocument6 pagesReview On SIW TechnologyNitinPas encore d'évaluation

- LC-3 ISA overviewDocument26 pagesLC-3 ISA overviewSarthak SrinivasPas encore d'évaluation

- LAN TopologiesDocument31 pagesLAN TopologiesDinku Minda100% (1)

- 73 Magazine 1968 10 OctoberDocument132 pages73 Magazine 1968 10 Octoberrodolfo ProkopovichPas encore d'évaluation

- B.Tech EEE112 Principles of Electrical and Electronics EngineeringDocument3 pagesB.Tech EEE112 Principles of Electrical and Electronics EngineeringAkash GandharPas encore d'évaluation

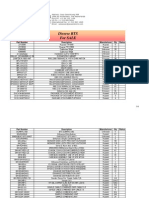

- Diverse BTS For Sale From Power Storm 4SN06200834Document4 pagesDiverse BTS For Sale From Power Storm 4SN06200834Mohamed KsimaPas encore d'évaluation

- Try Simple FET Preamplifier Circuit (Very High Impedance) - ElecCircuitDocument8 pagesTry Simple FET Preamplifier Circuit (Very High Impedance) - ElecCircuitABHIPas encore d'évaluation

- Solar PCU Inverter Three Phase PDFDocument2 pagesSolar PCU Inverter Three Phase PDFHarish Kumar GPas encore d'évaluation

- Wireless World 1948 12Document78 pagesWireless World 1948 12Jan PranPas encore d'évaluation

- Android Phone Controlled Spy RobotDocument4 pagesAndroid Phone Controlled Spy RobotInternational Journal of Innovative Science and Research Technology100% (1)

- Installation Manual Series PW 404: Electronic ModuleDocument7 pagesInstallation Manual Series PW 404: Electronic Modulemehdi810Pas encore d'évaluation

- QSK 5Document12 pagesQSK 5Adrian FewsterPas encore d'évaluation

- ASIC Design in The Silicon Sandbox - A Complete Guide To Building Mixed-Signal Integrated Circuits Keith BarrDocument428 pagesASIC Design in The Silicon Sandbox - A Complete Guide To Building Mixed-Signal Integrated Circuits Keith Barrrakheep123100% (2)

- Plotting V-I Curve of Ge DiodeDocument12 pagesPlotting V-I Curve of Ge DiodeIvy Loraine PuaPas encore d'évaluation

- 18cs442 MC-2Document2 pages18cs442 MC-2M.A rajaPas encore d'évaluation

- Práctica 1 TiristoresDocument15 pagesPráctica 1 TiristoresDorian JesusPas encore d'évaluation

- Register Transfer Level Design With Verilog: Verilog Digital System Design Z. Navabi, Mcgraw-Hill, 2005Document77 pagesRegister Transfer Level Design With Verilog: Verilog Digital System Design Z. Navabi, Mcgraw-Hill, 2005I am number 4Pas encore d'évaluation

- Amie Syllabus Sec B ElectronicsDocument22 pagesAmie Syllabus Sec B Electronicsvenkat100% (1)

- S Wave Ew Ew Ew 22 22dv10i Ts 64k deDocument2 pagesS Wave Ew Ew Ew 22 22dv10i Ts 64k deпавелPas encore d'évaluation

- 1155dBTE 504Document13 pages1155dBTE 504Shubham AgrawalPas encore d'évaluation

- 01 - Difference Between WCDMA and GSMDocument11 pages01 - Difference Between WCDMA and GSMAdil SumantriPas encore d'évaluation

- Chapter 20: Satellite Communications: Multiple ChoiceDocument5 pagesChapter 20: Satellite Communications: Multiple ChoiceJester JuarezPas encore d'évaluation

- Example-1: Power AmplifierDocument2 pagesExample-1: Power AmplifierKahina ZitouniPas encore d'évaluation

- Guide To Cache MemoryDocument5 pagesGuide To Cache MemoryVivek Pai KPas encore d'évaluation

- Assignment 1Document2 pagesAssignment 1mohammed229100% (1)

- Elektorlabs Magazine USA - July, August 2018Document116 pagesElektorlabs Magazine USA - July, August 2018Pugazh100% (2)

- To Study and Plot The I-V Characteristics of A P-N JunctionDocument2 pagesTo Study and Plot The I-V Characteristics of A P-N Junctionamuhammadahsan73Pas encore d'évaluation

- State Forest Service Exam Electronics KeyDocument83 pagesState Forest Service Exam Electronics KeyDeepak YugaPas encore d'évaluation

- Elnec SmartProg2 ManualDocument171 pagesElnec SmartProg2 ManualTamizhPas encore d'évaluation