Académique Documents

Professionnel Documents

Culture Documents

Editorial: More On Engineering Education - A Renaissance in The Offing?

Transféré par

Marco BertoldiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Editorial: More On Engineering Education - A Renaissance in The Offing?

Transféré par

Marco BertoldiDroits d'auteur :

Formats disponibles

EDITORIAL

More on Engineering Education A Renaissance in the Offing?

Strether Smith, Contributing Editor

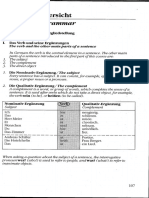

In my editorial A Commentary on the State of Engineering Education, for the July 2004 issue of this magazine I was brave enough to publish a diatribe describing my myopic view of the state of dirty-hands engineering education. In that editorial, I expressed the opinion that practical engineering had largely disappeared from the curriculum of most mechanical engineering schools (on the rash assumption that it had been there in the first place). The editorial included comments from an industry source that agreed with me and an opposing argument from a representative of academia that did not. The editorial requested feedback, and that is certainly what it produced: A rebuttal editorial (Oct 04) from Robert Bittle at TCU (Texas Christian University) describes the ABET (Accreditation Board for Engineering and Technology) and its effect on engineering schools with specific reference to the TCU program. The ABET is the recognized accreditor for college and university programs in applied science, computing, engineering and technology. Three rebuttal editorials from Peter Avitabile describe the program at the University of Massachusetts, Lowell, and discuss the trials and tribulations of engineering education in general (May, Jun & Jul 05. More than 30 messages from a wide variety of respondents. An invitation to discuss the matter as the keynote speaker at the Vibration Institute 2005 National Technical Training Symposium. I will leave it to the reader to review the excellent editorials by Professors Bittle and Avitabile. They describe the programs that are available at their schools that are designed to answer the criticisms in my original rant. The following is a discussion of my discourse with a lot of folks that care and my updated view of the situation. I have arbitrarily broken down the messages into three categories: Old engineering professionals Codgers Younger engineering professionals Youngsters Engineering school professors Educators The Codgers almost universally agreed with the premise of the original editorial. One particularly vehement response came from one author who requested anonymity: Hands-on courses have essentially disappeared or have become so watered down (with canned labs) that they are ineffective. It is almost impossible to hire a new graduate that has any ability to conduct a meaningful experiment. They dont know what questions experiments can answer, dont know how to define an appropriate experiment, dont know what diagnostics will be useful, dont know how to apply the diagnostics, dont know how to interpret the data, dont know how to do an error analysis to estimate error limits, dont know what instrumentation to use and what limitations are built in due to instrumentation choices and have no idea what conclusions to draw from the experiment. They cant do hand calculations to estimate results or to verify the order-of-magnitude answers from their computer programs. They do not have an appreciation for what can and cant be calculated and therefore cannot make appropriate comparisons between experiments and computer-generated numbers. Finally, they have no ability to write about the expected results of an experiment. Codgers that did not agree completely with me said that most schools do not produce dirty-hands engineers. Several discussed hiring practices that they thought separated the wheat from the chaff. There was also a common theme that ran through the Youngsters responses. All considered themselves to be dirtyhands types, but none gave much credit to their college education. The recurring theme was that their main practical experience came from playing with cars and/ or motorcycles and that their education reinforced that practical knowledge with theory and further examples. From Ed Milich came a typical response: I personally spent many hours working on motorcycles and cars while in school, and my hands-on knowledge of motorcycle and automotive mechanics served me invaluably in my analytical education. Conversely, my classroom education deepened my understanding of practical mechanics such as tuning engines. One can argue that any students understanding of both hands-on and analytical engineering is limited only by their education, talents, and curiosity. In any case, I can unequivocally state that recent university-trained engineering graduates have had a tremendous opportunity to develop their practical dirtyhands skills at the same time that they learned the fundamentals of analytical engineering. It is the responsibility of each engineer to make the most of these opportunities. A critical factor is found in Milichs last sentence. Its converse is a philosophical problem that we all hear regularly. All of the youngsters agreed that their classmates who did not bring dirty hands to the table left equally clean. In addition to the editorials, there were several responses from Educators that offer significant hope. Michel Louge from Cornell writes: When Dean Taylor, teamed up with Al George to create M&AE 225 Mechanical Synthesis back in the mid 1990s, their objective was to rejuvenate the teaching of mechanical engineering with real-life design situations. In that course, students learn team dynamics, computer-aided design, planning, benchmarking, reverse engineering, rapid prototyping and yes they also all learn to use lathes, milling machines and welding safely. Here we have what I think is a description of the critical change that is happening in engineering education. Recall that my original editorial was prompted by what I saw as a retreat from practical engineering instruction at Cornell in the 1960s. Louges response indicates that the Cornell faculty came to the same conclusion 30 years later and decided to do something about it. At about the same time, the program at TCU described in Robert Bittles editorial and Pat Walters contribution to my original piece was started. Other schools were experiencing the same renaissance during that period. The ABET program, discussed by Professor Bittle, also came on the scene about that time. My conclusion is that some colleges and universities have realized that there is a problem and have chosen to do something about it. Of course, what to do is not obvious. There have been huge advances in technology since the 1960s, and subject matter must be adjusted accordingly. Joseph Prahl from the Case School of Engineering says:

INSTRUMENTATION REFERENCE ISSUE

There is always a concern over how much to shift the curriculum away from drafting, free-hand sketching and lettering, wood shop, model shop, foundry or machine shop to make room in four years for new industrially relevant developments, such as solid modeling, rapid prototyping, computer-aided design and manufacturing, not to mention new conceptual developments such as, microelectro-mechanical systems, nanotechnology and modern numerical methods and codes such as M ATLAB and M ATHEMATICA . The fact is, there are many things that used to occupy immense amounts of time in past engineering curricula that are no longer needed or appropriate. We do not have to spend inordinate amounts of time learning to use log and trig tables, practicing how to interpolate to get accurate answers. This does not mean that we should not understand logs and exponents fundamentally, but we do not require the application of the tables the way we used to. We can apply our time to more worthy pursuits. Students today do not need to know how to use a slide rule or a lettering set or mechanical drawing instrument. It simply is not necessary. In my original editorial, I specifically lamented the passing of the foundry class at Cornell. I wrote a good foundation in sand casting is a good start toward understanding the difference between a good and bad shock response spectrum. This may be true but is obviously a stretch. Some topics have to go to make room for new things. There has been an obvious (and necessary) trend toward a more analytical curriculum in all schools. The computer, barely a concept when I was in college, has become our central tool, regardless of whether we are in analytical or experimental regimens. Fortunately, many schools have instituted, or held on to, practical mechanical programs of several types. I was fortunate to visit TCU and have Pat Walter give me a quick tour of their facilities. I discussed their industry-sponsored program with him and several of the students. This program requires the senior class (28 students) to produce a

product that is contracted by a requesting organization. That years project, sponsored by PCB, was to design and build a calibration system to characterize accelerometers in the 0.05 to 5 Hz frequency range. No simple job, and certainly one that had not been done before. The task included negotiation of specifications with the customer, design, construction, proof of performance, cost accounting and control, documentation, and sell-off to the end user. All of the project responsibility fell on the shoulders of the participants. Participation in this program is required for graduation. Many schools offer an alternative approach to dirty-hands experience. These optional extracurricular programs take advantage of competitions sponsored by a variety of industry and government organizations. Examples include Formula SAE, the Great Moonbuggy Race and a variety of autonomous-vehicle programs such as the DARPA Grand Challenge. These competitions provide real wrench-turning experience under highstress (industry-emulating) conditions. These programs are terrific. The only problem is that they are optional. If we are hiring graduates, we should look for ones that have participated. However, an issue that was disturbing to me arose in the DARPA Grand Challenge. Although it was an open competition, many of the teams were from academic institutions. In fact, the first three finishers were from schools. However, only one of these teams (that entered two cars that came in 2nd and 3rd) had significant student participation. It was obvious that their approach was to be a learning experience for the team members. Their school made the honor role that will be found at the end of this editorial. The winner did not. There is a side issue that deserves comment. In the original editorial I asked whether mechanical engineering students are required to have run a lathe and milling machine. In this case, I mean a real manually controlled machine, not the CNC (computer numerical control) variety. Most of the schools that I contacted had these machines but, in many cases, the students are not allowed to operate them because of liability con-

cerns. The machines were demonstrated and, of course, only good practices were displayed. The students did not have a chance to ruin a tool or a part because of impatience prompting too deep a cut. This is not an acceptable situation and these schools should either solve the liability problem or stop pretending that they are teaching dirty-hands principles. So, finally we are to my bottom line. My conclusion is that there definitely are colleges and universities that do offer practical, hands-on, education programs. However, many do not. The challenge to those of us that hire graduates or want to help young people get an education in mechanical regimens is to find schools and programs that produce the type of graduate that we want. Responses to my request for feedback produced the following short list of schools that offer a mix of high-quality academic and dirty-hands experience. These schools were recommended by graduates or demonstrated their capabilities by appropriate responses. In alphabetical order, they are: Carnegie Mellon Cornell Cal Poly Michigan State University Michigan Tech Texas Christian University (TCU) University of Massachusetts Lowell University of Missouri-Rolla I am sure that there are many more schools that should qualify for this honored list. Id like to publish another editorial in a year or so and would hope it includes a comprehensive list of schools that we should be contacting to hire their graduates or that we should be encouraging student engineers to attend. Please contact me if you would like to nominate others or have additional comments. Thanks to all of you who responded to the original editorial. I hope that it was obvious that my long-term intention was to show my premise was wrong. Although the jury is still out on most engineering schools, the situation is better than I had thought.

The author may be contacted at: strether. smith@ comcast.net.

SOUND AND VIBRATION/MARCH 2006

Vous aimerez peut-être aussi

- COOPERATIVE EDUCATION A Key Link Between Industry and Engineers in The MakingDocument4 pagesCOOPERATIVE EDUCATION A Key Link Between Industry and Engineers in The Makingbarbara_ropePas encore d'évaluation

- Whole Life Concept Final ReportDocument6 pagesWhole Life Concept Final Reportapi-356471405Pas encore d'évaluation

- Iron Warrior: Volume 3, Issue 5Document12 pagesIron Warrior: Volume 3, Issue 5The Iron WarriorPas encore d'évaluation

- Research Paper On Engineering MechanicsDocument4 pagesResearch Paper On Engineering Mechanicsgw1wayrw100% (1)

- Mechanical Engineering GuideDocument32 pagesMechanical Engineering GuideEduardo Andrés GonzálezPas encore d'évaluation

- Term Paper Topics For Mechanical EngineeringDocument4 pagesTerm Paper Topics For Mechanical Engineeringc5rggj4c100% (1)

- Research Paper Topics For MechanicalDocument7 pagesResearch Paper Topics For Mechanicalgvzfmq91100% (1)

- Thesis Proposal Sample For Electronics EngineeringDocument7 pagesThesis Proposal Sample For Electronics EngineeringCustomPaperSeattle100% (1)

- Teaching Statistics to Engineers EffectivelyDocument11 pagesTeaching Statistics to Engineers EffectivelybonesisalivePas encore d'évaluation

- Civil Engineering Dissertation SampleDocument5 pagesCivil Engineering Dissertation SampleBuyPapersForCollegeOnlineArlington100% (1)

- Term Paper Topics Related To Mechanical EngineeringDocument8 pagesTerm Paper Topics Related To Mechanical Engineeringc5pcnpd6Pas encore d'évaluation

- The Structure of Engineering R&D at IIT Bombay: Milind SohoniDocument7 pagesThe Structure of Engineering R&D at IIT Bombay: Milind Sohonik8iranPas encore d'évaluation

- Mechanical Engineering Dissertation TitlesDocument5 pagesMechanical Engineering Dissertation TitlesCustomPaperServicesUK100% (1)

- Resolving engineering problems ethicallyDocument5 pagesResolving engineering problems ethicallyAlwyne ReyesPas encore d'évaluation

- Mr. Jared C. Bemil: Department of Civil EngineeringDocument23 pagesMr. Jared C. Bemil: Department of Civil EngineeringjaredPas encore d'évaluation

- Mechanical Engineering Research Paper PDFDocument7 pagesMechanical Engineering Research Paper PDFlzpyreqhf100% (1)

- Research Paper Topics For Mechanical EngineeringDocument5 pagesResearch Paper Topics For Mechanical Engineeringafnkchhpffdbuu100% (1)

- Mechanical Thesis Proposal SampleDocument4 pagesMechanical Thesis Proposal SampleTodd Turner100% (1)

- Term Paper Topics For MechanicalDocument6 pagesTerm Paper Topics For Mechanicalea7e9pm9100% (1)

- Mechanical Engineering Dissertation Examples UkDocument4 pagesMechanical Engineering Dissertation Examples UkPaperWritingCompanyBillings100% (1)

- Research Paper Topics For Mechanical Engineering StudentsDocument7 pagesResearch Paper Topics For Mechanical Engineering StudentsafeawfxlbPas encore d'évaluation

- Studying Engineering - A Road Map To A Rewarding Career - Raymond B. Landis (Fourth Edition)Document574 pagesStudying Engineering - A Road Map To A Rewarding Career - Raymond B. Landis (Fourth Edition)Emily92% (37)

- Thesis Topics in Machine DesignDocument5 pagesThesis Topics in Machine Designemilyjoneswashington100% (2)

- Iit Research Papers in Civil EngineeringDocument8 pagesIit Research Papers in Civil Engineeringiimytdcnd100% (1)

- Thesis 2.1 ReviewDocument5 pagesThesis 2.1 Reviewafloblnpeewxby100% (2)

- Topics For Civil Engineering Research PaperDocument5 pagesTopics For Civil Engineering Research Paperlrqylwznd100% (1)

- Thesis Topics For Ece StudentsDocument8 pagesThesis Topics For Ece Studentsafcnfajtd100% (2)

- M Tech Thesis Topics in Environmental EngineeringDocument4 pagesM Tech Thesis Topics in Environmental Engineeringmindischneiderfargo100% (2)

- Mechanical Engineering Thesis PapersDocument6 pagesMechanical Engineering Thesis Papersh0dugiz0zif3100% (1)

- StatementDocument3 pagesStatementKombat Larib RichardPas encore d'évaluation

- Goldberg The Missing BasicsDocument12 pagesGoldberg The Missing BasicsLiu XinchengPas encore d'évaluation

- Coursework For ArchitectureDocument7 pagesCoursework For Architectureafjwrmcuokgtej100% (2)

- Encourage Engineering Careers Through Hands-On LearningDocument1 pageEncourage Engineering Careers Through Hands-On LearningSalsa_Picante_BabyPas encore d'évaluation

- Manufacturing Thesis IdeasDocument6 pagesManufacturing Thesis Ideastammymoncriefgrandrapids100% (2)

- The Missing Basics: Reflections on Transforming Engineering EducationDocument12 pagesThe Missing Basics: Reflections on Transforming Engineering EducationNicklas ReusPas encore d'évaluation

- List of Thesis Topics For Computer EngineeringDocument6 pagesList of Thesis Topics For Computer Engineeringgloriayoungdesmoines100% (2)

- Why Design Education Must ChangeDocument6 pagesWhy Design Education Must ChangeAlexPas encore d'évaluation

- Sample Research Paper Mechanical EngineeringDocument5 pagesSample Research Paper Mechanical Engineeringukefbfvkg100% (1)

- Dissertation Topics in Mechanical EngineeringDocument7 pagesDissertation Topics in Mechanical EngineeringProfessionalPaperWritingServiceVirginiaBeach100% (2)

- Sample Thesis Title Civil EngineeringDocument4 pagesSample Thesis Title Civil Engineeringdwnt5e3k100% (2)

- Research Paper On Solid MechanicsDocument8 pagesResearch Paper On Solid Mechanicsfvg4bacd100% (1)

- Free Engineering Research Paper DownloadDocument5 pagesFree Engineering Research Paper Downloadh03x2bm3100% (1)

- Mechanical Engineering Research Paper Free Download PDFDocument8 pagesMechanical Engineering Research Paper Free Download PDFdmkrajulgPas encore d'évaluation

- Engineering 2Document7 pagesEngineering 2api-242470233Pas encore d'évaluation

- Research Papers For Mechanical EngineeringDocument5 pagesResearch Papers For Mechanical Engineeringgudzdfbkf100% (1)

- List of PHD Thesis in Civil EngineeringDocument4 pagesList of PHD Thesis in Civil Engineeringafknqbqwf100% (2)

- Management Thesis DownloadDocument5 pagesManagement Thesis Downloaddianamarquezalbuquerque100% (2)

- Thesis Civil EngineeringDocument5 pagesThesis Civil Engineeringkatrekahowardatlanta100% (2)

- Automotive Thesis TopicsDocument4 pagesAutomotive Thesis Topicsaflnzraiaaetew100% (2)

- Engineer Research PaperDocument7 pagesEngineer Research Paperafeaxbgqp100% (1)

- Guidance for Engineering ScienceDocument3 pagesGuidance for Engineering ScienceTrần Hoàng ViệtPas encore d'évaluation

- Sample Research Paper Related To Civil EngineeringDocument7 pagesSample Research Paper Related To Civil EngineeringaflbuagdwPas encore d'évaluation

- Discourse Community Final DraftDocument9 pagesDiscourse Community Final Draftapi-412517546Pas encore d'évaluation

- Experiential Learning Opportunities Exploring The Impact of Engineering Solutions-A Collaborative Gened-Engineering EffortDocument11 pagesExperiential Learning Opportunities Exploring The Impact of Engineering Solutions-A Collaborative Gened-Engineering EffortSoumya Suhreed DasPas encore d'évaluation

- Computer Science Is More Important Than Calculus: The Challenge of Living Up To Our PotentialDocument4 pagesComputer Science Is More Important Than Calculus: The Challenge of Living Up To Our Potentialbdalcin5512Pas encore d'évaluation

- The Economy of Workshop Manipulation: A logical method of learning constructive mechanics. Arranged with questions for the use of apprentice engineers and studentsD'EverandThe Economy of Workshop Manipulation: A logical method of learning constructive mechanics. Arranged with questions for the use of apprentice engineers and studentsPas encore d'évaluation

- Schaum's Outline of Finite Element AnalysisD'EverandSchaum's Outline of Finite Element AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- The Praxis of Product Design in Collaboration with EngineeringD'EverandThe Praxis of Product Design in Collaboration with EngineeringPas encore d'évaluation

- Higher Education Computer Science: A Manual of Practical ApproachesD'EverandHigher Education Computer Science: A Manual of Practical ApproachesJenny CarterPas encore d'évaluation

- Electric Motor Signature AnalysisDocument119 pagesElectric Motor Signature AnalysisMarco Bertoldi100% (2)

- Sharepoint User Guide 2010Document12 pagesSharepoint User Guide 2010Marco BertoldiPas encore d'évaluation

- KurzMODBUSClientUserGuideDocument8 pagesKurzMODBUSClientUserGuideMarco BertoldiPas encore d'évaluation

- Robert Silverman 32 Beethoven NotesDocument33 pagesRobert Silverman 32 Beethoven NotesMarco Bertoldi100% (1)

- Using: Control ControlDocument6 pagesUsing: Control ControlMarco BertoldiPas encore d'évaluation

- Gas Flow Calculation Using Cv ValuesDocument1 pageGas Flow Calculation Using Cv ValuesCarlos TarquinoPas encore d'évaluation

- Article Flow Calculations For Valve SizingDocument13 pagesArticle Flow Calculations For Valve Sizingashfaq-matte-7993Pas encore d'évaluation

- 08 Reduced Order ObserverDocument6 pages08 Reduced Order ObserverMarco BertoldiPas encore d'évaluation

- 180144A Flow Unit Conversion ChartDocument1 page180144A Flow Unit Conversion ChartALP69Pas encore d'évaluation

- Simplest MotorDocument9 pagesSimplest MotorMarco BertoldiPas encore d'évaluation

- An 960Document12 pagesAn 960Engr. AbdullahPas encore d'évaluation

- Fluidized Catalytic Cracker Catalyst Selection GuideDocument11 pagesFluidized Catalytic Cracker Catalyst Selection GuideMarco BertoldiPas encore d'évaluation

- Machine Condition Monitoring: Best Practice CatalogDocument19 pagesMachine Condition Monitoring: Best Practice CatalogMarco Bertoldi100% (1)

- Experimental Modal AnalysisDocument11 pagesExperimental Modal Analysisrs0004Pas encore d'évaluation

- Engineering Design Guideline - Furnace Rev02 WebDocument23 pagesEngineering Design Guideline - Furnace Rev02 WebShashank MuduliPas encore d'évaluation

- Gramatica Germana PDFDocument10 pagesGramatica Germana PDFIvan DoruPas encore d'évaluation

- Cracked Gas CompressorDocument28 pagesCracked Gas CompressorMarco Bertoldi100% (3)

- The Missing Knob On Your Random Vibration Controller: Philip Van Baren, Vibration Research Corporation, Jenison, MichiganDocument6 pagesThe Missing Knob On Your Random Vibration Controller: Philip Van Baren, Vibration Research Corporation, Jenison, MichiganMarco BertoldiPas encore d'évaluation

- 058467Document18 pages058467Marco Bertoldi100% (1)

- (Course) PLC Communications in A Process Control SystemDocument8 pages(Course) PLC Communications in A Process Control SystemPROMO95Pas encore d'évaluation

- Improving Fan System PerformanceDocument58 pagesImproving Fan System PerformanceMarco BertoldiPas encore d'évaluation

- D Efficient OperationDocument5 pagesD Efficient OperationMarco BertoldiPas encore d'évaluation

- Technote 8 - Guidelines For Drawing SchematicsDocument13 pagesTechnote 8 - Guidelines For Drawing SchematicsMarco BertoldiPas encore d'évaluation

- CV of Bidisha Zaman for Assistant Professor PositionDocument2 pagesCV of Bidisha Zaman for Assistant Professor Positionshahnewaz.eeePas encore d'évaluation

- PHYA11H3 Syllabus 2023Document7 pagesPHYA11H3 Syllabus 2023박정원Pas encore d'évaluation

- A Conceptual Framework For Infusing Behavior Change Theories Into Program DesignDocument10 pagesA Conceptual Framework For Infusing Behavior Change Theories Into Program DesignrahimisaadPas encore d'évaluation

- Sundo Qi GongDocument2 pagesSundo Qi GongMiguel Angel Villafuerte Kanemoto100% (1)

- Literacy in The PlaygroundDocument7 pagesLiteracy in The PlaygroundS TANCREDPas encore d'évaluation

- IragbijiDocument2 pagesIragbijiAfolabi Muyideen IdrisPas encore d'évaluation

- Poptropica Lessons PLAN Starter LevelDocument13 pagesPoptropica Lessons PLAN Starter LevelMiss JuliPas encore d'évaluation

- Master of Theology (THM) : ObjectivesDocument6 pagesMaster of Theology (THM) : ObjectiveshgmontenegroPas encore d'évaluation

- Beach and Pedersen (2019) Process Tracing Methods. 2nd EditionDocument330 pagesBeach and Pedersen (2019) Process Tracing Methods. 2nd EditionLuis Aguila71% (7)

- Reading Practice Test 1 - IELTS Academic - Take IELTSDocument2 pagesReading Practice Test 1 - IELTS Academic - Take IELTSM Teresa Leiva0% (1)

- Learning Technological Capability For Vietnam'S Industrial Upgrading: Challenges of The GlobalizationDocument29 pagesLearning Technological Capability For Vietnam'S Industrial Upgrading: Challenges of The GlobalizationNguyễn HảiPas encore d'évaluation

- Cambridge International Examinations: Design and Technology 0445/11 May/June 2017Document4 pagesCambridge International Examinations: Design and Technology 0445/11 May/June 2017knPas encore d'évaluation

- Iare TKM Lecture NotesDocument106 pagesIare TKM Lecture Notestazebachew birkuPas encore d'évaluation

- Kedir SaidDocument5 pagesKedir Saidmubarek oumerPas encore d'évaluation

- Cybernetics and The Social SciencesDocument13 pagesCybernetics and The Social SciencesXavier MartínezPas encore d'évaluation

- ZumbroShopper13 10 02Document12 pagesZumbroShopper13 10 02Kristina HicksPas encore d'évaluation

- SWOT AnalysisDocument9 pagesSWOT AnalysisAnjali SinghPas encore d'évaluation

- Avaliação Competencias Sociais 7 12Document27 pagesAvaliação Competencias Sociais 7 12Cristina BarreiraPas encore d'évaluation

- Unit 9. Choosing A Career (1) : OpportunityDocument7 pagesUnit 9. Choosing A Career (1) : OpportunityNguyễn ThảoPas encore d'évaluation

- Cyrano Scene I LessonDocument4 pagesCyrano Scene I Lessonapi-279609624Pas encore d'évaluation

- Educ 101Document35 pagesEduc 101Cyrell Joshua Salas100% (1)

- Texas Wing - Mar 2011Document32 pagesTexas Wing - Mar 2011CAP History LibraryPas encore d'évaluation

- Ability Grouping PresentationDocument17 pagesAbility Grouping Presentationapi-604614058Pas encore d'évaluation

- Publishing As Pearson (Imprint) S. W. Nunnally: Construction Methods and Management, 8 EdDocument23 pagesPublishing As Pearson (Imprint) S. W. Nunnally: Construction Methods and Management, 8 EdmikramPas encore d'évaluation

- Syllabi PG (09-06-16)Document401 pagesSyllabi PG (09-06-16)prembiharisaranPas encore d'évaluation

- Housing Information: (1) On-Campus DormitoryDocument4 pagesHousing Information: (1) On-Campus DormitoryNico Illarregui HelPas encore d'évaluation

- Evidence Based PracticeDocument4 pagesEvidence Based PracticeChandu RajPas encore d'évaluation

- Higher SuperstitionDocument47 pagesHigher SuperstitionsujupsPas encore d'évaluation

- Numerical Control of Machine Tools PDFDocument2 pagesNumerical Control of Machine Tools PDFBruce MartinPas encore d'évaluation

- Individual SportsDocument17 pagesIndividual SportsNedelyn PedrenaPas encore d'évaluation