Académique Documents

Professionnel Documents

Culture Documents

Proposing A Model For Production Agility Measurement, Using Industrial Automation Effectiveness, With Case Study in Amol School Facilities Company

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Proposing A Model For Production Agility Measurement, Using Industrial Automation Effectiveness, With Case Study in Amol School Facilities Company

Droits d'auteur :

Formats disponibles

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

Proposing a Model for Production Agility Measurement, Using Industrial Automation Effectiveness, with Case Study in Amol School Facilities Company

Shahab Hosseinzadeh Malek Jahan 1, Seyed Esmail Najafi 2, Ali Hosseinzadeh Kashan 3 and Nadia Bahadoran 4

1

Department of Industrial Engineering, Najafabad Branch, Islamic Azad University, Isfahan, Iran

Department of Industrial Engineering, Science and Research Branch, Islamic Azad University, Tehran, Iran Department of Industrial Engineering, Science and Research Branch, Islamic Azad University, Tehran, Iran

4

Department of Industrial Engineering, Science and Technology of Mazandaran, Babol, Iran

ABSTRACT

Following advent of new scopes of science and technology and their applications in industry, drastic progresses have occurred in this field; automation is an instance of such phenomena. Application of industrial automation plays a crucial part in making the producing companies agile. In fact, agility concept serves as an organizational guideline and model, and industrial automation is regarded as an approach for implementing this target. For this purpose in the current research, agility degrees of post-automation and pre-automation production are determined based on the proposed practical model through demonstrating statistical data observed before and after implementation of the automation process and partitioning these data on the diagram. In addition, impact of industrial automation is analyzed on agility indices of production. Then, the resulting Agilization value is measured.

Keywords: Agility Degree, Agilization, Industrial Automation.

1. INTRODUCTION

Drastic transformations have occurred in the scope of global industry, production, and commerce in the current industrial era and specifically during the last two decades. And, production and industrial units, due to their important role in this respect which influences growth and development of developing countries, shall welcome such transformations through benefiting from the newest science and technology findings to keep pace with the global trend and apply methods for improvement and promotion of their production and economic activities in quantitative and qualitative aspects. They can accordingly have competition ability in the present competitive environment where the commodity production cycles are shortening, clients' needs are getting diversified and delivery durations are decreasing. The traditional (conventional) production methods no longer meet the market requirements and items such as fast delivery, quality, flexibility, optimal design, reliability, and ultimately, productivity development and elimination of losses are new competitive weapons. For the same purpose and in order to achieve these goals, a new concept referred to as "automation" emerges, which signifies automatic control and is extensively applied in different industries nowadays. Application of automation in large, medium and small companies include utilization of robots and automated industrial machines which contributes to promotion of qualitative and quantitative level of products in developing countries through facilitation of production processes, but also leads to elimination (dismissal) of workforce in these countries. This transformation remarkably affects productivity promotion via enhancing quality, quantity, flexibility and reducing the costs. Industrial automation is an example of evolutionary and forward movement of human societies toward progress. Some research works have been conducted in this regard. For instance, Javarshian & Zenouzi (2003) in a paper entitled "Assessing Role of Automation in Promoting Productivity Level of Production Units" studied role of automation in promoting organizations' productivities through listing types of automation and identifying the key elements of this promotion. Also, in another part of their research, they investigated the obstacles and resistances against implementation of automation. At the end, a statistical comparison was presented concerning implementation

Volume 2, Issue 3, March 2013

Page 242

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

of automation based on data from different countries of the world [1]. In an article entitled "Efficiency of Industrial Automation of Complex-Structure Systems", Yaroshenko (2002) analyzed role and position of automation in complex-structure organizations in real and continuous times (without working hiatuses). They mentioned this case as a significant example in implementation of industrial automation and controllable systems [2]. Through a research concerning impact of high-speed machines in computerized and control and automation, Hon (2006) studied role and application of high-speed machines and numerical control in advancing the production process and operations. He analyzed the plans and requirements for progress of these techniques via exploring their demands in implementation of industrial automation [3]. Itskovich (2010) provides a verifiable and documented assessment of efficiency and agility in a paper entitled "Approach of Assessing Efficiency of Automation Systems" taking into accounts the initial data acquired through analyzing efficiency and performance of automation systems in their different lifecycles [4]. In a research article about computerized control for agile system, Brennan (2011) designed a modular system based on computerized control intended to coordinate the speed and change for establishing a flexible and also to realize productivity, which is an objective of all production systems, he also implied to intense global competitive pressures leading to transformations in the production system and movement toward automated production [5]. Zhlke and Ollinger (2012) also have viewed the system agility from the attitude of automation network and concepts of physical cyber systems as well as service-based architecture in a researchs work concerning agile automation systems based on physical cyber systems and service-based architecture [6]. The formerly conducted research works in this area have mainly either studied implementation of industrial automation in different production systems as well as the role of industrial automation in industries during their different life cycles or have analyzed relationship of this technology with numerical control and high-speed machines. Additionally, alternative studies have also considered the role of automation in improving productivity of the organization and its upcoming challenges. Nonetheless, in spite of all the research works conducted as of today in this scope, it seems that no research has ever been carried out to propose a model for measuring organizational agility using industrial automation. Industrial automation represents an approach for implementing agility (agilization) in the organization and is among the items affecting industrial indices. Hence, the current research deals with this subject. In the present research, after a brief literature review, the next section initially depicts automation and agility concepts in order to offer a general preface of the subject. Then, the problem is stated and the proposed model for measuring organizational agility is discussed. In the subsequent section, the research carried out in this field by the authors' research team in AMOL School Facilities Company, is analyzed as a case study and typical example of industrial automation implementation in developing countries. Finally, the necessary analyses are presented in the results and discussions sections concerning the obtained findings and the advantages.

2. AUTOMATION

Automation is derived from the Greek word "Automatos". Generally Overview, automation signifies application of machines in performing works that are risky, tiring and complicated or time-consuming for individuals. It is essentially based on methods, systems and skills. Automation is in fact a technology that connects with applications such as mechatronics and computer for production of commodities and provision of services. Automation represents operation processing using a variety of machineries and electronic and pneumatic instruments. Industrial automation is a system that oversees all industrial activities including the stages of design, selection, execution, installation, production and sales; it handles and controls the tasks intelligently. Official automation is also classified in this scope that could be effective for accelerating and unification process of organizational affairs along with company's solidarity. However, the present research focuses on industrial automation only.

3. AGILITY

Agility or speed of action of an organization means maximal flexibility such that not only it responds to the changes in product, market and customer's requirements, but also provides opportunities to be recognized as the superior organization among the opponents. Agile production signifies enabling the organization to respond to the continuous and unpredictable changes of the competitive environments [7]. Actually, agility originates from flexible production systems. It was primarily presumed that flexibility could be only achieved through implementing automation in construction and production aimed at better responding to variations in the volume or quantity of the products. But, this idea was then extended to a wider concept and concept of agility was devised as an organizational guideline and index. Agility is an extensive capability of the business which incorporates organizational structures, information systems, transportation processes and also people's attitudes [8]. Agility means taking use of the knowledge of market and

Volume 2, Issue 3, March 2013

Page 243

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

virtual companies for benefiting from profitable opportunities in instable markets [9].

4. STATEMENT OF PROBLEM

Agility essentially means ability of a company to survive in a competitive environment with predicted and continuous changes, and in other words, quick responsiveness to continuous market changes based on customers' variable tastes and values for new products and services. In the first look, agility seems to be the same as flexibility while the latter refers to production capability of different products in a joint production line, but the former signifies capability of changing from one production line to another among the different production lines. Change is an acceptable and routine fact for an agile manager. The main concerns of such manager are reduction of the final cost, improvement of product quality, reduction of delivery duration, change in production volume, and further satisfaction of customers' requirements. These items altogether constitute the agility dimensions. These dimensions were proposed according to the reference model of agile production by MERIDITE and FRANCIS and include: agile strategy, agile processes, agile relations, and agile personnel (staff or manpower).

5. METHODOLOGY

5.1. Proposing a Theoretical Model Automation and Agilization of the organization in the current competitive era and acquisition of its abundant advantages for overtaking the opponents and gaining further profit and credit have encouraged the organizations to take steps in this respect by means of employing researchers and novel technologies. Actually, agility of any organization, particularly production organizations, is reliant on rapid responsiveness, flexibility, unified process and elimination of losses. Automation can also be among the highly useful tools for organizational agility. Application of automation might be attributed to the absence of skilled and accessible manpower and/or high costs of the workforce that orientates the organizations to implement this plan to overcome the aforementioned problems. Yet, the numerous advantages of technology shall not be neglected. The following items can be listed among the advantages of implementing this plan in the respective company: Reduction of the production process duration: Implementation of industrial automation enables faster response to the consumers' needs in addition to fluent and easy implementation of production operations that in turn leads to rapid execution of the process and prevention from waste of time. Thereby, customer's consent as the priority of all organizations will be also attracted. Reduction of costs: Besides reduction of costs associated with payments to the human workforce that has been working prior to automation, this transformation considerably lowers rate of waste production due to proper execution of the process and prevention from human errors, and consequently, the price of raw materials is reduced as well. Furthermore, instantaneous manufacturing and implementation of just-in-time production will become possible. Elimination and reduction of wastes results in reduction of costs, and ultimately, increase of profitability. Overall, it can be stated that remarkable reduction of costs was observed in the present study. Facilitation of procedures: Through automation of the process, the operational procedures are remarkably facilitated and just one operator will be present in the production line. Quality improvement: By implementing the automation process, different operations are executed more accurately and rapidly and quality of products, which is of great significance for the sales, reaches a highly favorable level. Thus, further sales of the products and more profits are gained for the company besides the customers' satisfaction. Increase in production capacity: Production capacity or quantity is also increased with automation of the production line, enabling the company to achieve its suitable production level for meeting the current market requirements and also converting the potential markets into real achievements and maintaining its competitive position in the market followed by gaining further profits. Reduction of the needed space: Automation provides the possibility for the process to be carried out in a smaller space, and of course, at a higher quality and larger quantity through industrializing the cities and restricting the innovation space, or in other words, shrinkage of the company's operational and working area. Other advantages achieved via this plan include enhancement of control level through further supervision and planning, identicalness of product quality thanks to elimination of human errors, improved flexibility due to programmability of the plan, mitigation of environmental pollution, which is one of the major concerns of human in the present century. By proposing a practical version of the respective model in the current research, impact of industrial automation on the agility of production line is analyzed and agility degree is measured based on the research model.

Volume 2, Issue 3, March 2013

Page 244

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

Figure 1 The practical model proposed in this research A) Agile strategy: This component of model is focused on agility dimensions. Sub-scale of discipline determines organizations policies. Sub-scale of strategic commitment reflects strategic commitment and sub-scale of control and supervision is also used for controlling organizations policies in alignment with the major strategy of the organization. B) Agile processes: This component of model focuses on processes of the organization that act as backup for the organizational agility. Sub-scale of fast solution to the problem for coping with the probable variations and rich and ample information systems are utilized for participatory decision-making in the system; a flexible system is in turn composed of systems and software. C) Agile relations: This component of model emphasizes the external relations of the organization. Sub-scale of operational partnerships is for benefitting from resources and capabilities of two or several organizations. Sub-scale of committed providers is among significant agility elements that improves organizations competence. Sub-scale of customers profound appreciation results in loyalty of the current and also potential customers of the organization. D) Agile personnel: This component of model concentrates on managing the organizations manpower. Sub-scale of fast and capable decision-making leads to increase in the speed of reaction to changes. Sub-scale of multi-purpose and flexible personnel also contributes to doubling of organizations capability in production process. Sub-scale of continuous learning -as one of the most important agility factors - is also prerequisite of a learner company and a consistent source of agility. 5.2. Measuring Agility Degree using the Proposed Model Now, to assess the research result, sum of companys performance in terms of major components represents the degree and category of the companys agility. Hence, Figure 1 illustrates how to measure the agility degree taking into account the major and minor components in the recommended model through the following formulas.

n Ai

s 1 m

Ns

(1)

AD

i 1

Ai

(2) AD: Purity degree Ai: Performance of the i-th major component Ns: Performance of the s-th minor component Then, to measure the agility degree, in the first step, performance levels of sub-scales of each component are calculated from the major components. To do so, a continuum from 1 to 100 is illustrated and all minor components are assessed in the range of this spectrum. Based on this strategy, first the permissible upper and lower limits of agility for all minor components are determined.

Volume 2, Issue 3, March 2013

Page 245

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

Each percentile of this continuum is the basis for scores of minor agility components. It means that performance of industrial units for each sub-scale is a value between the respective standards which equals companys score caused by applying the sub-scale. Nevertheless, with regard to some components such as volume of the inputs that are negatively correlated to increase in the companys agility degree, it must be noted that the continuum direction is inversed for alignment of the negative data. And in the inverse state, scores of components is computed so as to nullify the negative impact of correlation of these components on production agility.

AD n Ns i 1s 1 m

(3)

After calculation of all sub-scales, sum of scores of all calculated minor components and performance scores of each major component are obtained according to Formula (1). Following calculation of performance for all major components, it comes to evaluate the companys agility degree. In this step, sum of agility scores of agile components obtained from the former step- are calculated through formula (2) and the companys total score is accordingly determined. The final value is positive, which is designated agility degree in the present research.

6. CASE STUDY ANALYSIS

Production companies, including Amol School Facilities Company in which the current plant was implemented, are seeking an Agilization of their production and sales process to achieve goals like cost reduction, flexibility, qualitative and quantitative improvement. The respective company follows commodity-production style (product-based), and accordingly, unification of production process will play an important role in operation speed, increase of production capacity, reduction of production duration and productivity improvement. Amol School Facilities Company manufactures products such as student desk and seat, university student seat, dormitory metal wardrobe, computer chair, and a variety of other seats. The whole production includes school and university school seat and desks. Previously, production cycle was as shown below:

Figure 2 Executive procedures of production process before automation But, our research team's plan implemented in this company consists of two general parts: layout design and industrial automation. Having collected the needed data such as: precise identification of product, manufacturing mechanism of each section, number of equipment, function of each equipment, number of operators in each section and equipment, material transportation paths including delivery of the initial material and loading of the final product, and other diverse information, the team all along got full knowledge of the process and then commenced the design stage for implementation by processing the raw data and the resulting acquired information. Parallel to the layout design team that deals with information processing and design of the factory's layout, the automation team started designing equipment for automating the following sections: de-lubrication, phosphate treatment, rinsing, and drying and coloring (painting or drying) system.

Volume 2, Issue 3, March 2013

Page 246

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

Figure 3 Executive procedures of production process after automation After completion of research team's job and preparation of the layout design and industrial automation equipment, the operational work was performed in site for reforming the layout of the former equipment and installation of the newly designed industrial automation equipment. As such, the new process resumed working in a novel context and with more agility. 6.1. Statistical Observations Before the implementation of layout design and industrial automation, 28 operators were averagely working in the entire operational sectors of the company; implementation of the respective plan reduced the operators to 17 and this reduction of operators signifies reduction in manpower expenses, and as a result, an increase of profit for the company. The following table demonstrates the working sectors. Table 1 Four sectors of the company Set Section A Section B Section C Section D Cutting Press Welding De fat Phosphate Rinse Dryer Spray paint Dryer Press Cutting Sandy Handling Nylon Wrapping Assembly Sub Set

Different sections in each sector, and in the higher level, the four sectors represent the constituents of the company and each commensurately plays its own crucial role in the production process. Accordingly, appropriate and efficient linkages between them and absence of bottlenecks in these relations coupled with sufficient number of personnel is greatly significant in this regard. Comparative diagram of the number of personnel (operators) before and after implementing automation is illustrated in Figure 4, perfectly indicating how manpower has reduced in number.

Figure 4 Diagram of number of personnel before and after implementation of automation

Volume 2, Issue 3, March 2013

Page 247

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

As previously discussed, automation process increases the production capacity via elimination of losses and hence enhances the company's output, i.e., the final product. Having carried out industrial automation in the respective company, average production capacity is approximately 3500 with the current 17 operators while the former production capacity was nearly half of this value with the number of operators working before the automation.

Figure 5 comparative diagrams of production capacity (a) and manpower (b) Regarding the coloring quality, it must be also stated that quality of the product's color or paint was remarkably enhanced such that it cannot be compared to the pre-automation status. Prior to implementing the automation, the product failed to have the desirable quality, but uniform color spraying and homogeneous dye surface after automation contributes to favorable quality of the final product, attracting further customers' satisfaction that results in more profit for the company and continuation of the production. 6.2. Measuring the Agility Degree Extent of Agilization through automation process can be assessed by calculating the agility degrees before and after implementing automation. A suitable range of this value that might be related to company's objectives could attract the satisfaction of the company and customers. In this step, the desired value can be achieved by using hierarchical system of scales and sub-scales in the current research model and via benefiting from the viewpoints of industrial and academic elites. This parameter is evaluated twice (before and after automation) using the following formulas. Value of agility degree before automation process in the production line:

m AD previous n [ Ns previous ] 300

i 1s 1

(4) Value of agility degree after automation process in the production line:

m ADnext n [ Ns next ] 820

i 1s 1

(5)

As observed, value of agility degree, as the result of measuring this parameter based on four major indices (scales) and 12 sub-scales, equals 300 before implementing automation, which indicates an unfavorable status according to Table 2. In contrast, this value equals 820 following implementation of automation, which is suggestive of a tolerable status. Table 2 Degree, status, and percentage of agility O Agility Status of Agility 1-240 Highly Undesirable 240-480 Undesirable 480-720 Average 720-960 Tolerable 960-1200 Favorable

Volume 2, Issue 3, March 2013

Page 248

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

Agility percent Basic Agility Agility Relative Excellent Agility

Given the agility degree values before and after automation process, the value of Agility degree acquired through formula 6 can be evaluated now. The obtained value designated as "Agilization value" is a positive value.

m Agility deg AD AD next AD previous m n [ Ns next Ns previous ] 520 n [ Ns next ] m n [ Ns previous ]

i 1s 1

i 1s 1

(6)

i 1s 1

This value, i.e. 520 is the Agilization degree resulting from automation process which is an acceptable and excellent value for the respective company.

7. DISCUSSION AND CONCLUSION

With industrial growth of developing countries and need to application of novel technologies in this scope for reducing costs and increasing profitability, particularly during the recent decade that economic growths of many countries have encountered problems and even declined, it further seems necessary to provide the contexts of just-in-time and agile production by taking a comprehensive and quality and quantity-based approach through implementation of plans like industrial and even official automation. Accordingly, the basic requirements for modernization of industry in these countries will be guaranteed. As an endorsement for this approach, implementation of automation in Amol School Facilities Company through avoiding traditional and manual production led to reduction in costs of time loss, raw materials and human force as well as mitigation of human errors and its impact on the product quality. The clients' dissatisfaction was consequently alleviated to a great extent and also the production capacity increased contributing to more financial achievements for the company. Measurement of agility degree is a means to assess the Agilization process of the companies and could serve as a practical and useful index for strategic and overall management of the organization. Further research works in different industries need to be conducted for future demands in this respect. Their findings shall be applied and extrapolated to other similar companies aimed at advancing the industrialization trend of countries and their progressive economic growth.

REFERENCES

[1] Javershian, Bita., Zenouzi, Aseman., Assessing role of automation in promotion of productivity level of production units, Fourth Conference of Research and Development Centers of Mines and Industries Development, 2003. [2] Yaroshenko, A. V., Automation of the recovery of efficiency of complex structure system, Automation and Remote Control, Vol. 63, No. 7, 2002, pp. 1191-1198. [3] Hon, KKB., The impact of high speed machining on computing and automation, International Journal of automation and computing, No.1, 2006, pp.63-68. [4] Itskovich, E. L., Methods of efficiency evolution of automation system, Automation and Remote Control, Vol. 63, No. 7, 2010, pp. 1230-1239. [5] Brennan. R. W., Computer control for agile manufacturing systems, Agile Manufacturing: The 21st Century Competitive Strategy, 2011, pp. 499514. [6] Zhlke, D. and Ollinger, L., Agile automation systems based on cyber-physical systems and service-oriented architectures, Advances in Automation and Robotics, Vol. 1, LNEE. 122, 2012, pp. 567-574. [7] Mottaghi.H., Production and Operations Management, Kiomars Publications, 2004. [8] Christopher, M. and Towill, D.R., Supply Chain Migration from Lean and Functional to Agile and Customized, International Journal of Supply Chain Management, vol. 5, No. 4, 2000, pp 206-213. [9] Naylor,J.B., Naim. M, Berry.D., Leagility: Integrating the lean and agile manufacturing paradigms in the total supply chain, International Journal of Production Economics No. 62, 1999, pp107118.

Volume 2, Issue 3, March 2013

Page 249

International Journal of Application or Innovation in Engineering & Management (IJAIEM)

Web Site: www.ijaiem.org Email: editor@ijaiem.org, editorijaiem@gmail.com Volume 2, Issue 3, March 2013 ISSN 2319 - 4847

CORRESPONDING AUTHOR

Shahab Hosseinzadeh Malek Jahan graduated in Iran with BS degree Industrial Engineering in 2010 at MIT University, Babol, Iran. Currently, his MSc Student of Industrial Engineering at Najafabad Branch, Islamic Azad University, Isfahan, Iran. He is Members of Elite of Young Researchers Club Iran from the year 2011 so far. He is interested in Lean-Agile System, multi criteria decision making, Discrete Event simulation and Engineering Management. His published research articles appear in International Conference on Innovation, Engineering Management and Technology-Amsterdam (ICIEMT 2012), Statistical Conference-Tehran (ISC11) and Industrial engineering & system conference-Isfahan (IESC2012), International Conference on Traffic and Transportation Engineering (ICTTE2013).

OTHERS AUTHORS

Seyed Esmail Najafi is an Assistant Professor of Industrial Engineering Department at the Islamic Azad University, Science and Research Branch in Tehran, Iran. He received his B.A. in Power & Water University of Technology (PWUT), his M.S. in Islamic Azad University, Science and Research Branch and his Ph.D. in Industrial Engineering from Science and Research Branch in Tehran, Iran. His research interests decision making, Engineering management and strategic management. His published research articles appear in American Journal of Scientific Research, International Journal of Business and Commerce. Ali Hosseinzadeh kashan received his Ph.D. in Industrial Engineering from Amirkabir University of Technology, Tehran, Iran and has been working in the field of applied optimization since 2004. His research interests include combinatorial optimization with special emphasis on production scheduling, facility location and grouping problems. His current research focuses on developing approximation algorithms for real world engineering design problems. He has published over 25 refereed scientific papers, where some of them introduce new algorithms to optimization. Kashan has served as a referee for several outstanding journals such as: IEEE Transactions on Evolutionary Computations, Omega, Computers & Operations Research, Journal of the Operational Research Society, Computers & Industrial Engineering, and International Journal of Production Research. He has received several awards from Iran National Elite Foundation and holds a post doctoral fellowship at Amirkabir University of Technology with financial support of that Foundation. Nadia Bahadoran graduated in Iran with BS degree Industrial Engineering in 2011 at MIT University, Babol, Iran. Currently, she is MSc. Student of Industrial Engineering at Science and Technology of Mazandaran, Babol, Iran. She is interested in Lean-Agile System, multi criteria decision making, Discrete Event simulation, linear programming and Engineering management. His published research articles appear in Industrial engineering & system conference-Isfahan (iesc2012), International Conference on Traffic and Transportation Engineering (ICTTE2013).

Volume 2, Issue 3, March 2013

Page 250

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The Mexican Innovation System: A System's Dynamics PerspectiveDocument12 pagesThe Mexican Innovation System: A System's Dynamics PerspectiveInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- An Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewDocument9 pagesAn Importance and Advancement of QSAR Parameters in Modern Drug Design: A ReviewInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Customer Satisfaction A Pillar of Total Quality ManagementDocument9 pagesCustomer Satisfaction A Pillar of Total Quality ManagementInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Experimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterDocument7 pagesExperimental Investigations On K/s Values of Remazol Reactive Dyes Used For Dyeing of Cotton Fabric With Recycled WastewaterInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Detection of Malicious Web Contents Using Machine and Deep Learning ApproachesDocument6 pagesDetection of Malicious Web Contents Using Machine and Deep Learning ApproachesInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Design and Detection of Fruits and Vegetable Spoiled Detetction SystemDocument8 pagesDesign and Detection of Fruits and Vegetable Spoiled Detetction SystemInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- THE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSDocument7 pagesTHE TOPOLOGICAL INDICES AND PHYSICAL PROPERTIES OF n-HEPTANE ISOMERSInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Study of Customer Experience and Uses of Uber Cab Services in MumbaiDocument12 pagesStudy of Customer Experience and Uses of Uber Cab Services in MumbaiInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Soil Stabilization of Road by Using Spent WashDocument7 pagesSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Staycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityDocument10 pagesStaycation As A Marketing Tool For Survival Post Covid-19 in Five Star Hotels in Pune CityInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Analysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyDocument6 pagesAnalysis of Product Reliability Using Failure Mode Effect Critical Analysis (FMECA) - Case StudyInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Challenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19Document10 pagesChallenges Faced by Speciality Restaurants in Pune City To Retain Employees During and Post COVID-19International Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Performance of Short Transmission Line Using Mathematical MethodDocument8 pagesPerformance of Short Transmission Line Using Mathematical MethodInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Impact of Effective Communication To Enhance Management SkillsDocument6 pagesThe Impact of Effective Communication To Enhance Management SkillsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- A Digital Record For Privacy and Security in Internet of ThingsDocument10 pagesA Digital Record For Privacy and Security in Internet of ThingsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- A Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)Document10 pagesA Comparative Analysis of Two Biggest Upi Paymentapps: Bhim and Google Pay (Tez)International Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Synthetic Datasets For Myocardial Infarction Based On Actual DatasetsDocument9 pagesSynthetic Datasets For Myocardial Infarction Based On Actual DatasetsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Advanced Load Flow Study and Stability Analysis of A Real Time SystemDocument8 pagesAdvanced Load Flow Study and Stability Analysis of A Real Time SystemInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- A Deep Learning Based Assistant For The Visually ImpairedDocument11 pagesA Deep Learning Based Assistant For The Visually ImpairedInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Secured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpDocument12 pagesSecured Contactless Atm Transaction During Pandemics With Feasible Time Constraint and Pattern For OtpInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Anchoring of Inflation Expectations and Monetary Policy Transparency in IndiaDocument9 pagesAnchoring of Inflation Expectations and Monetary Policy Transparency in IndiaInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Impact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryDocument8 pagesImpact of Covid-19 On Employment Opportunities For Fresh Graduates in Hospitality &tourism IndustryInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Predicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsDocument10 pagesPredicting The Effect of Fineparticulate Matter (PM2.5) On Anecosystemincludingclimate, Plants and Human Health Using MachinelearningmethodsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Plagiarism Ragavn EX CECRI DirectorDocument4 pagesPlagiarism Ragavn EX CECRI Directorsivas54Pas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Mechanical Engineering 4 Year PlanDocument2 pagesMechanical Engineering 4 Year PlanMark OsbornePas encore d'évaluation

- Kasiraja ResumeDocument2 pagesKasiraja Resumekumar pPas encore d'évaluation

- Mechanical EngineeringDocument622 pagesMechanical Engineeringganesan 001186% (7)

- Anurag Anand CV Data Scientist Mu-SigmaDocument2 pagesAnurag Anand CV Data Scientist Mu-SigmaAnurag AnandPas encore d'évaluation

- ASME PTC 22 (1997) Gas Turbines PDFDocument46 pagesASME PTC 22 (1997) Gas Turbines PDFDaniel OrigelPas encore d'évaluation

- Method EngineeringDocument9 pagesMethod EngineeringChiaki Hidayah100% (1)

- Autonomic Computing - Principles, Design and ImplementationDocument298 pagesAutonomic Computing - Principles, Design and ImplementationJack Naquib Echevarria Cisneros50% (2)

- Engineering Program ListDocument115 pagesEngineering Program ListNoman HassanPas encore d'évaluation

- Stakeholder Management - Case StudyDocument11 pagesStakeholder Management - Case StudyAkki BakkiPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 8TH SEM PRO Ack, CertificateDocument3 pages8TH SEM PRO Ack, Certificateprinceofnation_21Pas encore d'évaluation

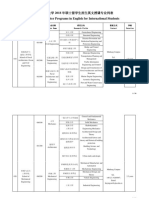

- SJTU 2018 Master Programs in English For International StudentsDocument10 pagesSJTU 2018 Master Programs in English For International StudentshashimhasnainhadiPas encore d'évaluation

- Asme B31-2Document71 pagesAsme B31-2mcpaoloniPas encore d'évaluation

- Prime Contracts To Large BusinessesDocument83 pagesPrime Contracts To Large BusinessesTekskills MKPas encore d'évaluation

- Classroom Observation Schedule.2018Document4 pagesClassroom Observation Schedule.2018Saiza BarrientosPas encore d'évaluation

- HKU Admission Scores - OdsDocument12 pagesHKU Admission Scores - OdsbobokakaPas encore d'évaluation

- Guidance Notes For Ceng Candidates 67285Document75 pagesGuidance Notes For Ceng Candidates 67285johnbullasPas encore d'évaluation

- Rizal Tech University PICE-CESS Christmas party committeesDocument1 pageRizal Tech University PICE-CESS Christmas party committeesraymartPas encore d'évaluation

- Leaflet - Ic-Quest 2015 - BdceDocument2 pagesLeaflet - Ic-Quest 2015 - BdceSaurabh PednekarPas encore d'évaluation

- Civil Handbook Web ContentDocument22 pagesCivil Handbook Web ContentHarish Malladihalli0% (1)

- Engineering Rubric For SO (E) Modern Tool UsageDocument1 pageEngineering Rubric For SO (E) Modern Tool UsageDaniel Bobis100% (1)

- Senior High School (SHS) Subject Offerings Per Track/Strand: St. Camillus College of Manaoag Foundation, IncDocument6 pagesSenior High School (SHS) Subject Offerings Per Track/Strand: St. Camillus College of Manaoag Foundation, Inctabilin100% (1)

- Forest City Ratner Modular Opportunity Brief, 1/6/12Document5 pagesForest City Ratner Modular Opportunity Brief, 1/6/12Norman Oder100% (1)

- Paavai Engineering College B.Tech Food Technology 2nd Sem Results 2020Document1 pagePaavai Engineering College B.Tech Food Technology 2nd Sem Results 2020pravincrPas encore d'évaluation

- Nust Institute of Civil Engineering (NICE) : Course CurriculumDocument2 pagesNust Institute of Civil Engineering (NICE) : Course CurriculumSAK100% (1)

- Ssss SN&N Jun Sept 2010 IssueDocument68 pagesSsss SN&N Jun Sept 2010 IssueKTMOPas encore d'évaluation

- MSG 00305Document15 pagesMSG 00305Nazeeh Abdulrhman AlbokaryPas encore d'évaluation

- Saep 1650Document21 pagesSaep 1650Branko_62Pas encore d'évaluation

- Student GuideDocument100 pagesStudent GuideCiscoexam Fdo100% (1)

- A Technical History of The SEIDocument329 pagesA Technical History of The SEISoftware Engineering Institute PublicationsPas encore d'évaluation

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)D'EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Évaluation : 5 sur 5 étoiles5/5 (2)

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressD'EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressÉvaluation : 5 sur 5 étoiles5/5 (1)