Académique Documents

Professionnel Documents

Culture Documents

Codes For Staad Pro India

Transféré par

Akhlaq HussainDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Codes For Staad Pro India

Transféré par

Akhlaq HussainDroits d'auteur :

Formats disponibles

STAAD.

Pro 2007

INTERNATIONAL DESIGN CODES

DAA037810-1/0001

A Bentley Solutions Center

www.reiworld.com

www.bentley.com/staad

Indian Codes

9-1

Concrete Design Per IS456

9A.1 Design Operations

STAAD has the capabilities of performing concrete design based

on limit state method of IS: 456 (2000).

9A.2 Section Types for Concrete Design

The following types of cross sections for concrete members can be

designed.

For Beams Prismatic (Rectangular & Square), T-Beams and

L-shapes

For Columns Prismatic (Rectangular, Square and Circular)

9A.3 Member Dimensions

Concrete members which will be designed by the program must

have certain section properties input under the MEMBER

PROPERTY command. The following example shows the required

input:

Section

9A

Concrete Design Per IS456

Section 9A 9-2

UNIT MM

MEMBER PROPERTY

1 3 TO 7 9 PRISM YD 450. ZD 250.

11 13 PR YD 350.

14 TO 16 PRIS YD 400. ZD 750. YB 300. ZB 200.

will be done accordingly. In the above input, the first set of

members are rectangular (450 mm depth and 250mm width) and

the second set of members, with only depth and no width provided,

will be assumed to be circular with 350 mm diameter. The third set

numbers in the above example represents a T-shape with 750 mm

flange width, 200 width, 400 mm overall depth and 100 mm flange

depth (See section 6.20.2). The program will determine whether

the section is rectangular, flanged or circular and the beam or

column design

9A.4 Design Parameters

The program contains a number of parameters which are needed to

perform design as per IS:456(2000). Default parameter values

have been selected such that they are frequently used numbers for

conventional design requirements. These values may be changed to

suit the particular design being performed. Table 8A.1 of this

manual contains a complete list of the available parameters and

their default values. It is necessary to declare length and force

units as Millimeter and Newton before performing the concrete

design.

9A.5 Slenderness Effects and Analysis

Consideration

Slenderness effects are extremely important in designing

compression members. The IS:456 code specifies two options by

which the slenderness effect can be accommodated (Clause 39.7).

Section 9A 9-3

One option is to perform an exact analysis which will take into

account the influence of axial loads and variable moment of inertia

on member stiffness and fixed end moments, the effect of

deflections on moment and forces and the effect of the duration of

loads. Another option is to approximately magnify design

moments.

STAAD has been written to allow the use of the first options. To

perform this type of analysis, use the command PDELTA

ANALYSIS instead of PERFORM ANALYSIS. The PDELTA

ANALYSIS will accommodate all requirements of the second-

order analysis described by IS:456, except for the effects of the

duration of the loads. It is felt that this effect may be safely

ignored because experts believe that the effects of the duration of

loads are negligible in a normal structural configuration.

Although ignoring load duration effects is somewhat of an

approximation, it must be realized that the approximate evaluation

of slenderness effects is also an approximate method. In this

method, additional moments are calculated based on empirical

formula and assumptions on sidesway

(Clause 39.7.1 and 39.7.1.1,IS: 456 - 2000).

Considering all these information, a PDELTA ANALYSIS, as

performed by STAAD may be used for the design of concrete

members. However the user must note, to take advantage of this

analysis, all the combinations of loading must be provided as

primary load cases and not as load combinations. This is due to the

fact that load combinations are just algebraic combinations of

forces and moments, whereas a primary load case is revised during

the P-delta analysis based on the deflections. Also note that the

proper factored loads (like 1.5 for dead load etc.) should be

provided by user. STAAD does not factor the loads automatically.

9A.6 Beam Design

Beams are designed for flexure, shear and torsion. If required the

effect the axial force may be taken into consideration. For all

Concrete Design Per IS456

Section 9A

9-4

these forces, all active beam loadings are prescanned to identify

the critical load cases at different sections of the beams. The total

number of sections considered is 13( e.g. 0.,.1,.2,.25,.3,.4,.5,.6,.7,.

75,.8,.9 and 1). All of these sections are scanned to determine the

design force envelopes.

Design for Flexure

Maximum sagging (creating tensile stress at the bottom face of the

beam) and hogging (creating tensile stress at the top face)

moments are calculated for all active load cases at each of the

above mentioned sections. Each of these sections is designed to

resist both of these critical sagging and hogging moments. Where

ever the rectangular section is inadequate as singly reinforced

section, doubly reinforced section is tried. However, presently the

flanged section is designed only as singly reinforced section under

sagging moment. It may also be noted all flanged sections are

automatically designed as rectangular section under hogging

moment as the flange of the beam is ineffective under hogging

moment. Flexural design of beams is performed in two passes. In

the first pass, effective depths of the sections are determined with

the assumption of single layer of assumed reinforcement and

reinforcement requirements are calculated. After the preliminary

design, reinforcing bars are chosen from the internal database in

single or multiple layers. The entire flexure design is per formed

again in a second pass taking into account of the changed effective

depths of sections calculated on the basis of reinforcement provide

after the preliminary design. Final provisions of flexural

reinforcements are made then. Efforts have been made t o meet the

guideline for the curtailment of reinforcements as per IS:456-2000

(Clause 26.2.3). Although exact curtailment lengths are not

mentioned explicitly in the design output (finally which will be

more or less guided by the detailer taking into account of other

practical consideration), user has the choice of printing

reinforcements provided by STAAD at 11 equally spaced sections

from which the final detail drawing can be prepared.

Section 9A

9-5

Design for Shear

Shear reinforcement is calculated to resist both shear forces and

torsional moments. Shear design are performed at 11 equally

spaced sections (0.to 1.) for the maximum shear forces amongst

the active load cases and the associated torsional moments. Shear

capacity calculation at different sections without the shear

reinforcement is based on the actual tensile reinforcement

provided by STAAD program. Two-legged stirrups are provided to

take care of the balance shear forces acting on these sections.

As per Clause 40.5 of IS:456-2000 shear strength of sections (< 2d

where d is the effective depth) close to support has been enhanced,

subjected to a maximum value of t

cmax

.

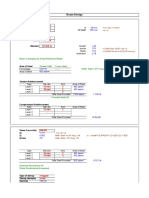

Beam Design Output

The default design output of the beam contains flexural and shear

reinforcement provided at 5 equally spaced (0,.25,.5,.75 and 1.)

sections along the length of the beam. User has option to get a

more detail output. All beam design outputs are given in IS units.

An example of rectangular beam design output with the default

output option (TRACK 0.0) is presented below:

Concrete Design Per IS456

Section 9A

9-6

============================================================================

B E A M N O. 12 D E S I G N R E S U L T S

M20 Fe415 (Main) Fe415 (Sec.)

LENGTH: 4000.0 mm SIZE: 250.0 mm X 350.0 mm COVER: 30.0 mm

DESIGN LOAD SUMMARY (KN MET)

----------------------------------------------------------------------------

SECTION |FLEXTURE (Maxm. Sagging/Hogging moments)| SHEAR

(in mm) | P MZ MX Load Case | VY MX Load Case

----------------------------------------------------------------------------

0.0 | 0.00 0.00 0.00 4 | 29.64 1.23 4

| 0.00 -25.68 1.23 4 |

400.0 | 0.00 0.00 0.00 4 | 27.97 1.23 4

| 0.00 -16.05 1.23 4 |

800.0 | 0.00 0.00 0.00 4 | 25.12 1.23 4

| 0.00 -7.17 1.23 4 |

1200.0 | 0.00 0.97 0.49 5 | 21.11 1.23 4

| 0.00 -0.14 1.32 6 |

1600.0 | 0.00 6.77 1.23 4 | 15.93 1.23 4

| 0.00 0.00 0.00 4 |

2000.0 | 0.00 11.06 1.23 4 | 9.59 1.23 4

| 0.00 0.00 0.00 4 |

2400.0 | 0.00 13.04 1.23 4 | 2.08 1.23 4

| 0.00 0.00 0.00 4 |

2800.0 | 0.00 12.45 1.23 4 | -5.43 1.23 4

| 0.00 0.00 0.00 4 |

3200.0 | 0.00 9.55 1.23 4 | -11.77 1.23 4

| 0.00 0.00 0.00 4 |

3600.0 | 0.00 4.73 1.23 4 | -16.95 1.23 4

| 0.00 0.00 0.00 4 |

4000.0 | 0.00 0.00 0.00 4 | -25.48 1.23 4

| 0.00 -17.36 1.23 4 |

----------------------------------------------------------------------------

SUMMARY OF REINF. AREA (Sq.mm)

----------------------------------------------------------------------------

SECTION 0.0 mm 1000.0 mm 2000.0 mm 3000.0 mm 4000.0 mm

----------------------------------------------------------------------------

TOP 259.04 161.29 0.00 0.00 176.31

REINF. (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm)

BOTTOM 0.00 160.78 160.78 160.78 0.00

REINF. (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm)

----------------------------------------------------------------------------

SUMMARY OF PROVIDED REINF. AREA

----------------------------------------------------------------------------

SECTION 0.0 mm 1000.0 mm 2000.0 mm 3000.0 mm 4000.0 mm

----------------------------------------------------------------------------

TOP 4-10 3-10 2-10 2-10 3-10

REINF. 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s)

BOTTOM 2-12 2-12 2-12 2-12 2-12

REINF. 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s)

SHEAR 2 legged 8 2 legged 8 2 legged 8 2 legged 8 2 legged 8

REINF. @ 100 mm c/c @ 100 mm c/c @ 100 mm c/c @ 100 mm c/c @ 100 mm c/c

----------------------------------------------------------------------------

============================================================================

Section 9A

9-7

9A.7 Column Design

Columns are designed for axial forces and biaxial moments at the

ends. All active load cases are tested to calculate reinforcement.

The loading which yield maximum reinforcement is called the

critical load. Column design is done for square, rectangular and

circular sections. By default, square and rectangular columns and

designed with reinforcement distributed on each side equally for

the sections under biaxial moments and with reinforcement

distributed equally in two faces for sections under uniaxial

moment. User may change the default arrangement of the

reinforcement with the help of the parameter RFACE (see Table

8A.1). Depending upon the member lengths, section dimensions

and effective length coefficients specified by the user STAAD

automatically determine the criterion (short or long) of the column

design. All major criteria for selecting longitudinal and transverse

reinforcement as stipulated by IS:456 have been taken care of in

the column design of STAAD. Default clear spacing between main

reinforcing bars is taken to be 25 mm while arrangement of

longitudinal bars.

Column Design Output

Default column design output (TRACK 0.0) contains the

reinforcement provided by STAAD and the capacity of the section.

With the option TRACK 1.0, the output contains intermediate

results such as the design forces, effective length coefficients,

additional moments etc. A special output TRACK 9.0 is introduced

to obtain the details of section capacity calculations. All design

output is given in SI units. An exampl e of a long column design

(Ref.Example9 of SP:16, Design Aids For Reinforced Concrete to

IS:456-1978) output (with option TRACK 1.0) is given below.

Concrete Design Per IS456

Section 9A

9-8

============================================================================

C O L U M N N O. 1 D E S I G N R E S U L T S

M20 Fe415 (Main) Fe415 (Sec.)

LENGTH: 3000.0 mm CROSS SECTION: 250.0 mm dia. COVER: 40.0 mm

** GUIDING LOAD CASE: 5 BRACED LONG COLUMN

DESIGN FORCES (KNS-MET)

-----------------------

DESIGN AXIAL FORCE (Pu) : 62.0

About Z About Y

INITIAL MOMENTS : 2.21 32.29

MOMENTS DUE TO MINIMUM ECC. : 1.24 1.24

SLENDERNESS RATIOS : 12.00 12.00

MOMENTS DUE TO SLENDERNESS EFFECT : 1.12 1.12

MOMENT REDUCTION FACTORS : 1.00 1.00

ADDITION MOMENTS (Maz and May) : 1.12 1.12

TOTAL DESIGN MOMENTS : 3.32 33.40

REQD. STEEL AREA : 1822.71 Sq.mm.

MAIN REINFORCEMENT : Provide 17 - 12 dia. (3.92%, 1922.65 Sq.mm.)

(Equally distributed)

TIE REINFORCEMENT : Provide 8 mm dia. rectangular ties @ 190 mm c/c

SECTION CAPACITY (KNS-MET)

--------------------------

Puz : 992.70 Muz1 : 36.87 Muy1 : 36.87

INTERACTION RATIO: 1.00 (as per Cl. 38.6, IS456)

============================================================================

Section 9A

9-9

Table 9A.1 Indian Concrete Design IS456 Parameters

Parameter Default Description

Name Value

FYMAIN 415 N/mm

2

Yield Stress for main reinforcing

steel.

FYSEC 415 N/mm

2

Yield Stress for secondary

reinforcing steel.

FC 30 N/mm

2

Concrete Yield Stress.

CLEAR 25 mm

40 mm

For beam members.

For column members

MINMAIN 10 mm Minimum main reinforcement

bar size.

MAXMAIN 60 mm Maximum main reinforcement

bar size.

MINSEC 8 mm Minimum secondary

reinforcement bar size.

MAXSEC 12 mm Maximum secondary

reinforcement bar size.

BRACING 0.0 BEAM DESIGN

A value of 1.0 means the effect

of axial force will be taken into

account for beam design.

COLUMN DESIGN

A value of 1.0 means the column

is unbraced about major axis.

A value of 2.0 means the column

is unbraced about minor axis.

A value of 3.0 means the column

is unbraced about both axis.

RATIO 4.0 Maximum percentage of

longitudinal reinforcement in

columns.

Concrete Design Per IS456

Section 9A

9-10

Table 9A.1 Indian Concrete Design IS456 Parameters

Parameter Default Description

Name Value

RFACE 4.0 A value of 4.0 means longitudinal

reinforcement in column is arranged

equally along 4 faces.

A value of 2.0 invokes 2 faced

distribution about major axis.

A value of 3.0 invokes 2 faced

distribution about minor axis.

WIDTH ZD Width to be used for design. This value

defaults to ZD as provided under

MEMBER PROPERTIES.

DEPTH YD Total depth to be used for design. This

value defaults to YD as provided under

MEMBER PROPERTIES.

TRACK 0.0 BEAM DESIGN:

For TRACK = 0.0, output consists of

reinforcement details at START, MIDDLE

and END.

For TRACK = 1.0, critical moments are

printed in addition to TRACK 0.0 output.

For TRACK = 2.0, required steel for

intermediate sections defined by

NSECTION are printed in addition to

TRACK 1.0 output.

COLUMN DESIGN:

With TRACK = 0.0, reinforcement details

are printed.

With TRACK = 1.0, column interaction

analysis results are printed in addition to

TRACK 0.0 output.

With TRACK = 2.0, a schematic

interaction diagram and intermediate

interaction values are printed in addition

to TRACK 1.0 output.

With TRACK = 9.0, the details of

section capacity calculations are

printed.

REINF 0.0 Tied column. A value of 1.0 will mean

spiral reinforcement.

Section 9A

9-11

Table 9A.1 Indian Concrete Design IS456 Parameters

Parameter Default Description

Name Value

ELZ 1.0 Ratio of effective length to actual length of

column about major axis.

ELY 1.0 Ratio of effective length to actual length of

column about minor axis.

ULY 1.0 Ratio of unsupported length to actual

length of column about minor axis.

ULZ 1.0 Ratio of unsupported length to actual

length of column about major axis.

TORSION 0.0 A value of 0.0 means torsion to be

considered in beam design.

A value of 1.0 means torsion to be

neglected in beam design.

SPSMAIN 25 mm Minimum clear distance between main

reinforcing bars in beam and column. For

column centre to centre distance between

main bars cannot exceed 300mm.

SFACE 0.0 Face of support location at start of beam. It

is used to check against shear at the face

of the support in beam design. The

parameter can also be used to check

against shear at any point from the start of

the member.

EFACE 0.0 Face of support location at end of beam.

The parameter can also be used to check

against shear at any point from the end of

the member. (Note: Both SFACE and

EFACE are input as positive numbers).

Concrete Design Per IS456

Section 9A

9-12

Table 9A.1 Indian Concrete Design IS456 Parameters

Parameter Default Description

Name Value

ENSH 0.0 Perform shear check against enhanced

shear strength as per Cl. 40.5 of

IS456:2000.

ENSH = 1.0 means ordinary shear check to

be performed ( no enhancement of shear

strength at sections close to support)

For ENSH = a positive value(say x ), shear

strength will be enhanced up to a distance

x from the start of the member. This is used

only when a span of a beam is subdivided

into two or more parts. (Refer note )

For ENSH = a negative value(say y),

shear strength will be enhanced up to a

distance y from the end of the member.

This is used only when a span of a beam is

subdivided into two or more parts.(Refer

note)

If default value (0.0) is used the program

will calculate Length to Overall Depth ratio.

If this ratio is greater than 2.5, shear

strength will be enhanced at sections (<2d)

close to support otherwise ordinary shear

check will be performed.

RENSH 0.0 Distance of the start or end point of the

member from its nearest support. This

parameter is used only when a span of a

beam is subdivided into two or more parts.

(Refer note)

Bar combination has been introduced for detailing. Please refer section 8A.8 for

details.

Notes: Value of ENSH parameter (other than 0.0 and 1.0) is used only

when the span of a beam is subdivided into two or more parts. When this

condition is aroused RENSH parameter is also to be used.

Once a parameter is specified, its value stays at that specified

number till it is specified again. This is the way STAAD works for all

codes.

Section 9A

9-13

The span of the beam is subdivided four parts, each of length L

metre. The shear strength will be enhanced up to X metre from

both supports. The input should be the following:

Steps:

ENSH L MEMB 1 => Shear strength will be enhanced

throughout the length of the member 1,

positive sign indicates length

measured from start of the member

ENSH (X-L) MEMB 2 => Shear strength will be enhanced up to

a length (X-L) of the member 2, length

measured from the start of the member

ENSH L MEMB 4 => Shear strength will be enhanced

throughout the length of the member 4,

negative sign indicates length

measured from end of the member

ENSH (X-L) MEMB 3 => Shear strength will be enhanced up to

a length (X-L) of the member 3, length

measured from the end of the member

RENSH L MEMB 2 3 => Nearest support lies at a distance L

from both the members 2 and 3.

DESIGN BEAM 1 TO 4=> This will enhance the shear strength

up to length X from both ends of the

beam consisting of members 1 to 4 and

gives spacing accordingly.

Concrete Design Per IS456

Section 9A

9-14

At section = y1 from start of member 1 av = y1

At section = y2 from the start of member 2 av = y2+L

At section = y3 from the end of member 3 av = y3+L

At section = y4 from end of member 4 av = y4

where tc, enhanced = 2dtc/av

At section 0.0, av becomes zero. Thus enhanced shear strength will

become infinity. However for any section shear stress cannot

exceed tc, max. Hence enhanced shear strength is limited to a

maximum value of tc, max.

9A.8 Bar Combination

Initially the program selects only one bar to calculate the number

of bars required and area of steel provided at each section along

the length of the beam. Now, two bar diameters can be specified to

calculate a combination of each bar to be provided at each section.

The syntax for bar combination is given below.

START BAR COMBINATION

MD1 <bar diameter> MEMB <member list>

MD2 <bar diameter> MEMB <member list>

END BAR COMBINATION

Section 9A

9-15

MD2 bar diameter should be greater than MD1 bar diameter. The typical

output for bar combination is shown below:

OUTPUT FOR BAR COMBINATION

--------------------------------------------------------------

| M A I N R E I N F O R C E M E N T |

--------------------------------------------------------------

SECTION | 0.0- 2166.7 | 2166.7- 6500.0 | 6500.0- 8666.7 |

| mm | mm | mm |

--------------------------------------------------------------

TOP | 6-20 + 1-25| 2-20 + 1-25 | 2-20 |

| in 2 layer(s)| in 1 layer(s) | in 1 layer(s) |

Ast Reqd| 2330.22 | 1029.90 | 582.55 |

Prov| 2376.79 | 1119.64 | 628.57 |

Ld (mm) | 940.2 | 940.2 | 940.2 |

--------------------------------------------------------------

BOTTOM | 4-20 | 2-20 | 2-20 |

|in 1 layer(s) | in 1 layer(s) | in 1 layer(s) |

Ast Reqd| 1165.11 | 582.55 | 582.55 |

Prov| 1257.14 | 628.57 | 628.57 |

Ld (mm) | 940.2 | 940.2 | 940.2 |

-------------------------------------------------------------

The beam length is divided into three parts, two at its ends and one at span.

Ld gives the development length to be provided at the two ends of each

section.

9A.9 Wall Design in accordance with IS 456-2000

Design of walls in accordance with IS 456-2000 is available in

STAAD.Pro.

Design is performed for in-plane shear, in-plane and out-of-plane

bending and out-of-plane shear. The wall has to be modeled using

STAADs Surface elements. The use of the Surface element

enables the designer to treat the entire wall as one entity. It greatly

simplifies the modeling of the wall and adds clarity to the analysis

and design output. The results are presented in the context of the

entire wall rather than individual finite elements thereby allowing

users to quickly locate required information.

Concrete Design Per IS456

Section 9A

9-16

The program reports shear wall design results for each load

case/combination for user specified number of sections given by

SURFACE DIVISION (default value is 10) command. The shear

wall is designed at these horizontal sections. The output includes

the required horizontal and vertical distributed reinforcing, the

concentrated (in-plane bending) edge reinforcing and the link

required for out-of-plane shear.

General format:

START SHEARWALL DESIGN

CODE INDIAN

FYMAIN f1

FC f2

HMIN f3

HMAX f4

VMIN f5

VMAX f6

EMIN f7

EMAX f8

LMIN f9

LMAX f10

CLEAR f11

TWOLAYERED f12

KSLENDER f13

DESIGN SHEARWALL LIST shearwall-list

END

Section 9A

9-17

The following table explains the parameters used in the shear wall

design. Note: Once a parameter is specified, its value stays at

that specified number till it is specified again. This is the way

STAAD works for all codes.

SHEAR WALL DESIGN PARAMETERS

Parameter Name Default

Value

Description

FYMAIN 415 Mpa

Yield strength of steel, in current units.

FC 30 Mpa

Compressive strength of concrete, in current

units.

HMIN 8

Minimum size of horizontal reinforcing bars

(range 6 mm 36 mm). If input is 6 (integer

number) the program will assume 6 mm diameter

bar.

HMAX 36 Maximum size of horizontal reinforcing bars

(range 6 mm 36 mm). If input is 6 (integer

number) the program will assume 6 mm diameter

bar.

VMIN 8 Minimum size of vertical reinforcing bars (range

6mm 36mm). If input is 6 (integer number) the

program will assume 6 mm diameter bar.

VMAX 36 Maximum size of vertical reinforcing bars (range

6mm 36mm). If input is 6 (integer number) the

program will assume 6 mm diameter bar.

EMIN 8 Minimum size of vertical reinforcing bars located

in edge zones (range 6mm 36mm). If input is 6

(integer number) the program will assume 6 mm

diameter bar.

EMAX 36 Maximum size of vertical reinforcing bars located

in edge zones (range 6mm 36mm). If input is 6

(integer number) the program will assume 6 mm

diameter bar.

LMIN 6 Minimum size of links (range 6mm 16mm). If

input is 6 (integer number) the program will

assume 6 mm diameter bar.

Concrete Design Per IS456

Section 9A

9-18

SHEAR WALL DESIGN PARAMETERS

Parameter Name Default

Value

Description

LMAX 16 Maximum size of links (range 6mm 16mm). If

input is 6 (integer number) the program will

assume 6 mm diameter bar.

CLEAR 25 mm Clear concrete cover, in current units.

TWOLAYERED 0 Reinforcement placement mode:

0 - single layer, each direction

1 - two layers, each direction

KSLENDER 1.0 Slenderness factor for finding effective height.

Table 6

The following example illustrates the input for the definition of

shear wall and design of the wall.

Example

.

.

SET DIVISION 12

SURFACE INCIDENCES

2 5 37 34 SUR 1

19 16 65 68 SUR 2

11 15 186 165 SUR 3

10 6 138 159 SUR 4

.

.

.

SURFACE PROPERTY

1 TO 4 THI 18

SUPPORTS

1 7 14 20 PINNED

2 TO 5 GEN PIN

6 TO 10 GEN PIN

Section 9A

9-19

11 TO 15 GEN PIN

19 TO 16 GEN PIN

.

.

.

SURFACE CONSTANTS

E 2.17185e+007

POISSON 0.17

DENSITY 23.5616

ALPHA 1e-005

.

.

START SHEARWALL DES

CODE INDIAN

UNIT NEW MMS

FC 25

FYMAIN 415

TWO 1

VMIN 12

HMIN 12

EMIN 12

DESIGN SHEA LIST 1 TO 4

END

Notes

1. Command SET DIVISION 12 indicates that the surface

boundary node-to-node segments will be subdivided into 12

fragments prior to finite element mesh generation.

2. Four surfaces are defined by the SURFACE INCIDENCES

command.

3. The SUPPORTS command includes the new support

generation routine. For instance, the line 2 TO 5 GEN PIN

assigns pinned supports to all nodes between nodes 2 and 5.

As the node-to-node distances were previously subdivided

by the SET DIVISION 12 command, there will be an

Concrete Design Per IS456

Section 9A

9-20

additional 11 nodes between nodes 2 and 5. As a result, all

13 nodes will be assigned pinned supports. Please note that

the additional 11 nodes are not individually accessible to the

user. They are created by the program to enable the finite

element mesh generation and to allow application of

boundary constraints.

4. Surface thickness and material constants are specified by the

SURFACE PROPERTY and SURFACE CONSTANTS,

respectively.

5. The shear wall design commands are listed between lines

START SHEARWALL DES and END. The CODE

command selects the design code that will be the basis for

the design. For Indian code the parameter is INDIAN. The

DESIGN SHEARWALL LIST command is followed by a

list of previously defined Surface elements intended as shear

walls and/or shear wall components.

Technical Overview

The program implements provisions of section 32 of IS 456-2000

and relevant provisions as referenced therein, for all active load

cases. The following steps are performed for each of the horizontal

sections of the wall.

Checking of slenderness limit

The slenderness checking is done as per clause no. 32.2.3. The

default effective height is the height of the wall. User can change

the effective height. The limit for slenderness is taken as 30.

Design for in-plane bending and vertical load (denoted by Mz

& Fy in the shear wall force output)

Walls when subjected to combined in-plane horizontal and vertical

forces produce in-plane bending in conjunction with vertical load.

According to clause no. 32.3.1, in-plane bending may be neglected

in case a horizontal cross section of the wall is always under

compression due combined effect of horizontal and vertical loads.

Otherwise, the section is checked for combined vertical load and

Section 9A

9-21

in-plane moment as column with axial load and uni -axial bending.

For this purpose, the depth is taken as 0.8 x horizontal length of

wall and breadth is the thickness of the wall. The reinforcement is

concentrated at both ends (edges) of the wall. The edge

reinforcement is assumed to be distributed over a length of 0.2

times horizontal length on each side. Minimum reinforcements are

according to clause no. 32.5.(a). Maximum 4% reinforcement is

allowed.

Design for in-plane shear (denoted by Fxy in the shear wall

force output)

By default, the program does not design only at the critical section

but at all the horizontal sections. By suitable use of the surface

division command, design at critical section as per clause no.

32.4.1 can be performed.

The design for in-plane shear is done as per clause no. 32.4. The

nominal shear stress is calculated as per clause no. 32.4.2 and it is

checked with the maximum allowable shear stress as per clause no.

32.4.2.1. The design shear strength of concrete is calculated as per

clause no. 32.4.3. Design of shear reinforcement is done as per

clause no. 32.4.4. Minimum reinforcements are as per clause no.

32.5.

Design for vertical load and out-of-plane vertical bending

(denoted by Fy and My respectively in the shear wall force

output)

Apart from the in-plane bending and horizontal shear force, the

wall is also subjected to out -of-plane bending in the vertical and

horizontal directions. The part of the wall which is not having

edge reinforcements (i.e. a zone of depth 0.6 x Length of the wall),

is designed again as column under axial load (i.e. vertical load)

and out-of-plane vertical bending. The minimum reinforcements

and maximum allowable spacings of reinforcements are as per

clause no. 32.5

Concrete Design Per IS456

Section 9A

9-22

Design for out-of-plane horizontal bending (denoted by Mx in

the shear wall force output)

The horizontal reinforcement which is already provided for in-

plane shear is checked against out -of-plane horizontal bending.

The wall is assumed as a slab for this purpose.

Design for out-of-plane shears (denoted by Qx and Qy in the

shear wall force output)

The out-of-plane shear arises from out -of-plane loading. The

nominal shear stresses are calculated as per clause no. 40.1.

Maximum allowable shear stresses are as per table 20. For shear

force in the vertical direction, shear strength of concrete section is

calculated as per section 4.1 of SP 16 : 1980 considering vertical

reinforcement as tension reinforcement. Similarly, for shear force

in the horizontal direction, shear strength of concrete section is

calculated considering horizontal reinforcement as tension

reinforcement. Shear reinforcements in the form of links are

computed as per the provisions of clause no. 40.4.

Shear Wall Design With Opening

The Surface element has been enhanced to allow design of shear

walls with rectangular openings. The automatic meshing algorithm

has been improved to allow variable divisions along wall and

opening(s) edges. Design and output are available for user selected

locations.

Description

Shear walls modeled in STAAD.Pro may include an unlimited

number of openings. Due to the presence of openings, the wall

may comprise up with different wall panels.

Section 9A

9-23

1. Shear wall set-up

Definition of a shear wall starts with a specification of the surface

element perimeter nodes, meshing divisions along node-to-node

segments, opening(s) corner coordinates, and meshing divisions of

four edges of the opening(s).

SURFACE INCIDENCE n1, ..., ni SURFACE s DIVISION sd1, ...,

sdj -

RECOPENING x1 y1 z1 x2 y2 z2 x3 y3 z3 x4 y4 z4 DIVISION

od1, ..., odk

where,

n1, ..., ni - node numbers on the perimeter of the shear wall,

s - surface ordinal number,

sd1, ..., sdj - number of divisions for each of the node-to-node

distance on the surface perimeter,

x1 y1 z1 (...) - coordinates of the corners of the opening,

od1, ..., odk - divisions along edges of the opening.

Note:

If the sd1, ..., sdj or the od1, ..., odk list does not include all node-

to-node segments, or if any of the numbers listed equals zero, then

the corresponding division number is set to the default value (=10,

or as previously input by the SET DIVISION command).

Default locations for stress/force output, design, and design output

are set as follows:

SURFACE DIVISION X xd

SURFACE DIVISION Y yd

Concrete Design Per IS456

Section 9A

9-24

where,

xd - number of divisions along X axis,

yd - number of divisions along Y axis.

Note:

xd and yd represent default numbers of divisions for each edge of

the surface where output is requested. The output is provided for

sections located between division segments. For example, if the

number of divisions = 2, then the output will be produced for only

one section (at the center of the edge).

2. Stress/force output printing

Values of internal forces may be printed out for any user -defined

section of the wall. The general format of the command is as

follows:

PRINT SURFACE FORCE (ALONG ) (AT a) (BETWEEN d1, d2)

LIST s1, ...,si

where,

- local axis of the surface element (X or Y),

a - distance along the axis from start of the member

to the full cross-section of the wall,

d1, d2 - coordinates in the direction orthogonal to ,

delineating a fragment of the full cross-section for

which the output is desired. **

s1, ...,si - list of surfaces for output generation

** The range currently is taken in terms of local axis. If the local

axis is directed away from the surface, the negative range is to be

entered.

Section 9A

9-25

Note:

If command ALONG is omitted, direction Y (default) is assumed.

If command AT is omitted, output is provided for all sections

along the specified (or default) edge. Number of sections will be

determined from the SURFACE DIVISION X or SURFACE

DIVISION Y input values. If the BETWEEN command is

omitted, the output is generated based on full cross-section width.

3. Definition of wall panels

Input syntax for panel definition is as follows:

START PANEL DEFINITION

SURFACE i PANEL j ptype x1 y1 z1 x2 y2 z2 x3 y3 z3 x4 y4 z4

END PANEL DEFINITION

where,

i - ordinal surface number,

j - ordinal panel number,

ptype - panel type, one of: WALL, COLUMN, BEAM

x1 y1 z1 (...) - coordinates of the corners of the panel,

4. Shear wall design

The program implements different provisions of design of walls as

per code BS 8110. General syntax of the design command is as

follows:

START SHEARWALL DESIGN

(...)

DESIGN SHEARWALL (AT c) LIST s

END SHEARWALL DESIGN

Concrete Design Per IS456

Section 9A

9-26

Note:

If the command AT is omitted, the design proceeds for all cross

sections of the wall or panels, as applicable, defined by the

SURFACE DIVISION X or SURFACE DIVISION Y input

values.

a. No panel definition.

Design is performed for the specified horizontal full cross-section,

located at a distance c from the origin of the local coordinates

system. If opening is found then reinforcement is provided along

sides of openings. The area of horizontal and vertical bars

provided along edges of openings is equal to that of the respective

interrupted bars.

b. Panels have been defined.

Only wall panel design is supported in Indian code.

9-27

Concrete Design Per IS13920

9A1.1 Design Operations

Earthquake motion often induces force large enough to cause

inelastic deformations in the structure. If the structure is brittle,

sudden failure could occur. But if the structure is made to behave

ductile, it will be able to sustain the earthquake effects better with

some deflection larger than the yield deflection by absorption of

energy. Therefore ductility is also required as an essential element

for safety from sudden collapse during severe shocks.

STAAD has the capabilities of performing concrete design as per

IS 13920. While designing it satisfies all provisions of IS 456

2000 and IS 13920 for beams and columns.

9A1.2 Section Types for Concrete Design

The following types of cross sections for concrete members can be

designed.

For Beams Prismatic (Rectangular & Square) & T-shape

For Columns Prismatic (Rectangular, Square and Circular)

Section

9A1

Concrete Design Per IS13920

Section 9A1

9-28

9A1.3 Design Parameters

The program contains a number of parameters that are needed to

perform design as per IS 13920. It accepts all parameters that are

needed to perform design as per IS:456. Over and above it has

some other parameters that are required only when designed is

performed as per IS:13920. Default parameter values have been

selected such that they are frequently used numbers for

conventional design requirements. These values may be changed to

suit the particular design being performed. Table 8A1.1 of this

manual contains a complete list of the available parameters and

their default values. It is necessary to declare length and force

units as Millimeter and Newton before performing the concrete

design.

9A1.4 Beam Design

Beams are designed for flexure, shear and torsion. If required the

effect of the axial force may be taken into consideration. For all

these forces, all active beam loadings are prescanned to identify

the critical load cases at different sections of the beams. The total

number of sections considered is 13. All of these sections are

scanned to determine the design force envelopes.

For design to be performed as per IS:13920 the width of the

member shall not be less than 200mm(Clause 6.1.3). Also the

member shall preferably have a width-to depth ratio of more than

0.3 (Clause 6.1.2).

The factored axial stress on the member should not exceed 0.1fck

(Clause 6.1.1) for all active load cases. If it exceeds allowable

axial stress no design will be performed.

Section 9A1

9-29

Design for Flexure

Design procedure is same as that for IS 456. However while

designing following criteria are satisfied as per IS-13920:

1. The minimum grade of concrete shall preferably be M20. (Clause

5.2)

2. Steel reinforcements of grade Fe415 or less only shall be used.

(Clause 5.3)

3. The minimum tension steel ratio on any face, at any section, is

given by

min

= 0.24\fck/fy (Clause 6.2.1b)

The maximum steel ratio on any face, at any section, is given by

max

= 0.025 (Clause 6.2.2)

4. The positive steel ratio at a joint face must be at least equal to half

the negative steel at that face. (Clause 6.2.3)

5. The steel provided at each of the top and bottom face, at any

section, shall at least be equal to one-fourth of the maximum

negative moment steel provided at the face of either joint. (Clause

6.2.4)

Design for Shear

The shear force to be resisted by vertical hoops is guided by the

Clause 6.3.3 of IS 13920:1993 revision. Elastic sagging and

hogging moments of resistance of the beam section at ends are

considered while calculating shear force. Plastic sagging and

hogging moments of resistance can also be considered for shear

design if PLASTIC parameter is mentioned in the input file. (Refer

Table 8A1.1)

Shear reinforcement is calculated to resist both shear forces and

torsional moments. Procedure is same as that of IS 456.

Concrete Design Per IS13920

Section 9A1

9-30

The following criteria are satisfied while performing design for

shear as per Cl. 6.3.5 of IS-13920:

The spacing of vertical hoops over a length of 2d at either end of

the beam shall not exceed

a) d/4

b) 8 times the diameter of the longitudinal bars

In no case this spacing is less than 100 mm.

The spacing calculated from above, if less than that calculated

from IS 456 consideration is provided.

Beam Design Output

The default design output of the beam contains flexural and shear

reinforcement provided at 5 equally spaced sections along the

length of the beam. User has option to get a more detail output. All

beam design outputs are given in IS units. An example of

rectangular beam design output with the default output option

(TRACK 1.0) is presented below:

Section 9A1

9-31

============================================================================

B E A M N O. 11 D E S I G N R E S U L T S

M20 Fe415 (Main) Fe415 (Sec.)

LENGTH: 3500.0 mm SIZE: 250.0 mm X 350.0 mm COVER: 30.0 mm

DESIGN LOAD SUMMARY (KN MET)

----------------------------------------------------------------------------

SECTION |FLEXTURE (Maxm. Sagging/Hogging moments)| SHEAR

(in mm) | P MZ MX Load Case | VY MX Load Case

----------------------------------------------------------------------------

0.0 | 0.00 0.00 0.00 4 | 17.67 0.00 4

| 0.00 -2.74 0.00 5 |

291.7 | 0.00 1.15 0.00 5 | 16.26 0.00 4

| 0.00 0.00 0.00 4 |

583.3 | 0.00 4.61 0.00 5 | 13.97 0.00 4

| 0.00 0.00 0.00 4 |

875.0 | 0.00 7.44 0.00 5 | 10.78 0.00 4

| 0.00 0.00 0.00 4 |

1166.7 | 0.00 9.41 0.00 5 | 6.69 0.00 4

| 0.00 0.00 0.00 4 |

1458.3 | 0.00 10.33 0.00 5 | 1.10 0.00 5

| 0.00 0.00 0.00 4 |

1750.0 | 0.00 9.98 0.00 5 | -3.60 0.00 5

| 0.00 0.00 0.00 4 |

2041.7 | 0.00 8.23 0.00 5 | -10.02 0.00 4

| 0.00 0.00 0.00 4 |

2333.3 | 0.00 5.21 0.00 5 | -15.00 0.00 4

| 0.00 0.00 0.00 4 |

2625.0 | 0.00 1.14 0.00 5 | -19.08 0.00 4

| 0.00 0.00 0.00 4 |

2916.7 | 0.00 0.00 0.00 4 | -22.27 0.00 4

| 0.00 -3.79 0.00 5 |

3208.3 | 0.00 0.00 0.00 4 | -24.57 0.00 4

| 0.00 -9.35 0.00 5 |

3500.0 | 0.00 0.00 0.00 4 | -25.97 0.00 4

| 0.00 -15.34 0.00 5 |

*** DESIGN SHEAR FORCE AT SECTION 0.0 IS 68.60 KN.

- CLAUSE 6.3.3 OF IS-

13920

*** DESIGN SHEAR FORCE AT SECTION 3500.0 IS 75.24 KN.

- CLAUSE 6.3.3 OF IS-

13920

----------------------------------------------------------------------------

SUMMARY OF REINF. AREA (Sq.mm)

----------------------------------------------------------------------------

SECTION 0.0 mm 875.0 mm 1750.0 mm 2625.0 mm 3500.0 mm

----------------------------------------------------------------------------

TOP 226.30 0.00 0.00 0.00 226.30

REINF. (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm)

BOTTOM 0.00 203.02 203.02 203.02 0.00

REINF. (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm) (Sq. mm)

----------------------------------------------------------------------------

SUMMARY OF PROVIDED REINF. AREA

----------------------------------------------------------------------------

SECTION 0.0 mm 875.0 mm 1750.0 mm 2625.0 mm 3500.0 mm

----------------------------------------------------------------------------

TOP 3-10 2-10 2-10 2-10 3-10

REINF. 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s)

BOTTOM 2-12 2-12 2-12 2-12 2-12

REINF. 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s) 1 layer(s)

SHEAR 2 legged 8 2 legged 8 2 legged 8 2 legged 8 2 legged 8

REINF. @ 100 mm c/c @ 150 mm c/c @ 150 mm c/c @ 150 mm c/c @ 100 mm c/c

----------------------------------------------------------------------------

============================================================================

Concrete Design Per IS13920

Section 9A1

9-32

9A1.5 Column Design

Columns are designed for axial forces and biaxial moments per IS

456:2000. Columns are also designed for shear forces as per

Clause 7.3.4. All major criteria for selecting longitudinal and

transverse reinforcement as stipulated by IS:456 have been taken

care of in the column design of STAAD. However following

clauses have been satisfied to incorporate provisions of IS 13920:

1. The minimum grade of concrete shall preferably be M20.

(Clause 5.2)

2. Steel reinforcements of grade Fe415 or less only shall be used.

(Clause 5.3)

3. The minimum dimension of column member shall not be less

than 200 mm. For columns having unsupported length

exceeding 4m, the shortest dimension of column shall not be

less than 300 mm. (Clause 7.1.2)

4. The ratio of the shortest cross-sectional dimension to the

perpendicular dimension shall preferably be not less than 0.4.

(Clause 7.1.3)

5. The spacing of hoops shall not exceed half the least lateral

dimension of the column, except where special confining

reinforcement is provided. (Clause 7.3.3)

6. Special confining reinforcement shall be provided over a

length l

o

from each joint face, towards mid span, and on either

side of any section, where flexural yielding may occur. The

length l

o

shall not be less than a) larger lateral dimension of

the member at the section where yielding occurs, b) 1/6 of

clear span of the member, and c) 450 mm. (Clause 7.4.1)

7. The spacing of hoops used as special confining reinforcement

shall not exceed of minimum member dimension but need

not be less than 75 mm nor more than 100 mm. (Clause 7.4.6)

Section 9A1

9-33

8. The area of cross-section of hoops provided are checked

against the provisions for minimum area of cross-section of

the bar forming rectangular, circular or spiral hoops, to be

used as special confining reinforcement. (Clause 7.4.7 and

7.4.8)

Column Design Output

Default column design output (TRACK 0.0) contains the

reinforcement provided by STAAD and the capacity of the section.

With the option TRACK 1.0, the output contains intermediate

results such as the design forces, effective length coefficients,

additional moments etc. A special output TRACK 9.0 is introduced

to obtain the details of section capacity calculations. All design

output is given in SI units. An example of a column design output

(with option TRACK 1.0) is given below.

============================================================================

C O L U M N N O. 3 D E S I G N R E S U L T S

M20 Fe415 (Main) Fe415 (Sec.)

LENGTH: 3000.0 mm CROSS SECTION: 350.0 mm X 400.0 mm COVER: 40.0 mm

** GUIDING LOAD CASE: 5 END JOINT: 2 SHORT COLUMN

DESIGN FORCES (KNS-MET)

-----------------------

DESIGN AXIAL FORCE (Pu) : 226.7

About Z About Y

INITIAL MOMENTS : 0.64 146.28

MOMENTS DUE TO MINIMUM ECC. : 4.53 4.53

SLENDERNESS RATIOS : - -

MOMENTS DUE TO SLENDERNESS EFFECT : - -

MOMENT REDUCTION FACTORS : - -

ADDITION MOMENTS (Maz and May) : - -

TOTAL DESIGN MOMENTS : 4.53 146.28

** GUIDING LOAD CASE: 5

Along Z Along Y

DESIGN SHEAR FORCES : 43.31 76.08

REQD. STEEL AREA : 3313.56 Sq.mm.

MAIN REINFORCEMENT : Provide 12 - 20 dia. (2.69%, 3769.91 Sq.mm.)

(Equally distributed)

CONFINING REINFORCEMENT : Provide 10 mm dia. rectangular ties @ 85 mm c/c

over a length 500.0 mm from each joint face towards

midspan as per Cl. 7.4.6 of IS-13920.

TIE REINFORCEMENT : Provide 10 mm dia. rectangular ties @ 175 mm c/c

SECTION CAPACITY (KNS-MET)

--------------------------

Puz : 2261.52 Muz1 : 178.71 Muy1 : 150.75

INTERACTION RATIO: 1.00 (as per Cl. 39.6, IS456:2000)

============================================================================

********************END OF COLUMN DESIGN RESULTS********************

Concrete Design Per IS13920

Section 9A1

9-34

Note: Once a parameter is specified, its value stays at that

specified number till it is specified again. This is the way

STAAD works for all codes.

Table 9A1.1 Indian Concrete Design IS13920 Parameters

Parameter

Name

Default Value Description

FYMAIN 415 N/mm

2

Yield Stress for main reinforcing steel.

FYSEC 415 N/mm

2

Yield Stress for secondary reinforcing steel.

FC 30 N/mm

2

Concrete Yield Stress.

CLEAR 25 mm

40 mm

For beam members.

For column members

MINMAIN 10 mm Minimum main reinforcement bar size.

MAXMAIN 60 mm Maximum main reinforcement bar size.

MINSEC 8 mm Minimum secondary reinforcement bar size.

MAXSEC 12 mm Maximum secondary reinforcement bar size.

BRACING 0.0 BEAM DESIGN

A value of 1.0 means the effect of axial force

will be taken into account for beam design.

COLUMN DESIGN

A value of 1.0 means the column is unbraced

about major axis.

A value of 2.0 means the column is unbraced

about minor axis.

A value of 3.0 means the column is unbraced

about both axis.

RATIO 4.0 Maximum percentage of longitudinal

reinforcement in columns.

RFACE 4.0 A value of 4.0 means longitudinal

reinforcement in column is arranged equally

along 4 faces.

A value of 2.0 invokes 2 faced distribution

about major axis.

Section 9A1

9-35

Table 9A1.1 Indian Concrete Design IS13920 Parameters

Parameter

Name

Default Value Description

A value of 3.0 invokes 2 faced distribution

about minor axis.

WIDTH ZD Width to be used for design. This value

defaults to ZD as provided under MEMBER

PROPERTIES.

DEPTH YD Total depth to be used for design. This value

defaults to YD as provided under MEMBER

PROPERTIES.

ELZ 1.0 Ratio of effective length to actual length of

column about major axis.

ELY 1.0 Ratio of effective length to actual length of

column about minor axis.

REINF 0.0 Tied column. A value of 1.0 will mean spiral

reinforcement.

TORSION 0.0 A value of 0.0 means torsion to be

considered in beam design.

A value of 1.0 means torsion to be neglected

in beam design.

TRACK 0.0 BEAM DESIGN:

For TRACK = 0.0, output consists of

reinforcement details at START, MIDDLE

and END.

For TRACK = 1.0, critical moments are

printed in addition to TRACK 0.0 output.

For TRACK = 2.0, required steel for

intermediate sections defined by NSECTION

are printed in addition to TRACK 1.0 output.

COLUMN DESIGN:

With TRACK = 0.0, reinforcement details are

printed.

With TRACK = 1.0, column interaction

analysis results are printed in addition to

TRACK 0.0 output.

Concrete Design Per IS13920

Section 9A1

9-36

Table 9A1.1 Indian Concrete Design IS13920 Parameters

Parameter

Name

Default Value Description

With TRACK = 2.0, a schematic interaction

diagram and intermediate interaction values

are printed in addition to TRACK 1.0 output.

SPSMAIN 25 mm Minimum clear distance between main

reinforcing bars in beam and column. For

column centre to centre distance between

main bars cannot exceed 300mm.

SFACE 0.0 Face of support location at start of beam. It is

used to check against shear at the face of

the support in beam design. The parameter

can also be used to check against shear at

any point from the start of the member.*

EFACE 0.0 Face of support location at end of beam. The

parameter can also be used to check against

shear at any point from the end of the

member. (Note: Both SFACE and EFACE

are input as positive numbers).*

ENSH 0.0 Perform shear check against enhanced

shear strength as per Cl. 40.5 of IS456:2000.

ENSH = 1.0 means ordinary shear check to

be performed ( no enhancement of shear

strength at sections close to support)

For ENSH = a positive value(say x ), shear

strength will be enhanced up to a distance x

from the start of the member. This is used

only when a span of a beam is subdivided

into two or more parts. (Refer note after

Table 8A.1 )

For ENSH = a negative value(say y), shear

strength will be enhanced up to a distance y

from the end of the member. This is used

only when a span of a beam is subdivided

into two or more parts.(Refer note after Table

8A.1)

If default value (0.0) is used the program will

calculate Length to Overall Depth ratio. If this

ratio is greater than 2.5, shear strength will

be enhanced at sections (<2d) close to

support otherwise ordinary shear check will

Section 9A1

9-37

Table 9A1.1 Indian Concrete Design IS13920 Parameters

Parameter

Name

Default Value Description

be performed.

RENSH 0.0 Distance of the start or end point of the

member from its nearest support. This

parameter is used only when a span of a

beam is subdivided into two or more parts.

(Refer note after Table 8A.1)

EUDL None Equivalent u.d.l on span of the beam. This

load value must be the unfactored load on

span. During design the load value is

multiplied by a factor 1.2. If no u.d.l is defined

factored shear force due to gravity load on

span will be taken as zero. No elastic or

plastic moment will be calculated. Shear

design will be performed based on analysis

result.(Refer note)

GLD None Gravity load number to be considered for

calculating equivalent u.d.l on span of the

beam, in case no EUDL is mentioned in the

input. This loadcase can be any static

loadcase containing MEMBER LOAD on the

beam which includes UNI, CON, LIN and

TRAP member loading. CMOM member

loading is considered only when it is

specified in local direction. FLOOR LOAD is

also considered.

The load can be primary or combination load.

For combination load only load numbers

included in load combination is considered.

The load factors are ignored. Internally the

unfactored load is multiplied by a factor 1.2

during design.

If both EUDL and GLD parameters are

mentioned in the input mentioned EUDL will

be considered in design

Note :

No dynamic (Response spectrum, 1893,

Time History) and moving load cases are

considered.

CMOM member loading in global direction is

Concrete Design Per IS13920

Section 9A1

9-38

Table 9A1.1 Indian Concrete Design IS13920 Parameters

Parameter

Name

Default Value Description

not considered.

UMOM member loading is not considered.

PLASTIC 0.0 Default value calculates elastic hogging and

sagging moments of resistance of beam at its

ends.

A value of 1.0 means plastic hogging and

sagging moments of resistance of beam to

be calculated at its ends.

IPLM 0.0 Default value calculates elastic/plastic

hogging and sagging moments of resistance

of beam at its ends.

A value of 1.0 means calculation of

elastic/plastic hogging and sagging moments

of resistance of beam to be ignored at start

node of beam. This implies no support exists

at start node.

A value of -1.0 means calculation of

elastic/plastic hogging and sagging moments

of resistance of beam to be considered at

start node of beam. . This implies support

exists at start node.

A value of 2.0 means calculation of

elastic/plastic hogging and sagging moments

of resistance of beam to be ignored at end

node of beam. This implies no support exists

at end node.

A value of -2.0 means calculation of

elastic/plastic hogging and sagging moments

of resistance of beam to be considered at

end node of beam. . This implies support

exists at end node. **

IMB 0.0 Default value calculates elastic/plastic

hogging and sagging moments of resistance

of beam at its ends.

A value of 1.0 means calculation of

Section 9A1

9-39

Table 9A1.1 Indian Concrete Design IS13920 Parameters

Parameter

Name

Default Value Description

elastic/plastic hogging and sagging moments

of resistance of beam to be ignored at both

ends of beam. This implies no support exist

at either end of the member.

A value of -1.0 means calculation of

elastic/plastic hogging and sagging moments

of resistance of beam to be considered at

both ends of beam. This implies support exist

at both ends of the member.**

COMBINE 0.0 Default value means there will be no member

combination.

A value of 1.0 means there will be no printout

of sectional force and critical load for

combined member in the output.

A value of 2.0 means there will be printout of

sectional force for combined member in the

output.

A value of 3.0 means there will be printout of

both sectional force and critical load for

combined member in the output. ***

HLINK Spacing of

longitudinal bars

measured to the

outer face

Longer dimension of the rectangular

confining hoop measured to its outer face. It

shall not exceed 300 mm as per Cl. 7.4.8. If

hlink value as provided in the input file does

not satisfy the clause the value will be

internally assumed as the default one. This

parameter is valid for rectangular column.

Bar combination has been introduced for detailing. Please refer section 8A1.6 for

details.

* EFACE and SFACE command is not valid for member combination.

** IPLM and IMB commands are not valid for member combination.

These commands are ignored for members forming physical member.

Concrete Design Per IS13920

Section 9A1

9-40

*** The purpose of COMBINE command is the following:

1. If a beam spanning between two supports is subdivided into many

sub-beams this parameter will combine them into one member. It

can also be used to combine members to form one continuous

beam spanning over more than two supports.

2. When two or more members are combined during design plastic or

elastic moments will be calculated at the column supports. At all

the intermediate nodes (if any) this calculation will be ignored.

Please note that the program only recognizes column at right angle

to the beam. Inclined column support is ignored.

3. It will calculate sectional forces at 13 sections along the length of

the combined member.

4. It will calculate critical loads (similar to that of Design Load

Summary) for all active load cases during design.

Beams will be combined only when DESIGN BEAM command is

issued.

The following lines should be satisfied during combination of

members:

1. Members to be combined should have same sectional properties if

any single span between two column support s of a continuous

beam is subdivided into several members.

2. Members to be combined should have same constants (E, Poi ratio,

alpha,

density and beta angle)

3. Members to be combined should lie in one straight line.

4. Members to be combined should be continuous.

5. Vertical members (i.e. columns) cannot be combined.

6. Same member cannot be used more than once to form two different

combined members.

7. The maximum number of members that can be combined into one

member is 299.

Section 9A1

9-41

Note:

Sectional forces and critical load for combined member output will

only be available when all the members combined are successfully

designed in both flexure and shear.

ENSH and RENSH parameters will have to be provided (as and

when necessary) even if physical member has been formed.

The following lines show a standard example for design to be

performed in IS 13920.

STAAD SPACE

UNIT METER MTON

JOINT COORDINATES

..

MEMBER INCIDENCES

..

MEMBER PROPERTY INDIAN

..

CONSTANTS

.

SUPPORTS

.

DEFINE 1893 LOAD

ZONE 0.05 I 1 K 1 B 1

SELFWEIGHT

JOINT WEIGHT

.

LOAD 1 SEISMIC LOAD IN X DIR

1893 LOAD X 1

LOAD 2 SEISMIC LOAD IN Z DIR

1893 LOAD Z 1

LOAD 3 DL

MEMBER LOAD

UNI GY -5

LOAD 4 LL

Concrete Design Per IS13920

Section 9A1

9-42

MEMBER LOAD

. UNI GY -3

LOAD COMB 5 1.5(DL+LL)

3 1.5 4 1.5

LOAD COMB 6 1.2(DL+LL+SLX)

1 1.2 3 1.2 4 1.2

LOAD COMB 7 1.2(DL+LL-SLX)

1 1.2 3 1.2 4 -1.2

LOAD COMB 8 1.2(DL+LL+SLZ)

2 1.2 3 1.2 4 1.2

LOAD COMB 9 1.2(DL+LL-SLZ)

2 1.2 3 1.2 4 -1.2

PDELTA ANALYSIS

LOAD LIST 5 TO 9

START CONCRETE DESIGN

CODE IS13920

UNIT MMS NEWTON

FYMAIN 415 ALL

FC 20 ALL

MINMAIN 12 ALL

MAXMAIN 25 ALL

TRACK 2.0 ALL

*** Unfactored gravity load on members 110 to 112 is 8 t/m

(DL+LL) i.e. 78.46 New/mm

EUDL 78.46 MEMB 110 TO 112

** Members to be combined into one physical member

COMBINE 3.0 MEMB 110 TO 112

*** Plastic moment considered

PLASTIC 1.0 MEMB 110 TO 112

DESIGN BEAM 110 TO 112

DESIGN COLUMN

END CONCRETE DESIGN

FINISH

Section 9A1

9-43

9A1.6 Bar Combination

Initially the program selects only one bar to calculate the number

of bars required and area of steel provided at each section along

the length of the beam. Now two bar diameters can be specified to

calculate a combination of each bar to be provided at each section.

The syntax for bar combination is given below.

START BAR COMBINATION

MD1 <bar diameter> MEMB <member list>

MD2 <bar diameter> MEMB <member list>

END BAR COMBINATION

MD2 bar diameter should be greater than MD1 bar diameter. The

typical output for bar combination is shown below:

OUTPUT FOR BAR COMBINATION

----------------------------------------------------------------------------

| M A I N R E I N F O R C E M E N T |

----------------------------------------------------------------------------

SECTION | 0.0- 2166.7 | 2166.7- 6500.0 | 6500.0- 8666.7 |

| mm | mm | mm |

----------------------------------------------------------------------------

TOP | 6-20 + 1-25 | 2-20 + 1-25 | 2-20 |

| in 2 layer(s) | in 1 layer(s) | in 1 layer(s) |

Ast Reqd| 2330.22 | 1029.90 | 582.55 |

Prov| 2376.79 | 1119.64 | 628.57 |

Ld (mm) | 940.2 | 940.2 | 940.2 |

----------------------------------------------------------------------------

BOTTOM | 4-20 | 2-20 | 2-20 |

| in 1 layer(s) | in 1 layer(s) | in 1 layer(s) |

Ast Reqd| 1165.11 | 582.55 | 582.55 |

Prov| 1257.14 | 628.57 | 628.57 |

Ld (mm) | 940.2 | 940.2 | 940.2 |

----------------------------------------------------------------------------

The beam length is divided into three parts, two at its ends and one

at span. Ld gives the development length to be provided at the two

ends of each section.

Concrete Design Per IS13920

Section 9A1

9-44

Sample example showing calculation of design shear force as per

Clause 6.3.3

For Beam No. 1 and 2

Section Width b 250 mm

Depth D 500 mm

Characteristic Strength of Steel fy 415 N/sq. mm

Characteristic Strength of Concrete fck 20 N/sq. mm

Clear Cover 25 mm

Bar Diameter 12 mm

Effective Depth d 469 mm

Eudl w 6.5 N/sq. mm

Length L 4000 mm

Ast_Top_A 339.29 sq. mm

Ast_Bot_A 226.19 sq. mm

Ast_Top_B 226.19 sq. mm

Ast_Bot_B 339.29 sq. mm

Section 9A1

9-45

Steps

Calculation of Simple Shear

Simple shear from

gravity load on span =

Va = Vb = 1.2 * w * L / 2 = 15600N

Calculation of Moment Of Resistances Based On Area Of Steel Provided

Sagging Moment Of

Resistance of End A

Mu, as =

0.87 * fy * Ast_Bot_A * d *

( 1 - Ast_Bot_A * fy / b * d * fck)

= 36768130.05 N

Hogging Moment Of

Resistance of End A

Micah =

0.87 * fy * Ast_Top_A * d *

( 1 - Ast_Top_A * fy / b * d * fck)

= 54003057.45 N

Sagging Moment Of

Resistance of End A

Mu, bs =

0.87 * fy * Ast_Bot_B * d *

( 1 - Ast_Bot_B * fy / b * d * fck)

= 54003057.45 N

Hogging Moment Of

Resistance of End A

Mob =

0.87 * fy * Ast_Top_B * d * ( 1 -

Ast_Top_B* fy / b * d * fck)

= 36768130.05 N

Calculation of Shear Force Due To Formation Of Plastic Hinge At Both

Ends Of The Beam Plus The Factored Gravity Load On Span

FIG1: SWAY TO RIGHT

Vur,a = Va - 1.4 [ ( Mu,as + Mu,bh ) / L ] = -10137.69104 N

Vur,b = Va + 1.4 [ ( Mu,as + Mu,bh ) / L ] = 41337.69104 N

Concrete Design Per IS13920

Section 9A1

9-46

FIG2: SWAY TO LEFT

Vul,a = Va + 1.4 [ ( Mu,ah + Mu,bs ) / L ] = 53402.14022 N

Vul,b = Va - 1.4 [ ( Mu,ah + Mu,bs ) / L ] = - 22202.14022 N

Design Shear Force

Shear Force From Analysis At End A , Va,anl = 11.56 N

Design Shear Force At End A, Vu,a = Max ( Va,anl, Vur,a, Vul,a) = 53402.14022 N

Shear Force From Analysis At End B , Vb,anl = -6.44 N

Design Shear Force At End B, Vu,b = Max ( Vb,anl, Vur,b, Vul,b) = 41337.69104 N

For Beam No. 3

Section Width b 300 mm

Depth D 450 mm

Characteristic Strength of Steel fy 415 N/sq. mm

Characteristic Strength of Concrete fck 20 N/sq. mm

Clear Cover 25 mm

Bar Diameter 12 mm

Effective Depth d 419 mm

Eudl w 6.5 N/sq. mm

Length L 3000 mm

Ast_Top_A 226.19 sq. mm

Ast_Bot_A 339.29 sq. mm

Ast_Top_B 452.39 sq. mm

Ast_Bot_B 226.19 sq. mm

Section 9A1

9-47

Calculation of Simple Shear

Simple shear from

gravity load on span =

Va = Vb = 1.2 * w * L / 2 = 11700N

Calculation of Moment Of Resistances Based On Area Of Steel Provided

Sagging Moment Of

Resistance of End A

Mu,as =

0.87 * fy * Ast_Bot_A * d *

( 1 - Ast_Bot_A * fy / b * d * fck)

= 48452983 N

Hogging Moment Of

Resistance of End A

Mu,ah =

0.87 * fy * Ast_Top_A * d *

( 1 - Ast_Top_A * fy / b * d * fck)

= 32940364.5 N

Sagging Moment Of

Resistance of End A

Mu,bs =

0.87 * fy * Ast_Bot_B * d *

( 1 - Ast_Bot_B * fy / b * d * fck)

= 32940364.5 N

Hogging Moment Of

Resistance of End A

Mu,bh =

0.87 * fy * Ast_Top_B * d * ( 1 -

Ast_Top_B* fy / b * d * fck)

= 63326721.3 N

Calculation of Shear Force Due To Formation Of Plastic Hinge At Both

Ends Of The Beam Plus The Factored Gravity Load On Span

FIG1: SWAY TO RIGHT

Vur,a = Va - 1.4 [ ( Mu,as + Mu,bh ) / L ] = -40463.862 N

Vur,b = Va + 1.4 [ ( Mu,as + Mu,bh ) / L ] = 63863.862 N

Concrete Design Per IS13920

Section 9A1

9-48

Vul,a = Va + 1.4 [ ( Mu,ah + Mu,bs ) / L ] = 42444.3402 N

Vul,b = Va - 1.4 [ ( Mu,ah + Mu,bs ) / L ] = -15144.34 N

Design Shear Force

Shear Force From Analysis At End A , Va,anl =

-10.31 N

Design Shear Force At End A, Vu,a = Max ( Va,anl, Vur,a, Vul,a) = 42444.3402 N

Shear Force From Analysis At End B , Vb,anl =

-23.81 N

Design Shear Force At End B, Vu,b = Max ( Vb,anl, Vur,b, Vul,b) = 63863.862 N

9-49

Steel Design Per IS800

9B.1 Design Operations

STAAD contains a broad set of facilities for designing structural

members as individual components of an analyzed structure. The

member design facilities provide the user with the ability to carry

out a number of different design operations. These facilities may

be used selectively in accordance with the requirements of the

design problem. The operations to perform a design are:

- Specify the members and the load cases to be considered in the

design.

- Specify whether to perform code checking or member

selection.

- Specify design parameter values, if different from the default

values.

- Specify whether to perform member selection by optimization.

These operations may be repeated by the user any number of times

depending upon the design requirements. The entire ISI steel

section table is supported. Section 8B.13 describes the

specification of steel sections.

Section

9B

Steel Design Per IS800

Section 9B

9-50

9B.2 General Comments

This section presents some general statements regarding the

implementation of Indian Standard code of practice (IS:800-1984)

for structural steel design in STAAD. The design philosophy and

procedural logistics for member selection and code checking are

based upon the principles of allowable stress design. Two major

failure modes are recognized: failure by overstressing, and failure

by stability considerations. The flowing sections describe the

salient features of the allowable stresses being calculated and the

stability criteria being used. Members are proportioned to resist

the design loads without exceeding the allowable stresses and the

most economic section is selected on the basis of least weight

criteria. The code checking part of the program checks stability

and strength requirements and reports the critical loading

condition and the governing code criteria. It is generally assumed

that the user will take care of the detailing requirements like

provision of stiffeners and check the local effects such as flange

buckling and web crippling.

9B.3 Allowable Stresses

The member design and code checking in STAAD are based upon

the allowable stress design method as per IS:800 (1984). It is a

method for proportioning structural members using design loads

and forces, allowable stresses, and design limitations for the

appropriate material under service conditions. It would not be

possible to describe every aspect of IS:800 in this manual. This

section, however, will discuss the salient features of the allowable

stresses specified by IS:800 and implemented in STAAD.

Appropriate sections of IS:800 will be referenced during the

discussion of various types of allowable stresses.

Section 9B

9-51

9B.3.1 Axial Stress

Tensile Stress

The allowable tensile stress, as calculated in STAAD as per IS:800

is described below.

The permissible stress in axial tension, o

at

in MPa on the net

effective area of the sections shall not exceed

o

at

= 0.6 f

y

where,

f

y

= minimum yield stress of steel in Mpa

Compressive Stress

Allowable compressive stress on the gross section of axially

loaded compression members shall not exceed 0.6f

y

nor the

permissible stress o

ac

calculated based on the following formula:

(Clause: 5.1.1)

f f

n

cc

f

n

y

f

o =

+

0 6 .

[( )

( )

]

where,

o

ac

= Permissible stress in axial compr ession, in Mpa

f

y

= Yield stress of steel, in Mpa

f

cc

= Elastic critical stress in compression = t

2

E/

2

E = Modulus of elasticity of steel, 2 X 10

5

Mpa

=l/r = Slenderness ratio of the member, ratio of the effective

length to appropriate radius of gyration

n = A factor assumed as 1.4.

Steel Design Per IS800

Section 9B

9-52

9B.3.2 Bending Stress

The allowable bending stress in a member subjected to bending is

calculated based on the following formula: (Clause: 6.2.1)

o

bt

or

o

bc

= 0.66 f

y

where,

o

bt

= Bending stress in tension

o

bc

= Bending stress in compression

f

y

= Yield stress of steel, in MPa

For an I-beam or channel with equal flanges bent about the axis of

maximum strength (z-z axis), the maximum bending compressive

stress on the extreme fibre calculated on the effective section shall

not exceed the values of maximum permissible bending compressive

stress. The maximum permissible bending compressive stress shall be

obtained by the following formula: (Clause: 6.2.2)

6.2.3) : (Clause

]

)

f

y

(

n

)

f

cb

(

n

[

1/n

f y f cb

0.66

bc

+

=

where,

f

y

= Yield stress of steel, in Mpa

n = A factor assumed as 1.4.

f

cb

= Elastic critical stress in bending, calculated by the

following formula:

f k X k Y

c

c

= + [ ]

Section 9B

9-53

where,

X Y

IT

r D

MP

y

r

= + 1

1

20 1

Y =

26.5x10

( / )

k

1

= a coefficient to allow for reduction in thickness or

breadth of flanges between points of effective lateral

restraint and depends on , the ratio of the total area of

both flanges at the point of least bending moment to the

corresponding area at the point of greatest bending

moment between such points of restraint.

k

2

= a coefficient to allow for the inequality of flanges, and

depends on e, the ratio of the moment of inertia of the

compression flange alone to that of the sum of the moment

of the flanges each calculated about its own axis parallel to

the y-yaxis of the girder, at the point of maximum bending

moment.

1 = effective length of compression flange

r

y

= radius of gyration of the section about its axis of