Académique Documents

Professionnel Documents

Culture Documents

Process Risk Reliability Book Chapter 7 Reliability Availability Maintainability

Transféré par

Giannos KastanasCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Process Risk Reliability Book Chapter 7 Reliability Availability Maintainability

Transféré par

Giannos KastanasDroits d'auteur :

Formats disponibles

Relia bility, Ava ila bility

and Maintainability

CHAPTER CONTENTS

Introduction... program....... safety.... Definitions Failure Modes Failure Rates" ConstanUExponential Distribution. . Failure Rate Data........ Conditional Probability/Bayes' Theorem.

Benefits of a RAM Reliability and

.....

.............347 ................34g ...............3sl

....352

.....35s

...........356

.......

.35g

.............364

.....364

INTRODUCTION

Reliabiliry Availability, and Maintainability (RAID pfogfams are anintegral part of any risk management system. techniques possess many similarities to those used for -RAM safety that were discussed in chaptet" < 5. However, ,rr.t.f difference between R \M and safery analyses is ^ia to talk that itls possible about optimum reliabiliry i.e., the point at which a dollar spent on improving reliability leaos to less than a cost-avefaged dollar in benefits, as ilrustrated k nig.rr."7.t. \rith safety, however, there is no real optimum yalue; all incidents are unacceptable. Figure 7.1 shows that as funds are initiaily expended on improved reliab'ity, the incfemental fevenue is greater than the money spent (when factored over the normal capital investment period). However, there is an optimum point, above which a d,ollar spent on improved reliability generates less than a dollar ir, iir" cycle incremental revenue (i.e. the srope of the curwe becomes lessthan uniry). r" f.u.rr.., there is rarery sufficient data to be abre to develop a curye such as Figure 7.1 with precision. Never_ theless, it is usefur to keep in mind that a reliabirity prog.um is not, in and of itserf, its own justification' It has to demonstfate that an investment in reliability will lead to an increase in profits. Figure 7'2 shows three causes for losses. The first is that the sales of the product are down. Even though the facility can make product, the market is not buying it, so rates have to be cut back' The second cause in nlgure 7.2 is todo with scheduled turnarounds during which equipment that cannot be mlintained while it is operating is workecl on. (A strong asset integrity program may help reduce the amount oiri-. needed for such

Process Risk and Reliability Manaeement Copyright O 2010, Ian Surton. publishecl by Elsevier Inc. AII righrs

resened.

347

CHAPTER

Reliability, Availability and Maintainability

o o

c,

Expenditure

FIGURE 7.1

Reliability Payout

on flnding and correcting the important few factors that contribure

scheduled downtime, and ignoring the unimportant many.

turnarounds but they are not usually part of the RAM process.) Non-sc:.,: the third element in Figure 7.2, are the focus of this chapter. Naturally, it is not possible to identify and correct all possible cau:.: ,,: loss. Therefore it is suggested that the pareto principle (described in ch,::- * to flnd and correct the major problem areas, as shown in Figure 7 .3. The r ,crs {

:

ifiililillllll

.,1*, t[-rn:

l$lllnniiiluia:r*,r':

i'tfillilllttllUUlrur:r

r d-[

v i:ll

n"

[ ]T - , qlr {tililftt|:::.,i!.1:i,-1 .[ i ! ''lll1Pnlt ' i[ ]

lll[0][:IlY:u,$i

fllliiutlgr:ry

illillllilii'

fiimlil

;,.j.Lili:

_itu a

llFu"le:Lla,'ri

BENEFITS OF A RAM PROGRAM

The benefits of an effective RAM program include the following:

Increased Production

A reliable facility will make more money because it will operate for lr-::.Er: of time . The extra production will increase revenlles (assuming that the i:r.-ii

FIGURE

7.2

tf,ltilffiiumE

Loss Categories

-x

Benefits of a RAM program 349

FilTURE

7.3

sell all that it makes). Furthermore, the incremental production is very profltabre because all of the fixed and semi-fixed costs of production such as rents and salaries will have been covered by the base-line production.

semi-fixed costs such as payro', taxes, equipm.nt d.pr..iation, and rent4ease payments' It is in the range go% to roo% that the profits are made. Therefore, if availability can be increased by ,,only,, l%, frombSy" ,o 9G%, profitability will increase by 2O%.

Increased profitability Figure 7.4 shows a faclity where the first 9O%

of theproduction covers fixed and

100%

96% 95%

Profit Range

Fixed Costs Range

FIGURE

7.4

Reliability and Profitabiliiy

350

CHAPTER

Reliabitity, Availabitity and Maintainabitity

Increased Productivity An unreliable facility will experience increased losses, most of *-i::i ,. shutdown and re-start, for reasons such as flaring of waste gases :: -spec products, and reduced reactor selectivities. such situations 1 . , r:rL i: a loss of materials but also create an increase in energy consumpti,::_ :,:-.]. equipment items will have to be cooled down and then re-heare : JlLu items such as pumps, compfessors, and fired heatefs have to "r..: even thoLrgh they are on total recycle.

..

iln4mtllllllnlllilllllrllilllililnllill

r]limfl|lfllil|lll]]llrrril|[l mnrr

Minimal Investment Productivity improvements can often be achieved with minimal ;.;1.q; example, a pump in production-critical service may fail once eref-. --:-::-: If each pump failure leads to production losses of $ 15,000 then the --- uii" this problem is $60,000. Investigation into the pump failures shos s ::; down rate could be greatly reduced if a preventive maintenance S1'Sir:: ir, implemented, so that problems can be addressed before the pump ".- . ilii, is predicted that the new failure rate will be once per year, equi\-alr:: $15,000 per year. Hence the annual savings that flow from thi pre\--:.,, : nance pfogfam ate $45,000. If the preventive maintenance system .i, : -r;iil costs say $10,000 to implement and $5,000 per year to run, then trr ::. over a period of five years is $190,000 (ignoring the discounted r-al:: and the return on investment is very high indeed.

iji

llllllil

i,,ri

ittturu

LlLiiLtttii

illilllhrtttrtrir

Lr:rrl,

riil'

il1ffi

llllllillltllllilllillrr rillnruY'l

urr!,,..

\m&ililtnu

tmlilil{illlllllilr'

nilr'illtfillrur

ir,,

111,1y

Jr:l

ilmlllilllllllllllilllLlllilllr )llH.ll:

illlmilillll

L l*lltm

iuulf0l',illiiijf|rrrillllllrrrrrui

Reduced Maintenance Costs W.hen a facility operates smoothly, the cost of maintenance goes i -;, l fewer spare parts will have to be purchased, and labor costs - parir- _-irr,"i' time will be reduced.

!illllllltlttillutllri(1',q,r1r':ltr

'lllJllsllllllllLltLlfifl 1r]m1N1,

Reduced Inventories The response to reliability problems is often to increase the number ,-, and the qlrantify of raw materials. As reliability improves, these inveni reduced. Reduced Capital Costs

\llllllrjillililfilt(iiiuilt'lilj:

rq

llfillll

lil1t11tttl

,,ur"'-"

'i

,,ilI{finll rlllLl tr'1tliu"'](

flllll I

11ll('1t"u1

r.,1rl

RAM program is effective at squeezing more production frc,: equipment, it may be possible to postpone or cancel plans to builc t:,_: facilities. Customer Satisfaction A facility that operates reliably will have more satisfied customers bec._..: will be fewer problems with off-spec products and missed deliven- dart:

Personal Recognition

If the

lllllllllli'lllllri

illli I

ilrll,

;

I r

llllllllllfllirr:ll.]1lnu'ir

lllli'lillil

Lll'l

ll'llt lliiii

': I

r':tria,r'i

trntliltttttltlll r'L

llliiijlll,,,,i

.rl i;

lt."T

Lilllllllll','nu'r'r

r111lllLil(il**lillrill

i

llll

facility manager when he was evaluating some reliability software. Hi r,-r,r the software salesperson, "I see what yoll're selling you're selling job se _--,.*:r,

Managers recognize that a smoothly operating facility makes them look g,-, ,_ iT :ltilr]r, eyes of their bosses, whereas frequent upsets and shutdowns reflect neg:=, : i the perception of a manager's competence. This insight was recognize : :, ,r*il,rr,,

111tilll rfiril,,

""":tllttttltlliil

1111ln't(t

rf:r

\,.1r

rlLLrt*

"fl

llllllll'1lll,r

-.ll:lii:lll:ll]

lllllllunrln:r,

u

"r:'il

L[

1-

Moreover, when a facility is running smoothly, a manager has time to der-e1 .: r{r,${{ and positive programs that develop both his or her own career and the cer..:*.

"llllmt i i.

,iillllllllNiill

i',,,lil* r::

ittrrj

rrr ,, Li ',I,"\i,LL

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Labc Warranty Technical Manual v8 Low Res PDFDocument374 pagesLabc Warranty Technical Manual v8 Low Res PDFGiannos KastanasPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Labc Warranty Technical Manual v8 Low Res PDFDocument374 pagesLabc Warranty Technical Manual v8 Low Res PDFGiannos KastanasPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Creating CAD Block: Block Make Block Convert To BlockDocument3 pagesCreating CAD Block: Block Make Block Convert To BlockGiannos KastanasPas encore d'évaluation

- Creating A Fillet:: From The Modify Menu. To Specify The Fillet RadiusDocument1 pageCreating A Fillet:: From The Modify Menu. To Specify The Fillet RadiusGiannos KastanasPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Cad Layers - Autocad Tutorial: Line TypesDocument4 pagesCad Layers - Autocad Tutorial: Line TypesGiannos KastanasPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- 6 Rotated BackgroundDocument5 pages6 Rotated BackgroundGiannos KastanasPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Drawing A Rectangular Polyline: Method 1:: Rectangle DDocument1 pageDrawing A Rectangular Polyline: Method 1:: Rectangle DGiannos KastanasPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- 12 Wind Energy Malta ARioloDocument37 pages12 Wind Energy Malta ARioloGiannos KastanasPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- 3 How To Draw A CircleDocument1 page3 How To Draw A CircleGiannos KastanasPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- 60 AutoCAD Tips in 60 Minutes FinalDocument21 pages60 AutoCAD Tips in 60 Minutes FinalRp SinghPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Buildings Under Refurb and RetrofitDocument11 pagesBuildings Under Refurb and RetrofitGiannos KastanasPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Intoduction To WeldingDocument334 pagesIntoduction To WeldingAsad Bin Ala QatariPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Complaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYDocument38 pagesComplaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYscl1116953Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Powerful Communication Tools For Successful Acupuncture PracticeDocument4 pagesPowerful Communication Tools For Successful Acupuncture Practicebinglei chenPas encore d'évaluation

- English PoemDocument4 pagesEnglish Poemapi-276985258Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- COT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Document2 pagesCOT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Don Mariano Marcos Elementary SchoolPas encore d'évaluation

- Manual of GardeningDocument812 pagesManual of GardeningPrakash PatelPas encore d'évaluation

- Removing Eyelid LesionsDocument4 pagesRemoving Eyelid LesionsMohammad Abdullah BawtagPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Hodgkin LymphomaDocument44 pagesHodgkin LymphomaisninePas encore d'évaluation

- Fundamental Molecular Biology: GenomesDocument45 pagesFundamental Molecular Biology: GenomesMoonHoLeePas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Online Games and Academic AchievementDocument25 pagesOnline Games and Academic AchievementJasmine GamoraPas encore d'évaluation

- As Level Chemistry Practical Paper 3 - GCE GuideDocument1 pageAs Level Chemistry Practical Paper 3 - GCE GuideJamal AldaliPas encore d'évaluation

- Group 5 - Ethical PrinciplesDocument11 pagesGroup 5 - Ethical Principlesvirgo paigePas encore d'évaluation

- Emerging Re-Emerging Infectious Disease 2022Document57 pagesEmerging Re-Emerging Infectious Disease 2022marioPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Electric Field Summary NotesDocument11 pagesElectric Field Summary NotesVoyce Xavier PehPas encore d'évaluation

- 21 05 20 Montgomery AssocDocument1 page21 05 20 Montgomery AssocmbamgmPas encore d'évaluation

- Proposed Child Right's Policy FrameworkDocument2 pagesProposed Child Right's Policy FrameworkCrisDBPas encore d'évaluation

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDocument14 pagesMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47Pas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Cis MSCMDocument15 pagesCis MSCMOliver DimailigPas encore d'évaluation

- Essay Type ExaminationDocument11 pagesEssay Type ExaminationValarmathi83% (6)

- Thai Guava Production PDF by VNRDocument29 pagesThai Guava Production PDF by VNRDatta100% (2)

- Full Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter ChapterDocument34 pagesFull Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter Chapterpeeepochaq15d100% (9)

- Lecture 8 - ThermodynamicsDocument65 pagesLecture 8 - ThermodynamicsHasmaye PintoPas encore d'évaluation

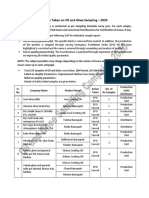

- Action Taken On Oil and Ghee Sampling - 2020Document2 pagesAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiPas encore d'évaluation

- Disorders of The Reproductive SystemDocument10 pagesDisorders of The Reproductive SystemRose Kathreen Quintans AuxteroPas encore d'évaluation

- Case StudyDocument7 pagesCase StudyLeighvan PapasinPas encore d'évaluation

- Butt Weld Cap Dimension - Penn MachineDocument1 pageButt Weld Cap Dimension - Penn MachineEHT pipePas encore d'évaluation

- A.8. Dweck (2007) - The Secret To Raising Smart KidsDocument8 pagesA.8. Dweck (2007) - The Secret To Raising Smart KidsPina AgustinPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Aromatic Electrophilic SubstitutionDocument71 pagesAromatic Electrophilic SubstitutionsridharancPas encore d'évaluation

- MAOH600 Ropu 48 Presentation Script and ReferencesDocument10 pagesMAOH600 Ropu 48 Presentation Script and ReferencesFano AsiataPas encore d'évaluation

- UgpeDocument3 pagesUgpeOlety Subrahmanya SastryPas encore d'évaluation