Académique Documents

Professionnel Documents

Culture Documents

Seawater Line Design Review

Transféré par

Mohammad ShahjahanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Seawater Line Design Review

Transféré par

Mohammad ShahjahanDroits d'auteur :

Formats disponibles

Seawater Line Design Review

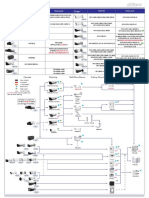

1. Existing Facilities: a) Seawater Supply Pumps (Equipment No. V29-G-V0103/V0104 & V0105): There are two motor driven pumps (V29-G-V0103/V0104) and one diesel engine driven (emergency) pump (V29-G-V0105). During normal operation, only one motor-driven pump running. Pumps Discharge Pressure: 685.3 kPa (abs) Flow Rate : 841.5 Liter/Sec (3,029 CuM/Hr) b) 32 FRP Seawater Supply Line: 1. From pump (Point-A) to YR Jetty fence (Point-B): New RTR aboveground 2,050 meter long. 2. From YR Jetty fence (Point-B) to Luberef II fence (Point-C): Underground old FRP line 3,500 meter long. c) Seawater Filters (M-8006A/B/C): Each of these filters has capacity of 1,377 CuM/Hr. d) Cooling water/Seawater Exchanger (M-8002A/B/C): For the seawater design pressure of these exchangers is 10BarG. e) 32 Seawater Return Line: 1. From Luberef II fence (Point-C) to outfall (Point-D): Underground old FRP line 4,500 meter long. f) PSVs: Two PSVs (PZV# 481 & 482) are installed on the 32 seawater discharge header near the seawater pumps.

These PSVs are installed in parallel. Discharge capacity of each PSV is 1,514.7 m3/hr (total: 3,029.4m3/hr), which equals to one pumps capacity. g) Vacuum Breakers: In the off-plot area, on the seawater supply line, two vacuum breakers (PZV# 487 & 488) and on the return line one vacuum breaker (PZV#489) installed. Each of these vacuum breakers has 905 CuM/Hr capacity. In side Luberef II fence, three vacuum breakers (80VSV 8030A/B/C) are installed downstream of the cooling water/seawater exchangers (M-8002A/B/C). Each of these vacuum breakers has 905 CuM/Hr capacity. 2. Expected Incidences: a) Start-up of the supply system: If the line is kept idle for even a short period, it will be filled with air (sucked through the vacuum breakers), especially at the pump discharge header, expansion loops and the jump-over. To avoid high air-pressure build-up inside the line, prior to start-up of the pump, the air should be fully vented/released through vents/air releasers b) Pump failure: In case of sudden pump failure/stoppage, vacuum will be created in the line. The highest vacuum will be created at the pump discharge header (near to the pumps). 1. To avoid vacuum, need to install enough size and number of vacuum breakers. c) Sudden start-up of the second pump: When the second pump starts (by manual or auto) while the first pump is running, pressure in the line will go up. To avoid pressure surge in the line, enough size and number of PSVs needed. d) Pump switch-over: In case of rough switchover of the pumps (pumps stopped or two pumps run together for a while, the line will be under vacuum or pressure respectively for a while). To avoid creation of vacuum and pressure surge, need to install enough size and number of vacuum breakers and PSVs respectively.

3. Deficiencies in the Existing Facilities : a) 32 FRP Seawater Supply Line: 1. From pump to YR Jetty fence: The new RTR aboveground 2,050-meter long line has only two undersized vacuum breakers. At the time of single pump shutdown, the vacuum creation at the header would be 3,029 CuM/Hr (equal to the single pump flow rate). However, the existing vacuum breaker (PZV# 487) has the capacity of 905 CuM/Hr, which is one-third of the required capacity. 2. From YR Jetty fence to Luberef II fence: Underground old FRP line 3,500 meter long line does not have any vacuum breaker. This line is always under the soil pressure. Therefore, slight line internal vacuum would help in rupturing the line. 3. The three vacuum breakers (80VSV 8030A/B/C) installed downstream of the cooling water/seawater exchangers (M-8002A/B/C) are under-designed. Also, since these vacuum breakers are installed on downstream of the seawater exchangers (M8002A/B/C) and the filters (M-8006A/B/C), these cant serve well for the seawater supply line. These vacuum breakers help the seawater return line better. b) 32 Seawater Return Line: The vacuum breaker PZV-489 is installed outside the YR Jetty fence, around 500 meters from the out-fall. Nearly 3,000 meters long underground line on upstream side of the above PZV do not have any vacuum breaker and the vacuum breakers beside M-8002 A/B/C are undersized. c) Air Releasers: To avoid high air-pressure build-up inside the line, prior to start-up of the pump or operation change the air should be fully vented/released. There is no air releaser available on the whole seawater system. 4. Calculations: a) Energy (head) at the time of one pump operating at a capacity of 3,000CuM/Hr: 1. Energy at Point-A = P + V2/2g + Z + Ep + Hf =

P= Pressure V2/2g= Kinetic energy Z= Relative position (elevation) Ep= Added energy (by pump) Hf= Lost energy (friction losses)

4. Recommendations: a) Replace PZV-487 with a 3,000 CuM/Hr capacity combined vacuum breaker & air releaser. b) Relocate the PZV-488 to the expansion loop near to the YR Jetty fence and replace it with a PZV combined with vacuum breaker & air releaser. c) Install a combined vacuum breaker & air releaser on the old underground seawater supply line near the existing 1 sampling, in-between the YR Jetty fence and the Luberef II fence. d) Replace the three vacuum breakers in between the seawater filters (M-8006A/B/C) and the cooling water/seawater exchangers (M-8002A/B/C) with combined vacuum breaker & air releaser of capacity 1,500 CuM/Hr each. e) Install air releasers on all expansion loops and jumpover at YR Jetty area (in between Point-A and Point-B).

5. Probable Cause of Year 2001 & 2003 Line Ruptures: a) Year 2001: Due to power failure the motor driven pump (V29-G-V0103/V0104) stopped, which caused sucking of air into the line through the vacuum breaker PSV-487 at the seawater header. Soon the diesel engine pump was started. After a while the power restored and one of the motor driven pumps automatically started. Due to two pumps combined running, pressure surged in the line and pressure of the trapped air inside the around 30 meter long jumpover next to the header extremely surged (kinetic energy in the flowing water

converted to pressure energy in the trapped air), which caused rupture of the line. After the rupture, pressure at that location quickly dropped, which caused backward flow of the water and consequently created vacuum in the line. Since the underground portion of the line already under soil pressure, it could not withstand the created vacuum and ruptured outside the Luberef II fence. Therefore, two ruptures caused at a time. b) Year 2003: This time also similar incident and rupture like in year 2001 happened. For the periodical maintenance (running) of the diesel engine driven pump, to switch-over the pump operation, the motor driven pump was stopped for a while, which caused sucking of air in the line through the vacuum breaker PSV-487. When the diesel driven pump started, pressure surged in the line and pressure of the trapped air inside the around 30 meter long jumpover next to the header extremely surged (kinetic energy in the flowing water converted to pressure energy in the trapped air), which caused rupture of the line. After the rupture, pressure at that location quickly dropped, which caused backward flow of the water and consequently created vacuum in the line. Since the underground portion of the line already under soil pressure, it could not withstand the created vacuum hence, ruptured. Since the jumpover portion was insulated and only air came out at this location, nobody noticed rupture at the jumpover, only noticed rupture at the underground portion near to Luberef II. -------------------------------------------------------- X -----------------------------------------------------------

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Clinical Ultrasound A How-To GuideDocument146 pagesClinical Ultrasound A How-To GuideNacko Stavreski67% (3)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Earth and Life Science DLLDocument6 pagesEarth and Life Science DLLGsoon Sibulan100% (3)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Configuration & Options List: 30Xw0452 1752 Water Cooled Liquid ChillerDocument22 pagesConfiguration & Options List: 30Xw0452 1752 Water Cooled Liquid ChillerOctavio Farid Rossi YumhaPas encore d'évaluation

- Basic Principles of Local GovernmentDocument72 pagesBasic Principles of Local GovernmentAnne Camille SongPas encore d'évaluation

- Celiac DiseaseDocument14 pagesCeliac Diseaseapi-355698448100% (1)

- SSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANDocument2 pagesSSX Diaphragm: Truextent® Replacement Diaphragms For JBL and RADIANIvica IndjinPas encore d'évaluation

- The Dedication of the Broken Hearted SailorDocument492 pagesThe Dedication of the Broken Hearted SailorGabriele TorresPas encore d'évaluation

- Ca2Document8 pagesCa2ChandraPas encore d'évaluation

- Hexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5Document22 pagesHexagon MI GLOBAL S DataSheet Letter EN NAFTA Rel5dudecastro1542Pas encore d'évaluation

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDocument31 pagesAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcPas encore d'évaluation

- SmartRunway SmartLandingDocument39 pagesSmartRunway SmartLandingMikePas encore d'évaluation

- Guidelines On Dissolution Profile Comparison: Udrun ReitagDocument10 pagesGuidelines On Dissolution Profile Comparison: Udrun ReitagRaju GawadePas encore d'évaluation

- Mahle KFWA MAIN Data SheetDocument4 pagesMahle KFWA MAIN Data SheetRudnikPas encore d'évaluation

- r05320202 Microprocessors and Micro ControllersDocument7 pagesr05320202 Microprocessors and Micro ControllersSri LalithaPas encore d'évaluation

- Sample Field Trip ReportDocument6 pagesSample Field Trip ReportBILAL JTTCPas encore d'évaluation

- Patient Positioning: Complete Guide For Nurses: Marjo S. Malabanan, R.N.,M.NDocument43 pagesPatient Positioning: Complete Guide For Nurses: Marjo S. Malabanan, R.N.,M.NMercy Anne EcatPas encore d'évaluation

- Specs Mantilla UV BT8800 Oct 2014Document2 pagesSpecs Mantilla UV BT8800 Oct 2014Julio MendezPas encore d'évaluation

- Project Data Collection & Risk ReportingDocument2 pagesProject Data Collection & Risk Reportinggambler yeagerPas encore d'évaluation

- Radar PPNDocument5 pagesRadar PPNSawaf MfPas encore d'évaluation

- Fendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKDocument5 pagesFendering For Tugs: Mike Harrison, Trelleborg Marine Systems, UKRizal RachmanPas encore d'évaluation

- r32 - Rb26dett Ecu PinoutDocument1 pager32 - Rb26dett Ecu PinouttospotPas encore d'évaluation

- Products and Services For Consumers: True / False QuestionsDocument65 pagesProducts and Services For Consumers: True / False QuestionsThúy HiềnPas encore d'évaluation

- SDE1 V1 G2 H18 L P2 M8 - SpecificationsDocument1 pageSDE1 V1 G2 H18 L P2 M8 - SpecificationsCleverson SoaresPas encore d'évaluation

- DerbyCityCouncil Wizquiz Presentation PDFDocument123 pagesDerbyCityCouncil Wizquiz Presentation PDFShubham NamdevPas encore d'évaluation

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakPas encore d'évaluation

- Causes and Effects of PollutionDocument6 pagesCauses and Effects of PollutionNhư NgọcPas encore d'évaluation

- Arta Fridei Kahlo A Fost Intotdeauna o ReactieDocument13 pagesArta Fridei Kahlo A Fost Intotdeauna o ReactieAlta DaianPas encore d'évaluation

- IMRAD - G1 PepperDocument13 pagesIMRAD - G1 PepperRomero, Ken Angelo B.Pas encore d'évaluation

- Kingspan Spectrum™: Premium Organic Coating SystemDocument4 pagesKingspan Spectrum™: Premium Organic Coating SystemNikolaPas encore d'évaluation

- Kuffner Final PresentationDocument16 pagesKuffner Final PresentationSamaa GamalPas encore d'évaluation