Académique Documents

Professionnel Documents

Culture Documents

Boiler Tube Failure Analysis 1

Transféré par

Himanshu ChaturvediDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Boiler Tube Failure Analysis 1

Transféré par

Himanshu ChaturvediDroits d'auteur :

Formats disponibles

Study Report of Superheater & Economiser Coil Failure Gas and Oil Fired Boiler

Super heater coil failure: After going through various records and data available at site, we are of the opinion that boiler was run with lesser feed water temperature (around 80 Deg. C) to economiser inlet for prolonged period. Boiler steam loading was not carried out as per the standard practice and unit was run at low steam load for long duration right from the start of the plant. The above two factor would have led to too much of thermal stress to material of superheater coils due to insufficient steam cooling of coils. We also understand from site that during start up time the metal temperature of superheater coils were kept beyond its safe working limit of 490 Deg. C (T 11 material) for longer duration, which is also confirmed by the metallurgical report of Petroleum Corporation . With high total dissolved solids (TDS) due to improper control of drum water chemistry (CBD) during start up compounded with high water level operation in steam drum, we presume priming of water into superheater coils has taken place which has led to excessive thermal stress to tube metal and its subsequent failure as report from the site. We are also of the opinion, after inspecting the quality of superheater bends, Ovality percentage at bend has not been kept as per Standard specified by IBR and bends are having visible knuckle at start and end of the bends. The stretching of material at bend portion is very high resulting thinning of tube wall thickness as shown in the photograph below:

We also understand from site that one crack has been observed in one of the header stub welding due to poor quality of weld carried out at site as shown below:.

Various lugs provided in the superheater coils for maintaining the coil pitch is not properly positioned and welded at site as shown below:

Economiser coil failures: We understand from the site that four times economiser weld joints carried out at factory has failed due to poor joint preparation and weld quality. This has in turn damaged adjacent tubes in the bend sections of the economiser coils. All the above failures have taken place at gas inlet side (Economiser water outlet side) which clearly indicates that the initialization of reported economiser failure is not due to Sulphur dew point

corrosion to the outer surface. We have also seen the cut sample of failed samples at weld location by the inspection department and we are of the opinion that welding of coils were carried out without proper joint preparation as per standard engineering practice. We have noticed weld joints were not provided with proper root gap leading to

insufficient penetration of the weld material as shown in the photograph below:

From the records we could find only one pin hole failure in the finned section of economiser which is in the gas flow path of economiser assembly as shown in the photograph given below:

The water jetting out of this pin hole has damaged the adjacent tube fins due to extended running of the boiler in leaked conditions. Such type of pin hole failure is normally attributed to oxygen corrosion and in this case also since the boiler was run for quit some time without deaerated water we of the opinion that the pin hole developed in the parent material of the finned section may be due to internal corrosion set in because of presence of oxygen in the water. Since the boiler is running on furnace oil firing during the above mentioned period, the SO3 present in the flue gas reacted with water coming out of failed tube to form sulphuric acid over the surface of adjacent tube/fins and aggravated the external corrosion. We have noticed that from the cut bends of economiser section, quite a few weld joints were without proper edge preparation/root gap provisions. We may have to investigate at shop quality control, the procedure they have followed to pass such type of inferior quality weld joints in economiser assembly. Since boiler design working pressure is low, we keep our fingers crossed to observe that rest of the joints will not give further trouble in the near future.

Client have also provided refractory materials to reduce gas leakage local to economiser bends as shown in the photograph below restricting the thermal movement for the economiser coils inadvertently. The same has to be removed before raising the temperature in the boiler.

We have explained to clients how the gas leakage is kept to minimum level through sleeve provided in the tube plate when the boiler is operation. To avoid acid due point corrosion to the bends in the dead chamber of economiser assembly we have also impressed upon clients the importance of maintaining feed water temperature to economiser inlet header above 130 Deg. C. The insulation provide for the economiser casing appears to be adequate to avoid corrosion to casing plates due to Sulphur dew point. We have also requested clients to provide drain stub for all three sections of economiser to easily identify coil leak during the boiler operation.

Vous aimerez peut-être aussi

- Cooling Systems: Don'T Underestimate The Problems Caused by Condenser Tube LeaksDocument5 pagesCooling Systems: Don'T Underestimate The Problems Caused by Condenser Tube Leakspym1506gmail.comPas encore d'évaluation

- Rayalaseema Thermal Power Plant ReportDocument24 pagesRayalaseema Thermal Power Plant ReportHarish Reddy50% (2)

- Etd Epri p91 FailuresDocument9 pagesEtd Epri p91 FailuresJustin Morse100% (1)

- NTPC Barh Summer Training Report (Electrical)Document44 pagesNTPC Barh Summer Training Report (Electrical)Mithilesh91% (35)

- Selecting Tubing Materials For Power Generation Heat ExchangersDocument20 pagesSelecting Tubing Materials For Power Generation Heat ExchangersPing Apiwat100% (1)

- Plant Startup Shutdown Sequence Description ForRelease PDFDocument65 pagesPlant Startup Shutdown Sequence Description ForRelease PDFRahil TasawarPas encore d'évaluation

- Flow Accelerated Corrosion: Forms, Mechanisms and Case StudiesDocument13 pagesFlow Accelerated Corrosion: Forms, Mechanisms and Case StudiesMuralimohan MolabantiPas encore d'évaluation

- Corrosion Protection of CondesateDocument8 pagesCorrosion Protection of CondesateArselan Mustafa KhanPas encore d'évaluation

- Boiler Operating CourseDocument74 pagesBoiler Operating Courseknx175Pas encore d'évaluation

- Management of Top of Line Corrosion in Wet Gas LinesDocument10 pagesManagement of Top of Line Corrosion in Wet Gas LineslunloonPas encore d'évaluation

- Corrosion Problems During Oil and Gas Production and Its MitigationDocument15 pagesCorrosion Problems During Oil and Gas Production and Its MitigationjesiPas encore d'évaluation

- Astm A333 PDFDocument2 pagesAstm A333 PDFgaminPas encore d'évaluation

- Quality Control Plan For Painting Work PDFDocument2 pagesQuality Control Plan For Painting Work PDFSrinivasa100% (1)

- Quality Control Plan For Painting Work PDFDocument2 pagesQuality Control Plan For Painting Work PDFSrinivasa100% (1)

- Alkali Boil Out ProcedureDocument7 pagesAlkali Boil Out Procedureismail karmanaPas encore d'évaluation

- CSWIP 3.2 Course Material For Radiographic InterpretationDocument52 pagesCSWIP 3.2 Course Material For Radiographic InterpretationSrinivasa100% (7)

- Economizers Operating and Maintenance PracticesDocument0 pageEconomizers Operating and Maintenance PracticespariskosPas encore d'évaluation

- Failure Analysis and Creep Remaining Life of Hydrogen Reformer Outlet Pigtail TubesDocument12 pagesFailure Analysis and Creep Remaining Life of Hydrogen Reformer Outlet Pigtail TubesAndrea CalderaPas encore d'évaluation

- 42 - Extensive Feedwater Quality Control and Monitoring Concept For Preventing Chemistry-Related Failures of Boiler Tubes in A Subcritical Thermal Power PlantDocument12 pages42 - Extensive Feedwater Quality Control and Monitoring Concept For Preventing Chemistry-Related Failures of Boiler Tubes in A Subcritical Thermal Power PlantBehnam RamouzehPas encore d'évaluation

- Boiler Hydro Test-StepsDocument6 pagesBoiler Hydro Test-StepsAbdul Gafoor Shaikh100% (1)

- 226 Eddystone Station UnitDocument24 pages226 Eddystone Station UnitsbktcePas encore d'évaluation

- Typical Boiler Erection SequenceDocument83 pagesTypical Boiler Erection SequenceSrinivasa100% (1)

- Boiler RLADocument4 pagesBoiler RLAGaneshPas encore d'évaluation

- Paper-Creep Life Estimation of T22Document9 pagesPaper-Creep Life Estimation of T22Parmanand RautPas encore d'évaluation

- RLA in High Temp Zones of Power Plant ComponentsDocument7 pagesRLA in High Temp Zones of Power Plant ComponentsEzhil Vendhan PalanisamyPas encore d'évaluation

- 1314276003newsletter Reduce Boiler Tube Leakages in Your Power StationDocument7 pages1314276003newsletter Reduce Boiler Tube Leakages in Your Power StationNorman IskandarPas encore d'évaluation

- Biological Treatment of Microbial Corrosion: Opportunities and ChallengesD'EverandBiological Treatment of Microbial Corrosion: Opportunities and ChallengesPas encore d'évaluation

- Superheater Corrosion in USC Power PlantDocument136 pagesSuperheater Corrosion in USC Power PlantDanie-Els100% (1)

- CFBC Maintenance CostDocument16 pagesCFBC Maintenance Costyogeshmangal1317100% (1)

- Corrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, IndiaDocument76 pagesCorrosion CAUSES and MECHANISM Arumugam Anna University, Chennai, Indiadeviprasadh.a100% (3)

- HRSG Final InspectionDocument8 pagesHRSG Final Inspectionmkarahan100% (1)

- Failure Modes of RBIDocument5 pagesFailure Modes of RBIMuhammad OmarPas encore d'évaluation

- Reheat Steam SystemDocument13 pagesReheat Steam SystemTan Nguyen HuuPas encore d'évaluation

- OsidationDocument49 pagesOsidationSadhasivam VeluPas encore d'évaluation

- DESUPERHEATERDocument4 pagesDESUPERHEATERghkashyap1Pas encore d'évaluation

- Engineering 360 - Engineer's Guide To Boiler Tube InspectionsDocument3 pagesEngineering 360 - Engineer's Guide To Boiler Tube InspectionsIsmal AdrianPas encore d'évaluation

- Why Is TSPDocument4 pagesWhy Is TSPAbhi SharmaPas encore d'évaluation

- An Experience With CFBC Boiler Tube FailuresDocument61 pagesAn Experience With CFBC Boiler Tube Failuresparthi20065768100% (2)

- Posiflow Technology of Doosan Babcock For Supercritical BoilersDocument12 pagesPosiflow Technology of Doosan Babcock For Supercritical BoilersKarthick VelayuthamPas encore d'évaluation

- Book - Creep High Temperature Component Analysis Overview of Assesment and Design ProceduresDocument89 pagesBook - Creep High Temperature Component Analysis Overview of Assesment and Design ProceduresHamdani NurdinPas encore d'évaluation

- Creep and Life Assessment of Engineering Components in Power Plants and Process IndustriesDocument30 pagesCreep and Life Assessment of Engineering Components in Power Plants and Process IndustriesThomas TuckerPas encore d'évaluation

- Treatment and Corrosion Control of Cooling WaterDocument57 pagesTreatment and Corrosion Control of Cooling Waterlonelystar19Pas encore d'évaluation

- Failure of PigtailsDocument32 pagesFailure of Pigtailsbarry nancoo100% (1)

- Troubleshooting ST Path Damage MechanismsDocument40 pagesTroubleshooting ST Path Damage Mechanismsjerezg25100% (1)

- Centralloy G4852 Micro R (Cast Austenitic Stainless Steel)Document2 pagesCentralloy G4852 Micro R (Cast Austenitic Stainless Steel)Anonymous w6TIxI0G8lPas encore d'évaluation

- Making O&M More EfficientDocument7 pagesMaking O&M More EfficientNadia AlvaradoPas encore d'évaluation

- Fired Heater Optimization - AmteckDocument12 pagesFired Heater Optimization - Amteckbazil17Pas encore d'évaluation

- Definition, Mechanism and Factor Affecting Sour CorrosionDocument12 pagesDefinition, Mechanism and Factor Affecting Sour CorrosionArielPas encore d'évaluation

- HRSG Users Group 26-04-14 Inspecting HRSG During Planned OutagesDocument57 pagesHRSG Users Group 26-04-14 Inspecting HRSG During Planned OutagesLurdesAlmeida100% (1)

- Corrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantDocument11 pagesCorrosion Failures of AISI Type 304 Stainless Steel in A Fertiliser PlantAndrea CalderaPas encore d'évaluation

- Handout PDFDocument51 pagesHandout PDFSCE SOLAPURPas encore d'évaluation

- ASME Coal Sampling Test ProcedureDocument4 pagesASME Coal Sampling Test ProcedureRoby SzPas encore d'évaluation

- HRST Boiler Biz - Volume 15 Issue 1 - 2014Document8 pagesHRST Boiler Biz - Volume 15 Issue 1 - 2014IlkuPas encore d'évaluation

- Once Through BoilerDocument8 pagesOnce Through BoilerRamalingam PrabhakaranPas encore d'évaluation

- Chapter 14 Boiler System Failures: Deaerator CrackingDocument22 pagesChapter 14 Boiler System Failures: Deaerator CrackingVijay RajaindranPas encore d'évaluation

- Understanding Tube Failures in High Pressure Boilers PDFDocument2 pagesUnderstanding Tube Failures in High Pressure Boilers PDFPravin KumarPas encore d'évaluation

- Investigation of Carbon Steel and Stainless Steel Corrosion in A MEA Based CO2 Removal PlantDocument8 pagesInvestigation of Carbon Steel and Stainless Steel Corrosion in A MEA Based CO2 Removal PlantBenedict LimPas encore d'évaluation

- 30 Ncmer037Document16 pages30 Ncmer037Arslan ArshadPas encore d'évaluation

- Cold End CorrosionDocument15 pagesCold End Corrosiondafteri11Pas encore d'évaluation

- Closed Cooling Water SystemDocument8 pagesClosed Cooling Water SystemtheoPas encore d'évaluation

- Water-Chemistry, Outage-Maintenance Best Practices Highlight Steam Plant WorkshopDocument8 pagesWater-Chemistry, Outage-Maintenance Best Practices Highlight Steam Plant Workshopnktiah1207Pas encore d'évaluation

- Certificate of Analysis: National Institute of Standards and TechnologyDocument5 pagesCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosPas encore d'évaluation

- 1584Document6 pages1584malsttarPas encore d'évaluation

- Steam Boiler Inspections Using Remote Field Testing: by Mynor Celis, P.Eng, Russell NDE SystemsDocument11 pagesSteam Boiler Inspections Using Remote Field Testing: by Mynor Celis, P.Eng, Russell NDE SystemsAnonymous lmCR3SkPrKPas encore d'évaluation

- Creep - Iwshibli PDFDocument32 pagesCreep - Iwshibli PDFIvanUribePas encore d'évaluation

- CBI Welding Journal Vert Plate Apr04Document0 pageCBI Welding Journal Vert Plate Apr04Mahendra RathorePas encore d'évaluation

- Southern Company/MHI Ltd. Plant Barry CCS DemonstrationDocument23 pagesSouthern Company/MHI Ltd. Plant Barry CCS Demonstrationrecsco2100% (1)

- Status of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229Document57 pagesStatus of Advanced Ultra-Supercritical Pulverised Coal Technology - ccc229sarangss100% (1)

- Module 4c - Corrosion Resistant Alloys (CRA's)Document11 pagesModule 4c - Corrosion Resistant Alloys (CRA's)Anonymous 7yN43wjlPas encore d'évaluation

- Plugging of Boiler Tubes - AQ9 PDFDocument6 pagesPlugging of Boiler Tubes - AQ9 PDFВиталий РунцивPas encore d'évaluation

- How To Boost HRSG Performance and Increase Your Plant's Bottom LineDocument28 pagesHow To Boost HRSG Performance and Increase Your Plant's Bottom Lineabdulyunus_amir100% (1)

- Condition Assessmen B&W Chap 45Document22 pagesCondition Assessmen B&W Chap 45Busairi AchmadPas encore d'évaluation

- Cathotic ProtectionDocument5 pagesCathotic Protectionkrishna_swaroop99Pas encore d'évaluation

- Asset Integrity Management A Complete Guide - 2020 EditionD'EverandAsset Integrity Management A Complete Guide - 2020 EditionPas encore d'évaluation

- Visit To PenthouseDocument12 pagesVisit To PenthouseTiu TonPas encore d'évaluation

- Wind Velocity AWS D1 - 1 2020Document1 pageWind Velocity AWS D1 - 1 2020SrinivasaPas encore d'évaluation

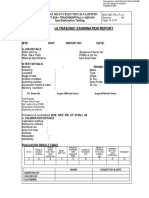

- UT Report PDFDocument1 pageUT Report PDFSrinivasaPas encore d'évaluation

- Model Ultrasonic Unit Calibration Report PDFDocument1 pageModel Ultrasonic Unit Calibration Report PDFSrinivasaPas encore d'évaluation

- PWHT For T 23 PanelDocument12 pagesPWHT For T 23 PanelSrinivasaPas encore d'évaluation

- Indian Banks With IMPSDocument2 pagesIndian Banks With IMPSSrinivasaPas encore d'évaluation

- Fabrication Guidelines For P91Document23 pagesFabrication Guidelines For P91SrinivasaPas encore d'évaluation

- Indices: Quick Reference Sheets 1Document3 pagesIndices: Quick Reference Sheets 1SrinivasaPas encore d'évaluation

- Is 13445 1 1992Document14 pagesIs 13445 1 1992kalgithPas encore d'évaluation

- What Is Lamont Boiler?Document3 pagesWhat Is Lamont Boiler?Muhammad Fahmi HidayatullohPas encore d'évaluation

- WBS and Its DescriptionDocument7 pagesWBS and Its DescriptionhinahanifPas encore d'évaluation

- Boilers, Boiler Fittings and Steam Offtakes: Academic Manual AC/18/03Document68 pagesBoilers, Boiler Fittings and Steam Offtakes: Academic Manual AC/18/03kISHOREPas encore d'évaluation

- Boiler Soot-Blowing in Power Plants - Compressed Air Best PracticesDocument8 pagesBoiler Soot-Blowing in Power Plants - Compressed Air Best PracticesRoland NicolasPas encore d'évaluation

- Tharmal 2Document48 pagesTharmal 2Prittam Kumar JenaPas encore d'évaluation

- BoilersDocument8 pagesBoilersKarthiKeyanPas encore d'évaluation

- NicholsonDocument177 pagesNicholsonParth AggarwalPas encore d'évaluation

- Summer Training IN Andhra Pradesh Power Generation Corporation - (Apgenco)Document17 pagesSummer Training IN Andhra Pradesh Power Generation Corporation - (Apgenco)Goutham ReddyPas encore d'évaluation

- Thermodynamics Lab ManualDocument100 pagesThermodynamics Lab ManualNottaAmandeepSingh80% (5)

- Steam Orifice TrapsDocument31 pagesSteam Orifice TrapsPhanhai KakaPas encore d'évaluation

- DDR - PC0631 - Drawing Received RegisterDocument19 pagesDDR - PC0631 - Drawing Received RegisterBansi RebariPas encore d'évaluation

- Chapter 1 HeatDocument10 pagesChapter 1 HeatJikni NoblePas encore d'évaluation

- Initial Heating of Turbine & Turbine Rolling: Problems & PrecautionsDocument27 pagesInitial Heating of Turbine & Turbine Rolling: Problems & PrecautionsMukesh Kumar VaishnavPas encore d'évaluation

- Modeling of Superheater Operation in A Steam Boiler: January 2014Document16 pagesModeling of Superheater Operation in A Steam Boiler: January 2014Iman QurbanovPas encore d'évaluation

- Energy Engineering Notes Module 1Document34 pagesEnergy Engineering Notes Module 1sandesh CMPas encore d'évaluation

- Steam Bench: ObjectiveDocument6 pagesSteam Bench: Objectiveحسين عمريPas encore d'évaluation

- Armstrong - SH Series Bimetallic TrapsDocument2 pagesArmstrong - SH Series Bimetallic TrapsTaylorPas encore d'évaluation