Académique Documents

Professionnel Documents

Culture Documents

Nec

Transféré par

chandanmoti780Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Nec

Transféré par

chandanmoti780Droits d'auteur :

Formats disponibles

How To Use The National Electrical Code

Table of Contents:

The NFPA

Code Changes

Why is The NEC So Hard to Figure Out?

Understanding the Terms and Theories

Layout of the NEC

How to Use The NEC

Customizing Your Code Book

Different Interpretations

National Electrical Code NFPA 70

Summary

Extracted from Mike Holt's best selling book Understanding the National Electrical Code.

Attitude A certain attitude is needed to understand the NEC. There are many different

types of electrical installations, but the Code could not begin to consider all of them.

However, to be successful in the electrical industry, you must understand the NEC. I

hope this book will excite you to learn more about the Code. I have to say that the

more I learn, the more I realize how much there still is to learn. As this book

progresses, you will develop some insight into these rules. Yes, there are gray areas,

but generally the meaning is quite clear.

The National Electrical Code (NFPA Volume 70) has been published, edited, and

revised since 1897 and has been sponsored by the National Fire Protection

Association (NFPA) since 1911. The NEC is considered by some to be the finest

building code standard of its kind. The NEC is used not only throughout most of the

United States, but also in some other countries throughout the world, such as Mexico

and Puerto Rico.

The original electrical code was developed by the combined efforts of the insurance,

electrical, and architectural industries. The first electrical code was assembled by the

National Association of Fire Engineers in 1897.

The NFPA

The National Fire Protection Association (NFPA) has many other standards besides

the NEC that are related to the electrical field. The NFPA standards (including the

NEC) are in effect only if the legal jurisdictions have adopted them as law.

The twenty NFPA Code Panels responsible for the NEC often consult with the

technical experts and members responsible for other NFPA standards. The NEC rules

should correlate with the regulations in other NFPA standards.

Code Changes

Anyone may suggest a change to the National Electrical Code by submitting a

proposal to the National Fire Protection Association. If you would like to submit a

code change to the 1999 NEC, be sure to submit it no later than November 1999.

When submitting changes, keep in mind that the primary purpose of the NEC is the

protection of life and property. At the front of the NEC there are detailed instructions

on how to submit a code change.

Why is the NEC so hard to figure out?

Learning to use the NEC is like learning to play the game of chess. If you have never

played chess, you will need to learn the terms used to identify the game pieces, the

theory of how each piece moves and how the pieces are set up on the board. Once you

have this basic understanding of the game, you may start to play the game; but all you

can do is make crude moves because you don't completely understand how the pieces

work together.

To play the game well, you need to study the rules, understand the subtle and

complicated strategies, and then practice, practice and more practice.

Learning the terms, theory, and layout of the NEC gives you just enough knowledge

to be dangerous. The hard part is understanding how all the parts work together.

Perhaps the most difficult part is the subtle meanings in the Code rules themselves.

The rules in the NEC are not as simple as we would want them to be. There are

thousands of different applications of electrical installations and there cannot be a

specific Code rule for every application. You must learn the purpose of the NEC and

then use common sense when you applying the rule. Please don't get so caught up

with the rule, that you forget to use common sense.

This book is designed to help you with electrical terms, theories, and how to

understand the NEC rules. A companion workbook that contains over 1,000 questions

is available to give you the practice you need on how to use the NEC.

Understanding Terms and Theory

Terms

There are many technical words and phrases used in the NEC. It is crucial that you

understand the meanings of words like ground, grounded, grounding, and neutral. If

you do not clearly understand the terms used in the Code, you will not understand the

rule itself.

It isn't always the technical words that require close attention. In the NEC, even the

simplest words can make a big difference. The word "or" can mean an alternate

choices for equipment, wiring methods, or other requirements. Sometimes, the word

"or" can mean any item in a group. The word "and" can mean an additional

requirement or any item in a group. Be aware of how simple words are used.

Electricians, engineers, and other trade-related professionals have created their own

terms and phrases. This is what we call slang. One of the problems with a slang terms

is that they mean different things to different people and they are not used in the NEC.

Example, the words sub-feeder and bond wire. The proper names associated with

most slang terms have been identified. This book should help you understand the

proper terms so that you no longer need to use the slang terms.

Theory

Theory is simply understanding how and why things work the way they do. Why can

a bird sit on an energized power line without getting shocked? Why does installing a

lot of wires close together reduce the amount of current they can individually carry?

Why can't a single conductor be installed in a metal raceway? Why can the circuit

breaker to a motor circuit be 40 amperes, when the conductors are only rated 20

amperes? Why can't a 20-ampere receptacle be installed on a 15-ampere circuit? If

you understand why or how things work you will probably understand the Code rules.

Layout of the NEC

Contrary to popular belief, the NEC is a fairly well organized document, although

parts of it are somewhat vague. Understanding the NEC structure and writing style is

extremely important to understand and use the Code book effectively. The National

Electrical Code is organized into 12 components.

1. Chapters (major categories)

2. Articles (individual subjects)

3. Parts (divisions of an Article)

4. Sections, Lists, and Tables (Code rules)

5. Exceptions (Code rules)

6. Fine Print Notes (explanatory material, not mandatory Code language)

7. Definitions (Code rules)

8. Superscript Letter X

9. Marginal Notations, Code changes (|) and deletions (bullet)

10. Table of Contents

11. Index

12. Appendices

A short description of each component follows:

1. Chapters.

There are nine chapters in the NEC. Each chapter is a group of articles, parts, sections,

and tables. The nine chapters fall into four categories:

Chapters 1 through 4: General Rules

Chapters 5 through 7: Specific Rules (Motion Picture Projectors, Recreational

Vehicles, Cranes and Hoists, X-Ray Equipment, etc.)

Chapter 8: Communication Systems (Radio and Television Equipment and Cable TV

Systems)

Chapter 9: Physical Properties and NEC Examples (Tables for conductor and

raceways)

2. Articles.

The NEC contains approximately 125 articles. An article is a specific subject, such as:

1. Article 110 - General Requirements

2. Article 250 - Grounding

3. Article 300 - Wiring Methods

4. Article 430 - Motors

5. Article 500 - Hazardous (classified) Locations

6. Article 680 - Swimming Pools

7. Article 725 - Control Wiring

8. Article 800 - Communication Wiring

3. Parts.

When an article is sufficiently large, the article is subdivided into parts. The parts

break down the main subject of the article into organized groups of information. For

example Article 250 contains nine parts, such as:

1. Part A-General

2. Part B-Circuit and System Grounding

3. Part C-Grounding Electrode System

Caution The "Parts" of a Code Article are not included in the Section numbers.

Because of this, we have a tendency to forget what "Part" the Code rule is relating to.

For example, Table 110-34 gives the dimensions of working space clearances in front

of electrical equipment. If we are not careful, we might think that this table applies to

all electrical installations. But Section 110-34 is located in Part C Over-600 volt

Systems of Article 110! The working clearance rule for under-600 volt systems is

located in Part A of Article 110, in Table 110-26.

4. Sections, Lists, and Tables (Code rules).

Section - Each actual Code rule is called a Section and is identified with numbers,

such as Section 225-26. A Code Section may be broken down into subsections by

letters in parentheses, and numbers in parentheses may further break down each

subsection. For example, the rule that requires all receptacles in a bathroom to be

GFCI protected is contained in Section 210-8(a)(1).

Note: Note. Many in the electrical industry incorrectly use the term "Article"" when

referring to a Code Section.

List - The 1999 NEC has changed the layout of some Sections that contain lists of

items. If a list is part of a numeric subsection, such as Section 210-52(a)(2), then the

items are listed as a., b., c., etc. However, if a list is part of a Section, then the items

are identified as (1), (2), (3), (4), etc.

Tables - Tables. Many Code requirements are contained within Tables which are a

systematic list of Code rules in an orderly arrangement. For example, Table 300-15

lists the burial depths of cables and raceways.

5. Exceptions.

Exceptions are italicized and provide an alternative to a specific rule. There are two

types of exceptions: mandatory and permissive. When a rule has several exceptions,

those exceptions with mandatory requirements are listed before those written in

permissive language.

(a) Mandatory Exception. A mandatory exception uses the words "shall" or "shall

not." The word "shall" in an exception means that if you are using the exception, you

are required to do it in a particular way. The term "shall not" means that you cannot

do something.

(b) Permissive Exception. A permissive exception uses such words as "shall be

permitted", which means that it is accepted to do it in this way.

6. Fine Print Notes.

Fine Print Notes (FPN) are explanatory material, not Code rules. Fine print notes

attempt to clarify a rule or give assistance, but they are not a Code requirement. For

example, FPN No. 4 of Section 210-19(a) states that the voltage drop for branch

circuits should not exceed 3% of the circuit voltage. This is not a Code requirement

but only a suggestion; there is no NEC requirement for conductor voltage drop.

7. Definitions.

Definitions are listed in Article 100 and throughout the NEC. In general, the

definitions listed in Article 100 apply to more than one Code Article, such as "branch

circuit", which is used in many Articles.

Definitions at the beginning of a specific Article applies only to that Article. For

example, the definition of a "Swimming Pool" is contained in Section 680-4 because

this term applies only to the requirements of Article 680 - Swimming Pools.

Definitions located in a Part of an Article apply only to that Part of the Article. For

example, the definition of "motor control circuit" applies only to Article 430, Part F.

Definitions located in a Code Section apply only to that Code Section. For example,

the definition of "Festoon Lighting" located in Section 225-6(b) applies only to the

requirements contained in Section 225-6.

8. Superscript Letter x.

This superscript letter is used only in Chapter 5. The superscript letter X means the

material was extracted from other NFPA documents. Appendix A, at the back of the

Code Book, identifies the NFPA document and the section(s) that the material was

extracted from.

9. Changes and Deletions.

Changes and deletions to the 1996 NEC are identified in the margins of the 1999 NEC

in the following manner: Changes are marked with a vertical line (|) and deletions of a

Code rule are identified by a bullet.

10. Table of Contents.

The Table of Contents located in the front of the Code book displays the layout of the

Chapters, Articles, and Parts as well as their location in the Code book.

11. Index.

We all know the purpose of an index, but it's not that easy to use. You really need to

know the correct term. Often it's much easier to use the Table of Contents.

12. Appendices.

There are four appendices in the 1999 NEC:

Appendix A - Extract Information

Appendix B - Ampacity Engineering Supervision

Appendix C - Conduit and Tubing Fill Tables

Appendix D - Electrical Calculation Examples

How to use the NEC

How fast you find things in the NEC depends on your experience. Experienced Code

users often use the Table of Contents instead of the index.

For example, what Code rule indicates the maximum number of disconnects permitted

for a service?

Answer. You need to know that Article 230 is for Services and that it contains a Part

F. Disconnection Means. If you know this, using the Table of Contents, you'll see that

the answer is contained at page 66.

People frequently use the index which lists subjects in alphabetical order. It's usually

the best place to start for specific information. Unlike most books, the NEC index

does not list page numbers; it lists Sections, Tables, Articles, parts, and appendices by

their Section number.

Note. Many people say the Code takes them in circles, and sometimes it does.

However, this complaint is often heard from inexperienced persons who don't

understand electrical theory, electrical terms, and electrical practices.

Different Interpretations

Anytime there is more than one electrical person in the same room, they will argue

Code. When people have a difference of opinion, it's often because one is talking

about one point and the other is talking about another, or simply they don't know what

they're talking about.

Electricians, contractors, some inspectors, and others love arguing Code

interpretations and discussing Code requirements. Discussing the Code and its

application with others is a great way to increase your knowledge of the NEC and

how it can be used.

I have taken great care in researching the Code rules in this book. But I'm not perfect.

If you disagree with my comments, please feel free to contact me personally. I enjoy

discussing Code just as much as the next guy. I hope you learn that when you argue a

Code rule, you use the specific Code section(s) and you don't just throw words into

the conversation.

Note. At times in this book I have supported my comments by referring to The

National Electrical Code Committee Report on Proposals [ROP], and at times to The

National Electrical Code Committee Report on Comments [ROC]. This document is

available from the NFPA by contacting them directly.

Warning: Understanding and knowing the Code can cause people to go around

showing their co-workers how brilliant they are (I know I did). If you are going to

explain the Code, please do it in a positive way and be constructive with your

comments. If you know more about the Code than your supervisor or inspector (and

everyone thinks he or she does), be careful how you explain your position. Attitude is

everything.

Customizing your Code Book

One way for you to get comfortable with your Code book is to customize it to meet

your needs. This you can do by highlighting, underlining Code rules, and using

convenient tabs.

Highlighting and Underlining. As you read through this book, highlight in the NEC

book those Code rules that are important to you such as yellow for general interest,

and orange for rules you want to find quickly. As you use the Index and the Table of

Contents, highlight terms in those areas as well. Underline or circle key words and

phrases in the NEC with a red pen (not a lead pencil) and use a 6 inch ruler to keep

lines straight and neat.

Because of the new format of the 1999 NEC (81/2 x 11), I highly recommend that you

highlight in green the Parts of at least the following Articles.

Article 230 - Services

Article 250 - Grounding

Article 410 - Fixtures

Article 430 - Motors

Tabbing the NEC. Tabbing the NEC permits you to quickly access Code Article,

Section, or Tables. However, too many tabs will defeat the purpose.

Experience has shown that the best way to tab the Code book is to start by placing the

last tab first and the first tab last (start at the back of the book and work your way

toward the front). Install the first tab, then place each following tab so that they do not

overlap the information of the previous tab.

The following is a list of Articles and Sections I most commonly refer to. Place a tab

only on the Section s or Articles that are important to you.

1 Index, Page 621

2 Examples: Appendix D, Page 609

3 Raceway Fill Tables: Appendix C, Page 585

4 Conductor Area: Table 5 of Chapter 9, Page 564

5 Raceway Area: Table 4 of Chapter 9, Page 562

6 Satellites and Antennas: Article 820, Page 545

7 Communication: Article 800, Page 533

8 Fiber Optic Cables: Article 770, Page 527

9 Fire Alarms: Article 760, Page 519

10 Control Circuits: Article 725, Page 510

11 Emergency Circuits: Article 700, Page 501

12 Pools, Spas and Fountains: Article 680, Page 476

13 Electric Signs: Article 600, Page 433

14 Marinas: Article 555, Page 431

15 Mobile/Manufactured: Article 550, Page 398

16 Carnivals, Circuses, and Fairs: Article 525, Page 387

17 Health Care Facilities: Article 517, Page 359

18 Gasoline Dispensers: Article 514, Page 346

19 Hazardous Locations: Article 500, Page 309

20 Transformers: Article 450, Page 290

22 Air-Conditioning: Article 440, Page 283

23 Motors: Article 430, Page 256

24 Electric Space Heating: Article 424, Page 241

25 Appliances: Article 422, Page 236

26 Lighting Fixtures: Article 410, Page 225

27 Cords: Article 400, Page 211

28 Panelboards: Article 384, Page 207

29 Switches: Article 380, Page 204

30 Outlet and Junction Boxes: Article 370, Page 191

31 Flexible Metal Conduit: Article 350, Page 175

32 Electrical Metallic Tubing: Article 348, Page 172

33 Rigid Nonmetallic Conduit: Article 347, Page 169

34 Nonmetallic-Sheathed Cable: Article 336, Page 159

35 Electrical Nonmetallic Tubing: Article 331, Page 154

36 Cable Trays: Article 318, Page 140

37 Conductor Ampacity: Table 310-16 , Page 126

38 Wiring Methods: Article 300, Page 105

39 Grounding and Bonding: Article 250, Page 80

40 Overcurrent Protection: Article 240, Page 70

41 Services: Article 230, Page 61

42 Outside Feeder/Branch Circuit: Article 225, Page 55

43 Service/Feeder Calculations: Article 220, Page 48

44 Feeders: Article 215, Page 46

45 Branch Circuits: Article 210, Page 37

46 General Requirements: Article 110, Page 26

47 Definitions: Article 100, Page 19

48 Table of Contents, Page 2

National Electrical Code (NFPA 70)

Article 90 is the Introduction to the National Electrical Code. As with most

introductions, this article is often skipped. To understand the NEC and its

application better, it is very important that you thoroughly read and review this

article.

Article 90 - Introduction

90-1 Purpose

(a) Practical Safeguarding. The purpose of the NEC is the protection of persons and

property by minimizing the risks caused by the use of electricity, Fig. 1-1.

(b) Adequacy. The Code is intended for the application of safety. When the rules of

the NEC are complied with, an installation is expected to be essentially free from

hazards. However, when installations comply with the NEC, this does not mean that

the electrical system will be efficient, convenient, adequate for good service, or that it

will work properly.

(FPN, Fine Print Note) Hazards can occur because of overloading of circuits and

improper installation of equipment. These problems often arise because the original

installation did not provide for future expansion, which is not required by the Code.

Caution: The NEC does not contain any rule that requires consideration for future

expansion of electrical use. The NEC is concerned solely with safety; but the

electrical designer must be concerned with safety, efficiency, convenience, good

service, and future expansion. Often, electrical systems are designed and installed that

exceed NEC requirements. However, the inspector does not have the authority to

require installations to exceed the NEC requirements, unless additional requirements

have been adopted by local ordinance.

(b) Intention. The Code is not a how-to book; it is not intended as a design

specification or an instruction manual for untrained persons.

90-2 Scope

The National Electrical Code is not intended to apply to all electrical installations.

Sub-section (a) explains what is covered and sub-section (b) explains what is not

covered by the NEC.

(a) Covered. The Code covers most electrical installations, including most buildings,

mobile homes, recreational vehicles, floating buildings, yards, carnivals, parking and

other lots, and private industrial substations. Also covered are conductors and

equipment that connect to the supply of electricity, conductors and equipment outside

on the premises, and the installation of fiber optic cable.

Installation within buildings used by the electric utility, such as office buildings,

warehouses, garages, machine shops, and recreational buildings that are not an

integral part of a generating plant, substation, or control center must be installed in

accordance with the NEC.

(b) Not Covered. The Code does not cover:

1. (1) Installations in cars, trucks, boats, ships, planes, electric trains, or

underground mines.

2. (2) Self-propelled mobile surface mining machinery and their attendant

electrical trailing cable.

3. (3) Railway power, signaling and communications wiring.

4. (4) Communications equipment under the exclusive control of a

communication utility, such as telephone and cable TV companies, are

covered by their own wiring and equipment rules and are not required to

comply with the NEC. However, the interior and exterior wiring of

phone, communications, and CATV not under the exclusive control of

communication utilities must comply with NEC Chapter 8.

5. (5) Installations, including associated lighting, under the exclusive

control of electric utilities for the purpose of power generation,

distribution, control, transformation, and transmission are not required to

comply with the NEC. This includes installations located in buildings

used exclusively by utilities for such purposes, outdoors on property

owned or leased by the utility, or on public highways, streets, roads, etc.,

or outdoors on private property by established rights such as easements.

Note. Any wiring installation such as lighting fixtures on private property without

established rights (such as easements) and not intended for the purpose of

communications, metering, generation, control, transformation, transmission, and

distribution of electric energy, must be installed according to the NEC requirements,

even if installed by the electric utility, Fig. 1-3.

90-3 Code Arrangement

The Code is divided into the Introduction and nine chapters. These chapters are

divided as follow:

General rules: Introduction and Chapters 1 through 4 apply in general to all

installations, this represents the scope of this book.

Special rules: Chapters 5 through 7 apply to special occupancies, equipment, or

conditions and may modify the general rules of Chapters 1 through 4. Examples

include; aircraft hangers, health care facilities, x-ray equipment, etc.

Communications Systems: Chapter 8 covers communications systems (phone,

CATV, satellite dishes, etc.). This chapter of the NEC is independent of the other

chapters. This means that the rules of Chapters 1 through 4 do not apply to Chapter 8,

unless there is a specific reference in Chapter 8 to a rule in Chapters 1 through 4.

Tables: Chapter 9 consists of tables that are used for raceway sizing and conductor

fill and voltage drop.

90-4 Enforcement

The NEC, while purely advisory, is intended to be a document that can be adopted by

governmental bodies and other inspection departments. It is up to these bodies, states,

counties, cities, etc., to adopt the NEC as a legal requirement for electrical

installations.

The enforcement of complying with the NEC falls under the authority having

jurisdiction. For the purposes of this book, the authority having jurisdiction (AHJ) will

be considered the electrical inspector. Generally, the electrical inspector is employed

by some government agency and is responsible to an advisory council or board for his

or her decisions or rulings.

An inspector's authority and responsibilities include:

Interpretation of the NEC Rules. This means that the inspector must have a specific

rule upon which to base his/her interpretations. If an inspector rejects your

installation, you have the right to know the specific NEC rule that you violated, but

naturally, we must be realistic in the recognition that we must often submit to a higher

authority, Fig. 1-4.

Note. The art of getting along with the electrical inspector, is knowing what the Code

says and when to choose your battles.

Approval of Equipment and Materials. The electrical inspector is the person who

decides the approval of equipment. However, if equipment is listed by a qualified

electrical testing laboratory (listing agency), its internal wiring does not need to be

reinspected at the time of installation [90-7].

Warning:

Only the inspector can approve equipment [90-4]. He or she can reject the use of any

equipment and can approve nonlisted equipment. The primary basis of equipment

approval by the inspector is listing and labeling by qualified testing laboratories [90-7

and 110-2].

Waiver of Rules. Waiver of specific requirements of the Code or permitting alternate

methods. When an installation does not comply with normal NEC rules, the inspector

may waive specific requirements of the Code or permit alternate methods. This is

permitted only where it is ensured that equivalent electrical safety can be achieved.

Waiver of new Code requirements on materials. Waiver of new Code

requirements. If the 1999 Code requires materials, products, or construction that are

not yet available, the inspector may allow materials, products, and construction

methods that were acceptable in the 1996 Code.

Note. It takes time for manufacturers to redesign, manufacture, and distribute new

products to meet new Code requirements.

Ensure that equipment is installed properly [90-7]. It is the inspector's

responsibility to ensure that the equipment is installed according to the equipment's

listed or labeled instructions [110-3(b)].

Equipment Installation. It is the inspector's responsibility to ensure that the electrical

equipment is installed to the equipment listing or labeling instructions. The inspector

is also responsible for detecting any field modification of equipment. Listed

equipment may not be modified in the field without the approval of the listing agency

or the electrical inspector [90-7, 110-3(b)].

90-5 Mandatory Rules and Explanatory Material

(a) Mandatory Rules. Rules that identify actions that are specifically required or

prohibited are characterized by the use of the terms "shall" or "shall not."

Section 110-3(b) states that listed or labeled equipment "shall" be installed, used, or

both, in accordance with any instructions included in the listing or labeling.

(b) Permissive Rules. Rules which identify actions that are allowed but not required,

such as options or alternative methods are characterized by the use of the terms "shall

be permitted" or "shall not be required." A "permissive rule" is often an exception to

the general requirement.

Section 250-102(d) states that the equipment bonding jumper can be installed inside

or outside of a raceway or enclosure.

(c) Explanatory Material. Explanatory material, such as references to other

standards, references to related Sections of the Code, or information related to a Code

rule is included in the form of a Fine Print Note (FPN). Fine Print Notes are

informational only and are not to be enforced. Most FPN's contain a reference to

another related Code Section.

90-6 Formal Interpretations

National Fire Protection Association (NFPA) formal interpretation procedures are

listed in the Regulations Governing Committee Projects, available from the NFPA

Secretary of the Standards Council. This is a very time-consuming process and is

rarely done. Not only that, but formal interpretations are not legally binding.

90-7 Product Safety

Product safety evaluation is done by nationally recognized independent testing

laboratories that publish lists of equipment that meet nationally recognized test

standards. Products and materials that are listed, labeled, or identified by a responsible

and respected organization, are the basis of approval by the electrical inspector.

National testing laboratories decrease the need for inspectors to reinspect or evaluate

the electrical equipment at the time of installation.

Summary

The purpose of the NEC is for the protection of persons and property.

The NEC is a safety standard.

The NEC is not intended as a design specification or an instruction manual for

untrained persons.

The NEC covers most electrical installations, but not all.

The NEC does not cover cars, trucks, boats, ships, planes, underground mines, trains,

utility controlled communication equipment, and utility power distribution locations.

The NEC covers commercial parking lot lighting installed by the electric utility on

private property.

The NEC is divided into an Introduction and nine Chapters.

Product evaluation is done by nationally recognized independent testing laboratories,

not the electrical inspector.

The authority having jurisdiction (AHJ) approves the use of products and enforces the

requirements of the NEC, but they cannot make-up their own rules.

Mandatory Code rules use the word shall.

Permissive Rules identify actions that are allowed but not required, such as options or

alternative methods.

Explanatory material is contained in the Fine Print Notes (FPNs).

Product safety evaluation is done by nationally recognized independent testing

laboratories.

If you would like the information (with graphics), please consider ordering my

best selling book "Understanding the 1999 National Electrical Code". Call my

office toll free 1-888-NEC CODE or Click here for more details.

God Bless, Mike

1926.404(a)

Use and identification of grounded and grounding conductors -

1926.404(a)(1)

Identification of conductors. A conductor used as a grounded conductor shall be identifiable and distinguishable from all other

conductors. A conductor used as an equipment grounding conductor shall be identifiable and distinguishable from all other conductors.

1926.404(a)(2)

Polarity of connections. No grounded conductor shall be attached to any terminal or lead so as to reverse designated polarity.

1926.404(a)(3)

Use of grounding terminals and devices. A grounding terminal or grounding-type device on a receptacle, cord connector, or attachment

plug shall not be used for purposes other than grounding.

1926.404(b)

Branch circuits -

1926.404(b)(1)

Ground-fault protection -

1926.404(b)(1)(i)

General. The employer shall use either ground fault circuit interrupters as specified in paragraph (b)(1)(ii) of this section or an assured

equipment grounding conductor program as specified in paragraph (b)(1)(iii) of this section to protect employees on construction sites.

These requirements are in addition to any other requirements for equipment grounding conductors.

..1926.404(b)(1)(ii)

1926.404(b)(1)(ii)

Ground-fault circuit interrupters. All 120-volt, single-phase 15- and 20-ampere receptacle outlets on construction sites, which are not a

part of the permanent wiring of the building or structure and which are in use by employees, shall have approved ground-fault circuit

interrupters for personnel protection. Receptacles on a two-wire, single-phase portable or vehicle-mounted generator rated not more

than 5kW, where the circuit conductors of the generator are insulated from the generator frame and all other grounded surfaces, need

not be protected with ground-fault circuit interrupters.

1926.404(b)(1)(iii)

Assured equipment grounding conductor program. The employer shall establish and implement an assured equipment grounding

conductor program on construction sites covering all cord sets, receptacles which are not a part of the building or structure, and

equipment connected by cord and plug which are available for use or used by employees. This program shall comply with the following

minimum requirements:

1926.404(b)(1)(iii)(A)

A written description of the program, including the specific procedures adopted by the employer, shall be available at the jobsite for

inspection and copying by the Assistant Secretary and any affected employee.

1926.404(b)(1)(iii)(B)

The employer shall designate one or more competent persons (as defined in 1926.32(f)) to implement the program.

1926.404(b)(1)(iii)(C)

Each cord set, attachment cap, plug and receptacle of cord sets, and any equipment connected by cord and plug, except cord sets and

receptacles which are fixed and not exposed to damage, shall be visually inspected before each day's use for external defects, such as

deformed or missing pins or insulation damage, and for indications of possible internal damage. Equipment found damaged or

defective shall not be used until repaired.

..1926.404(b)(1)(iii)(D)

1926.404(b)(1)(iii)(D)

The following tests shall be performed on all cord sets, receptacles which are not a part of the permanent wiring of the building or

structure, and cord- and plug-connected equipment required to be grounded:

1926.404(b)(1)(iii)(D)(1)

All equipment grounding conductors shall be tested for continuity and shall be electrically continuous.

1926.404(b)(1)(iii)(D)(2)

Each receptacle and attachment cap or plug shall be tested for correct attachment of the equipment grounding conductor. The

equipment grounding conductor shall be connected to its proper terminal.

1926.404(b)(1)(iii)(E)

All required tests shall be performed:

1926.404(b)(1)(iii)(E)(1)

Before first use;

1926.404(b)(1)(iii)(E)(2)

Before equipment is returned to service following any repairs;

1926.404(b)(1)(iii)(E)(3)

Before equipment is used after any incident which can be reasonably suspected to have caused damage (for example, when a cord set

is run over); and

1926.404(b)(1)(iii)(E)(4)

At intervals not to exceed 3 months, except that cord sets and receptacles which are fixed and not exposed to damage shall be tested

at intervals not exceeding 6 months.

..1926.404(b)(1)(iii)(F)

1926.404(b)(1)(iii)(F)

The employer shall not make available or permit the use by employees of any equipment which has not met the requirements of this

paragraph (b)(1)(iii) of this section.

1926.404(b)(1)(iii)(G)

Tests performed as required in this paragraph shall be recorded. This test record shall identify each receptacle, cord set, and cord- and

plug-connected equipment that passed the test and shall indicate the last date it was tested or the interval for which it was tested. This

record shall be kept by means of logs, color coding, or other effective means and shall be maintained until replaced by a more current

record. The record shall be made available on the jobsite for inspection by the Assistant Secretary and any affected employee.

1926.404(b)(2)

Outlet devices. Outlet devices shall have an ampere rating not less than the load to be served and shall comply with the following:

1926.404(b)(2)(i)

Single receptacles. A single receptacle installed on an individual branch circuit shall have an ampere rating of not less than that of the

branch circuit.

1926.404(b)(2)(ii)

Two or more receptacles. Where connected to a branch circuit supplying two or more receptacles or outlets, receptacle ratings shall

conform to the values listed in Table K-4.

1926.404(b)(2)(iii)

Receptacles used for the connection of motors. The rating of an attachment plug or receptacle used for cord- and plug-connection of a

motor to a branch circuit shall not exceed 15 amperes at 125 volts or 10 amperes at 250 volts if individual overload protection is

omitted.

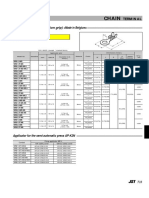

TABLE K-4 - Receptacle Ratings for Various Size Circuits

________________________________________________________________

|

| Receptacle

Circuit rating amperes | rating

| amperes

______________________________________|________________________

|

15 ...................................| Not over 15.

20 ...................................| 15 or 20.

30 ...................................| 30.

40 ...................................| 40 or 50.

50 ...................................| 50.

______________________________________|________________________

..1926.404(c)

1926.404(c)

Outside conductors and lamps -

1926.404(c)(1)

600 volts, nominal, or less. Paragraphs (c)(1)(i) through (c)(1)(iv) of this section apply to branch circuit, feeder, and service conductors

rated 600 volts, nominal, or less and run outdoors as open conductors.

1926.404(c)(1)(i)

Conductors on poles. Conductors supported on poles shall provide a horizontal climbing space not less than the following:

1926.404(c)(1)(i)(A)

Power conductors below communication conductors-30 inches (762 mm).

1926.404(c)(1)(i)(B)

Power conductors alone or above communication conductors: 300 volts or less-24 inches (610 mm); more than 300 volts-30 inches

(762 mm).

1926.404(c)(1)(i)(C)

Communication conductors below power conductors: with power conductors 300 volts or less-24 inches (610 mm); more than 300

volts-30 inches (762 mm).

1926.404(c)(1)(ii)

Clearance from ground. Open conductors shall conform to the following minimum clearances:

1926.404(c)(1)(ii)(A)

10 feet (3.05 m)-above finished grade, sidewalks, or from any platform or projection from which they might be reached.

1926.404(c)(1)(ii)(B)

12 feet (3.66 m)-over areas subject to vehicular traffic other than truck traffic.

1926.404(c)(1)(ii)(C)

15 feet (4.57 m)-over areas other than those specified in paragraph (c)(1)(ii)(D) of this section that are subject to truck traffic.

..1926.404(c)(1)(ii)(D)

1926.404(c)(1)(ii)(D)

18 feet (5.49 m)-over public streets, alleys, roads, and driveways.

1926.404(c)(1)(iii)

Clearance from building openings. Conductors shall have a clearance of at least 3 feet (914 mm) from windows, doors, fire escapes, or

similar locations. Conductors run above the top level of a window are considered to be out of reach from that window and, therefore,

do not have to be 3 feet (914 mm) away.

1926.404(c)(1)(iv)

Clearance over roofs. Conductors above roof space accessible to employees on foot shall have a clearance from the highest point of the

roof surface of not less than 8 feet (2.44 m) vertical clearance for insulated conductors, not less than 10 feet (3.05 m) vertical or

diagonal clearance for covered conductors, and not less than 15 feet (4.57 m) for bare conductors, except that:

1926.404(c)(1)(iv)(A)

Where the roof space is also accessible to vehicular traffic, the vertical clearance shall not be less than 18 feet (5.49 m), or

1926.404(c)(1)(iv)(B)

Where the roof space is not normally accessible to employees on foot, fully insulated conductors shall have a vertical or diagonal

clearance of not less than 3 feet (914 mm), or

1926.404(c)(1)(iv)(C)

Where the voltage between conductors is 300 volts or less and the roof has a slope of not less than 4 inches (102 mm) in 12 inches

(305 mm), the clearance from roofs shall be at least 3 feet (914 mm), or

..1926.404(c)(1)(iv)(D)

1926.404(c)(1)(iv)(D)

Where the voltage between conductors is 300 volts or less and the conductors do not pass over more than 4 feet (1.22 m) of the

overhang portion of the roof and they are terminated at a through-the-roof raceway or support, the clearance from roofs shall be at

least 18 inches (457 mm).

1926.404(c)(2)

Location of outdoor lamps. Lamps for outdoor lighting shall be located below all live conductors, transformers, or other electric

equipment, unless such equipment is controlled by a disconnecting means that can be locked in the open position or unless adequate

clearances or other safeguards are provided for relamping operations.

1926.404(d)

Services -

1926.404(d)(1)

Disconnecting means -

1926.404(d)(1)(i)

General. Means shall be provided to disconnect all conductors in a building or other structure from the service-entrance conductors.

The disconnecting means shall plainly indicate whether it is in the open or closed position and shall be installed at a readily accessible

location nearest the point of entrance of the service-entrance conductors.

1926.404(d)(1)(ii)

Simultaneous opening of poles. Each service disconnecting means shall simultaneously disconnect all ungrounded conductors.

1926.404(d)(2)

Services over 600 volts, nominal. The following additional requirements apply to services over 600 volts, nominal.

1926.404(d)(2)(i)

Guarding. Service-entrance conductors installed as open wires shall be guarded to make them accessible only to qualified persons.

..1926.404(d)(2)(ii)

1926.404(d)(2)(ii)

Warning signs. Signs warning of high voltage shall be posted where unauthorized employees might come in contact with live parts.

1926.404(e)

Overcurrent protection -

1926.404(e)(1)

600 volts, nominal, or less. The following requirements apply to overcurrent protection of circuits rated 600 volts, nominal, or less.

1926.404(e)(1)(i)

Protection of conductors and equipment. Conductors and equipment shall be protected from overcurrent in accordance with their ability

to safely conduct current. Conductors shall have sufficient ampacity to carry the load.

1926.404(e)(1)(ii)

Grounded conductors. Except for motor-running overload protection, overcurrent devices shall not interrupt the continuity of the

grounded conductor unless all conductors of the circuit are opened simultaneously.

1926.404(e)(1)(iii)

Disconnection of fuses and thermal cutouts. Except for devices provided for current-limiting on the supply side of the service

disconnecting means, all cartridge fuses which are accessible to other than qualified persons and all fuses and thermal cutouts on

circuits over 150 volts to ground shall be provided with disconnecting means. This disconnecting means shall be installed so that the

fuse or thermal cutout can be disconnected from its supply without disrupting service to equipment and circuits unrelated to those

protected by the overcurrent device.

..1926.404(e)(1)(iv)

1926.404(e)(1)(iv)

Location in or on premises. Overcurrent devices shall be readily accessible. Overcurrent devices shall not be located where they could

create an employee safety hazard by being exposed to physical damage or located in the vicinity of easily ignitable material.

1926.404(e)(1)(v)

Arcing or suddenly moving parts. Fuses and circuit breakers shall be so located or shielded that employees will not be burned or

otherwise injured by their operation.

1926.404(e)(1)(vi)

Circuit breakers -

1926.404(e)(1)(vi)(A)

Circuit breakers shall clearly indicate whether they are in the open (off) or closed (on) position.

1926.404(e)(1)(vi)(B)

Where circuit breaker handles on switchboards are operated vertically rather than horizontally or rotationally, the up position of the

handle shall be the closed (on) position.

1926.404(e)(1)(vi)(C)

If used as switches in 120-volt, fluorescent lighting circuits, circuit breakers shall be marked "SWD."

1926.404(e)(2)

Over 600 volts, nominal. Feeders and branch circuits over 600 volts, nominal, shall have short-circuit protection.

1926.404(f)

Grounding. Paragraphs (f)(1) through (f)(11) of this section contain grounding requirements for systems, circuits, and equipment.

1926.404(f)(1)

Systems to be grounded. The following systems which supply premises wiring shall be grounded:

..1926.404(f)(1)(i)

1926.404(f)(1)(i)

Three-wire DC systems. All 3-wire DC systems shall have their neutral conductor grounded.

1926.404(f)(1)(ii)

Two-wire DC systems. Two-wire DC systems operating at over 50 volts through 300 volts between conductors shall be grounded unless

they are rectifier-derived from an AC system complying with paragraphs (f)(1)(iii), (f)(1)(iv), and (f)(1)(v) of this section.

1926.404(f)(1)(iii)

AC circuits, less than 50 volts. AC circuits of less than 50 volts shall be grounded if they are installed as overhead conductors outside of

buildings or if they are supplied by transformers and the transformer primary supply system is ungrounded or exceeds 150 volts to

ground.

1926.404(f)(1)(iv)

AC systems, 50 volts to 1000 volts. AC systems of 50 volts to 1000 volts shall be grounded under any of the following conditi ons,

unless exempted by paragraph (f)(1)(v) of this section:

1926.404(f)(1)(iv)(A)

If the system can be so grounded that the maximum voltage to ground on the ungrounded conductors does not exceed 150 volts;

1926.404(f)(1)(iv)(B)

If the system is nominally rated 480Y/277 volt, 3-phase, 4-wire in which the neutral is used as a circuit conductor;

1926.404(f)(1)(iv)(C)

If the system is nominally rated 240/120 volt, 3-phase, 4-wire in which the midpoint of one phase is used as a circuit conductor; or

..1926.404(f)(1)(iv)(D)

1926.404(f)(1)(iv)(D)

If a service conductor is uninsulated.

1926.404(f)(1)(v)

Exceptions. AC systems of 50 volts to 1000 volts are not required to be grounded if the system is separately derived and is supplied by

a transformer that has a primary voltage rating less than 1000 volts, provided all of the following conditions are met:

1926.404(f)(1)(v)(A)

The system is used exclusively for control circuits,

1926.404(f)(1)(v)(B)

The conditions of maintenance and supervision assure that only qualified persons will service the installation,

1926.404(f)(1)(v)(C)

Continuity of control power is required, and

1926.404(f)(1)(v)(D)

Ground detectors are installed on the control system.

1926.404(f)(2)

Separately derived systems. Where paragraph (f)(1) of this section requires grounding of wiring systems whose power is derived from

generator, transformer, or converter windings and has no direct electrical connection, including a solidly connected grounded circuit

conductor, to supply conductors originating in another system, paragraph (f)(5) of this section shall also apply.

..1926.404(f)(3)

1926.404(f)(3)

Portable and vehicle-mounted generators -

1926.404(f)(3)(i)

Portable generators. Under the following conditions, the frame of a portable generator need not be grounded and may serve as the

grounding electrode for a system supplied by the generator:

1926.404(f)(3)(i)(A)

The generator supplies only equipment mounted on the generator and/or cord- and plug-connected equipment through receptacles

mounted on the generator, and

1926.404(f)(3)(i)(B)

The noncurrent-carrying metal parts of equipment and the equipment grounding conductor terminals of the receptacles are bonded to

the generator frame.

1926.404(f)(3)(ii)

Vehicle-mounted generators. Under the following conditions the frame of a vehicle may serve as the grounding electrode for a system

supplied by a generator located on the vehicle:

1926.404(f)(3)(ii)(A)

The frame of the generator is bonded to the vehicle frame, and

1926.404(f)(3)(ii)(B)

The generator supplies only equipment located on the vehicle and/or cord- and plug-connected equipment through receptacles

mounted on the vehicle or on the generator, and

1926.404(f)(3)(ii)(C)

The noncurrent-carrying metal parts of equipment and the equipment grounding conductor terminals of the receptacles are bonded to

the generator frame, and

1926.404(f)(3)(ii)(D)

The system complies with all other provisions of this section.

..1926.404(f)(3)(iii)

1926.404(f)(3)(iii)

Neutral conductor bonding. A neutral conductor shall be bonded to the generator frame if the generator is a component of a separately

derived system. No other conductor need be bonded to the generator frame.

1926.404(f)(4)

Conductors to be grounded. For AC premises wiring systems the identified conductor shall be grounded.

1926.404(f)(5)

Grounding connections -

1926.404(f)(5)(i)

Grounded system. For a grounded system, a grounding electrode conductor shall be used to connect both the equipment grounding

conductor and the grounded circuit conductor to the grounding electrode. Both the equipment grounding conductor and the grounding

electrode conductor shall be connected to the grounded circuit conductor on the supply side of the service disconnecting means, or on

the supply side of the system disconnecting means or overcurrent devices if the system is separately derived.

1926.404(f)(5)(ii)

Ungrounded systems. For an ungrounded service-supplied system, the equipment grounding conductor shall be connected to the

grounding electrode conductor at the service equipment. For an ungrounded separately derived system, the equipment grounding

conductor shall be connected to the grounding electrode conductor at, or ahead of, the system disconnecting means or overcurrent

devices.

1926.404(f)(6)

Grounding path. The path to ground from circuits, equipment, and enclosures shall be permanent and continuous.

..1926.404(f)(7)

1926.404(f)(7)

Supports, enclosures, and equipment to be grounded -

1926.404(f)(7)(i)

Supports and enclosures for conductors. Metal cable trays, metal raceways, and metal enclosures for conductors shall be grounded,

except that:

1926.404(f)(7)(i)(A)

Metal enclosures such as sleeves that are used to protect cable assemblies from physical damage need not be grounded; and

1926.404(f)(7)(i)(B)

Metal enclosures for conductors added to existing installations of open wire, knob-and-tube wiring, and nonmetallic-sheathed cable

need not be grounded if all of the following conditions are met:

1926.404(f)(7)(i)(B)(1)

Runs are less than 25 feet (7.62 m);

1926.404(f)(7)(i)(B)(2)

Enclosures are free from probable contact with ground, grounded metal, metal laths, or other conductive materials; and

1926.404(f)(7)(i)(B)(3)

Enclosures are guarded against employee contact.

1926.404(f)(7)(ii)

Service equipment enclosures. Metal enclosures for service equipment shall be grounded.

1926.404(f)(7)(iii)

Fixed equipment. Exposed noncurrent-carrying metal parts of fixed equipment which may become energized shall be grounded under

any of the following conditions:

1926.404(f)(7)(iii)(A)

If within 8 feet (2.44 m) vertically or 5 feet (1.52 m) horizontally of ground or grounded metal objects and subject to employee

contact.

..1926.404(f)(7)(iii)(B)

1926.404(f)(7)(iii)(B)

If located in a wet or damp location and subject to employee contact.

1926.404(f)(7)(iii)(C)

If in electrical contact with metal.

1926.404(f)(7)(iii)(D)

If in a hazardous (classified) location.

1926.404(f)(7)(iii)(E)

If supplied by a metal-clad, metal-sheathed, or grounded metal raceway wiring method.

1926.404(f)(7)(iii)(F)

If equipment operates with any terminal at over 150 volts to ground; however, the following need not be grounded:

1926.404(f)(7)(iii)(F)(1)

Enclosures for switches or circuit breakers used for other than service equipment and accessible to qualified persons only;

1926.404(f)(7)(iii)(F)(2)

Metal frames of electrically heated appliances which are permanently and effectively insulated from ground; and

1926.404(f)(7)(iii)(F)(3)

The cases of distribution apparatus such as transformers and capacitors mounted on wooden poles at a height exceeding 8 feet (2.44

m) above ground or grade level.

..1926.404(f)(7)(iv)

1926.404(f)(7)(iv)

Equipment connected by cord and plug. Under any of the conditions described in paragraphs (f)(7)(iv)(A) through (f)(7)(iv)(C) of this

section, exposed noncurrent-carrying metal parts of cord- and plug-connected equipment which may become energized shall be

grounded:

1926.404(f)(7)(iv)(A)

If in a hazardous (classified) location (see 1926.407).

1926.404(f)(7)(iv)(B)

If operated at over 150 volts to ground, except for guarded motors and metal frames of electrically heated appliances if the appliance

frames are permanently and effectively insulated from ground.

1926.404(f)(7)(iv)(C)

If the equipment is one of the types listed in paragraphs (f)(7)(iv)(C)(1) through (f)(7)(iv)(C)(5) of this section. However, even though

the equipment may be one of these types, it need not be grounded if it is exempted by paragraph (f)(7)(iv)(C)(6).

1926.404(f)(7)(iv)(C)(1)

Hand held motor-operated tools;

1926.404(f)(7)(iv)(C)(2)

Cord- and plug-connected equipment used in damp or wet locations or by employees standing on the ground or on metal floors or

working inside of metal tanks or boilers;

1926.404(f)(7)(iv)(C)(3)

Portable and mobile X-ray and associated equipment;

1926.404(f)(7)(iv)(C)(4)

Tools likely to be used in wet and/or conductive locations;

1926.404(f)(7)(iv)(C)(5)

Portable hand lamps.

..1926.404(f)(7)(iv)(C)(6)

1926.404(f)(7)(iv)(C)(6)

Tools likely to be used in wet and/or conductive locations need not be grounded if supplied through an isolating transformer with an

ungrounded secondary of not over 50 volts. Listed or labeled portable tools and appliances protected by a system of double insulation,

or its equivalent, need not be grounded. If such a system is employed, the equipment shall be distinctively marked to indicate that the

tool or appliance utilizes a system of double insulation.

1926.404(f)(7)(v)

Nonelectrical equipment. The metal parts of the following nonelectrical equipment shall be grounded: Frames and tracks of electrically

operated cranes; frames of nonelectrically driven elevator cars to which electric conductors are attached; hand-operated metal shifting

ropes or cables of electric elevators, and metal partitions, grill work, and similar metal enclosures around equipment of over IkV

between conductors.

1926.404(f)(8)

Methods of grounding equipment -

1926.404(f)(8)(i)

With circuit conductors. Noncurrent-carrying metal parts of fixed equipment, if required to be grounded by this subpart, shall be

grounded by an equipment grounding conductor which is contained within the same raceway, cable, or cord, or runs with or encloses

the circuit conductors. For DC circuits only, the equipment grounding conductor may be run separately from the circuit conductors.

1926.404(f)(8)(ii)

Grounding conductor. A conductor used for grounding fixed or movable equipment shall have capacity to conduct safely any fault

current which may be imposed on it.

..1926.404(f)(8)(iii)

1926.404(f)(8)(iii)

Equipment considered effectively grounded. Electric equipment is considered to be effectively grounded if it is secured to, and in

electrical contact with, a metal rack or structure that is provided for its support and the metal rack or structure is grounded by the

method specified for the noncurrent-carrying metal parts of fixed equipment in paragraph (f)(8)(i) of this section. Metal car frames

supported by metal hoisting cables attached to or running over metal sheaves or drums of grounded elevator machines are also

considered to be effectively grounded.

1926.404(f)(9)

Bonding. If bonding conductors are used to assure electrical continuity, they shall have the capacity to conduct any fault current which

may be imposed.

1926.404(f)(10)

Made electrodes. If made electrodes are used, they shall be free from nonconductive coatings, such as paint or enamel; and, if

practicable, they shall be embedded below permanent moisture level. A single electrode consisting of a rod, pipe or plate which has a

resistance to ground greater than 25 ohms shall be augmented by one additional electrode installed no closer than 6 feet (1.83 m) to

the first electrode.

1926.404(f)(11)

Grounding of systems and circuits of 1000 volts and over (high voltage) -

1926.404(f)(11)(i)

General. If high voltage systems are grounded, they shall comply with all applicable provisions of paragraphs (f)(1) through (f)(10) of

this section as supplemented and modified by this paragraph (f)(11).

1926.404(f)(11)(ii)

Grounding of systems supplying portable or mobile equipment. Systems supplying portable or mobile high voltage equipment, other

than substations installed on a temporary basis, shall comply with the following:

..1926.404(f)(11)(ii)(A)

1926.404(f)(11)(ii)(A)

Portable and mobile high voltage equipment shall be supplied from a system having its neutral grounded through an impedance. If a

delta-connected high voltage system is used to supply the equipment, a system neutral shall be derived.

1926.404(f)(11)(ii)(B)

Exposed noncurrent-carrying metal parts of portable and mobile equipment shall be connected by an equipment grounding conductor

to the point at which the system neutral impedance is grounded.

1926.404(f)(11)(ii)(C)

Ground-fault detection and relaying shall be provided to automatically de-energize any high voltage system component which has

developed a ground fault. The continuity of the equipment grounding conductor shall be continuously monitored so as to de-energize

automatically the high voltage feeder to the portable equipment upon loss of continuity of the equipment grounding conductor.

1926.404(f)(11)(ii)(D)

The grounding electrode to which the portable or mobile equipment system neutral impedance is connected shall be isolated from and

separated in the ground by at least 20 feet (6.1 m) from any other system or equipment grounding electrode, and there shall be no

direct connection between the grounding electrodes, such as buried pipe, fence or like objects.

..1926.404(f)(11)(iii)

1926.404(f)(11)(iii)

Grounding of equipment. All noncurrent-carrying metal parts of portable equipment and fixed equipment including their associated

fences, housings, enclosures, and supporting structures shall be grounded. However, equipment which is guarded by location and

isolated from ground need not be grounded. Additionally, pole-mounted distribution apparatus at a height exceeding 8 feet (2.44 m)

above ground or grade level need not be grounded.

[54 FR 24334, June 7, 1989; 61 FR 5507, Feb. 13, 1996]

1926.405(a)

Wiring methods. The provisions of this paragraph do not apply to conductors which form an integral part

of equipment such as motors, controllers, motor control centers and like equipment.

1926.405(a)(1)

General requirements -

1926.405(a)(1)(i)

Electrical continuity of metal raceways and enclosures. Metal raceways, cable armor, and other metal

enclosures for conductors shall be metallically joined together into a continuous electric conductor and

shall be so connected to all boxes, fittings, and cabinets as to provide effective electrical continuity.

1926.405(a)(1)(ii)

Wiring in ducts. No wiring systems of any type shall be installed in ducts used to transport dust, loose

stock or flammable vapors. No wiring system of any type shall be installed in any duct used for vapor

removal or in any shaft containing only such ducts.

..1926.405(a)(2)

1926.405(a)(2)

Temporary wiring -

1926.405(a)(2)(i)

Scope. The provisions of paragraph (a)(2) of this section apply to temporary electrical power and lighting

wiring methods which may be of a class less than would be required for a permanent installation. Except

as specifically modified in paragraph (a)(2) of this section, all other requirements of this subpart for

permanent wiring shall apply to temporary wiring installations. Temporary wiring shall be removed

immediately upon completion of construction or the purpose for which the wiring was installed.

1926.405(a)(2)(ii)

General requirements for temporary wiring -

1926.405(a)(2)(ii)(A)

Feeders shall originate in a distribution center. The conductors shall be run as multiconductor cord or

cable assemblies or within raceways; or, where not subject to physical damage, they may be run as open

conductors on insulators not more than 10 feet (3.05 m) apart.

1926.405(a)(2)(ii)(B)

Branch circuits shall originate in a power outlet or panelboard. Conductors shall be run as multiconductor

cord or cable assemblies or open conductors, or shall be run in raceways. All conductors shall be

protected by overcurrent devices at their ampacity. Runs of open conductors shall be located where the

conductors will not be subject to physical damage, and the conductors shall be fastened at intervals not

exceeding 10 feet (3.05 m). No branch-circuit conductors shall be laid on the floor. Each branch circuit

that supplies receptacles or fixed equipment shall contain a separate equipment grounding conductor if

the branch circuit is run as open conductors.

..1926.405(a)(2)(ii)(C)

1926.405(a)(2)(ii)(C)

Receptacles shall be of the grounding type. Unless installed in a complete metallic raceway, each branch

circuit shall contain a separate equipment grounding conductor, and all receptacles shall be electrically

connected to the grounding conductor. Receptacles for uses other than temporary lighting shall not be

installed on branch circuits which supply temporary lighting. Receptacles shall not be connected to the

same ungrounded conductor of multiwire circuits which supply temporary lighting.

1926.405(a)(2)(ii)(D)

Disconnecting switches or plug connectors shall be installed to permit the disconnection of all

ungrounded conductors of each temporary circuit.

1926.405(a)(2)(ii)(E)

All lamps for general illumination shall be protected from accidental contact or breakage. Metal-case

sockets shall be grounded.

1926.405(a)(2)(ii)(F)

Temporary lights shall not be suspended by their electric cords unless cords and lights are designed for

this means of suspension.

1926.405(a)(2)(ii)(G)

Portable electric lighting used in wet and/or other conductive locations, as for example, drums, tanks,

and vessels, shall be operated at 12 volts or less. However, 120-volt lights may be used if protected by a

ground-fault circuit interrupter.

1926.405(a)(2)(ii)(H)

A box shall be used wherever a change is made to a raceway system or a cable system which is metal

clad or metal sheathed.

1926.405(a)(2)(ii)(I)

Flexible cords and cables shall be protected from damage. Sharp corners and projections shall be

avoided. Flexible cords and cables may pass through doorways or other pinch points, if protection is

provided to avoid damage.

..1926.405(a)(2)(ii)(J)

1926.405(a)(2)(ii)(J)

Extension cord sets used with portable electric tools and appliances shall be of three-wire type and shall

be designed for hard or extra-hard usage. Flexible cords used with temporary and portable lights shall be

designed for hard or extra-hard usage.

NOTE: The National Electrical Code, ANSI/NFPA 70, in Article 400, Table 400-4, lists various types of

flexible cords, some of which are noted as being designed for hard or extra-hard usage. Examples of

these types of flexible cords include hard service cord (types S, ST, SO, STO) and junior hard service cord

(types SJ, SJO, SJT, SJTO).

1926.405(a)(2)(iii)

Guarding. For temporary wiring over 600 volts, nominal, fencing, barriers, or other effective means shall

be provided to prevent access of other than authorized and qualified personnel.

1926.405(b)

Cabinets, boxes, and fittings.

1926.405(b)(1)

Conductors entering boxes, cabinets, or fittings. Conductors entering boxes, cabinets, or fittings shall be

protected from abrasion, and openings through which conductors enter shall be effectively closed.

Unused openings in cabinets, boxes, and fittings shall also be effectively closed.

1926.405(b)(2)

Covers and canopies. All pull boxes, junction boxes, and fittings shall be provided with covers. If metal

covers are used, they shall be grounded. In energized installations each outlet box shall have a cover,

faceplate, or fixture canopy. Covers of outlet boxes having holes through which flexible cord pendants

pass shall be provided with bushings designed for the purpose or shall have smooth, well-rounded

surfaces on which the cords may bear.

..1926.405(b)(3)

1926.405(b)(3)

Pull and junction boxes for systems over 600 volts, nominal. In addition to other requirements in this

section for pull and junction boxes, the following shall apply to these boxes for systems over 600 volts,

nominal:

1926.405(b)(3)(i)

Complete enclosure. Boxes shall provide a complete enclosure for the contained conductors or cables.

1926.405(b)(3)(ii)

Covers. Boxes shall be closed by covers securely fastened in place. Underground box covers that weigh

over 100 pounds (43.6 kg) meet this requirement. Covers for boxes shall be permanently marked "HIGH

VOLTAGE." The marking shall be on the outside of the box cover and shall be readily visible and legible.

1926.405(c)

Knife switches. Single-throw knife switches shall be so connected that the blades are dead when the

switch is in the open position. Single-throw knife switches shall be so placed that gravity will not tend to

close them. Single-throw knife switches approved for use in the inverted position shall be provided with a

locking device that will ensure that the blades remain in the open position when so set. Double-throw

knife switches may be mounted so that the throw will be either vertical or horizontal. However, if the

throw is vertical, a locking device shall be provided to ensure that the blades remain in the open position

when so set.

..1926.405(d)

1926.405(d)

Switchboards and panelboards. Switchboards that have any exposed live parts shall be located in

permanently dry locations and accessible only to qualified persons. Panelboards shall be mounted in

cabinets, cutout boxes, or enclosures designed for the purpose and shall be dead front. However,

panelboards other than the dead front externally-operable type are permitted where accessible only to

qualified persons. Exposed blades of knife switches shall be dead when open.

1926.405(e)

Enclosures for damp or wet locations.

1926.405(e)(1)

Cabinets, fittings, and boxes. Cabinets, cutout boxes, fittings, boxes, and panelboard enclosures in damp

or wet locations shall be installed so as to prevent moisture or water from entering and accumulating

within the enclosures. In wet locations the enclosures shall be weatherproof.

1926.405(e)(2)

Switches and circuit breakers. Switches, circuit breakers, and switchboards installed in wet locations shall

be enclosed in weatherproof enclosures.

1926.405(f)

Conductors for general wiring. All conductors used for general wiring shall be insulated unless otherwise

permitted in this Subpart. The conductor insulation shall be of a type that is suitable for the voltage,

operating temperature, and location of use. Insulated conductors shall be distinguishable by appropriate

color or other means as being grounded conductors, ungrounded conductors, or equipment grounding

conductors.

1926.405(g)

Flexible cords and cables -

1926.405(g)(1)

Use of flexible cords and cables -

1926.405(g)(1)(i)

Permitted uses. Flexible cords and cables shall be suitable for conditions of use and location. Flexible

cords and cables shall be used only for:

..1926.405(g)(1)(i)(A)

1926.405(g)(1)(i)(A)

Pendants;

1926.405(g)(1)(i)(B)

Wiring of fixtures;

1926.405(g)(1)(i)(C)

Connection of portable lamps or appliances;

1926.405(g)(1)(i)(D)

Elevator cables;

1926.405(g)(1)(i)(E)

Wiring of cranes and hoists;

1926.405(g)(1)(i)(F)

Connection of stationary equipment to facilitate their frequent interchange;

1926.405(g)(1)(i)(G)

Prevention of the transmission of noise or vibration; or

1926.405(g)(1)(i)(H)

Appliances where the fastening means and mechanical connections are designed to permit removal for

maintenance and repair.

1926.405(g)(1)(ii)

Attachment plugs for cords. If used as permitted in paragraphs (g)(1)(i)(C), (g)(1)(i)(F), or (g)(1)(i)(H) of

this section, the flexible cord shall be equipped with an attachment plug and shall be energized from a

receptacle outlet.

1926.405(g)(1)(iii)

Prohibited uses. Unless necessary for a use permitted in paragraph (g)(1)(i) of this section, flexible cords

and cables shall not be used:

..1926.405(g)(1)(iii)(A)

1926.405(g)(1)(iii)(A)

As a substitute for the fixed wiring of a structure;

1926.405(g)(1)(iii)(B)

Where run through holes in walls, ceilings, or floors;

1926.405(g)(1)(iii)(C)

Where run through doorways, windows, or similar openings, except as permitted in paragraph

(a)(2)(ii)(1) of this section;

1926.405(g)(1)(iii)(D)

Where attached to building surfaces; or

1926.405(g)(1)(iii)(E)

Where concealed behind building walls, ceilings, or floors.

1926.405(g)(2)

Identification, splices, and terminations -

1926.405(g)(2)(i)

Identification. A conductor of a flexible cord or cable that is used as a grounded conductor or an

equipment grounding conductor shall be distinguishable from other conductors.

1926.405(g)(2)(ii)

Marking. Type SJ, SJO, SJT, SJTO, S, SO, ST, and STO cords shall not be used unless durably marked on

the surface with the type designation, size, and number of conductors.

1926.405(g)(2)(iii)

Splices. Flexible cords shall be used only in continuous lengths without splice or tap. Hard service flexible

cords No. 12 or larger may be repaired if spliced so that the splice retains the insulation, outer sheath

properties, and usage characteristics of the cord being spliced.

..1926.405(g)(2)(iv)

1926.405(g)(2)(iv)

Strain relief. Flexible cords shall be connected to devices and fittings so that strain relief is provided which

will prevent pull from being directly transmitted to joints or terminal screws.

1926.405(g)(2)(v)

Cords passing through holes. Flexible cords and cables shall be protected by bushings or fittings where

passing through holes in covers, outlet boxes, or similar enclosures.

1926.405(h)

Portable cables over 600 volts, nominal. Multiconductor portable cable for use in supplying power to

portable or mobile equipment at over 600 volts, nominal, shall consist of No. 8 or larger conductors

employing flexible stranding. Cables operated at over 2000 volts shall be shielded for the purpose of

confining the voltage stresses to the insulation. Grounding conductors shall be provided. Connectors for

these cables shall be of a locking type with provisions to prevent their opening or closing while energized.

Strain relief shall be provided at connections and terminations. Portable cables shall not be operated with

splices unless the splices are of the permanent molded, vulcanized, or other equivalent type. Termination

enclosures shall be marked with a high voltage hazard warning, and terminations shall be accessible only

to authorized and qualified personnel.

1926.405(i)

Fixture wires -

1926.405(i)(1)

General. Fixture wires shall be suitable for the voltage, temperature, and location of use. A fixture wire

which is used as a grounded conductor shall be identified.

..1926.405(i)(2)

1926.405(i)(2)

Uses permitted. Fixture wires may be used:

1926.405(i)(2)(i)

For installation in lighting, fixtures and in similar equipment where enclosed or protected and not subject

to bending or twisting in use; or

1926.405(i)(2)(ii)

For connecting lighting fixtures to the branch-circuit conductors supplying the fixtures.

1926.405(i)(3)

Uses not permitted. Fixture wires shall not be used as branch-circuit conductors except as permitted for

Class 1 power-limited circuits.

1926.405(j)

Equipment for general use -

1926.405(j)(1)

Lighting fixtures, lampholders, lamps, and receptacles -

1926.405(j)(1)(i)

Live parts. Fixtures, lampholders, lamps, rosettes, and receptacles shall have no live parts normally

exposed to employee contact. However, rosettes and cleat-type lampholders and receptacles located at

least 8 feet (2.44 m) above the floor may have exposed parts.

..1926.405(j)(1)(ii)

1926.405(j)(1)(ii)

Support. Fixtures, lampholders, rosettes, and receptacles shall be securely supported. A fixture that

weighs more than 6 pounds (2.72 kg) or exceeds 16 inches (406 mm) in any dimension shall not be

supported by the screw shell of a lampholder.

1926.405(j)(1)(iii)

Portable lamps. Portable lamps shall be wired with flexible cord and an attachment plug of the polarized

or grounding type. If the portable lamp uses an Edison-based lampholder, the grounded conductor shall

be identified and attached to the screw shell and the identified blade of the attachment plug. In addition,

portable handlamps shall comply with the following:

1926.405(j)(1)(iii)(A)

Metal shell, paperlined lampholders shall not be used;

1926.405(j)(1)(iii)(B)

Handlamps shall be equipped with a handle of molded composition or other insulating material;

1926.405(j)(1)(iii)(C)

Handlamps shall be equipped with a substantial guard attached to the lampholder or handle;

1926.405(j)(1)(iii)(D)

Metallic guards shall be grounded by the means of an equipment grounding conductor run within the

power supply cord.

1926.405(j)(1)(iv)

Lampholders. Lampholders of the screw-shell type shall be installed for use as lampholders only.

Lampholders installed in wet or damp locations shall be of the weatherproof type.

..1926.405(j)(1)(v)

1926.405(j)(1)(v)