Académique Documents

Professionnel Documents

Culture Documents

Retrieval of Stuck Pig PDF

Transféré par

yasir_anjumTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Retrieval of Stuck Pig PDF

Transféré par

yasir_anjumDroits d'auteur :

Formats disponibles

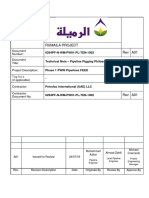

RETRIEVAL OF STUCK PIG IN 8 GAS PIPELINE

By Yasir Anjum

The objectives of "pigging" a pipeline include not only running pigs for maintaining continuous operation and optimizing efficiency, but to do the work without sticking the pig. Getting the pig stuck rarely happens in a pipeline which is pigged routinely, but can happen when pigging frequency of a pipeline is not adequate, or because of maintenance issues or if for any reason pipeline could not be pigged for a long time. Well design pigging programs are required in these situations. It is noteworthy here that cleaning pig run of a pipeline which is not pigged for quiet long period, needs to be progressive rather than aggressive. Jumping intermediate pigging runs of well-defined cleaning program may result in excess debris being carried out with pig & results in plug formation in front of pig, and often a stuck pig situation is encountered. If a pig becomes stuck, it is important to identify the cause. Restoring the flow in the line is the first priority. Usually one of two conditions exists when a pig is stuck: fluid bypasses around the pig, or there is a complete blockage of the flow. Before performing any technique for pig retrieval, a detailed analysis of plug formation and the hazards involved in it must be identified. A stuck pig or formation of a hydrate plug can generate fast transient movements of large solid objects in natural gas pipelines, and may cause inadequate control of pig velocity during receiving operations. Creating a pressure jump across a stuck pig can dislodge it but can also create a sudden displacement; propelling the pig at high velocities and potentially damaging pipe bends or elbows. Generally following practices are followed as indicated in order: Increase the flow rate and line pressure, but do not exceed MAOP of the pipeline. Reduce pressure from the line by venting towards the launcher as well as receiver. Reducing pressure allows the pig to relax to its original shape. Allow pressure to dissipate. After that again re-pressure the line in an attempt to drive the pig through the restriction and venting from the receiver side, repeating five to ten times. In worst case we need to remove the blockage ahead of the PIG for which we first need to find its exact physical location on ground. Several methods such as using Magnetic compass, PIDS, Radiography, Boroscopic inspection, hammering etc. are employed for confirming the location. We carry out Hot Tapping at suitable positions to vent out the debris through suitable venting arrangement. After that again re-pressure the line in an attempt to drive the pig through the restriction. In case above method fails, we go for Cutting out the pipeline to retrieve the PIG from the pipeline. This presentation also includes a case study on recovery of stuck pig in CIL 8 Gas Pipeline in southern section of pipeline.

Vous aimerez peut-être aussi

- PiggingDocument18 pagesPiggingمحمد العراقي50% (2)

- An Introduction To Pipeline Pigging2Document6 pagesAn Introduction To Pipeline Pigging2Muhammad Awais IshaquePas encore d'évaluation

- Pipeline Pigging: o o o o o oDocument7 pagesPipeline Pigging: o o o o o oAnonymous 70lCzDJv100% (1)

- Pig Launcher and ReceiverDocument5 pagesPig Launcher and ReceiverEbby Onyekwe88% (8)

- Why Pigs Get StuckDocument16 pagesWhy Pigs Get StuckAmir HoseiniPas encore d'évaluation

- PiggingDocument5 pagesPiggingDendi AriyonoPas encore d'évaluation

- Pig SignallersDocument10 pagesPig Signallersprincensikan23Pas encore d'évaluation

- ILI Pipeline CostDocument3 pagesILI Pipeline CostyogacruisePas encore d'évaluation

- Pipeline Pigging and CleaninDocument11 pagesPipeline Pigging and CleaninVidyasen67% (3)

- Pipeline Drying ProceduresDocument6 pagesPipeline Drying Proceduresronald rodrigoPas encore d'évaluation

- Pig SignallersDocument10 pagesPig SignallersFebryn NgkPas encore d'évaluation

- How To Detect Pigging Stuck LocationDocument5 pagesHow To Detect Pigging Stuck LocationyogacruisePas encore d'évaluation

- Case Studies in Pre Inspection: CleaningDocument4 pagesCase Studies in Pre Inspection: CleaningSamtron610Pas encore d'évaluation

- 03 Selecting The Right PigDocument36 pages03 Selecting The Right PigAdmin MigasPas encore d'évaluation

- 2001 Speed Control of Pig Using Bypass Flow in Natural Gas Pipeline PDFDocument6 pages2001 Speed Control of Pig Using Bypass Flow in Natural Gas Pipeline PDFvictorc.galvaoPas encore d'évaluation

- A Tale of Three Pigs: Pigging Incident 1Document4 pagesA Tale of Three Pigs: Pigging Incident 1biksutong100% (1)

- Cleaning and Smart PiggingDocument8 pagesCleaning and Smart PiggingAde Aris SatriaPas encore d'évaluation

- 38G - Pipeline PiggingDocument23 pages38G - Pipeline Piggingambadaeng100% (1)

- 2013 04 ROSEN SlidesDocument29 pages2013 04 ROSEN SlidesAnonymous WCG2HjPybJ100% (1)

- Black Powder in PipelineDocument3 pagesBlack Powder in Pipelinesrlodhi100% (1)

- 42 Inch Flare Hot TappingDocument4 pages42 Inch Flare Hot Tappingavi07me4uPas encore d'évaluation

- 0804 - Pipeline InstallationDocument29 pages0804 - Pipeline Installationahmed abdohPas encore d'évaluation

- MDPE Work ProcedureDocument18 pagesMDPE Work ProcedureANURAG YADAVPas encore d'évaluation

- An Introduction To Pipeline PiggingDocument12 pagesAn Introduction To Pipeline Piggingrobiged100% (2)

- Process Pigging SystemDocument22 pagesProcess Pigging Systemkingathur26681100% (1)

- How Does Pipeline Pigging WorkDocument3 pagesHow Does Pipeline Pigging WorkrajasekharboPas encore d'évaluation

- Pig Handling System Brochure PDFDocument6 pagesPig Handling System Brochure PDFKRUNAL SHAHPas encore d'évaluation

- Pigging MFL or Ut TechniqueDocument13 pagesPigging MFL or Ut Techniquesathish_iyengarPas encore d'évaluation

- Pipeline Pigging SpecificationDocument5 pagesPipeline Pigging SpecificationGhofurRiyantoPas encore d'évaluation

- Nitrogen MsdsDocument6 pagesNitrogen MsdssalcabesPas encore d'évaluation

- Line BreakDocument30 pagesLine Breakmanoranjan singhPas encore d'évaluation

- Tank Cleaning ProcessDocument7 pagesTank Cleaning ProcessgbogboiwePas encore d'évaluation

- Chemical Assisted Pipeline Pigging Cleaning OperationsDocument7 pagesChemical Assisted Pipeline Pigging Cleaning OperationsfernandoiescPas encore d'évaluation

- Typical Acid Cleaning Procedure For Compressor LinesDocument1 pageTypical Acid Cleaning Procedure For Compressor Linesrenjithv_4Pas encore d'évaluation

- Pipeline Integrity and Difficult To Pig PipelinesDocument158 pagesPipeline Integrity and Difficult To Pig Pipelinesfrank71FERRERPas encore d'évaluation

- Compressed Gas Cylinders PowerPointDocument20 pagesCompressed Gas Cylinders PowerPointInspire KharianPas encore d'évaluation

- Un Pig Gable PipelinesDocument2 pagesUn Pig Gable Pipelinesqammas100% (1)

- Pipeline PiggingDocument28 pagesPipeline PiggingYehia Hassan100% (1)

- MS-HKSS-Pigging Testing Drying Rev A - YNB 16''Document64 pagesMS-HKSS-Pigging Testing Drying Rev A - YNB 16''AAISATPas encore d'évaluation

- 6 MFL Tool Spec Rev 3.5Document1 page6 MFL Tool Spec Rev 3.5fadialkasrawiPas encore d'évaluation

- 0294PF-N-WM-PW01-PL-TEN-1002 - A01 Technical Note-Pipeline Pigging PhilosophyDocument15 pages0294PF-N-WM-PW01-PL-TEN-1002 - A01 Technical Note-Pipeline Pigging PhilosophyfadhilPas encore d'évaluation

- Pipeline DryingDocument2 pagesPipeline DryingAdan Farias de PinaPas encore d'évaluation

- Pipeline PiggingDocument14 pagesPipeline PiggingSumit Kaushik100% (1)

- Pipeline Pigging BrochureDocument14 pagesPipeline Pigging BrochureMiguel Gonzalez100% (1)

- Pigging MethodDocument9 pagesPigging MethodOrdu Henry OnyebuchukwuPas encore d'évaluation

- Pipeline Pigging Procedures For Polmaz LimitedDocument10 pagesPipeline Pigging Procedures For Polmaz Limitedobuse100% (2)

- Pigging IncidentDocument7 pagesPigging IncidentSajid SattarPas encore d'évaluation

- OES Crude Tank Cleaning ProceduresDocument3 pagesOES Crude Tank Cleaning ProceduresBach DoanPas encore d'évaluation

- Cleaning Pig Designs and ApplicationsDocument24 pagesCleaning Pig Designs and ApplicationsChristopher BrownPas encore d'évaluation

- Decommissioning Guidance 0Document22 pagesDecommissioning Guidance 0Bilal AhmadPas encore d'évaluation

- Anexo 9 Internal Floating RoofDocument4 pagesAnexo 9 Internal Floating RoofAdilmar E. Natãny100% (1)

- Repair Procedure Slug CatcherDocument4 pagesRepair Procedure Slug Catchershabbir626100% (1)

- Positive Pressure: HabitatDocument8 pagesPositive Pressure: HabitatgopuPas encore d'évaluation

- Introduction PSVDocument11 pagesIntroduction PSVNguyen Anh TungPas encore d'évaluation

- Pigging ProcedureDocument11 pagesPigging ProcedureEndika Alfan100% (9)

- Pigging TheoryDocument10 pagesPigging TheoryTarunPas encore d'évaluation

- AMPLDocument15 pagesAMPLAMitPas encore d'évaluation

- PiggingDocument47 pagesPiggingMohamed Adam100% (6)

- Pig Launching & Receiving ProceduresDocument11 pagesPig Launching & Receiving ProceduresBalasubramanianPas encore d'évaluation

- Workover Operations ManualDocument17 pagesWorkover Operations ManualAbdelhak Hadji100% (1)

- Metals and Mining - Sector Update-Jul-18-EDEL PDFDocument38 pagesMetals and Mining - Sector Update-Jul-18-EDEL PDFyasir_anjumPas encore d'évaluation

- Turbulance Transition in Pipe FlowDocument24 pagesTurbulance Transition in Pipe Flowyasir_anjumPas encore d'évaluation

- Physics Investigatory Project Class 12 TDocument18 pagesPhysics Investigatory Project Class 12 Tyasir_anjum75% (4)

- Turbulence in Astrophysics: Stars: V. M. CanutoDocument33 pagesTurbulence in Astrophysics: Stars: V. M. Canutoyasir_anjumPas encore d'évaluation

- Guidelines On Actual Tax Declaration Under Various Section 2016-17Document6 pagesGuidelines On Actual Tax Declaration Under Various Section 2016-17yasir_anjumPas encore d'évaluation

- Roache 1997Document38 pagesRoache 1997hawxflyPas encore d'évaluation

- DataSheet 5600 DseDocument2 pagesDataSheet 5600 Dseyasir_anjumPas encore d'évaluation

- Cluster OSDocument11 pagesCluster OSapi-27351105Pas encore d'évaluation

- English Communicative Sample PaperDocument11 pagesEnglish Communicative Sample Paperyasir_anjumPas encore d'évaluation

- Heat Treating The SteelDocument12 pagesHeat Treating The Steelyasir_anjumPas encore d'évaluation

- ResultsDocument1 pageResultsDorval DeschampsPas encore d'évaluation

- PipelineAndGasTechnology 2005-0405Document5 pagesPipelineAndGasTechnology 2005-0405yasir_anjumPas encore d'évaluation

- Traing Seminar PPT From BhelDocument17 pagesTraing Seminar PPT From Bhelyasir_anjumPas encore d'évaluation

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- 110 Principal StressesDocument2 pages110 Principal Stressesyasir_anjumPas encore d'évaluation

- Combinational Logic Circuit AssignmentDocument17 pagesCombinational Logic Circuit Assignmentyasir_anjumPas encore d'évaluation

- YogitaDocument1 pageYogitayasir_anjumPas encore d'évaluation

- Combinational Logic Circuit AssignmentDocument17 pagesCombinational Logic Circuit Assignmentyasir_anjumPas encore d'évaluation

- ICT-CSS-12 Q1 W2 Mod 4Document16 pagesICT-CSS-12 Q1 W2 Mod 4AJ Bacarisas RochaPas encore d'évaluation

- Safety Standard-Portable Pneumatic and Hand Operated Hand Tools-Aug09Document3 pagesSafety Standard-Portable Pneumatic and Hand Operated Hand Tools-Aug09madhulikaPas encore d'évaluation

- Implementation of A Simple Li Fi Based SystemDocument7 pagesImplementation of A Simple Li Fi Based SystemMadhuri RoyPas encore d'évaluation

- 8.5-MMD65R Report-Well Ru-473 - Comments by ChenDocument11 pages8.5-MMD65R Report-Well Ru-473 - Comments by ChenWHWENPas encore d'évaluation

- Eligibility Profile With Sample Formula - Fusion HCMDocument2 pagesEligibility Profile With Sample Formula - Fusion HCMJAI PRATAPPas encore d'évaluation

- Literature Review On GSM NetworkDocument6 pagesLiterature Review On GSM Networkxfeivdsif100% (1)

- Mini Caisson Design-CalculationsDocument6 pagesMini Caisson Design-CalculationsRobert SiqecaPas encore d'évaluation

- LiftMaster SL3000 Specification English 1 1 18Document5 pagesLiftMaster SL3000 Specification English 1 1 1828larrysjunkmailPas encore d'évaluation

- Ecu RepairDocument146 pagesEcu RepairNidhameddine Ben Ayed87% (46)

- ARCH592 4. Project Management in Architecture PDFDocument66 pagesARCH592 4. Project Management in Architecture PDFGlyrah Marie Dela TorrePas encore d'évaluation

- Soundfonts IntroducDocument5 pagesSoundfonts IntroducFaye SpukPas encore d'évaluation

- Trends Mapping Study Digital Skills Development in Tvet Teacher TrainingDocument56 pagesTrends Mapping Study Digital Skills Development in Tvet Teacher TrainingMila NurulPas encore d'évaluation

- DS100S ManualDocument23 pagesDS100S ManualJuan Francisco Sanchez MassadiPas encore d'évaluation

- Angular FrameworkDocument9 pagesAngular Frameworkvarsha dixitPas encore d'évaluation

- Serial Communication Protocol For Embedded Applica PDFDocument4 pagesSerial Communication Protocol For Embedded Applica PDFMarco RamirezPas encore d'évaluation

- "2003" Seminar Information: Volkswagen / AudiDocument7 pages"2003" Seminar Information: Volkswagen / AudiGina LópezPas encore d'évaluation

- Precision Balance KERN EW-N EG-NDocument3 pagesPrecision Balance KERN EW-N EG-NWaleed MuradPas encore d'évaluation

- Latest Developments in MED and MVC Thermal Desalination ProcessesDocument16 pagesLatest Developments in MED and MVC Thermal Desalination ProcessesraosudhPas encore d'évaluation

- PanouDocument2 pagesPanouMihaiNeacsuPas encore d'évaluation

- 2G-3G Model RFP Answered v1.0Document653 pages2G-3G Model RFP Answered v1.0AsadPas encore d'évaluation

- Lab - 03 Task On 2D ArrayDocument3 pagesLab - 03 Task On 2D ArrayShantoPas encore d'évaluation

- ButterWorth Filter (3 Pole Design)Document14 pagesButterWorth Filter (3 Pole Design)NelsonLucioRodriguezPenagosPas encore d'évaluation

- Manual Microsoft Excel 2016Document252 pagesManual Microsoft Excel 2016Cesar GarciaPas encore d'évaluation

- Gartner Market Guide For NACDocument18 pagesGartner Market Guide For NACdbf75Pas encore d'évaluation

- Yesko Code Bata OS Ko Project GarneDocument17 pagesYesko Code Bata OS Ko Project GarnetheonlygodPas encore d'évaluation

- Kaifa ManualDocument78 pagesKaifa Manualastrix10% (2)

- Olfa TalbiDocument1 pageOlfa TalbiGhassen JlassiPas encore d'évaluation

- LinkedIn Leadership Connect - Version 2.0Document16 pagesLinkedIn Leadership Connect - Version 2.0ponnam karthikPas encore d'évaluation

- 40ESS - Using Siebel State ModelDocument17 pages40ESS - Using Siebel State ModelAkhamiePatrickOshiokePas encore d'évaluation

- Installation - Check-List - Eng - Rev-10 For Cooling Tower Filtration UnitDocument10 pagesInstallation - Check-List - Eng - Rev-10 For Cooling Tower Filtration UnitMidha NeerPas encore d'évaluation