Académique Documents

Professionnel Documents

Culture Documents

LIGHTWEIGHT, NON-SAGGING BUILDING INSULATION

Transféré par

Anwar SyedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

LIGHTWEIGHT, NON-SAGGING BUILDING INSULATION

Transféré par

Anwar SyedDroits d'auteur :

Formats disponibles

BUILDING ROLL

LIGHT WEIGHT, NO SAGGING NOR SETTLING

www.kimmcoinsulation.com

ROCKINSUL BUILDING ROLL (RBR)

Glass scrim being non-corrosive does not deteriorate with time and ensures NO SAGGING in FSK faced KIMMCO Rockwool Building Roll over a period as it has least coefcient of thermal expansion.

DENSITY AND DIMENSIONS

Density (kg/m3) 36/48 Thickness (mm) min 40 60 30 60 max 50 100 50 100 Length (m) 5 to 10 5 to 8 5 to 8 4 to 7 1100 Width (mm) Density kg/m3 36 48 60 OTHER DENSITIES AVAILABLE Density lbs/ft 3 2.250 4.000 3.750

BR 36 48 60

60

PERFORMANCES WORKING TEMPERATURE Fibre FSK PERMANENCE:

KIMMCO Rockwool Building rolls are dimensionally stable under varying conditions of temperature and humidity, rot proof, odorless, non-hygroscopic and will not sustain vermin or fungus. No sag and settling so longer life.

For thermal and/or acoustic insulation of walls and roofs.

750 C o 100 C

THERMAL CONDUCTIVITY (K VALUE):

Thermal conductivity of Rockwool Building rolls tested n according to BS 874, ASTM C 177, 518; are shown in the following Table:

APPLICATIONS

For thermal and/or acoustic insulation of walls and roofs.

MEAN TEMPERATURE C 10 25 50 100

o

THERMAL CONDUCTIVITY FOR THE FOLLOWING DENSITIES W /m.K 36 kg/m3 0.036 0.039 0.047 0.057 48 kg/m3 0.033 0.035 0.042 0.051 60 kg/m3 0.031 0.033 0.038 0.046 2.250 lb/ft3 0.250 0.270 0.326 0.395 Btu.in/ft2.h. F 3.000 lb/ft3 0.229 0.243 0.291 0.354 3.750 lb/ft3 0.215 0.229 0.263 0.319

o

F 50 77 122 212

These are typical values subject to normal manufacturing and testing variances.

THERMAL RESISTANCE (R VALUE):

Thermal resistance is a key to direct measure of thermal performance of an insulation material. It is directly proportional to thickness of insulation. Lower the thickness of insulation material is lower the thermal resistance hence lower the thermal performance correspondingly. It is important to not that Mineral wool (rock wool / Glass wool /Slag wool) of low densities (<24kg/m3) do not retain its original thickness. It regains thickness between 50 90%.

DESCRIPTION

KIMMCO Rockwool Building Rolls are manufactured from stable rock bers bonded with thermosetting resins. Light in weight, strong and resilient. Easy to handle. Rock bers in Rockwool Building Rolls are ne and uniformly distributed that ensure excellent uniform thermal resistance of Building Roll FACINGS DESCRIPTION KIMMCO Rockwool Building Rolls are available with FSK (Aluminium Foil/glass scrim/Kraft paper laminate) facing which provides an efcient vapor barrier. Glass scrim, one of the components of FSK, is specially engineered that enable FSK to achieve very high tensile strength of more than 8000 N/m in longitudinal direction (MD). This high tensile strength helps in tightening the roll at the ends and to avoid welded wire mesh conventionally used to support insulation rolls when applied in PEB ceiling.

Minimum density of KIMMCO Rokwool Building Rolls as 36kg/m3 ensures no change in its thermal performance Thermal Resistance values of Rokwool Building Rolls for various thicknesses and densities are shown in following Table:

THICKNESS mm 30 40 50 60 75 100 inch 1.25 1.50 2.00 .50 3.00 4.00 BR 36 1.026 1.282 1.538 1.923 2.564

THERMAL RESISTANCE m .K/W BR 48 BR 60 0.909 1.143 1.212 1.429 1.515 1.714 1.818 2.143 2.273 2.857 3.030

2

AT 25 oC MEAN TEMP ft2.h.oF/Btu BR 36 BR 48 4.630 5.144 5.556 6.173 7.407 8.230 9.259 10.288 11.111 12.346 14.815 16.461

BR 60 5.463 6.556 8.741 10.926 13.112 17.482

AN EXAMPLE OF CALCULATION OF THERMAL TRANSMITTANCE (U VALUE) AT 25 oC MEAN TEMPERATURE FOR ROOF AND WALL: ROOF

CONFORMITY TO STANDARDS

KIMMCO Rockwool Building Rolls comply with the following standards: AMERICAN STANDARDS ASTM C 167, 168, 177,423, 518, 553, 665 13.8 & 13.9, 686, 991, 1045, 1101/1101M, 1104/1104M, 1136 (types 1&2),1335; E 84,96,136, 795 F.S. HH-B-100B (Type1), HH-I-521F, HH-I-558B

R Value ( ft .h.F/Btu )

2

Elements of Construction Out side Surface Air Resistance Metal sheet Rockwool Inside Surface Air Resistance

RTOTAL

40 mm 0.250 0 5.824 0.908 6.982 0.143

KIMMCO Rockinsul Building Roll (BR 36) 50mm 75mm 0.250 0.250 0 0 7.279 10.919 0.908 0.908 8.437 0.119 12.077 0.083

100mm 0.250 0 14.559 0.908 17 0.064

BRITISH STANDARDS BS 476 (parts 4,6 & 7), 874, 2972, 3533, 6676 (part 1) INDIAN STANDARDS IS 8183

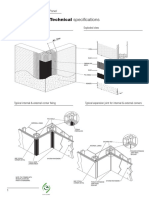

TYPICAL FIXING DETAILS

Wall Construction of light weight metal sheeted buildings are frequently uninsulated leading to extremely uncomfortable working conditions or excessive cooling requirements. KIMMCO Rockwool Building Roll can be tted to new and existing buildings to alleviate these problems. NEW CONSTRUCTION: KIMMCO Rockwool Building Roll is xed at the head of the wall and allowed to drape down the length. The insulation roll may be xed to sheeting rails with the faced side to the inside of the building if no lining sheets are to be used or alternatively by trapping the insulation between external and internal sheeting. Spacer Bars of Non compressible material should be used to prevent undue crushing of the insulation. EXISTING BUILDINGS: KIMMCO Rockwool Building Roll may be installed from within existing buildings by using a T Bar suspension gride and liner sheets, the insulation can be cut to suit the size of lining sheet and xed to the back of the sheet with adhesive or mechanical fasteners. The lining is then installed in the grid system in the normal manner. As an alternative to the above timber packing strips may be cut to suit the sheeting rails and screwed in place, x the Building Roll at the head of the wall by screws into the timber packer with a steel strip placed on top of the insulation directly over the packer. Repeat as required at other sheeting rail locations, ensuring that the Building roll are closely butted to each other with the edge anges overlapping.

U Value ( Btu/ ft2.h.F )

WALL

R Value ( ft2.h.F/Btu )

Elements of Construction 40 mm Out side Surface Air Resistance Metal sheet Rockwool Inside Surface Air Resistance Liner

RTOTAL

0 5.824 0 0.681 6.755 0.148

KIMMCO Rockwool Building Roll (BR 36) 50mm 75mm 100mm 0.250 0.250 0.250 0 0 0 7.279 10.919 14.559 0 0 0 0.681 0.681 0.681 8.21 11.85 15.49 0.122 0.084 0.065

U Value ( Btu/ ft2.h.F )

FIRE SAFETY: Unfaced KIMMCO Rockwool Building rolls are Non-combustible when tested in accordance to BS 476 (Part 4), ASTM E 136. FSK faced KIMMCO Rockwool Building rolls when tested in accordance to ASTM E84 / UL 723 / NFPA 255 achieve surface burning characteristics as follows: Flame Spread Index : < 25 Smoke Developed Index : < 50 Fire Hour Rating: Fire Hour Rating of an insulation material is very important. It reects the ability of an insulation material to resist the re for how much time. During re each extra minute is vital to save the life and property. Only Rock wool products among all Mineral wool (rock wool / Glass wool /Slag wool) products are recommended for FIRE Hour Rating. It achieves up to 2hrs FIRE Hour Rating. MOISTURE ABSORPTION: KIMMCO Rockwool Building Rolls achieve moisture absorption less than 1% by volume when tested in accordance with ASTM C 1101/1101M. KIMMCO Rockwool Building Rolls do not absorb moisture from the ambient air nor water by capillary attraction. Only water under pressure can enter the insulation products, but that will quickly dry out owing to the materials open cell structure. FSK faced KIMMCO Rockinsul Building rolls achieve water vapor permeance of < 0.02 perms when tested in accordance to ASTM E 96 desiccant method (Federal Standard HH-B-100B type 1). NON TOXIC: KIMMCO Rockwool Building Roll is not hazardous to health (See RIL MSDS) ACOUSTICS: Unfaced KIMMCO Rockwool Building rolls when tested in accordance to ASTM C 423 ( Mounting A as per ASTM E 795) achieve Sound Absorption Coefcient and NRC values as below:

METAL BUILDING ROOF

OVER PURLIN APPLICATION Fix end of Building Roll faced side down, at ridge and allow to unroll to eaves. At eaves, Roll should be cut and pulled taut. Each subsequent roll should be overlapped or butted to avoid gaps. Packing strips, equal in thickness to the insulation should be placed along the line of each purlin and xed through the rooiner to the purlin below. This avoids undue compression of the insulation. The roof cladding should be carried out in conjunction with the insulation work to avoid accidental damage. Fixing should be through the crown prole of the roong sheet and down through the spacer to the purlin below. Weathering sheets should be tted as insulation work progresses in order to avoid unnecessary damage to the insulation. Holes for hook bolts shall be sealed against water penetration. UNDER PURLIN APPLICATION After application of roof covering the internal lining and insulation can be carried out using a framework of light metal T sections suspended from the purlins by straps or hangers. a. Cut Building Roll to size and lay on lining board. To assist in handling, the insulation may be adhered or stapled to the lining board. Erect lining board and insulation within the metal T grid securing as required. b. Alternatively the insulation can be applied from rolls initially secured at the ridge and allowed to unroll progressively towards the eave in conjunction with the application of lining boards. It is important that the adjacent layers of insulation are sufciently overlapped to prevent heat loss or gain.

PRODUCT TYPE BR 36 BR 48

ABSORPTION COEFFICIENT AT THE OCTAVE FREQUENCIES Hz THICKNESS mm 50 75 100 50 100 125 0.10 0.23 0.29 0.08 0.39 250 0.42 0.81 0.90 0.46 0.88 500 0.93 0.88 0.95 0.94 1.04 1000 1.00 1.04 1.06 1.05 1.11 2000 0.96 0.99 0.99 0.99 1.01 4000 0.92 0.93 0.95 0.93 0.94 NRC 0.85 0.95 1.00 0.85 1.00

These are typical values subject to normal manufacturing and testing variances.

Vous aimerez peut-être aussi

- 1p - Energy Transfer - QP - Edexcel - Igcse - PhysicsDocument23 pages1p - Energy Transfer - QP - Edexcel - Igcse - PhysicsAishath WaheedaPas encore d'évaluation

- Energy-Efficient RefurbishmentDocument36 pagesEnergy-Efficient RefurbishmentNeedleandMortarPas encore d'évaluation

- Marine Joinery Outfitting PDFDocument43 pagesMarine Joinery Outfitting PDFÇÇağdaş_1Pas encore d'évaluation

- Insulation Roofs P11 40Document30 pagesInsulation Roofs P11 40Jennifer NavarroPas encore d'évaluation

- Shotcrete BrochureDocument6 pagesShotcrete Brochureit4scribdPas encore d'évaluation

- Marvels of Sayyiduna Imam HussainDocument52 pagesMarvels of Sayyiduna Imam HussainObaidRazaPas encore d'évaluation

- Ayrshire Steel FramingDocument41 pagesAyrshire Steel FramingingdanbeloiuPas encore d'évaluation

- Bolted ConnectionsDocument9 pagesBolted ConnectionsClaudioDuarte100% (1)

- Microsoft Word - Roofing & Re-RoofingDocument7 pagesMicrosoft Word - Roofing & Re-RoofingkokueiPas encore d'évaluation

- SyncroFlo - Sizing Booster Pumps - Latest Tricks and Trends - 2009 ASPE Technical SymposiumDocument71 pagesSyncroFlo - Sizing Booster Pumps - Latest Tricks and Trends - 2009 ASPE Technical SymposiumGecko1987Pas encore d'évaluation

- Pilkington Global Glass Handbook Architectural Products EnglishDocument217 pagesPilkington Global Glass Handbook Architectural Products EnglishSonali GungoosinghPas encore d'évaluation

- Roofing Insulation & Water ProofingDocument4 pagesRoofing Insulation & Water ProofingAnonymous 3eHGEDbxPas encore d'évaluation

- Upgraded Thermal Insulation for Minimizing Heat Losses in Cement PlantsDocument39 pagesUpgraded Thermal Insulation for Minimizing Heat Losses in Cement PlantsBalson VijaishPas encore d'évaluation

- Architectural DBR Festival Mall PDFDocument27 pagesArchitectural DBR Festival Mall PDFSamriddh DhareshwarPas encore d'évaluation

- Double Regulating Valves (2920W)Document8 pagesDouble Regulating Valves (2920W)Anwar SyedPas encore d'évaluation

- Corrugated Aluminum Jacketing CladdingDocument3 pagesCorrugated Aluminum Jacketing CladdingGia Minh Tieu TuPas encore d'évaluation

- Duct Liner (AFICO)Document4 pagesDuct Liner (AFICO)hshoooma65Pas encore d'évaluation

- Engine Room VentillationDocument36 pagesEngine Room VentillationAnwarul Shafiq AwalludinPas encore d'évaluation

- Construct cardboard building prototype guideDocument16 pagesConstruct cardboard building prototype guidePaul GrimesPas encore d'évaluation

- Architectural Record - July 2019 PDFDocument160 pagesArchitectural Record - July 2019 PDFebt555Pas encore d'évaluation

- Superlon 16 Pages CatalogDocument16 pagesSuperlon 16 Pages CatalogDevan SanmugamPas encore d'évaluation

- CA Silicate & Other Insulation - Surface Dew PointDocument5 pagesCA Silicate & Other Insulation - Surface Dew PointjagrutPas encore d'évaluation

- Locked SeamDocument8 pagesLocked SeamTony DuignanPas encore d'évaluation

- HVAC Specification Detail Guide: A Guide To Specifying ROCKWOOL Insulations For HVAC ApplicationsDocument40 pagesHVAC Specification Detail Guide: A Guide To Specifying ROCKWOOL Insulations For HVAC ApplicationsjgonzaloPas encore d'évaluation

- ESTIDAMA PBRS RE-R1 Prescriptive MethodologyDocument11 pagesESTIDAMA PBRS RE-R1 Prescriptive MethodologyAshraful HasanPas encore d'évaluation

- Hvac Factsheet BasicsDocument3 pagesHvac Factsheet BasicsAnwar SyedPas encore d'évaluation

- CDocument425 pagesCNikho Velayo DavidPas encore d'évaluation

- 62.191 SizingandSelectionDocument13 pages62.191 SizingandSelectionKo PaukPas encore d'évaluation

- Kimmco InsulationDocument7 pagesKimmco InsulationMujjo SahbPas encore d'évaluation

- KBR Leaflet EngDocument1 pageKBR Leaflet EngAnwar SyedPas encore d'évaluation

- TB 34 - Steel Building Frames June 2020 EarthingDocument8 pagesTB 34 - Steel Building Frames June 2020 EarthingRethish KochukavilakathPas encore d'évaluation

- Faced Duct Wrap Insulation Technical Data SheetDocument4 pagesFaced Duct Wrap Insulation Technical Data Sheethello1230Pas encore d'évaluation

- Flexi: The Perfect Friction Fit For Framed ConstructionsDocument11 pagesFlexi: The Perfect Friction Fit For Framed ConstructionsFadi HPas encore d'évaluation

- AFICO Heavy Density Pipe Insulation - NewDocument4 pagesAFICO Heavy Density Pipe Insulation - NewNickolas HeadPas encore d'évaluation

- Rockwool Acoustic Infill-SecDocument2 pagesRockwool Acoustic Infill-SecGiuseppe AlibertiPas encore d'évaluation

- Cold Bridging in Rainscreen Cladding SystemDocument5 pagesCold Bridging in Rainscreen Cladding SystemStephenPas encore d'évaluation

- Fireclad System BoralDocument8 pagesFireclad System BoralSuciul E ViuPas encore d'évaluation

- Award-Winning ISORAST Building System Offers World-Leading InsulationDocument27 pagesAward-Winning ISORAST Building System Offers World-Leading InsulationMarcin StęplowskiPas encore d'évaluation

- Aluminium Industry - Print Friendly - UkDocument8 pagesAluminium Industry - Print Friendly - UkCarlos BarriosPas encore d'évaluation

- Rockwool Slab Data Sheet - (ProRox Formerly RW Slab)Document7 pagesRockwool Slab Data Sheet - (ProRox Formerly RW Slab)stuart3962Pas encore d'évaluation

- Rockwool Roll, Twin Roll and Rollbatt Data SheetDocument4 pagesRockwool Roll, Twin Roll and Rollbatt Data Sheetalex42pdfPas encore d'évaluation

- FRF Slabs: Thermal Insulation for Buildings and Industrial ApplicationsDocument16 pagesFRF Slabs: Thermal Insulation for Buildings and Industrial ApplicationsAmal RajPas encore d'évaluation

- Technical Bulletin TB-34: Steel House FramesDocument4 pagesTechnical Bulletin TB-34: Steel House FramesRaymond WongPas encore d'évaluation

- Rigid Pipe Covering (K450) : With Extr A Rig IDDocument6 pagesRigid Pipe Covering (K450) : With Extr A Rig IDraguhvacind4620Pas encore d'évaluation

- Building Design using Cold Formed Steel Sections: Fire ProtectionDocument39 pagesBuilding Design using Cold Formed Steel Sections: Fire ProtectionMia Su Siu YingPas encore d'évaluation

- Catalogue of Roof SheetDocument8 pagesCatalogue of Roof Sheetcvsatheeh1Pas encore d'évaluation

- bostik-paneltack-hm-dekton-tds-en-2020Document5 pagesbostik-paneltack-hm-dekton-tds-en-2020Miguel ZuzaPas encore d'évaluation

- Rocktech WM - RTWM 09Document4 pagesRocktech WM - RTWM 09arunrengarajPas encore d'évaluation

- Sealing SolutionsDocument21 pagesSealing Solutionssaravan1891Pas encore d'évaluation

- KBR InsulationDocument8 pagesKBR InsulationkennethPas encore d'évaluation

- KflexDocument8 pagesKflexEddie BoyzPas encore d'évaluation

- 9-EAFTechnical PaperV1Document15 pages9-EAFTechnical PaperV1chandirandelhiPas encore d'évaluation

- Gyprock 949 Strata Wall 201202Document24 pagesGyprock 949 Strata Wall 201202duckePas encore d'évaluation

- Epp 1792Document11 pagesEpp 1792burvanovPas encore d'évaluation

- Lemn Pin FinlandezDocument16 pagesLemn Pin FinlandezRoxana HuțanuPas encore d'évaluation

- Bitustick ALDocument45 pagesBitustick ALBavishPas encore d'évaluation

- Aluminium As A Building Material: Athira. P. R 101116007 Third Year B-ArchDocument10 pagesAluminium As A Building Material: Athira. P. R 101116007 Third Year B-ArchAshrutha HarshiniPas encore d'évaluation

- Lexan Polycarbonate 9030 Technical Properties Data SheetDocument6 pagesLexan Polycarbonate 9030 Technical Properties Data Sheetenki95823100% (1)

- Kingspan 20insulation Thermaroof 20tr22Document8 pagesKingspan 20insulation Thermaroof 20tr22Ady SasuPas encore d'évaluation

- Fire-Resistant Plasterboard: Non-Load Bearing Partition SystemsDocument16 pagesFire-Resistant Plasterboard: Non-Load Bearing Partition SystemsboyzesPas encore d'évaluation

- Thermazone Foilboard Insulation DatasheetDocument3 pagesThermazone Foilboard Insulation DatasheetSuthirak SumranPas encore d'évaluation

- Grainger Catalog 401Document1 pageGrainger Catalog 401sam_wolf009Pas encore d'évaluation

- Technical Specifications of EXIN Lightweight Building PanelDocument6 pagesTechnical Specifications of EXIN Lightweight Building Panelandrewb20050% (1)

- Foam Fillers Tapes Sealants BrochureDocument8 pagesFoam Fillers Tapes Sealants BrochureAppavoo DeelenPas encore d'évaluation

- Eng Trocellen DuctDocument6 pagesEng Trocellen DuctjacksonliPas encore d'évaluation

- CEB 711 - Structural Design II: Semester 2, 2020 2Document32 pagesCEB 711 - Structural Design II: Semester 2, 2020 2Asnil PrakashPas encore d'évaluation

- Prorox Datasheet Final WebDocument8 pagesProrox Datasheet Final WebMohd FadliPas encore d'évaluation

- Metecnopanel Information Guide NZDocument8 pagesMetecnopanel Information Guide NZbassouadPas encore d'évaluation

- Flexible Duct Insulated & Non InsulatedDocument4 pagesFlexible Duct Insulated & Non Insulatedali faragallahPas encore d'évaluation

- Isocop Rev 07-11-2012 - ENGLDocument15 pagesIsocop Rev 07-11-2012 - ENGLAlexandru RucareanuPas encore d'évaluation

- Insulation Selection Guide IIG-902Document2 pagesInsulation Selection Guide IIG-902surawutwijarnPas encore d'évaluation

- Comparison - GW and RWDocument3 pagesComparison - GW and RWmohanPas encore d'évaluation

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965D'EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Pas encore d'évaluation

- Ceramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsD'EverandCeramic Matrix Composites: Fiber Reinforced Ceramics and their ApplicationsWalter KrenkelPas encore d'évaluation

- Chart MNTHSDocument6 pagesChart MNTHSAnwar SyedPas encore d'évaluation

- Is Downloading From Scribd EasyDocument1 pageIs Downloading From Scribd EasyAnwar SyedPas encore d'évaluation

- TDSAlumRoll11 PDFDocument2 pagesTDSAlumRoll11 PDFAnwar SyedPas encore d'évaluation

- 41 How To Calculate Air Temp in Unconditioned Spaces PDFDocument3 pages41 How To Calculate Air Temp in Unconditioned Spaces PDFAnwar SyedPas encore d'évaluation

- TDSAlumRoll11 PDFDocument2 pagesTDSAlumRoll11 PDFAnwar SyedPas encore d'évaluation

- Below Grade Heat TransferDocument4 pagesBelow Grade Heat TransferAnwar SyedPas encore d'évaluation

- The Andhra Pradesh Reorganisation BillDocument63 pagesThe Andhra Pradesh Reorganisation Billnavn76Pas encore d'évaluation

- Leading Saudi Ceramics ManufacturerDocument94 pagesLeading Saudi Ceramics ManufacturerAnwar Syed100% (1)

- BY-CY Series PDFDocument36 pagesBY-CY Series PDFAnwar Syed0% (1)

- Retard Chamber RCDocument1 pageRetard Chamber RCAnwar SyedPas encore d'évaluation

- A S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentDocument2 pagesA S M GL4110 & GL4910 P R P: Utomatic Prinklers Odel Endent Ecessed EndentAnwar SyedPas encore d'évaluation

- GV Osy E200 PDFDocument1 pageGV Osy E200 PDFAnwar SyedPas encore d'évaluation

- Check Valves (83BS)Document2 pagesCheck Valves (83BS)Anwar SyedPas encore d'évaluation

- Check Valves (505BS)Document2 pagesCheck Valves (505BS)Anwar SyedPas encore d'évaluation

- Econcheck FDocument1 pageEconcheck FAnwar SyedPas encore d'évaluation

- Butterfly Valves (5820M)Document1 pageButterfly Valves (5820M)Anwar SyedPas encore d'évaluation

- Grooved Check Valve 2Document1 pageGrooved Check Valve 2Anwar SyedPas encore d'évaluation

- Auto Flow Control Valve (AFCV)Document9 pagesAuto Flow Control Valve (AFCV)Anwar SyedPas encore d'évaluation

- Ball Valves (1607S)Document1 pageBall Valves (1607S)Anwar SyedPas encore d'évaluation

- Check Valves (505BS)Document2 pagesCheck Valves (505BS)Anwar SyedPas encore d'évaluation

- Expansion Joints (5580)Document4 pagesExpansion Joints (5580)Anwar SyedPas encore d'évaluation

- OSYSU valve monitoring switchesDocument3 pagesOSYSU valve monitoring switchesAnwar SyedPas encore d'évaluation

- OSYSU valve monitoring switchesDocument3 pagesOSYSU valve monitoring switchesAnwar SyedPas encore d'évaluation

- Grooved Check Valve 1Document1 pageGrooved Check Valve 1Anwar SyedPas encore d'évaluation

- Mass Notification Systems UL2572Document8 pagesMass Notification Systems UL2572WillyWillyPas encore d'évaluation

- Cavity Wall-Method StatementDocument4 pagesCavity Wall-Method StatementMuhib sadeddeinPas encore d'évaluation

- BDM Seq Autumn 2010 v1 3Document4 pagesBDM Seq Autumn 2010 v1 3api-256617442Pas encore d'évaluation

- ArmaPET From Bottle To Foam 01Document7 pagesArmaPET From Bottle To Foam 01Somnath SekarPas encore d'évaluation

- Work Breakdown StructureDocument4 pagesWork Breakdown StructureGeethaPas encore d'évaluation

- Roof PondDocument23 pagesRoof PondVasu GandhiPas encore d'évaluation

- Alpha Vci.10 System Details - Placare HPLDocument14 pagesAlpha Vci.10 System Details - Placare HPLMaria ArionPas encore d'évaluation

- Thermal Wall Types and Area Calcs For PaceDocument16 pagesThermal Wall Types and Area Calcs For PacepratheeshPas encore d'évaluation

- Katalog Per-Eko enDocument13 pagesKatalog Per-Eko enapi-246705026Pas encore d'évaluation

- Social Housing-Santa MonicaDocument11 pagesSocial Housing-Santa MonicaSandhya MahendrenPas encore d'évaluation

- GCSE Science A Unit 3 Physics P1.1-P1.2Document31 pagesGCSE Science A Unit 3 Physics P1.1-P1.2Steve BishopPas encore d'évaluation

- 5 Nano Materials in Asphalt and TarDocument4 pages5 Nano Materials in Asphalt and TarSameh AhmedPas encore d'évaluation

- Albion Marine Deckhouse: AdvantagesDocument1 pageAlbion Marine Deckhouse: AdvantagesABHIROOP KPas encore d'évaluation

- Theories and Principles of Tropical DesignDocument37 pagesTheories and Principles of Tropical DesignMark Russell DimayugaPas encore d'évaluation

- ASTM-C533 - Calcium Silicate Block and Pipe Thermal InsulationDocument4 pagesASTM-C533 - Calcium Silicate Block and Pipe Thermal InsulationEspie SualogPas encore d'évaluation

- Metecno India CatalogueDocument50 pagesMetecno India CatalogueBharat SinghPas encore d'évaluation

- Greenmeadows DraftDocument38 pagesGreenmeadows DraftVholts Villa VitugPas encore d'évaluation

- P1 Test 1 Beginner QPDocument21 pagesP1 Test 1 Beginner QPLabeenaPas encore d'évaluation

- 09 Proceedings Phidac 2012 Nis September 2012Document486 pages09 Proceedings Phidac 2012 Nis September 2012Elena VasicPas encore d'évaluation

- ASHRAE 90.1 BLDG Envelop Table 2004Document1 pageASHRAE 90.1 BLDG Envelop Table 2004Shazwina ZakariaPas encore d'évaluation

- SECTION 07 57 13 Sprayed Polyurethane Foam RoofingDocument5 pagesSECTION 07 57 13 Sprayed Polyurethane Foam RoofingSuneesh PPas encore d'évaluation