Académique Documents

Professionnel Documents

Culture Documents

Idm 31

Transféré par

Sam RogerTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Idm 31

Transféré par

Sam RogerDroits d'auteur :

Formats disponibles

NICMAR NATIONAL INSTITUTE OF CONSTRUCTION MANAGEMENT AND RESEARCH

SCHOOL OF DISTANCE EDUCATION ASSIGNMENT Tendering & Contracting in Construction

PREPARED BY NAME OF COURSE REGISTRATION NO. Course NO. PAPER TITLE

: : : : :

G.Harish IDM Module M53

IDM 31 Tendering, Bidding, Contract Laws & Claims Management

ASSIGNMENT NO. DATE OF SUBMISSION NO OF PAGES

: : :

Page 1 of 29

CONTENTS 1 INTRODUCTION 2 CONTEXT 2.1 State Procurement Policy 2.2 Value for Money 3 THE TENDERING PROCESS 3.1 Approaches to Tendering 3.2 Tendering Process Phases 3.3 Road Construction Contract Tendering Process 4 TENDER PLANNING 4.1 Tender Planning Process 4.2 Planning the Tender Process 4.2.1 Methods of Choosing the Best Tender 4.2.2 Identification of Risk and Opportunity 4.2.3 Non-Price Selection Criteria 4.2.3 Determining the Tender Selection Criteria 4.3 Tender Evaluation Plan 5 TENDER DEVELOPMENT 5.1 Overview 5.2 Initiation of Financial Approval Process 5.3 Appointment of the Tender Assessment Panel 5.3.1 Establishing a Tender Assessment Panel 5.3.2 Requirement of Tender Assessment Panel 5.3.3 Probity Advisor 5.3.4 Forming the Expression of Interest (EOI) Documents 5.4 Forming the Tender Documents 5.4.1 Tender Documents/Design Prototype 5.4.2 Deciding the Tender Period 5.4.3 Setting the Defects Liability Period 5.4.4 Approval to Call Tenders 5.5.5 Pre-Tender Meetings and Site Inspections

Page 2 of 29

6. TENDER ANALYSIS PHAS

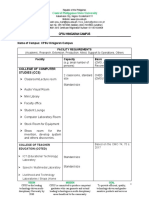

ASSIGNMENT PROBLEM: Government of Maharashtra is inviting tenders for highway project on international competitive bidding. Estimated project cost is INR 271.85 crores. Sealed tender for the following works are invited by the executive Engineer, World Bank project division, Aurangabad, from the Contractors registered with Government of Maharashtra in appropriate class. The bank tender forms shall be issued by Executive Engineer, World Bank project division, Aurangabad. Sealed tender forms will be received by the authority mentioned in the table below. Name work of Estimated cost Crores Rs Earnest Money deposit Type cost tender form Four laning of Aurangaba d S.H B.O.T lasur 30 vaijaipur Km.-67.2) 271.85 56,00,000 BOT 50000 24 & of Time for compln Class of contra ctor Bidder s Superintending engineer P.W circle,aurangabad on or before 27/1/09 upto 14.00 hrs Office chief engineer, P.W region Aurangab ad at on 16.00 05/01/09 hours. of Tender authority receiving Prebid details

Task. Describe in detail the tendering procedure to be followed for the above project from project conceptualizing stage to award of letter of intent or LOA. For the above project client wants to go for open tendering. Hence the client wants to get the full details and methodology. Appropriate assumptions can be made. Name of the Contractor: XYZ infrastructure private limited Scope of works : Four laning of Aurangabad lasur vaijaipur S.H 30 Km.-67.2) B.O.T

Page 3 of 29

Total Kms Type of Contract

: 67.2 Kms : BOT

Total Value of Contract: 271.85

Location Map of the Project:

Proposed Aurangabad to Vajaipur Road project

Method statements Method statement for Surveying Introduction Generally the entire construction project involves surveying, the following steps are proceed in road construction projects to covers the Traverse Survey, Temporary Bench Mark Survey, and Center Line Setting out, Center Line marking, Cross Section Survey and Submittal of Drawings. Abbreviations TBM Temporary Bench Mark GA Government Body Traffic Safety Management & Control Safety Awareness Meeting Safety awareness meeting has to be conducted every working day morning/every other day to brief the work force in the safety prevention measures. Traffic Safety will be discussed as a topic. Each survey group should be well awarded to follow specified instructions such as Barricading Boards and signalmen will be deployed to control the traffic flow during working time. The survey team should have practical knowledge to adjust following specified instructions that will not meet. Operating Procedure

Page 4 of 29

Site investigation has to be carried out for safety precautions prior to commencement of the work, in order to display relevant sign boards. Men at work 75m-100m ahead sign boards would be placed on both left hand side of the road. 25 m away from men at work sign Narrow Road/one lane traffic sign would be placed in order to notify the drivers with regard to road situation. Working area will be corded off with traffic cones to indicate setting out survey for the oncoming traffic to see on both sides. One way traffic ahead sign boards would be placed 90m ahead of working area in order to notify oncoming drivers. Traffic controllers would be deployed on both sides in order to control one way traffic. Photographs would be taken to disseminate and maintain traffic safety records. Radio communication system would be used where normal communication is impossible. After completion of the work, safety cones and barricade boards has to be removed accordingly. General Traffic Arrangement will illustrate In addition to following safety precaution has to be adopting to minimize accidents that can be happened. Safety helmets, traffic safety vests, boots, dust mask & gloves will be provided. Warning sign boards would be displayed through out the site. Monthly safety awareness program & training program would be conducted. First aid facilities would be provided. Safety officer has to visit the sites twice a day and required safety measures will be adopted at site. In addition, work discrepancies will be discussed in the following day morning at the safety meeting Resources Man Power 2 Site Engineers 2 Nos. Total Station 1 Safety Officer 4 Nos. Survey Staff 4 Surveyors 2 Nos. Level Instrument 22 Skill Laborers Equipment & Hand Tools 8 Flagmen 3 Nos. Tape (30m) 6 Nos. Tape (5m) 24 Nos. Traffic Cone

Page 5 of 29

1 No. Rope (30m Length) 6 Nos. Safety Sign Board 4 Nos. Walkie Talkie 1 Narrow Road Traffic Safety Sign Board Material Road Marking Concrete Nails Introduction The borrow excavation shall consists the operations such as site clearing, stripping of the overburden and stockpiling. Excavation would only be proceeded where those sites have been approved as borrow sites to be used in the construction work. Abbreviation QAE -Quality Assurance Engineer SE Site Engineer TO -Technical Officer QAS -Quality Assurance System ME - Materials Engineer(Contractor) TS - Technical Specification Resource Allocation Man power 1No-Supervisor. Unskilled labours Operators Equipments Track Back-hoe loaders Dump trucks

Quality Control Procedures Sampling testing Samples of soil would be taken from the borrow location and those samples would be placed in a polythene bag providing identification tag. All required tests would be carried out in the materials testing laboratory to confirm that those materials are in which category. After testing and with the satisfying results, excavation would be preceded and those materials would be stock piled at the site. Even the materials are properly stock piled at the site the materials in the stock pile would be tested before issuing for the construction purpose. No materials would be allowed to execute in the construction work until the required tests are completed and satisfied. Inspection check list

Page 6 of 29

To ensure that the all activities being performed with the expected quality, an inspection check list would be filled by the person in charge for the borrow excavation in case of preconstruction, during construction. The inspection check list shall include the specific requirements, safety and environmental measures. In case of the excavation of borrow materials, it is essential to have the designated limits of the borrow site to maximize the quality of the borrow materials. When the excavation is beyond the designated limit, it tends to mix with unsuitable materials. Methodology Clearing of the borrow site 1 The location and dimensions of the borrow pits would be identified as instructed by the Engineer. 2 All ordinary jungles, stumps and roots would be removed by a manual mean or using any other suitable equipment within the approved borrow area. 3 All removed matters would be collected to a place and then they would be disposed to a suitable disposal location or burned at the site with the judgment of the Engineer. Stripping of the overburden 1 The overburden would be removed up to the required depth by using suitable mechanical devise and those materials would not be allowed to mix with other materials classified as suitable for filling. 2 The all unsuitable materials would be disposed to a suitable disposal location by means of tipper trucks. Excavation 1 Borrow excavation would be carried out using a Back-hoe loader and would be properly stock piled with well-drain facilities. The material from the borrow pits would be blasted, ripped and excavated in a manner that will ensure the effective breaking down of the material in the borrow pit before it is loaded. 2 Rippable material which tends to break into large blocks would be cross ripped. Borrow materials would be confirmed to the requirement before the application. Dump trucks would be applied for the transportation of borrow material Method statement for Borrow Excavation Introduction The borrow excavation shall consists the operations such as site clearing, stripping of the overburden and stockpiling. Excavation would only be proceeded where those sites have been approved as borrow sites to be used in the construction work. Abbreviation QAE - Quality Assurance Engineer SE - Site Engineer

Page 7 of 29

TO - Technical Officer QAS - Quality Assurance System ME - Materials Engineer (Contractor) TS - Technical Specification Resource Allocation Man power 1 No Supervisor. Un skilled labors Operators Equipments Track Back-hoe loaders Dump trucks Quality Control Procedures Sampling and testing Samples of soil would be taken from the borrow location and those samples would be placed in a polythene bag providing identification tag. All required tests would be carried out in the materials testing laboratory to confirm that those materials are in which category. After testing and with the satisfying results, excavation would be preceded and those materials would be stock piled at the site. Even the materials are properly stock piled at the site the materials in the stock pile would be tested before issuing for the construction purpose. No materials would be allowed to execute in the construction work until the required tests are completed and satisfied. Inspection Check list To ensure that the all activities being performed with the expected quality, an inspection check list would be filled by the person in charge for the borrow excavation in case of preconstruction, during construction. The inspection check list shall include the specific requirements, safety and environmental measures. Dimension control In case of the excavation of borrow materials, it is essential to have the designated limits of the borrow site to maximize the quality of the borrow materials. When the excavation is beyond the designated limit, it tends to mix with unsuitable materials. Methodology Clearing of the borrow site 1 the location and dimensions of the borrow pits would be identified as instructed by the Engineer. 2 All ordinary jungles, stumps and roots would be removed by a manual mean or using any other suitable equipment within the approved borrow area. 3 All removed matters would be collected to a place and then they would be disposed to a suitable disposal location or burned at the site with the judgment of the Engineer.

Page 8 of 29

Stripping of the overburden 1 The overburden would be removed up to the required depth by using suitable mechanical devise and those materials would not be allowed to mix with other materials classified as suitable for filling. 2 The all unsuitable materials would be disposed to a suitable disposal location by means of tipper trucks. 1.0 Introduction Sub grade preparation shall be carried out using selected materials where the exposed surface is not suitable for the sub grade. 2.0 Abbreviation QAE - Quality Assurance Engineer SE - Site Engineer TO - Technical Officer QAS - Quality Assurance System ME - Materials Engineer (Contractor) TS - Technical Specification 3.0 Resource Allocation Man Power Site Engineer Technical Officer Single Supervisor Double Flagmen (minimum) Unskilled labors Operators Equipments & Tools Back-hoe loader Water pump Dump trucks Level Instrument Camber board/ Straight edges Mortar pans Mamoties Pick axes Crow-bars Wheel barrows Shovels Buckets Material Selected sub grade material which meets the engineering properties, approved by the Engineer

3.0 Quality Control Procedures 1. Sampling and testing Suitable materials would be employed in the preparation of sub grade as those materials have been classified to use as sub grade materials by the all preliminary tests done on it. Sampling of these materials would be made in a manner to identify easily their status of test and all the necessary details

Page 9 of 29

would be entered to the sample register. In case of placing these materials, the specified layer thickness and degree of compaction for each layer would be achieved. Field density test would be carried out in case of checking the degree of compaction according to the method stipulated in the relevant BS codes. 2. Inspection Check list To ensure that the all activities being performed with the expected quality, an inspection check list would be filled by the person in charge for this work in case of pre-construction, during construction. 3. Dimension Control Preparation of sub grade would be carried out according to the designed cross sections. The required depth and length of the excavation would be properly maintained during construction and those requirements would be checked with the inspection check list. 4.0 Methodology If the exposed layer of soil unsuitable for sub grade, these layers would be excavated up to the required depth by using a back-hoe loader and the required levels of the excavation would be controlled by the surveyor. Selected suitable material would be placed and compacted in successive layers by using rammers or vibrating rollers to a minimum depth of 150 mm. If the exposed layer of soil suitable for the sub grade, the layer would be thoroughly compacted by using vibrator rollers or rammers until reach the required compaction. The top 150mm sub grade layer in cut areas would be compacted to not less than 95% of the maximum dry density of the material at moisture content within 2% of the optimum moisture content as determined by AASHTO T-180. Water would be sprayed while compacting for achieving a better compaction. The surface of the finished sub grade would be neat and workmanlike and would have the form, super elevation, levels, grades and cross section.

1 INTRODUCTION Tendering for Major Works contains the concepts, policies, and procedures for tendering for Main Roads major works or material supply contracts. The tendering process defined aims to: Accommodate the State Procurement Policy requirements for whole-of-government outcomes; Complement Main Roads' project management methodologies; and Outline a process aimed at awarding contracts to those Tenderers that are best able to satisfy Value for Money requirements. An overview of the tendering process described in this manual is contained in Figure 3.1. Adequate planning and development of tender documentation are critical components of the tendering process. It is recommended that a consistent process is undertaken for each tender. This

Page 10 of 29

volume aids consistency by encouraging the use of the Tender Evaluation Plan pro-forma in Appendix B or the decision checklist in Appendix D. Any further clarifications regarding the use of this volume or its contents should be directed to the Director (Contracts & Standards), Road & Delivery Performance Division, Engineering and Technology Group. 2 CONTEXT 2.1 State Procurement Policy The State Procurement Policy1 recognizes the need for sound judgment to be made in the implementation of government objectives including: Advancing Government Priorities; Achieving value for money; and Ensuring probity and accountability for outcomes. These government objectives encompass the following priority requirements: Growing a diverse economy and creating jobs; Realizing the Smart State through education, skills and innovation; Managing urban growth and building Queensland's regions; Improving health care and strengthening services to the community; Protecting our children and enhancing community safety; Protecting the environment for a sustainable future; and Delivering responsive government. These priorities may be reviewed by government from time to time. It is necessary to consult the latest State Procurement Policy when formulating a procurement plan. Main Roads must identify and realise broader outcomes from its infrastructure program as well as achieving value through individual projects. To implement the State Procurement Policy, Main Roads has documented the following general procurement policies and procedures: Main Roads Corporate Procurement Plan; Departmental Purchasing Procedures; and Guidelines on the use of Probity Advisors. 2.2 Value for Money The State Procurement Policy defines "Value for Money" in broader terms than the initial cost of a project. Achieving value for money within the bounds of the State Procurement Policy requires consideration of: Contribution to the advancement of Government Priorities

Page 11 of 29

Non-price factors such as fitness for purpose, quality, service and support and sustainability considerations; and Cost related factors including whole-of-life costs and transaction costs associated with acquisition, use holding, maintenance and disposal Value for money is determined by the appropriate combination of price and non-price criteria for the specific project. 3 THE TENDERING PROCESS 3.1 Approaches to Tendering Main Roads uses the following generic approaches to tendering: Public invitation (Open Tender) Potential Contractors are informed of available works through advertising in media such as newspapers. For projects up to approximately $30 million, depending upon complexity,Tenderers are usually required to be either: Prequalified under MRPDS Major Works Prequalification System; or A registered specialist supplier. For federally funded projects above specific thresholds, Tenderers may be required to be National Code of Practice of Construction compliant. Refer to EN04 Compliance with the National Code of Practice for the Construction Industry. 3.2 Tendering Process Phases There are four distinct phases in the Main Roads tendering process as illustrated in Figure 3.1 below: 1.Tender Planning Phase 2.Tender Development Phase 3.Tender Analysis Phase 4.Contract Formation Phase The four tendering process phases are generic but can be applied to any contract type that is tendered on the open market or by private invitation, however, the steps within each phase vary greatly between contract types and in some cases the ECI and Alliance for example; the tendering process steps are only a rough fit into the generic process phases. Road Construction Contract; Design & Construct; Early Contractor Involvement; and Alliance.

Page 12 of 29

For guidance on the specifics of each contract type tendering process, including those not documented in this manual (in particular the Relational Incentive Contract (RIC), Road Maintenance Performance Contract (RMPC) and Public Private Partnership (PPP)), contact the Director (Project Delivery Improvement) or the Director (Contracts & Standards). For all other queries relating to the tendering process, contact the Director (Contracts & Standards). Refer also to the Standard Contract Provisions Roads10 volumes that discuss individual contract types in more detail. The basic steps of each tendering phase are explained in Sections 4,4,5 and 7. While in general these steps are applicable to all contract types following the generic tendering process, they are specifically applicable to the tendering of Road Construction Contracts. 3.3 Road Construction Contract Tendering Process The tendering process for a Road Construction Contract (RCC) is illustrated in Figure 3.2. Figure 3.2 shows a one stage tendering process but the RCC can also be tendered using a two stage process. In a two stage RCC tendering process an Expression of Interest would be called in the tender development phase to shortlist those eligible for full tendering. 3.3 Design & Construct The tendering process for a Design & Construct Contract (D&C) 3.4 Early Contractor Involvement The tendering process for an Early Contractor Involvement Contract (ECI) 3.5 Alliance The tendering process for an Alliance Contract

Page 13 of 29

4 TENDER PLANNING 4.1 Tender Planning Process

Page 14 of 29

Certain policies and principles apply when planning a tender process. The following guidance is included to undertaken. The tender planning process, as illustrated in Figure 4.1, includes the following actions that must be takenbefore finalizing the tender documentation: Selecting a Tendering Manager (delegated by the Principal); Defining the scope of work required to undertake the tender (project scope which includes risks and opportunities, timing, cost and contract type); and Preparing a suitable briefing document for the Tender Assessment Panel including timing, resources,and risk and opportunity aspects defined. Before tender planning commences, the Tendering Manager should be aware of the fundamental aspects of the project. This knowledge will help identify any risks there may be in the tendering process, thereby enabling the process to operate effectively. These aspects are detailed in the business case and include: Project scope and objectives; Stakeholders; Estimated construction cost and possible constructability issues; Project deadline; Issue definition and identification of impacts, especially potential environmental risks; Risk analysis, including identification of constraints and critical success factors; Planning activities undertaken to date; and Delivery strategy. ensure that tendering activities are thorough, competent and effectively planned and

4.2 Planning the Tender Process Planning the tender process increases the ability to manage risks and decreases the possibility of rework and delay. The Project Manager, on behalf of the Principal, decides on the method of tender

Page 15 of 29

evaluation, taking into account the opportunities and risks, along with the scale and complexity of the project. The Tendering Manager is required to undertake planning for the tender process which includes the following activities: Choosing the best tender; Identification of risk and opportunity; Non-price selection criteria; and Determining the tender selection criteria. When planning the tender assessment process, care must be taken to ensure the assessment period does not exceed the tender validity period detailed in the tender documents. The tender validity period is typically our to six months. If the project is complex or unusual, the tender validity period may be longer. Guidance should be sought from the Principal Manager (Contracts & Standards) when considering a tender validity period longer than six months. It is the role of the Tendering Manager to finalise the Annexure to the Conditions of Tendering (incorporating any particular requirements of the Project Manager or Principal) prior to finalising the tender documents. project specific clauses as required. 4.2.1 Methods of Choosing the Best Tender Volume 1 guides the development of a Project Delivery Strategy. The last decision to be made when compiling the strategy is to select a Sole Invitation or Open Market approach. For sole invitation tenders, the tender documents define initial requirements. Negotiations between Main Roads and the Tenderer will finalise the scope, cost, and quality of the works. These negotiations occur during the tender period and cover meeting both government and project-specific objectives. For Open Market tenders, there are a number of tender selection methods to choose from. Essentially they are based on the selection of a Tenderer through price and non-price selection criteria. When a two stage tendering process is used for works contracts and an Expression of Interest is used to short-list contractors, a non-related company shall be included in the shortlist. Related companies have acommon parent company which either owns outright or has a controlling interest in the related companies. Where related companies are bidding for work there has been a perception that there is a lack of competition. Inclusion of a non-related company in any short listing will preserve competition principles. Advice should be sought from a Probity Advisor if there is doubt about the process when related companiesare short- listed, or seek advice from the Director (Contracts & Standards). 4.2.2 Identification of Risk and Opportunity The early identification of risks and opportunities aids in their effective management. Evaluation of the significance of a risk or opportunity is essential when considering the appropriate project delivery option (refer Volume 1) and whether to use non-price criteria in the tender selection process. The following are examples of typical project risks and opportunities that need to be considered during the tendering process: This may involve adding

Page 16 of 29

1) Pavement rehabilitation and/or reconstruction in an urban environment. This may require the work to be staged, with the potential for significant disruption to through traffic, property access and business operations. This will require interaction with a number of parties such as environmental and cultural heritage, service authorities, individual property owners and local businesses. 2) Major construction works in a remote rural location. This may require liaising with local land owners for access for construction material, dealing with native title issues, local employment and training, environmental cultural heritage and so on. All risks and opportunities are to be assessed in accordance with AS3350 Risk Management11. It is imperative that the Tender Evaluation Plan identifies issues deemed to be significant. Examples include: Technical specialty and any unique competence requirements; Specific traffic management challenges (sequencing and staging); Constructability issues; Community relationship factors, including community and user group consultation; Communication requirements and capabilities; Safety and environment constraints; and Scheduling. The use of non-price criteria analysis enables the Tender Assessment Panel to broaden the "price only" tender analysis and decide on the "best value" tender. Non-price criteria can be used to address: Any project-specific requirements not adequately covered by the prequalification system; Emergent government priorities; and Industry cultural change initiatives that have not sufficiently matured to be incorporated in the prequalification system. Scheduling a Pre-Close of Tender meeting may also be an effective way of ensuring risks or opportunities are highlighted and discussed with Tenderers. 4.2.3 Non-Price Selection Criteria Ideally, it should be possible to significantly minimise project risks through effective planning, design and documentation by the Principal. In this instance, considering price only in the tender analysis is appropriate to allocate residual risk. Repetitive, routine or low-risk projects are good examples where price-only tender analysis is typically the most effective tendering methodology. However, if a project of any size or complexity has residual risks that are difficult to manage through design and documentation, mitigating the risk through the use of non-price criteria can be an effective strategy. Non-price criteria are factors, other than price, used to differentiate between acceptable tenders and select the best value for money tender where best value for money is not solely price dependent. Non-price criterion focuses upon a Tenderer's general capabilities in other areas, as the lowest-priced conforming tender does not necessarily represent the best value for money. Examples of non-price criteria include:

Page 17 of 29

Constructability; Specific skills or expertise directly relevant to the circumstances of a particular project that may Better satisfy critical project requirements; Innovation; Approach to the project in terms of understanding, resource strategy, supply chain management Which strongly contributes to the success of the project and sustainability of the industry; Environmental management; Traffic management; Approach to partnering/relationships; and Communications. Use of non-price selection criteria is recommended for all Main Roads contracts with an estimated value of$10 million or greater, and should be considered for all others. This complements the mandated requirement in Volume 1 that all the contracts with an estimated value over $10 million shall use "partnering" in the administration of the contract. Figure 4.2 illustrates the relationship between single-stage and two-stage selection processes. It is necessary to ensure that non-price criteria are expressed in a way that allows: A clear analysis of each Tenderer's approach to the project; Formation of performance indicators for each non-price criteria to measure efficiencies in methodology, resource strategy and other criteria; and Subsequent assessment of achievement of nominated project outcomes. Further information on the development and use of non-price selection is contained in Appendix G. 4.2.3 Determining the Tender Selection Criteria Risks and opportunities identified in the Business Case should be re-evaluated, assembled and weighted in accordance with their relative importance and uncertainty. Those deemed sufficiently important will provide the basis for non-price selection criteria. It is imperative this process is documented and included in the Tender Evaluation Plan. The Tender Evaluation Plan must also include the component attributes of the risks or opportunities and the means bywhich tender submissions are to be assessed. Determining the selection criteria and their relative weightings involves an element of subjective judgment and a good knowledge of the project objectives. Whenever non-price selection criteria are to be used, it is important that the Tender Assessment Panel be fully briefed on the project and its desired outcomes. The Tender Assessment Panel is responsible for, and must be fully involved in, the entire tender evaluation process. Relative weightings of the identified criteria (including the allocation of price and non-price criteria) should be determined by a disciplined process of comparative scoring of all the criteria against each other. A suggested model with a typical example is given in Appendix G. For less complex projects, it is acceptable for officers who are intimately familiar with a project, its Circumstances and its risk factors to establish the weighting factors. The nominated selection criteria and their relative weightings must be clearly documented in the Tender Evaluation Plan and approved by the Principal

Page 18 of 29

Figure 4.2 Relationship between Selection Processes and Non-Price Criteria 4.3 Tender Evaluation Plan Effective implementation of the activities that comprise the tendering process relies upon careful and thorough planning of the tender evaluation process. Regardless of the type of project delivery demonstrate probity and including the main methodology, a record of decisions must be kept to be able to decisions and responsibilities. A Tender Evaluation Plan details the procedures, policies, responsibilities, controls and anticipated outcomes of the tender evaluation process. In addition, it identifies the procurement objectives, risks and the proposed assessment criteria. The objectives of the Tender Evaluation Plan are to: Detail how the tender evaluation is to be undertaken and managed; Ensure the process is undertaken in an efficient manner; Ensure that no tender is given an unfair advantage or disadvantage; Aid in the observation of ethical and legal obligations during the tender evaluation phase; and

transparency. Appendix D contains a checklist of tendering process activities,

Page 19 of 29

Provide a baseline for measurement of progress and completion of the evaluation process. The Tender Evaluation Plan can also be used as part of the briefing for the Tender Assessment Panel. While a Tender Evaluation Plan is mandatory, the format used is discretionary. Appendix B contains generic Tender Evaluation Plans with the decision boxes and authorization hold-points. The use of such a plan will aid the Tendering Manager to manage and implement the tender evaluation process. While planning the tender evaluation process, a review of the project delivery methodology identified in the business case needs to be undertaken to confirm its relevance against any changes to the project. If it is concluded that the project delivery methodology needs to be revised, it will be evaluation planning again and reconfirm the Business Case, based necessary to undertake tender on the revised methodology. 4.3.1 Scope The Tender Evaluation Plan should include the following information (or cross-references to where the information can be readily accessed): Project objectives; Project background and relevant issues/circumstances; Tender selection methodology; Criteria proposed for tender evaluation; Methodology for qualitative/quantitative evaluation of alternative tenders; Stages proposed to evaluate the tenders; Evaluation process (preliminary and detail evaluation, how to identify criteria and apply weightings to calculate a score); Criteria and weighting approval process; and Probity and confidentiality requirements. 4.3.2 Format The Tendering Manager must record the key decisions during the tendering process. These recorded decisions need to be arranged so that the completed file forms a supporting document to the Tender Assessment Recommendation and Approval Form C5400 (Appendix F). The Tender Evaluation Plan template (Appendix B) provides a framework for this activity. It contains provision for recording all decisions made by the Tendering Manager and Tender Assessment Panel. An added advantage of this approach is that it facilitates review of decisions and processes through which they have been derived, for example: Assessment of effectiveness of procedures; Review of procedures in the event of a challenge to a decision to select a particular tender; and Transparency. 4.3.3 Probity Advisor In certain circumstances, the Principal may appoint a Probity Advisor to provide advice on tender evaluation methodology and subsequent tender evaluation activities. Any such decision, and the basis on which it was made, must be recorded in the Tender Evaluation Plan. A Probity Advisor must be

Page 20 of 29

appointed for a road project with a construction value greater than $30 million or a project which may exhibit a range of commercial-in-confidence attributes. appointment and involvement of a Probity Advisor. 4.3.3 Approval to Proceed The Tender Evaluation Plan needs to be approved before the tendering process can progress. It is the role of the Tendering Manager to obtain the appropriate level of approval. After the Tender Evaluation Plan has been approved, copies should be given to all members of the Tender Assessment Panel and the Probity Advisor (if appointed). 4.4 Brief for Tender Assessment Panel It is desirable to have a summary document that succinctly describes the project. This can be used by the Tendering Manager for briefing: Tender Assessment Panel members to ensure all members have a common understanding of the project objectives; and Specialist consultants or staff used to examine tenders. Most of the details required will already exist in documents such as the Tender Evaluation Plan (refer Appendix B), business case, design documents and other planning documentation. 5 TENDER DEVELOPMENT 5.1 Overview The tender development phase of the tendering process lies within the pre-tender period and comes afterthe following outcomes from the tender planning process: Appointment of the Tendering Manager; Completion of the Tender Evaluation Plan (refer Appendix B); Preparation of the summary material for the Tender Assessment Panel (if necessary); Development of a plan for the formation of the tender documents, including a risk management strategy, Timing and stakeholder management; and The indicative prequalification level required. During this phase of the tendering process, the Principal/Tendering Manager needs to consider the following: Appointment of the Tender Assessment Panel; Appointment of a Probity Advisor (if warranted); Compilation of EOI documents where a 2 stage process has been selected; Compilation of tender documents, including seeking approval to call tenders; Distribution/advertisement of tender documents; and Communication requirements with Tenderers including correspondence, Notice to Tenderers, logged telephone calls, pre-tender meetings, site inspections, interviews, request for clarifications and tender presentations; Section 5.3.3 provides guidance on the

Page 21 of 29

5.2 Initiation of Financial Approval Process The financial approval process starts with the Tendering Manager entering details of the proposed contract into the RIPA module "Financial Approval Process (FAP)". This can be done at the initial stages of the tendering process, preferably at the time of calling tenders, or at the commencement of the post-tendering process. The closing date of tenders and the expected date of completing the tender assessment are to be included. Refer to Section 8 for further information relating to the Financial Approval Process. 5.3 Appointment of the Tender Assessment Panel 5.3.1 Establishing a Tender Assessment Panel A Tender Assessment Panel is a group of persons nominated by the Principal to assess applications/tenders and make a recommendation to the endorser or approver on which would, in value for Main Roads. The recommendation is an opinion formed after their opinion, provide best

following the process in the tender documents for assessment of the tenders received. It is not binding on the endorser or approver. For reasons of probity, it is strongly recommended the Tender Assessment Panel is established before the invitation to tender. The Tender Assessment Panel shall consist of personnel with relevant experience, qualifications, and capability as follows: Mandatory at least one qualified engineer with appropriate experience in the delivery of Main Roads projects; Discretionary other officers with experience in procurement functions and sound knowledge of tendering practices relating to project management; and As required personnel with proven capability in the application of judgement in: - Definition of tender selection criteria; - Analysis of tenders; and/or - Application of project management principles. The membership and extent of the Tender Assessment Panel depends upon the size and complexity of the project: Low to moderate value or complexity the Tender Assessment Panel should have a minimum of two appropriately experienced Main Roads officers; High value or complexity the Tender Assessment Panel should have at least three members (a mix of departmental or non-departmental staff); and Sole invitation although a Tender Assessment Panel is not mandatory, the departmental representatives involved in negotiating a sole invitation have a responsibility to ensure the recommended conditions represent best value to the department. A Tender Assessment Panel may require additional assistance where specialized skills or additional resources are required, for example, to review specific aspects of an alternative tender or analyze an unusually low bid. When appointing members to the Tender Assessment Panel, the Principal may consider the appointment of:

Page 22 of 29

At least one senior Main Roads officer; The Main Roads officer involved in the preliminary or detailed design of the project, for example, Design Manager; and/or A person external to Main Roads or external to the District that might be managing the works, for example, Contract Administrator, Superintendent or Principal's Representative. The Tendering Manager should be a member of the Tender Assessment Panel, but not necessarily the chair. In general, the identity of members of the Tender Assessment Panel is not published, and membership should be treated with discretion and confidentiality. However, in two-stage selection or for projects where the Tender Assessment Panel interviews the Tenderers, revelation of the identity of Tender Assessment Panel members is inevitable. 5.3.2 Requirement of Tender Assessment Panel Once the Tender Assessment Panel is appointed, the Tendering Manager shall arrange for its members and others involved in the tendering process, to be briefed on: All relevant details of the project; and Probity requirements. Members of the Tender Assessment Panel and those involved in the tender assessment process must: Declare any conflicts or potential conflicts of interest; Treat all information as "commercial in confidence" throughout the tendering process; and Immediately notify the chair of the Tender Assessment Panel/Probity Advisor if a conflict of interest arises or if there is a breach of Main Roads' Code of Conduct.

5.3.3 Probity Advisor A Probity Advisor is a suitably qualified and experienced person not otherwise involved with the project and is free of any conflict of interest. Whilst no legal qualifications are necessary for the Probity Advisor role, many are legally qualified. A Probity Advisor may be appointed to: Assist and advise the Tendering Manager and the Tender Assessment Panel on the probity of the tendering process, including tender methodology, evaluation processes and subsequent assessment of tenders; and Provide assurance the tendering process is equitable and that it is properly and fairly applied in seeking tenders and assessing them (including compliance with all relevant policies and procedures). As mentioned in Section 2.3.3, there are certain circumstances where a Probity Advisor must be appointed, preferably before planning the tender evaluation. A Probity Advisor may also be considered in the following circumstances: The integrity of the project could be questioned; The project is politically sensitive and vulnerable to controversy;

Page 23 of 29

There has been a history of controversy and litigation in similar projects; It is anticipated there may be a tender from RoadTek, and independent scrutiny is essential to avoid the perception of bias and/or favouritism; The project is large and/or complex and there are significant risk factors and issues that dictate the selection criteria and their relative weightings; There are high costs involved for Tenderers (for example, Tenderers are required to outlay substantialresources and costs to prepare and submit a bid); The project is innovative and Tenderers and likely to be concerned about protecting their ideas (intellectual property); and Tender assessment process includes non-price selection criteria; The Probity Advisor is required to verify the: Evaluation methodology complies with relevant policies; and Tendering process in general, and invitations for and assessment of tenders in particular, have been properly and fairly undertaken. The Probity Advisor may choose to provide the necessary verification or reasons for non-verification: In the tender evaluation report; or As a separate document to the tender evaluation report, with any separate reports appended and cross-referenced. 5.3.4 Forming the Expression of Interest (EOI) Documents Where a two-stage process applies and an EOI is required, then it is not necessary to provide a high level of detail at this stage. At a minimum the documents provided should include: Preliminary information, containing a project description; Any preliminary design information considered appropriate at such an early stage; and An EOI response template. Provision of such details as a completed project brief, contract shell, detailed design information or Specifications is not recommended at this stage, simply because the two-stage process using an EOI is trying to minimize the effort required across the industry. Any detailed information provided may lead toTenderers commencing unwarranted work on full tender submissions. 5.4 Forming the Tender Documents 5.4.1 Tender Documents/Design Prototype The Tendering Manager is responsible for ensuring the various components of the tender documents are appropriate for the specific project and are complete in all respects: Design outputs: - Drawings (including standard drawings); - Schedules of quantities (an electronic schedule is made available to Tenderers); and - Specifications. Documents added to the above on behalf of the Tendering Manager will include: - Other tender schedules; - Conditions of Contract (general and supplementary, including annexures);

Page 24 of 29

- Conditions of Tendering (standard and supplementary, including annexures, schedules, nonprice selection criteria, selection criteria weightings, tender evaluation methodology, requirements for submissions and interviews); and - Other documents that may be required by Tenderers (for example, geotechnical reports, environmental impact assessments, etc). To achieve consistency, supplementary documentation for projects is to be minimised. The standard departmental contract documents are to be used without modification on all projects unless: They have been varied by an approved supplementary document; and Project specific circumstances dictate a change or additional conditions not covered by the standard or supplementary conditions. Refer to Policy No. EP133 Supplementary Conditions of Contract and Supplementary Specifications12 for further guidance on the use of non-standard specifications and supplementary Conditions of Contract. arranged with the Principal. This is to facilitate any necessary approvals prior to advertising. Contract document prototypes are to be provided to Contracts & Standards Branch for batching, a minimum of one week prior to the advertising of the tender. 5.4.2 Deciding the Tender Period The tender period should realistically allow for the amount of work involved in preparing and submitting a tender. This will vary according to the contract type selected. In general, the following should be taken into account when deciding the duration of the tender period: Time for the Tenderer to familiarize themselves with the project and brief and to circulate the documents to the tendering team (a pre-tender meeting may help here, see section 5.5.3); Time required to undertake any necessary design work; Additional time for developing any alternative designs where applicable; Time to prepare for and attend any tender period meetings; Time required to quantify and price the design, including obtaining quotes from sub-contractors and suppliers; Time to assess constructability issues; Time for the Tenderer's senior management to review and sign off the tender; and Time to prepare the various outline plans that may be required. Consideration should be given to the timing of calling tenders and the length of the tender period when significant industry breaks are due (for example, Christmas) and when other major tenders are being called (from Main Roads or other industry clients) in a similar time period. 5.4.3 Setting the Defects Liability Period The standard defect liability period to be used with Road Construction Contracts, Roadworks Performance Contracts and Minor Works Contracts managed by Main Roads is 90 days. If there are unusual project circumstances and it is considered that a longer period is required, the period should be assessed in accordance with the guidelines found in Appendix C and specifically approved by the

Page 25 of 29

District Director. The length of the Defects Liability Period for other contract types such as D&C, ECI, RIC and Alliance should be discussed with the Director (Contracts & Standards). Further discussion relating to setting the Defects Liability Period can be found in Appendix C. 5.4.4 Approval to Call Tenders Following the preparation of tender documents and receipt of approvals, the Principal is responsible for calling tenders. It is essential that no changes be made to the Tender Evaluation Plan once the tender methodology has been published in the tender documents. Once published, the tender documents may form a "process contract", the terms of which are described in the Conditions of Tendering. If the tender evaluation methodology used does not match the methodology described in the Conditions of Tendering, then it may be claimed that the "process contract" has been breached and the department may have to stop the process, recommence the process and possibly compensate unsuccessful Tenderers. 5.5.5 Pre-Tender Meetings and Site Inspections Pre-tender meetings are generally scheduled where the following exist: Non-standard specification details; Unusual circumstances in which a project is being undertaken; New or different Conditions of Tendering where additional information is important but unsuitable to include in the tender documents; and Unique or unusual technical requirements where additional information is important but unsuitable to include in the tender documents. Pre-tender meetings also provide the Tenderers with the ability to ask questions. Pre-tender meetings may be held on site but the potential cost and value to the Tenderers should be considered. The proceedings of all pre-tender meetings must be recorded. The meeting notes, which are a record of issues raised and advice given, shall be distributed as a Notice to Tenderers to all organizations that were issued with tender documents as soon as possible after the meeting. Pre-tender meetings must add value to the tendering process as they are a financial impost on the Tenderers and the Principal. The value of making a pre-tender meeting compulsory, where only the Tenderers that attended can lodge a conforming tender, should be carefully considered before such a meeting is imposed. The proposed agenda is to be included in the Tender Evaluation Plan approved by the Principal. 6.TENDER ANALYSIS PHASE 6.1 Overview Before commencing the tender analysis, the Principal or Tendering Manager should ensure: A Tender Assessment Panel (including a Probity Advisor if required) is appointed and, if required, identification of resources that can be called upon to aid the evaluation; The tender assessment process is defined (including timing, milestones, work distribution, etc); and

Page 26 of 29

The Tender Evaluation Plan is completed (refer Appendix B). Once the tender box has been opened, it is critical the tender assessment process is followed as per the Tender Evaluation Plan, or else a standard assessment process must be used. Departing from the defined process may result in: The need for reassessment; Discussions/recommendations being overturned; and A complaint or compensation claim from a Tenderer. Figure 6.1 indicates the roles and responsibilities during post-tender activities of the Tender Assessment Panel and Principal and provides an overview of the tender analysis process.

Page 27 of 29

Page 28 of 29

Page 29 of 29

Vous aimerez peut-être aussi

- Method Statements of Road WorksDocument37 pagesMethod Statements of Road Workslmthunzi74% (43)

- Road Works Method Statements GuideDocument37 pagesRoad Works Method Statements GuidePatricia JacksonPas encore d'évaluation

- Material Reconciliation 2011Document31 pagesMaterial Reconciliation 2011Sam Roger71% (14)

- Method Statements of Road WorksDocument38 pagesMethod Statements of Road WorksivanlewizPas encore d'évaluation

- Method Statement Road Construction 1Document39 pagesMethod Statement Road Construction 1AbirhamPas encore d'évaluation

- NCP 30Document11 pagesNCP 30Satya Yugandhar Gannamani100% (2)

- Object Oriented - Interview Questions: What Is OOP?Document18 pagesObject Oriented - Interview Questions: What Is OOP?Sam RogerPas encore d'évaluation

- Personalities in ConstructionDocument7 pagesPersonalities in ConstructionMicaela CruzPas encore d'évaluation

- Water Cooled Chiller GuideDocument5 pagesWater Cooled Chiller GuideMUHAMMAD TAHAPas encore d'évaluation

- NICMARDocument9 pagesNICMARMitra TammineniPas encore d'évaluation

- CR QS 3.5 - Service Manual For Download 2009-11-16Document605 pagesCR QS 3.5 - Service Manual For Download 2009-11-16Fernando Chavarría MarínPas encore d'évaluation

- Intuit Case Study - Analyzing Opportunities for QuickBooks Platform ExpansionDocument6 pagesIntuit Case Study - Analyzing Opportunities for QuickBooks Platform ExpansionAndrés Pérez100% (1)

- Quantitative Risk Assessment of Factors Affecting Construction ProjectsDocument10 pagesQuantitative Risk Assessment of Factors Affecting Construction ProjectsInternational Journal of Application or Innovation in Engineering & ManagementPas encore d'évaluation

- Router 6672 Connection Setup Scenarios - Rev2Document13 pagesRouter 6672 Connection Setup Scenarios - Rev2eng gamal100% (1)

- 3 BConstruction Stormwater Erosion Control PlansDocument4 pages3 BConstruction Stormwater Erosion Control Plans许爱文Pas encore d'évaluation

- Assignment Title Sustainable Materials For ConstructionDocument25 pagesAssignment Title Sustainable Materials For ConstructionSajjad HassanPas encore d'évaluation

- Protocol Interview QuestionsDocument10 pagesProtocol Interview QuestionsSam RogerPas encore d'évaluation

- PGPM31 M57Document29 pagesPGPM31 M57Shelly DelhiPas encore d'évaluation

- Catalog PDFDocument448 pagesCatalog PDFykuscuPas encore d'évaluation

- Design Review Checklist For Road ProjectsDocument93 pagesDesign Review Checklist For Road ProjectsFaez El-NinoPas encore d'évaluation

- ContentDocument148 pagesContentNusaibah YusofPas encore d'évaluation

- IDM-24 INFRASTRUCTURE Development-Power, and Oil & Gas Sector-11Document11 pagesIDM-24 INFRASTRUCTURE Development-Power, and Oil & Gas Sector-11samriddh25Pas encore d'évaluation

- Ebrd OprcDocument97 pagesEbrd Oprcyesuf abdulhakimPas encore d'évaluation

- Karuma Hydropower Road Upgrade DesignDocument60 pagesKaruma Hydropower Road Upgrade Design范小爷Pas encore d'évaluation

- Risk Management Strategies for PPP ProjectsDocument28 pagesRisk Management Strategies for PPP ProjectsSam Roger100% (2)

- 5G Bootcamp Day 2-Building 5G System PDFDocument18 pages5G Bootcamp Day 2-Building 5G System PDFfjwoemcuPas encore d'évaluation

- Nicmar Nicmar Institute of Construction Management and Research School of Distance EducationDocument13 pagesNicmar Nicmar Institute of Construction Management and Research School of Distance Educationrahulchauhan7869Pas encore d'évaluation

- Technical Proposal For - Mid Term Review of The Adaptation Fund Project - MoFDocument173 pagesTechnical Proposal For - Mid Term Review of The Adaptation Fund Project - MoFDereje DejenePas encore d'évaluation

- Infrastructure Development Cost OverrunsDocument9 pagesInfrastructure Development Cost OverrunsPrabhakar KhairatePas encore d'évaluation

- AC 150 - 5370 - 2 Operational Safety On Airprts During ConstructionDocument58 pagesAC 150 - 5370 - 2 Operational Safety On Airprts During ConstructionamsrPas encore d'évaluation

- PGPM 31 Nicmar Assignments 1Document28 pagesPGPM 31 Nicmar Assignments 1Manjunatha GPas encore d'évaluation

- Claims and Variations: Procedure CAP007M Contract Administration System (CAS) ManualDocument16 pagesClaims and Variations: Procedure CAP007M Contract Administration System (CAS) ManualHasitha AthukoralaPas encore d'évaluation

- PGPM 13Document9 pagesPGPM 13Junaid MohdPas encore d'évaluation

- MIS for efficient management of materials in hydropower construction projectDocument36 pagesMIS for efficient management of materials in hydropower construction projectVivek Rai100% (3)

- Encryption and Authentication Interview QuestionsDocument19 pagesEncryption and Authentication Interview QuestionsSam RogerPas encore d'évaluation

- Assignment - Tendering Bidding and ContractingDocument6 pagesAssignment - Tendering Bidding and ContractingPrabhakar KhairatePas encore d'évaluation

- Assignment Nicmar / Sode OfficeDocument6 pagesAssignment Nicmar / Sode OfficeJay VibhandikPas encore d'évaluation

- Nicmar AssignmentDocument17 pagesNicmar Assignmentanil_kishor_1Pas encore d'évaluation

- Assignment PG CM 22Document55 pagesAssignment PG CM 22punyadeepPas encore d'évaluation

- DN Pav 03026 02 PDFDocument42 pagesDN Pav 03026 02 PDFEng Venance MasanjaPas encore d'évaluation

- Managing & Controlling Airport Construction Projects - Jan 2001Document10 pagesManaging & Controlling Airport Construction Projects - Jan 2001TATATAHERPas encore d'évaluation

- Nicmar Assignment (PGQS 21)Document9 pagesNicmar Assignment (PGQS 21)Soumya SarangiPas encore d'évaluation

- Assignment Nicmar / Code OfficeDocument18 pagesAssignment Nicmar / Code OfficeNilesh SondigalaPas encore d'évaluation

- Assignment For NCP 31Document10 pagesAssignment For NCP 31LOUISJINUPas encore d'évaluation

- AssignmentPGPM 33Document15 pagesAssignmentPGPM 33Santosh Thakur100% (1)

- Evaluation of Coastal Aquifier in Ramanathapuram DistrictDocument67 pagesEvaluation of Coastal Aquifier in Ramanathapuram DistrictVinod VasanPas encore d'évaluation

- Productivity & Work Study Techniques in Construction ProjectsDocument20 pagesProductivity & Work Study Techniques in Construction ProjectssurenderPas encore d'évaluation

- Assignment Nicmar / Sode OfficeDocument18 pagesAssignment Nicmar / Sode Officeams2011100% (1)

- Final RFP For Ie Ts-IIDocument267 pagesFinal RFP For Ie Ts-IImallikarjuna rao bodduPas encore d'évaluation

- Develop Commercial Site Pune India 18% ProfitDocument18 pagesDevelop Commercial Site Pune India 18% ProfitLalit RangaPas encore d'évaluation

- Enhancement of Soil Index Properties by Adding Stone Dust MixDocument7 pagesEnhancement of Soil Index Properties by Adding Stone Dust MixInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Company ProfileDocument24 pagesCompany ProfileSiddharth JaloriPas encore d'évaluation

- PGPPM 14 Construction Contract & ConctractingDocument25 pagesPGPPM 14 Construction Contract & ConctractingVinod VasanPas encore d'évaluation

- Assignment PGPM 12 (HUMAN RESOURCE MANAGEMENT)Document14 pagesAssignment PGPM 12 (HUMAN RESOURCE MANAGEMENT)KISHAN MODHAPas encore d'évaluation

- NCP 27Document26 pagesNCP 27Atish kumar100% (1)

- Cost Reduction Techniques in Construction ProjectsDocument2 pagesCost Reduction Techniques in Construction ProjectsShahbaz ShahPas encore d'évaluation

- Assignment ON Construction Perssonel Management PGPM 13: Pooja Gupta PGPM Red No 211-04-31-9263-2133Document13 pagesAssignment ON Construction Perssonel Management PGPM 13: Pooja Gupta PGPM Red No 211-04-31-9263-2133Manish Gupta100% (1)

- UNRA Updated Job Posting Jan 15 2016Document184 pagesUNRA Updated Job Posting Jan 15 2016jadwongscribd100% (2)

- Indian Road Sector: Hybrid Annuity ModelDocument3 pagesIndian Road Sector: Hybrid Annuity ModelAjay Singh0% (1)

- PGPM 31Document24 pagesPGPM 31naveen jacobPas encore d'évaluation

- Mis - 32Document10 pagesMis - 32chtnyogiPas encore d'évaluation

- PGPM 31Document16 pagesPGPM 31Rutuja GameyPas encore d'évaluation

- 81507.docx NewDocument305 pages81507.docx NewShafqat NigarPas encore d'évaluation

- Frank Jar Curi Thesis DocumentDocument171 pagesFrank Jar Curi Thesis DocumentTATATAHERPas encore d'évaluation

- Ashok Kumar (Contracts Engineer)Document2 pagesAshok Kumar (Contracts Engineer)bolsamirPas encore d'évaluation

- Legal FrameworkDocument16 pagesLegal Frameworkஆக்ஞா கிருஷ்ணா ஷர்மாPas encore d'évaluation

- Guideline / Standard Operating Procedure (SOP) For Toll Notifications and Mandatory ETC Infrastructure in All Toll LanesDocument6 pagesGuideline / Standard Operating Procedure (SOP) For Toll Notifications and Mandatory ETC Infrastructure in All Toll LanesSourav BasuPas encore d'évaluation

- NICMAR-Assignment NCP21 1Document9 pagesNICMAR-Assignment NCP21 1MuraliKrishna NaiduPas encore d'évaluation

- NCP 30 AssignmentDocument37 pagesNCP 30 AssignmentPramod JadyePas encore d'évaluation

- Project Delivery Method A Complete Guide - 2020 EditionD'EverandProject Delivery Method A Complete Guide - 2020 EditionPas encore d'évaluation

- Section 400Document36 pagesSection 400Sam RogerPas encore d'évaluation

- SP1Document25 pagesSP1mugu12Pas encore d'évaluation

- Technical Risk TableDocument3 pagesTechnical Risk TableSam RogerPas encore d'évaluation

- Importance of Project Records for Disruption ClaimsDocument3 pagesImportance of Project Records for Disruption ClaimsSam RogerPas encore d'évaluation

- Mid Term Appraisal - 11th Plan FullDocument500 pagesMid Term Appraisal - 11th Plan FullDheeraj012Pas encore d'évaluation

- Presentation+ +Manish+ShahDocument106 pagesPresentation+ +Manish+ShahAtul PatelPas encore d'évaluation

- RCC Exam Dec2012 ExamTimeTableDocument4 pagesRCC Exam Dec2012 ExamTimeTablearunkumar_505Pas encore d'évaluation

- Database Connection For Primavera p6Document2 pagesDatabase Connection For Primavera p6Sam RogerPas encore d'évaluation

- Contracting ExcellenceDocument7 pagesContracting ExcellenceSam RogerPas encore d'évaluation

- Hotel Management Problems and Solutions For Students.Document9 pagesHotel Management Problems and Solutions For Students.Sam Roger100% (2)

- IscivilDocument33 pagesIscivilvignesh_freeboterPas encore d'évaluation

- Simple C ProgsDocument11 pagesSimple C ProgsAnshuman KrishnakumarPas encore d'évaluation

- 3 QSDocument3 pages3 QSSam RogerPas encore d'évaluation

- Interview Questions-Data StructureDocument5 pagesInterview Questions-Data StructureSam RogerPas encore d'évaluation

- Java ThreadingDocument3 pagesJava ThreadingSam RogerPas encore d'évaluation

- 1.budget and Cash FlowDocument10 pages1.budget and Cash FlowSam RogerPas encore d'évaluation

- Operating System Interview QuestionsDocument12 pagesOperating System Interview QuestionsSam RogerPas encore d'évaluation

- C interview questions on static variables, pointers, macros and moreDocument6 pagesC interview questions on static variables, pointers, macros and moreAnshuman KrishnakumarPas encore d'évaluation

- Interview Questions For Core Java - 2Document13 pagesInterview Questions For Core Java - 2Sam Roger100% (1)

- J2EE Interview QuestionsDocument8 pagesJ2EE Interview QuestionsSam RogerPas encore d'évaluation

- Simple C ProgramsDocument64 pagesSimple C ProgramsprabhakrishnanPas encore d'évaluation

- Java ScriptDocument10 pagesJava ScriptSam RogerPas encore d'évaluation

- C++ - Virtual FunctionsDocument20 pagesC++ - Virtual FunctionsSam RogerPas encore d'évaluation

- Aptitude Questions With AnswersDocument22 pagesAptitude Questions With AnswersSam RogerPas encore d'évaluation

- AptitudeDocument2 pagesAptitudeSam RogerPas encore d'évaluation

- Quality Planning Using APQP Phases Nicely ExplainedDocument5 pagesQuality Planning Using APQP Phases Nicely ExplainedsofihussainPas encore d'évaluation

- NFC Master IndexDocument1 099 pagesNFC Master IndexRyman RojasPas encore d'évaluation

- Resume Allison VincentDocument3 pagesResume Allison Vincentapi-351166570Pas encore d'évaluation

- A 2.2!21!17 05 Bitumen SprayerDocument1 pageA 2.2!21!17 05 Bitumen SprayerNisanth ThulasidasPas encore d'évaluation

- Feature Extraction Using Convolution Neural Networks (CNN) and Deep LearningDocument5 pagesFeature Extraction Using Convolution Neural Networks (CNN) and Deep LearningHarshitha SPas encore d'évaluation

- How industrial engineering can optimize mining operationsDocument6 pagesHow industrial engineering can optimize mining operationsAlejandro SanchezPas encore d'évaluation

- Multitrack HistoryDocument5 pagesMultitrack HistoryMatt GoochPas encore d'évaluation

- Test DocumentationDocument6 pagesTest DocumentationIrina ClaudiaPas encore d'évaluation

- PS-474 Induction Heat Tube Extraction PDFDocument4 pagesPS-474 Induction Heat Tube Extraction PDFحمودي معزPas encore d'évaluation

- T-Rex Installation ManualDocument2 pagesT-Rex Installation ManualVictor Bitar100% (2)

- Technical Data Sheet "Halley E": 100 125 160kVA 3Ph - 3PhDocument6 pagesTechnical Data Sheet "Halley E": 100 125 160kVA 3Ph - 3PhFlorin MPas encore d'évaluation

- DrivingDocument64 pagesDrivingjamb2316Pas encore d'évaluation

- PI Raptor300 enDocument14 pagesPI Raptor300 enmetalmak ltdaPas encore d'évaluation

- Robot - Wikipedia, The Free EncyclopediaDocument31 pagesRobot - Wikipedia, The Free Encyclopedianishith316Pas encore d'évaluation

- EURANEDocument19 pagesEURANEsatti2628Pas encore d'évaluation

- ECE 6130/4130: Advance VLSI Systems: Combinational Logic Styles: Part-II Dynamic Logic Other StylesDocument26 pagesECE 6130/4130: Advance VLSI Systems: Combinational Logic Styles: Part-II Dynamic Logic Other StylesRupesh ParabPas encore d'évaluation

- EMarkSheet-A Web Portal For Online Verification of Statement of Marks and Certificate For SSC and HSC (Maharashtra) 2Document1 pageEMarkSheet-A Web Portal For Online Verification of Statement of Marks and Certificate For SSC and HSC (Maharashtra) 2yuvrajPas encore d'évaluation

- Jakarta MCU Participants ListDocument20 pagesJakarta MCU Participants ListBeny FirmansyahPas encore d'évaluation

- Cpsu Hinigaran Campus: Central Philippines State UniversityDocument3 pagesCpsu Hinigaran Campus: Central Philippines State UniversityChristian anthony SerfinoPas encore d'évaluation

- Kidde - Spec - ECS - Novec 1230 - 8-14 PDFDocument7 pagesKidde - Spec - ECS - Novec 1230 - 8-14 PDFMarcio BritoPas encore d'évaluation

- Optimum 4-Cylinder Engine Design via 1D CFD SimulationDocument7 pagesOptimum 4-Cylinder Engine Design via 1D CFD SimulationZohaib AliPas encore d'évaluation

- IP5407 InjoinicDocument13 pagesIP5407 InjoinicWillyPVPas encore d'évaluation

- Project Design Procedure General PreparationsDocument2 pagesProject Design Procedure General PreparationsIoanPas encore d'évaluation

- Deakin Learning Futures AGENDA 2020 Stage 2: Assessment and Learning DesignDocument6 pagesDeakin Learning Futures AGENDA 2020 Stage 2: Assessment and Learning DesignAmel Abbas Abbas AbbakerPas encore d'évaluation